How to Forecast Customer Demand: Methods & Benefits

Skip the Scroll — Download the PDF

Download this blog as a PDF to revisit it whenever you want. We’ll email you a copy.

Table of Contents

** Minutes

Importance of demand forecasting for ecommerce

Examples of demand forecasting methods

Types of demand forecasting techniques

Factors influencing the customer demand life cycle

How to forecast demand in 4 steps [Infographic]

Picture this: it’s right before the winter holidays, and you are reordering inventory. You order the exact same amount you always do when you replenish stock – but when the holidays hit, you sell out almost immediately.

Cut to the next year, around the same time. You suspect this year will be as busy as last year and definitely don’t want to stock out again.

So, you look back in your records to see how many sales you made and how many backorders there were last season, and use that data to estimate how much inventory you’ll need. You end up ordering twice the stock you normally would, and sail through the holidays without a hitch.

This is a classic example of demand forecasting. By making data-driven predictions about sales, customer interest, order volume (rather than guessing blindly), ecommerce brands set themselves up to satisfy customers, save money, and streamline their entire supply chain.

In this article, we’ll dive deep into what demand forecasting is, what factors influence demand, how to forecast accurately, and how experts like ShipBob can help.

What is demand forecasting?

Demand forecasting is the process of estimating how much demand there will be for a product in the future. Demand is typically measured in sales, so the goal of demand forecasting is to predict how many units of a particular product you will sell in a given period of time.

If you forecast demand accurately, you’ll end up with enough inventory to fulfill all the customer orders for that product without accidentally overstocking (which increases your inventory holding costs) or understocking (which can lead to costly stockouts and backorders). You will also be able to improve decision-making across your supply chain, warehousing operations, and inventory management.

To forecast demand as accurately as possible, many brands track historical sales and order data, and analyze it for patterns that can help them predict what might happen again in the future.

Types of demand forecasting techniques

There are various ways businesses can forecast demand. All demand forecasting models leverage data and analytics over specific periods of time.

Macro-level

Macro-level demand forecasting looks at general economic conditions, external forces, and other broad things disrupting commerce. These factors keep a business in the know around portfolio expansion opportunities, market research intel, and other shifts in the market.

Micro-level

Demand forecasting at the micro-level can be specific to a particular industry, business, or customer segment (e.g., examining demand for a natural deodorant for millennial customers in Chicago, IL).

Short-term

Short-term demand forecasting looks to predict demand within a short period of time, usually less than 12 months. These demand forecasts often inform a brand’s day-to-day operations and inventory management (e.g., planning production needs for a Black Friday/Cyber Monday promotion).

Long-term

Long-term demand forecasting is looks to predict demand over a longer period of time, usually a year or more. Long-term forecasts help a brand identify and plan for seasonal patterns, may influence its growth trajectory, and informs its overall business strategy. For instance, if a brand forecasts high demand for the next five years, stakeholders may feel more comfortable opening a new facility, expanding internationally, or launching new channels.

Importance of demand forecasting for ecommerce

Without demand, there is no business. And without a thorough understanding of demand, businesses aren’t capable of making the right decisions about marketing spend, production, staffing, and more.

Preparing your budget

When you know how much inventory you’ll need to meet demand, you can create a budget you’ll stick to. Demand forecasting helps brands make strategic financial decisions that protect profit margins, improve cost-efficiency, streamline inventory accounting, and decrease overall spend.

Demand planning and scheduling production

Nothing kills scalability (or your reputation) faster than being sold out for weeks on end. Proper demand forecasting and inventory control can help you plan production correctly, so you have inventory on hand when your customers want it.

Demand forecasting also guides you as you choose what SKUs to invest in, so that you don’t end up with an insufficient amount of a popular product, and an excessive supply of a slow-moving or unsellable SKU. It can also help you with capacity planning across your fulfillment network, so you don’t accidentally exceed capacity at any facility.

Storing inventory

The more inventory you have on hand, the more expensive it is to store. With accurate demand forecasting, you can avoid accidental over-stocking, and the hefty holdings costs that come with it.

Developing a pricing strategy

Demand forecasting doesn’t just help you maintain ideal inventory levels – it can also enable you to price products based on demand.

For example, if there is a limited supply of a high-demand product, you can use the scarcity principle to increase the price as an exclusive offer. Alternatively, if you have an excess amount of a product that has little to no demand, you can put it on sale or bundle it with another product to move it out of your warehouse.

Sometimes, you can even manipulate demand through your pricing. For instance, if you choose to slash prices or put an item on promotion, demand may temporarily increase for that product. Conversely, if you are running low on a particular SKU, you may consider increasing price slightly to deter high demand levels that you wouldn’t be able to support.

By understanding the market and potential opportunities, businesses can grow, formulate competitive pricing, employ the right ecommerce marketing strategies, and invest in their growth.

Examples of demand forecasting methods

A small business may be on a conservative growth plan, while another company may be scaling or diversifying with aggressive growth plans. The demand forecasting examples below walk through a couple of different scenarios.

Example 1

A grocery store looks at sales trends from last year’s Thanksgiving week to prepare adequate inventory levels for the upcoming season. They look at sales leading into that week last year for seasonal products like turkeys, cranberries, and mashed potatoes.

It was a great holiday sale for them. But eight months ago, a competing grocery store opened four blocks away, so they’re unsure how Thanksgiving demand will be affected and if local customers will buy ingredients from their competitor.

At the same time, a lot of families continue to move into the neighborhood, and they’ve still grown an average of 1% month-over-month since the competing chain opened.

They plan to launch a few more ads than last year through channels that have proven a good ROI for them in the past and also offer some new deals to position themselves as the go-to Thanksgiving destination. Their calculations project a 5% increase in sales from last year.

Example 2

An up-and-coming direct-to-consumer cosmetics brand is growing quickly. Their current order volume is 10,000 orders per month, but based on their past sales data, upcoming ad campaigns, and general market conditions in the industry, they plan to do over 30,000 orders per month at this time next year.

Right now, they’re stocking a total of 75,000 units at varying levels across their 5 SKUs. Their order volume fluctuates quite a bit based on their replenishment cycle, and they restock inventory by SKU level at a rate of about every 90 days.

The average units they store will grow quickly while the cadence will remain the same. The last run of their main SKU was 30,000 units. They’re about to ship in another 50,000 units, and their next run will be 75,000 units.

They plan to continue to grow at that pace, so they are looking into whether they should purchase land, lease a warehouse, or outsource fulfillment to keep up with demand.

Factors influencing the customer demand life cycle

Many factors can impact demand or cause it to fluctuate. While these factors can vary from business to business or across industries, here are some of the most common needlemovers when it comes to ecommerce demand.

Seasonality

Seasonality refers to changes in order volume throughout a specific period of time. A highly seasonal brand may experience spikes and dips in demand around a particular time period, event, or season. For example, a grilling equipment brand may experience an influx of orders during the summer months and right before the 4th of July, as people tend to grill more during this season and for this holiday.

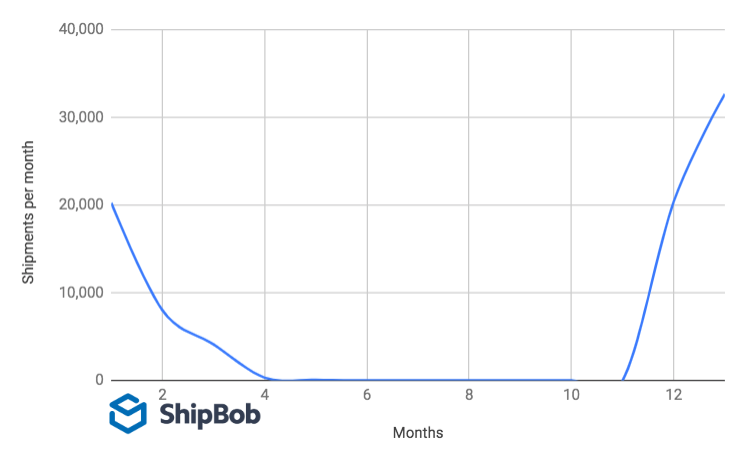

The chart below shows a ShipBob customer that runs an extremely seasonal business.

Seasonal demand often requires a business to reduce inventory on hand during the quiet months and then ramp up production and their operations workforce during peak season. That’s why many cyclical businesses outsource retail fulfillment to a professional fulfillment partner that can flex with demand and store inventory, pick items, pack boxes, and ship orders for them.

Competition

Competition affects demand as there are more options for your customers to choose from and more companies vying for their attention.

When a competitive force comes into play — whether it’s a direct competitor or a new kind of solution or alternative — demand may be skewed. This can take you by surprise, so an agile demand forecasting model can help you respond quickly.

Types of goods

Demand forecasting will be very different for different products and services, from perishable goods that expire quickly to subscription boxes that come at the same time each month.

It’s important to know the lifetime value of your customers (the total purchases they buy from you across channels over time), your average order value (how much they’re spending on each order), and the combinations of products ordered to improve demand forecasting.

Using this data, you can understand how to group or bundle items, drive more recurring revenue, and evaluate how one SKU affects or drives demand for another (e.g., razor and blade cartridge refill sales).

Geography

The geography of where your customers reside can greatly impact a demand forecast. For instance, if your ecommerce brand sells snow shovels, you will probably see higher demand in locations that get a lot of snow.

By forecasting demand geographically, you can monitor where your customers reside and store products in the regions where they are ordered most, so you don’t have to ship to far away destinations.

Where you manufacture and ship orders from may also affect demand, as it will impact delivery time. Say your brand fulfills orders from a single fulfillment center on the East Coast. Because they live close to the fulfillment center, customers on the East Coast could get their order delivered in 2 days, which may incentivize them to purchase and drive up demand. Customers on the West Coast, however, experience longer wait times and are less likely to convert.

“ShipBob’s technology streamlines inventory management across our network, ensuring optimal inventory allocation. Once the inventory is allocated correctly, passing orders to ShipBob is seamless. ShipBob automatically routes orders to the nearest warehouse to the customer. We receive notifications confirming the warehouse selected for shipping, eliminating inventory discrepancies between the warehouses. Efficient inventory allocation significantly impacts our outbound shipping costs, and with ShipBob, managing this has been effortless.”

Ali Shahid, COO of Our Place

How to forecast demand in 4 steps [Infographic]

Forecasting demand is an extremely challenging task. You want to be flexible enough to handle sporadic influxes but also take a long-term approach. Here are some tips for your business.

1. Set objectives

Demand forecasting should have a clear purpose. At its core, it predicts what, how much, and when customers will purchase.

With that in mind, begin the forecasting process by choosing:

- The time period for which you are forecasting demand (e.g., the next fiscal quarter)

- The specific product or general category you’re focusing on

- The audience and geography (e.g., customers in the northeast)

2. Collect and record data

With your parameters set, it’s time to collect your data.

In addition to recording historical sales data like the time and date of all orders, the SKU(s) included in each order, and the sales channel each order originates from, you should also track:

- SKU Velocity: how frequently a SKU is picked over a certain period of time

- Inventory Turnover Rate: how many times your entire inventory has been sold and then replaced within a given timeframe

- Average Order Value (or AOV): the average dollar amount a customer spends each time they place an order

- Return rate: the frequency with which each SKU is returned

- Stockout rate: how often your business sells out of a particular SKU, depleting available units of the SKU to 0

By tracking these inventory metrics over time, your business can forecast growth and trend projection on a more granular level and look back to see how your forecasts matched up to reality.

You may need to pull in other pieces of data, like market conditions, obsolete stock, frequency of stockouts, and other order details. Make sure any data you use is gathered properly to achieve the most reliable and accurate forecasts possible.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.

The analytics are super helpful. We download Excel files from the ShipBob dashboard all the time and use them to analyze everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time.”

Ines Guien, Vice President of Operations at Dossier

3. Measure and analyze data

With the right data in hand, the next step is the analyze it for patterns, trends, and other useful insights that could improve your future demand forecasts.

Start by comparing your predicted sales performance to your actual sales performance. Whether you perform this analysis manually or automate it, this repeatable data analysis is usually a simple method for gleaning insights that can help you adapt your next forecast.

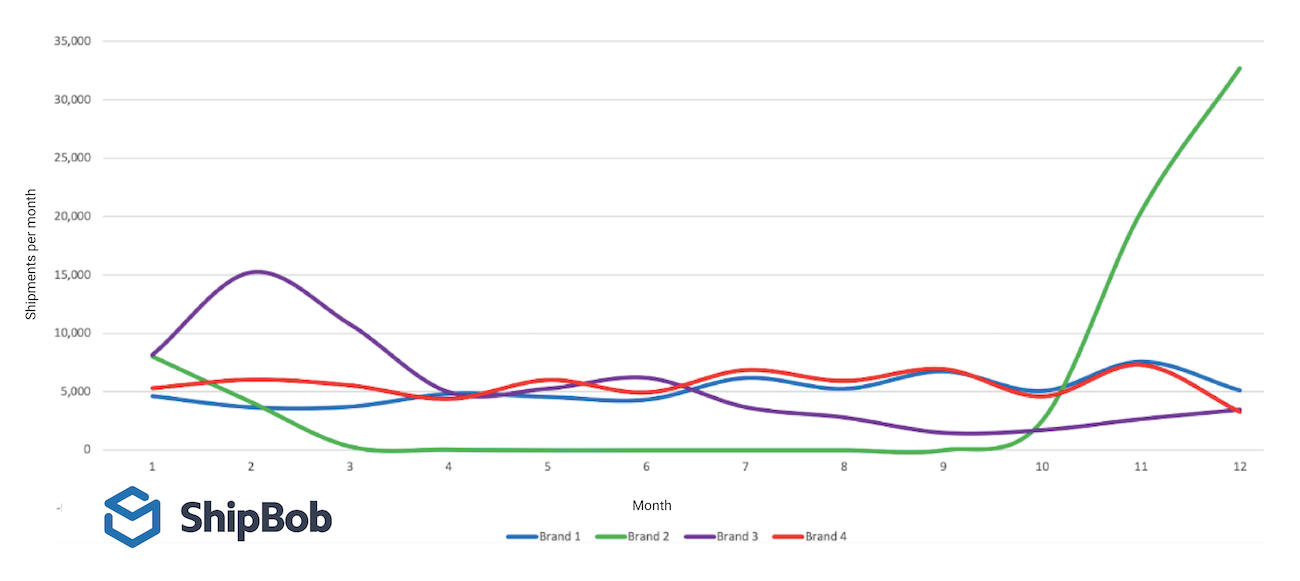

The chart below shows four different ShipBob customers on the same timeline, all of which have all shipped 60,000 total orders in the same year.

This data provides each brand with useful information that they can use to predict demand for next year and plan their inventory investment accordingly.

For example, Brand 1 sees that their sales levels were more or less consistent this past year. They don’t plan to do anything differently (no flash sales or promotions), and don’t anticipate any changes in the overall market. As a result, they forecast about the same level of sales, and reorder the same amount of inventory.

Brand 2 sees a different story. Because their sales volume was fairly low until it rose sharply in Month 10 last year, they know to be prepared for a similar pattern this year. As a result, they plan to keep just a little stock until Month 9 or 10, at which point they will order a ton of stock to meet the rising demand.

4. Budget accordingly

Once you have a feedback loop, you can set your next forecast (hopefully more accurately) and update your budget to allocate funds where they should go based on growth goals. If your demand forecast turns out to be accurate, this will save you a lot of money on inventory carrying costs, marketing spend, labor costs, and production.

How ShipBob makes demand forecasting easier

ShipBob’s proprietary software and merchant-facing dashboard provide ecommerce businesses with real-time visibility into their inventory.

With metrics like daily order status and performance, units on-hand, and days of inventory left, you can monitor today’s inventory activity before looking ahead.

When you’re ready to forecast demand for the future, you can look back at your inventory history. ShipBob automatically tracks data over time — including average units sold per day, order destinations, and SKU velocity — which you can use to optimize your forecast accuracy.

You’ll also have access to information on average storage, fulfillment, and shipping costs, as well as a suggested ideal distribution of inventory across locations to reduce these costs while optimizing for speed.

Here are just a few stories from ecommerce brands that have used ShipBob to improve their demand forecasting.

Quadrant

The esports and apparel brand leverages the “drop” model to create spikes in demand. With ShipBob’s intuitive analytics and dashboard, they can manage their inventory levels even on the busiest days and get orders out the door on time.

“Quadrant operates using a drop model, meaning we offer a select number of units each release and they sell out really fast. We run on the idea of “if you’re quick enough, you can get a piece.” Our last drop sold out in 18 minutes – it was amazing!

The key to this model is ensuring we are able to fulfill a massive spike in demand within a reasonable timeframe. With ShipBob, we are able to trust that orders will get out in a timely manner.

ShipBob has given us increased visibility thanks to the dashboard that allows us to easily manage stock and orders. That wasn’t possible for us before. Our relationship with ShipBob has been a game-changer for Quadrant, and it’s made my life so much easier. ShipBob is incredibly easy to use – that’s my favorite part about it.”

Will Kerr, Apparel Lead at Quadrant

IZIMINI

Children’s products brand IZIMINI loves the comprehensive visibility into inventory metrics that ShipBob’s dashboard provides, as well as how easy it is to use and navigate. They can access real-time data on inventory levels, and use automatic reorder notifications to avoid stockouts and stay prepared to meet forecasted demand.

“We love ShipBob’s technology. The dashboard is very intuitive. That’s what I like with ShipBob — there are lots of things I can do myself in the dashboard which wasn’t the case with my previous 3PL. The integrations are also very good. For my Shopify store, I just sync it and my new products show up straightaway in ShipBob. I like to look at the analytics in the ShipBob dashboard, knowing exactly what I have for storage. I can also set up alerts to know when I’m low on inventory for certain products to make replenishment easier. The bundling process is really good. Before ShipBob we would do it with an Excel table, which was a lot to manage.”

The IZIMINI team

PetLab Co.

As a highly successful pet wellness brand, PetLab Co. serves customers all across the US. They leverage ShipBob’s fulfillment center network and inventory distribution expertise to place inventory strategically and meet demand while reducing shipping times.

“Forecasting where demand will be highest is always a tricky exercise, especially when coupled with how much inventory we want to put into each fulfillment center. We’ve been working together with ShipBob to figure out how much inventory we want to place in each of the fulfillment centers so that we can get our products into customers’ hands as quickly as possible. This collaborative effort has definitely had its impact. In 2022, 79% of our orders with ShipBob reached customers within 0-4 days, and in 2023, this same stat was 85%. Year over year, that’s a 7.45% improvement on average.”

Stephanie Lee, Co-CEO at PetLab Co.

Conclusion

Demand forecasting helps brands make informed business decisions that affect everything from the inventory planning process to supply chain optimization. With customer expectations changing faster than ever, businesses need a method to forecast demand accurately.

If you’re looking for an ecommerce fulfillment solution to help you improve demand forecasting, learn more about how ShipBob helps you replenish stock and deliver the experience that customers want. Request a pricing quote of our fulfillment services below.

Demand forecasting FAQs

For ecommerce brands, forecasting projections is one of the toughest things to get right. Here are answers to some common questions about demand forecasting.

Why is demand forecasting important?

With a thorough understanding of demand, businesses can make better right decisions about marketing spend, production, staffing, and more. Through it will never be 100% accurate, forecasting demand can help you improve production lead times, increase operational efficiencies, save money, launch new products, and provide a better customer experience overall.

How is demand forecasting done?

There are various ways businesses can forecast demand. All forecasting models leverage data and analytics over specific periods of time. For instance, you can forecast demand on the macro-level (e.g., economic conditions, external forces, and other broad things disrupting commerce) or micro-level (e.g., particular industry, business, or customer segment). Or, you can determine future demand by short-term or long-term, depending on how you’ll use the data.

How do I build a demand forecasting model?

Forecasting demand is an extremely challenging task. You want to be flexible enough to handle sporadic influxes but also take a long-term approach. The first step is to set clear objectives, and make sure your objective satisfies your financial planners, product marketing, logistics, and operations teams in a non-biased way. You’ll also need a technology and systems in place to collect historical order accurately from your sales channels, so you can easily measure and analyze the data.

Forecasting demand can be time-consuming. By partnering with a logistics platform like ShipBob, you can access advanced analytics and distribution metrics to make the process much easier.

Are there any external factors that might impact demand?

External factors like seasonality, competition, geography, market conditions, global events like war or pandemics, and more can affect demand, even though they are not always within an ecommerce brand’s control.

What’s the difference between qualitative and quantitative demand forecasting?

Qualitative demand forecasting refers to forecasting demand through subjective or judgement-based means, such as market research, customer surveys, and expert input.

Quantitative demand forecasting refers to forecasting demand using hard data, including historical data, SKU velocity, inventory turnover rate, stockout rate, and more.