Inventory Optimisation Guide

To offset common inventory issues, it’s important to keep a close eye on your inventory and know how many units of each SKU you have at any given time. Fortunately, there are several solutions to optimise inventory and reduce risk.

In this article, you will learn inventory optimisation best practices for online retailers of all sizes.

So, what do you want to learn?

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is inventory optimisation?

Inventory optimisation is the process of maintaining the right amount of inventory required to meet demand, keep logistics costs low, and avoid common inventory issues such as stockouts, overstocking, and backorders.

Inventory optimisation is an ecommerce best practice and strategy that ensures stock control is managed efficiently by implementing tools, technology, processes, and techniques to track inventory in real time, better forecast demand, and optimise storage.

What are the main elements of inventory optimisation?

To always have the right amount of product ready to be fulfiled, you need to take into consideration storage capabilities, current inventory levels, supplier lead times and schedules, seasonal trends, and future campaigns.

Here is an overview of what’s involved in the inventory optimisation process.

Demand forecasting

Demand forecasting is the process of using historical data to estimate future demand for your products. Demand forecasting helps you make better-informed supply decisions that aim to predict the total sales and revenue for a future period of time.

Forecasting demand will never be 100% accurate, but it will significantly lower the risk of stockouts and improve customer satisfaction while optimising inventory levels.

Inventory replenishment

Inventory replenishment is the process of moving products from inventory storage to picking shelves, or receiving more inventory from the manufacturer.

The inventory replenishment process is important because it helps to ensure there is enough inventory ready to be picked and packed as soon as each order comes in. By restocking on inventory at the right time to meet demand, you can avoid backorders and delayed deliveries.

Inventory levels

Stocking too much inventory requires a lot of capital. Meanwhile, too little inventory leads to missed sales opportunities and upset customers.

Optimising inventory levels with the ideal amount of each product in stock can reduce the risk of common inventory issues, from high storage costs to out-of-stock items.

Healthy inventory levels are a clear sign of efficiency and profitability. It improves cash flow, optimises warehousing capacity, and builds brand loyalty and trust.

Inventory storage

Optimising inventory storage is a necessary part of running any business that sells physical goods. A cost-effective inventory storage system helps you manage your inventory to meet customer expectations, while allowing room for your business to grow.

Keep in mind that storage needs will vary from business to business, based on sales volume, product attributes, and locations shipped to and from. Finding ways to get strategic on storage is a major component of inventory optimisation.

Why is inventory optimisation important for ecommerce?

The rising popularity multichannel retailing coupled with the unpredictability caused by natural disasters, raw material shortages, manufacturing closures, and other factors can make it challenge to optimise your supply chain.

Fortunately, with the right tools, technology, and resources in place, you can better plan for the unexpected while still meeting demand and keeping logistics costs low.

Here are five reasons why inventory optimisation is important for future supply chain planning and growth.

1. Reduce operational costs

Costs associated with storage, warehousing, and general inventory management are all expenses that are associated with how well you optimise inventory.

If your business has poor inventory flow and high carrying costs, inventory optimisation can help to identify which items are slow-moving or fast-selling, as well as which warehouse locations makes the most sense to store certain items based on demand to reduce the time they sit on shelves.

2. Boost customer satisfaction

It’s most direct-to-consumer (DTC) brand’s deepest desire to keep customers satisfied. By optimising inventory, you can make sure that orders can be picked, packed, or kitted right away.

It’s tempting to want to overstock inventory just to be on the safe side. But by finding ways to optimise inventory, you can get smart about how much to have of each item and where to store your products geographically. This way, you can consistently meet demand, avoid inventory issues, and minimise storage costs.

3. Gain faster delivery options

Optimising inventory can help you track SKU performance across your distribution network. This allows you to strategically allocate inventory to warehouse locations where there is the most demand, so you can ensure that a bulk of your orders can be shipped quickly and at a lower costs.

Since inventory levels constantly fluctuate, it’s important to consider technology and automation to track inventory, especially if you store inventory in several locations. A solid inventory allocation strategy that’s tech-enabled and offers valuable insights can make a big impact on your shipping strategy.

4. Balance inventory levels

Knowing exactly which SKUs are available at your warehouse or distribution centre at any point in time helps with inventory accounting, profitability, and the ability to meet customer demand. By optimising inventory, the goal is to balance inventory levels, so you don’t stock up on too much or not enough.

Balancing inventory levels can help improve cash flow, optimise warehousing capacity, and enable you to consistently meet customer demand.

5. Prevent overstocking

Without the resources to make better inventory decisions often results in overstocking on inventory to be safe. However, overstocking can lead to not only higher carrying costs but also deadstock, which is caused by items that go unsellable due to seasonality, being past its expiration date, or a decrease in demand over time (e.g., the slowdown of face masks in the US now that millions of people are fully vaccinated).

Inventory optimisation techniques

Since optimising inventory is one of the most important components in operating an ecommerce supply chain, there are several techniques and best practices that businesses of any size can implement.

1. Use demand forecasting

Having the right tools and technology in place to forecast demand can help you make better-informed supply decisions that estimate the total sales and revenue for a future period of time.

To forecast demand, the most important data to have access to is historical order data, which provides insights on sales trends. With this type of data, you make better business decisions that improve supply chain efficiencies, save money, and deliver a better customer experience.

Inventory forecasting can also help in making decisions on when to run a flash sale, hire more staff, or rent more storage space (or outsource fulfilment).

As your business grows, it can become harder to forecast demand. That’s why ShipBob offers demand forecasting tools, including advanced analytics and distribution metrics to help you track SKU performance over time and plan better for the future.

2. Determine safety stock inventory

What do you do when there is a last-minute issue with a supplier or an unexpected surge in demand?

Safety stock, also known as ‘buffer inventory,’ is the excess product you keep on hand in case of an emergency or supply chain failure that causes less than average inventory to be available. To calculate an optimal amount of safety stock, you will need the following for each SKU:

- Maximum daily usage

- Maximum lead time

- Average daily usage

- Average lead time

With a 3PL partner like ShipBob who stores inventory and fulfils orders for you, calculating and managing safety stock becomes easier. With ShipBob, you’re given the tools and data needed to calculate your ideal reorder quantity and analytics on your inventory for a better ideas of how much safety stock you need to prevent stockouts.

3. Implement reorder point formula

While knowing how much minimum inventory to hold (including safety stock) is important, you will also need to determine optimal times to reorder.

Your reorder point needs to ensure that excess capital is not tied up in inventory and take any lead times into consideration (from your manufacturer, the time it takes your warehouse to receive and stow inventory, and other potential delays).

To calculate reorder points, here is the simple formula:

Reorder Point (ROP) = Demand during lead time + safety stock

Though the formula is simple, keeping tabs on when to reorder each product can be time-consuming and challenging.

However, if you partner with a 3PL like ShipBob, you can access inventory data and set automatic reorder points to save time and make the process more efficient.

ShipBob provides access to daily inventory history data at any point in time. You can search by item, filter by specific lot number, and account for inventory in transit.

4. Carry out inventory audits

Regular inventory audits, as well as proper warehouse receiving procedures, can help you track inventory more efficiently.

Holding costs (warehouse staffing, storage, inventory shrinkage, and depreciation costs) should be closely monitored and calculated to help ensure there aren’t major discrepancies.

Conducting audits can be time-consuming. Thankfully, there are solutions for online brands that automate and digitize the inventory monitoring process, including the ability to sync your online store with inventory management software or utilise a 3PL’s fulfilment software.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on.

I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

5. Keep tabs on SKUs

By syncing all your SKUs to an inventory management solution, you can easily track, update, and manage products across your your distribution network (and sales channels). This helps to avoid overselling or running out of inventory too soon.

If you partner with a 3PL like ShipBob, merging duplicate SKUs and managing inventory across a distribution network is easy. ShipBob connects with all leading ecommerce platforms in minutes. Once you connect your store and sync your products, you can:

- View real-time inventory levels by SKU.

- Set reorder points for each SKU based on the quantity at which you wish to be alerted to restock.

- Bundle different SKUs for promotions.

- Merge the same product across ecommerce platforms.

- Have different SKUs kitted and assembled before they are shipped.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

6. Distribute inventory across warehouses

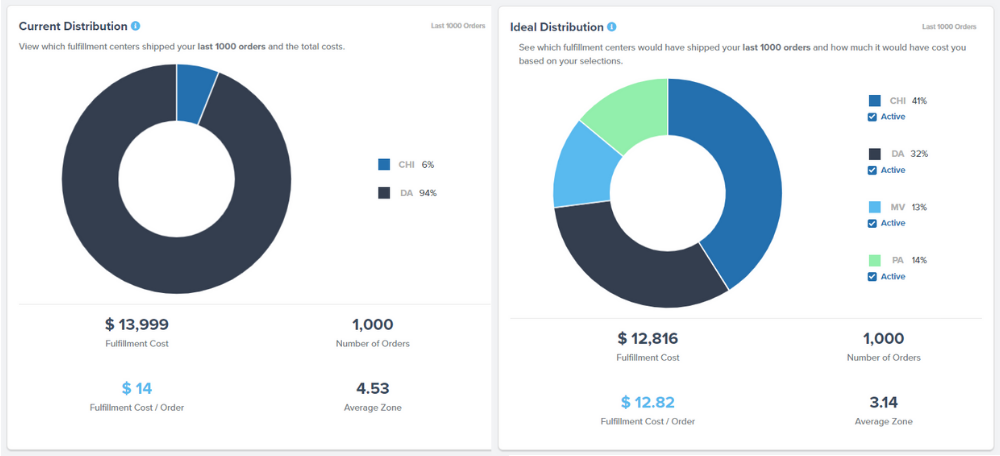

While centralised inventory is simpler to manage, it’s more important to store inventory close to where your demand is. When SKUs are strategically distributed across multiple fulfilment centres, orders can be delivered efficiently while reducing shipping costs.

Since ShipBob’s entire international fulfilment network is powered by the same technology, you’re given access to insights on SKU performance at each location compared to others by aggregating historical order data.

That way, you can make better decisions on how much to store at each location based on demand.

“ShipBob has multiple fulfilment centres, and all locations filter back into one centralised warehouse management system, so everything is under the ShipBob umbrella.

By distributing our inventory across these countries and regions, all of our customers are able to get their orders much faster while paying reasonable domestic shipping rates.”

Wes Brown, Head of Operations at Black Claw LLC

7. Use inventory management software

By implementing inventory management software, you can sync SKUs and orders to view all inventory, fulfilment centres, sales channels, and customers in one place.

Depending on the size of your business and budget, there are several inventory apps and other solutions to choose from that can help you easily track inventory in real time.

For instance, ShipBob not only stores inventory and fulfils orders but also offers built-in inventory optimisation tools, so merchants can easily track inventory across distribution centres, predict demand, set automatic reorder notification points, and have the reports to easily prepare for tax season.

“With ShipBob, we have access to live inventory management, knowing exactly how many units we have in each fulfilment centre. This not only helps with our overall process in managing and making sure our inventory levels are balanced but also for tax purposes at the end of the year.”

Matt Dryfhout, Founder & CEO of BAKblade

How ShipBob can help with inventory optimisation

Ecommerce store owners looking to efficiently optimise inventory can get the resources, technology, and expertise needed by partnering with a best-in-class 3PL like ShipBob.

ShipBob’s fulfilment technology provides built-in inventory optimisation solutions, including an advanced data and analytics reporting tool, which provides valuable insights that help you efficiently expand into new sales channels, distribution locations, and global markets.

Instead of spending all your time on optimising inventory and packing orders, rather than business growth, ShipBob can manage the entire ecommerce fulfilment process for you. By storing inventory in one or more of ShipBob’s fulfilment centres, you can track inventory in real time all from one dashboard.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.

The analytics are super helpful. We download Excel files from the ShipBob dashboard all the time and use them to analyse everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time.

Even the way their warehouse receiving orders (WROs) work for sending inventory is very straightforward.”

Ines Guien, Vice President of Operations at Dossier

With ShipBob, you can spend less time on inventory management, optimise your supply chain, automate fulfilment and improve your shipping strategy, all while saving time and money.

To learn more about how ShipBob can help you optimise inventory and streamline fulfilment, click the button below.

Inventory optimisation FAQs

Inventory optimisation not only helps you save money and improve inventory visibility, but also helps secure repeat customers by delivering a positive experience through fulfiling orders quickly and accurately. Here are responses to common questions around inventory optimisation.

How do you optimise inventory?

Optimising inventory involves attaining the perfect balance between demand and supply to avoid high storage costs as well as stockouts. There are several ways to optimise inventory: implementing inventory technology to track inventory in real time, calculate and automate reorder points, and forecast demand.

How does a 3PL optimise inventory?

By partnering with a 3PL like ShipBob, you’re given the data and analytics to optimise inventory, so you can strategically expand into more distribution locations. If you’re spending too much time manually tracking inventory or you lack the infrastructure and technology to optimise inventory efficiently, ShipBob can help (plus fulfil your orders fast). Since ShipBob owns the entire tech stack that powers our fulfilment centres, you can easily track inventory in real time and make better decisions on how much of each SKU to reorder and when.