Table of Contents

** Minutes

What are optimal inventory levels?

Why it’s important to maintain healthy levels of inventory

How to determine optimal inventory levels

5 best practices for maintaining optimal inventory levels

How ShipBob helps you maintain low inventory levels

Ask any online retailer and they will tell you that maintaining optimum inventory levels is a never-ending challenge — an elaborate juggling act.

Which SKUs are selling faster than you thought?

Which items are not selling at all?

By the time you figure out a good cadence, inventory levels shift again. Tracking inventory is an ongoing process if you want to optimize logistics costs and meet customer demand.

To avoid common inventory management challenges as you grow your business, read on to learn:

- The importance of maintaining inventory levels

- How to track inventory in real time

- How a third-party logistics (3PL) like ShipBob can help you optimize inventory to meet demand and save on costs

What are optimal inventory levels?

Optimal inventory levels are the ideal quantities of products that you should have in a fulfillment center(s) at any given time. By optimizing inventory levels, you reduce the risk of common inventory issues, from high storage costs to out-of-stock items.

Too much inventory can require too much capital, sit on shelves too long, or eventually become unsellable. But too little stock can lead to stockouts and backorders, which can reduce customer satisfaction.

When it comes to optimizing inventory levels, here are a few things to consider:

- It will be different for every brand.

- Each SKU may require a different optimal inventory level based on demand.

- Optimal inventory levels can change quickly (monthly, seasonally, and annually as you grow).

Ultimately, optimizing inventory becomes more complex as:

- Your order volume increases.

- You introduce more products.

- You expand your physical distribution.

Why it’s important to maintain healthy levels of inventory

Healthy inventory levels are a clear sign of efficiency and profitability across the ecommerce supply chain. By ensuring that you don’t stock up on too many or too few units, you improve cash flow, optimize warehousing capacity, and consistently meet customer demand, building brand loyalty and trust.

Hoarding too much inventory can come with costs as you risk overspending on holding costs or worse — sitting on a lot of inventory that’s lost value or is no longer sellable.

Aside from maintaining optimal inventory levels, a better understanding of your stock levels can help you with supply chain planning by knowing the best time to reorder more inventory, as well as improve inventory accuracy.

How to determine optimal inventory levels

Determining optimal inventory levels requires some math and the ability to work backwards using historical order and inventory data. You will also need to consider when to reorder inventory so that it arrives from your supplier in time to fulfill orders as soon as they are placed.

Here are three considerations with some best practices to determine optimal inventory levels for your business.

1. Inventory production lead times

Having an understanding of production lead times will help you make an informed decision about when inventory needs to be reordered to continuously keep desired levels of stock.

The amount of time it takes for your supplier or manufacturer to transform raw materials into finished goods after you place an order impacts how much inventory you will have and when. Here are few factors to keep in mind when calculating product lead time:

- Any breaks a manufacturer takes such as Chinese New Year shutdowns.

- How long it takes inventory to travel from the manufacturer to your warehouse.

- How long it takes to receive and store inventory.

2. Safety stock availability

Safety stock refers to extra ecommerce inventory that you set aside for unexpected circumstances such as a sudden surge in orders or delays in manufacturing or while in transit. To calculate safety stock, you will need to know the following:

- Maximum daily usage

- Maximum lead time

- Average daily usage

- Average lead time

To easily determine how much safety stock to store, try this simple safety stock calculator.

Another great way to calculate the optimal amount of inventory on hand, including safety stock, is the economic order quantity (EOQ) formula.

EOQ is a great way to find the optimal amount of inventory to meet customer demand while keeping ecommerce warehousing costs as low as possible.

3. Demand forecasting

Proper demand forecasting will enable you to make better predictions on future sales demand to determine how much inventory you will need during a certain period of time.

Taking the time to forecast demand helps you make better inventory decisions that can impact logistics operations and financials, from warehousing costs to staffing. Forecasting demand will rarely be 100% accurate, but it can give you better insights into your entire supply chain.

5 best practices for maintaining optimal inventory levels

As mentioned earlier, maintaining optimal inventory levels becomes more complex as you expand your supply chain. Maintaining healthy inventory levels is one of the most important aspects of running an online store as customers expect immediate order fulfillment.

Every online store requires a different inventory management strategy to track inventory efficiently, but here are some universal best practices for maintaining optimal inventory levels.

1. Implement an inventory tracking system

By knowing how much of each SKU is located at each geographic location, you can improve stock control across your distribution network. Inventory tracking systemsoffer such real-time access to stock levels across logistics centers and sales channels.

As you expand your supply chain, implementing an inventory tracking system is a surefire way to efficiently allocate inventory by having full access to real-time data.

2. Determine reorder points

The last thing any business owner wants to do is manually track inventory, as there will be no time for anything else. Once you determine your optimal level of inventory, you can set reorder points to help put the reorder process on autopilot.

A reorder point refers to the minimum level of inventory that determines when it’s time to reorder inventory. The reorder quantity you set should consider both customer demand and lead times. Most inventory apps also offer a feature that will automatically notify you when inventory levels reach a reorder point.

3. Use an inventory management system

With the right kind of technology that complements the supply chain at every stage, your distribution network can operate at maximum efficiency.

By implementing an inventory management system, you can sync SKUs and orders to view all inventory, fulfillment centers, sales channels, and customers in one place. Many fast-growing online brands use an inventory management system to help them track inventory in real time and automate inventory tasks to save on time and improve accuracy.

4. Communicate clearly with your supplier

Clear communication with suppliers about your expectations, and the new goods schedule, is a cornerstone of good inventory management. You also need to be mindful of any holidays or closures your manufacturer has, such as factory shutdowns.

Having access to insights into your suppliers’ operations should be harnessed and built into your inventory tracking strategy. Your suppliers play a huge role in your supply chain, so be sure to monitor their performance over time.

5. Carry out inventory audits

Undeniably, inventory audits and warehouse audits can be time-consuming tasks, especially if you’re dealing with a large amount of inventory and tracking it all manually using spreadsheets.

Thankfully, conducting inventory audits consistently can be automated and digitized by syncing your online store with an inventory storage system or a 3PL’s fulfillment technology.

How ShipBob helps you maintain low inventory levels

ShipBob works with thousands of brands in a wide range of industries to help them overcome inventory challenges. By outsourcing fulfillment to ShipBob, you gain access to valuable inventory management tools, real-time inventory tracking, and much more.

Our retail fulfillment solution offers access to a growing network of fulfillment centersall powered by the same tech stack, which provides you full visibility into inventory levels across locations from one dashboard. Here is an overview of how ShipBob can help you manage and optimize inventory levels.

Reports real-time inventory level data

By offering inventory tracking and reporting functionality, ShipBob shares real-time stock updates through its merchant-facing dashboard, which allows merchants to make better decisions on when to replenish inventory to avoid stockouts.

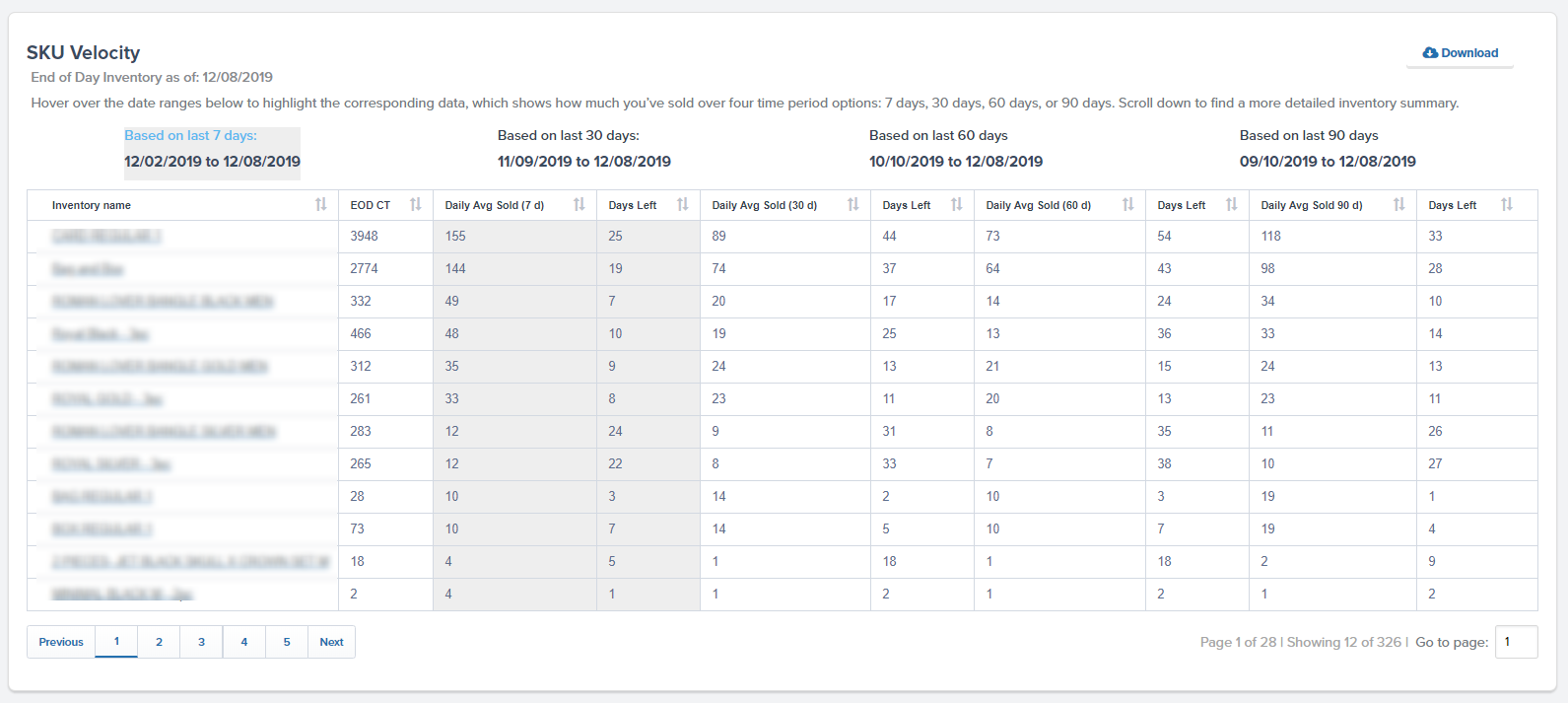

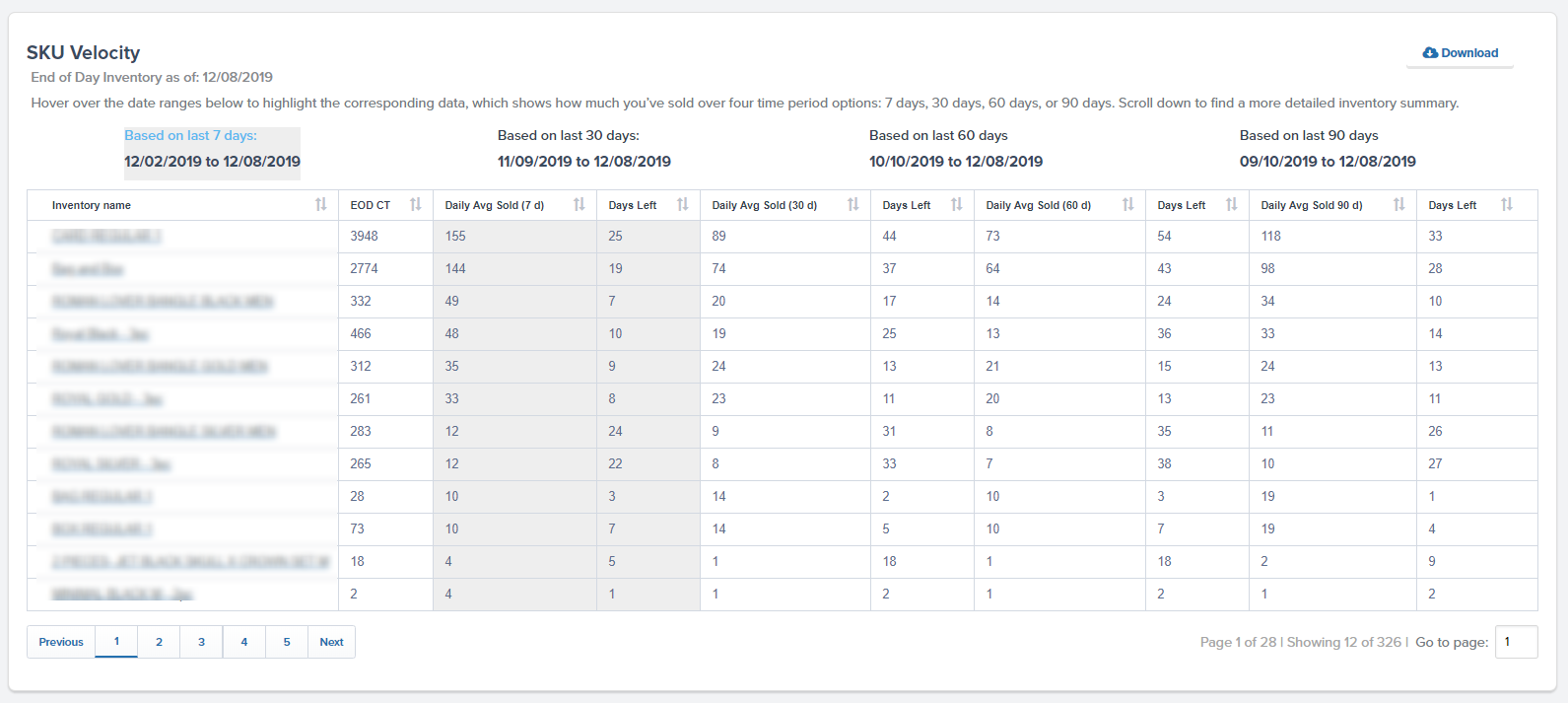

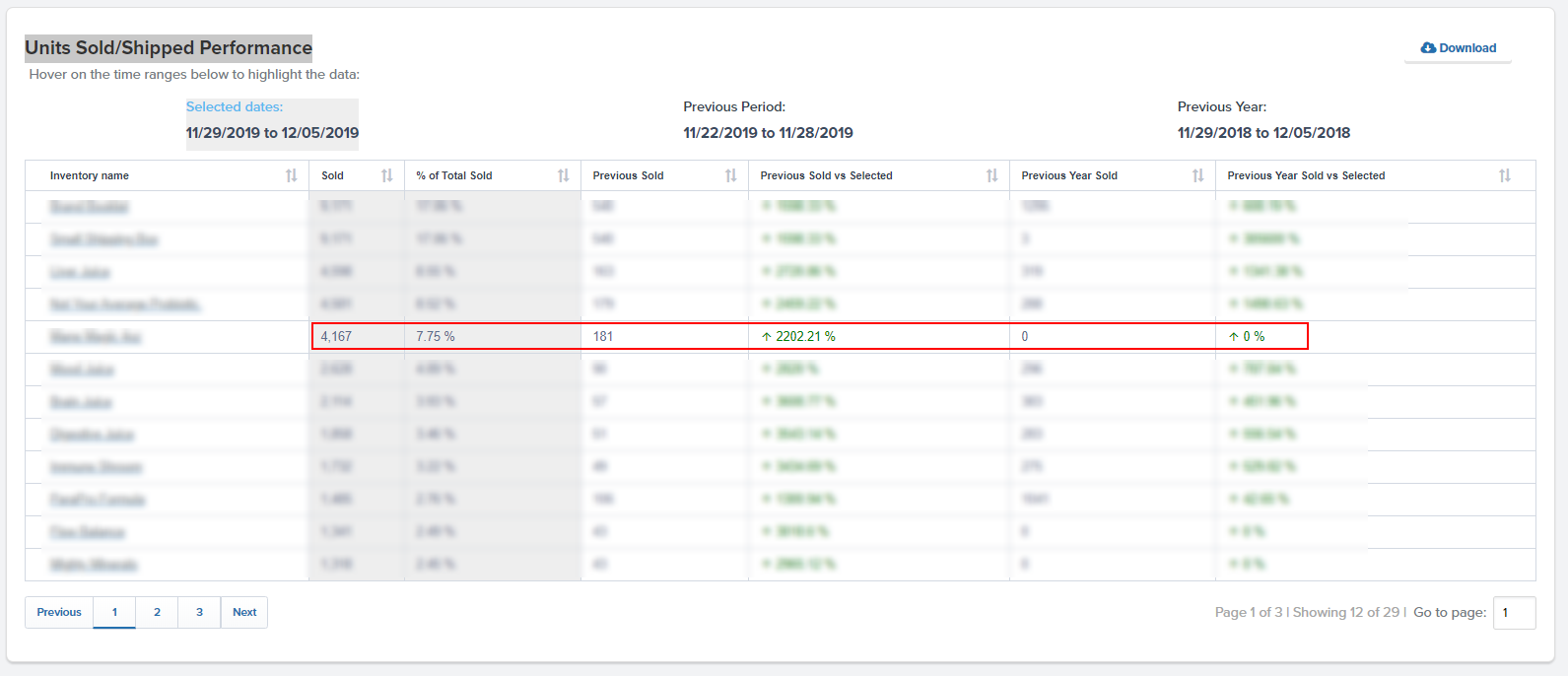

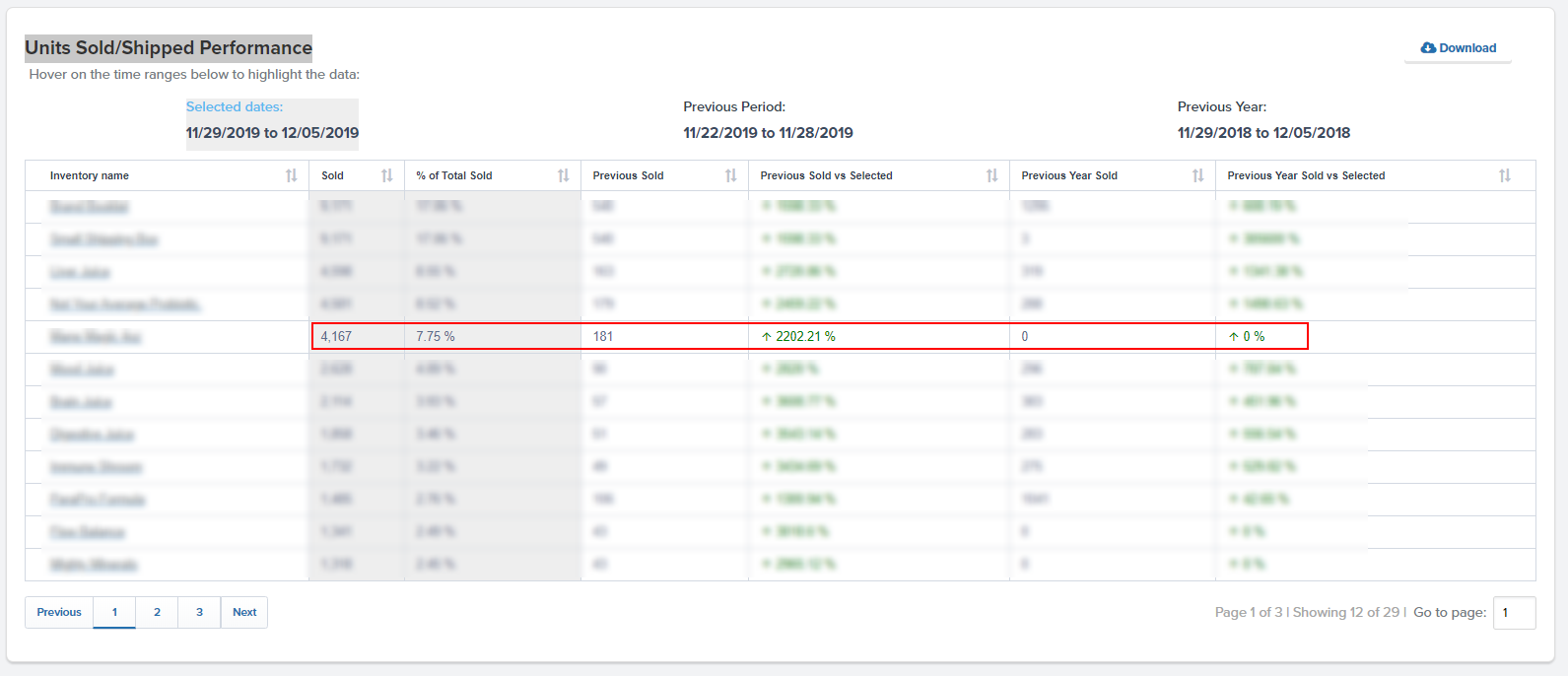

Our advanced analytics and reporting tool offers extensive insights into SKU performance across channels and real-time inventory reports that answer questions like:

- How much inventory do I currently have in each fulfillment center?

- What were my historical stock levels at any point in time, in any location?

- How many days do I have left until a SKU goes out of stock?

- When should I reorder inventory for each product?

- How often is each product sold across channels?

- If I run a flash sale on my site, how will it affect available inventory levels?

- How does current product demand compare to previous periods?

- How are my sales affected by different seasons and months?

- What are my best-selling items?

- Which items are not generating sales and incurring high warehousing fees?

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Reduces overall inventory costs

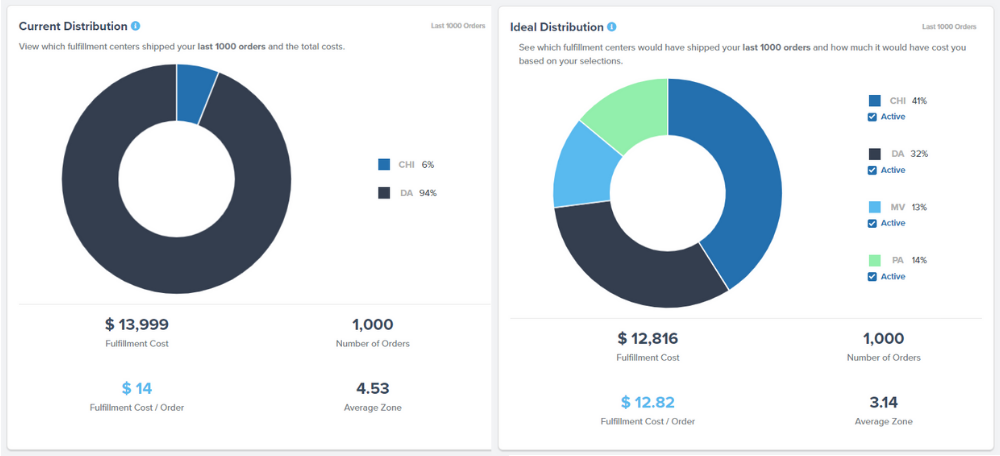

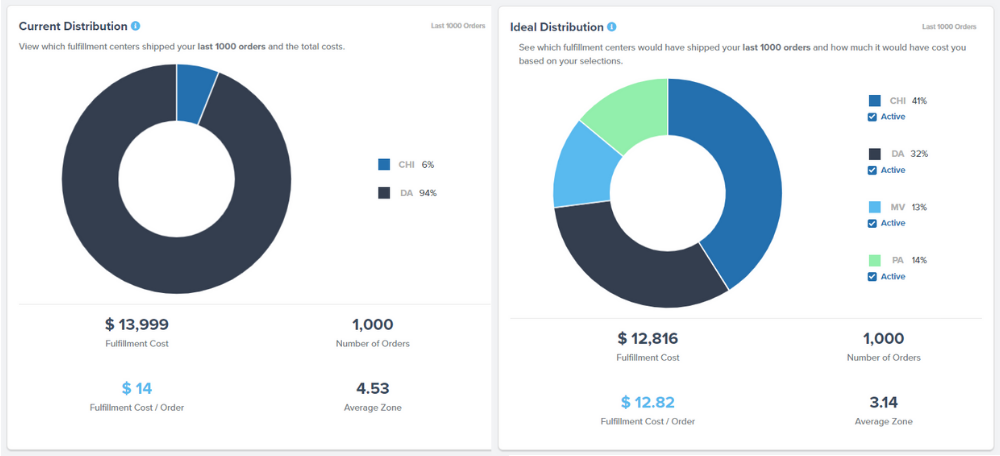

ShipBob makes it easy to expand into multiple fulfillment centers across the globe while still keeping tack of how much you’re spending on storage. Using the ShipBob dashboard, you can access data that provides answers to questions like:

- What is my average storage cost per unit?

- What is my average fulfillment cost per order?

- What is the total number of bins/shelves/pallets that I’m being charged for?

- How much money would I save on shipping if I changed my inventory’s fulfillment center locations?

In addition, we also help you optimize warehousing by providing the infrastructure you need, including global fulfillment locations, integrated technology, and expertise. Once we receive your inventory, we follow standardized processes to optimize storage to help save you on costs.

“My CPA even said to me, ‘Thank God you switched to ShipBob.’ ShipBob provides me clarity and insight to help me make business decisions when I need it, along with responsive customer support.”

Courtney Lee, founder of Prymal

Minimizes inventory waste

ShipBob’s technology makes it easier to forecast demand so you can reduce the risk of ordering too much inventory. With ShipBob’s inventory forecasting tools, you can efficiently stock inventory levels according to expected demand, as well as prevent inventory waste due to seasonality, past expiration dates, or otherwise unsellable product.

Also, having a clear view of inventory levels can help you avoid inventory shrinkage by maintaining control over your inventory.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

Automates reorder notifications to prevent stockouts

ShipBob provides historical inventory data you can use to calculate accurate reorder points, so you can take into consideration lead times and inventory receiving times as well. When the stock threshold level is reached, our inventory automation tool automatically sends a notification, so you can reorder.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Records real-time inventory counts at the SKU level

ShipBob’s inventory tracking software offers an on-demand view of all inventory on the SKU level and its performance, including unit sales per day. You’re given visibility into what is available, and where, as well as the real-time impact of potential changes.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

Allows for a distributed warehouse system as you grow

ShipBob offers a distributed warehouse network that helps you expand customer reach, reduce shipping costs, and speed up last-mile delivery.

Since ShipBob’s entire international fulfillment network is powered by the same technology, you get a sense of which items are selling faster at certain locations compared to others.

By aggregating historical order data, you get an analysis of whether you should centralize or decentralize inventory, which fulfillment centers you should stock more or less at, and how you can best allocate product across our network to efficiently meet demand.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

Conclusion

Keeping track of inventory levels as you expand into new warehouse locations and sell across multiple sales channels can get challenging. But a 3PL partner like ShipBob can help.

ShipBob offer a best-in-class fulfillment solution to help you maintain optimized, low inventory levels, set reorder notification points, and track inventory across channels. Our tech-enabled ecommerce fulfillment solution can help reduce logistics costs and prepare your business for the unexpected.

To learn more about ShipBob, click the link below to request custom pricing.

Improve inventory management with ShipBob’s WMS

For brands looking to store inventory and fulfill orders within their own warehouses, ShipBob’s warehouse management system (WMS) can provide better visibility and warehouse organization.

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfillment network) to streamline in-house inventory management and fulfillment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

For brands looking to scale internationally, ShipBob even offers a hybrid solution where merchants can employ ShipBob’s WMS technology in their own warehouses while simultaneously leveraging ShipBob’s fulfillment services in any of ShipBob’s fulfillment centers across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Inventory levels FAQs

Here are some answers to the most commonly asked questions about maintaining and optimizing inventory levels.

What are inventory levels?

‘Inventory levels’ refers to the amount of inventory you have available throughout your entire distribution network. By keeping track of inventory levels, you can consistently meet demand while only storing the inventory you need at a given period. Software tools that help inventory management and demand forecasting help online brands track and maintain inventory levels effectively.

What is the minimum level of inventory?

This is the bare minimum units of any inventory product that must be in stores or warehouses at all times. If the stocks fall below the minimum level, it could cause backorders, split shipments, and stockouts. The minimum inventory level varies depending on your storage space, SKU count, inventory turnover, days sales in inventory, and more.

What is the maximum inventory level?

Maximum inventory levels is the limit you set for how much inventory you have available at any given period. Maximum inventory amounts depend on your available capital, storage space, shelf-life of materials, SKU count, and average inventory turnover rate. Having a surplus of inventory can lead to dead stock (e.g., unsellable inventory) and higher carrying costs, which cuts into profit margins.

What is the optimal inventory level?

Optimal inventory levels are the ideal quantities of stock that you should have in a physical store or fulfillment center at any given time. Inventory levels that are optimized are not so high that you spend too much capital, you’re sitting on inventory that will take too long to sell through, and/or you risk obsolete stock. On the flip side, it’s not too little that you run out of stock.

How does ShipBob help maintain low inventory levels?

By offering inventory tracking and historical inventory data functionality, ShipBob provides real-time inventory updates all from one dashboard. This allows merchants to make better decisions on when to replenish inventory to avoid stockouts, backorders, and dead stock. Through ShipBob’s dashboard, you can view past inventory data, set reorder notification points, and track inventory across your entire distribution network to meet demand while optimizing storage costs.