Safety Stock Calculator

Calculating your safety stock allows you to better prepare for the unknown, without overspending on unnecessary inventory levels.

Learn About Safety StockSafety stock formula inputs

In order to calculate your safety stock accurately, you’ll need to know the following inputs.

Maximum daily usage refers to the maximum number of units you expect to sell in a day. This is based on your historical data.

Average daily usage refers to the average number of units you sell per day. Calculate your average based on recent historical data.

Maximum lead time refers to the maximum numbers of days it could take to receive new inventory, based on historical data.

Average lead time refers to the average number of days it typically takes to receive inventory, based on recent historical data.

[CP_CALCULATED_FIELDS id=14]

Take the guessing out of inventory management & fulfillment with ShipBob

1. Connect

Connect your store, import your products, then send us your inventory.

2. Store

We store your inventory in any combination of our fulfillment centers.

3. Ship

As soon as a customer places an order, we ship it from the nearest fulfillment center.

Distributed inventory

With ShipBob’s network of fulfillment centers, you can strategically split your inventory across our locations to get your products from point A to point B more quickly and affordably. Storing inventory near your customers helps reduce the shipping zones and costs associated with shipping orders to faraway destinations.

Distributed inventory also helps you stay competitive by offering fast shipping to your customers. When an order is placed, ShipBob’s algorithm automatically selects the warehouse and carrier that will give you the quickest turnaround at the best price. This strategy has helped our merchants bring 13% savings to their bottom line.

100% Coverage Across the Continental US

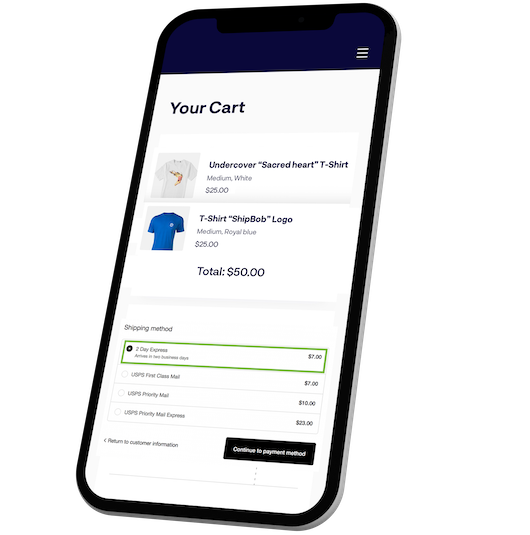

If you’re looking to expand into the United States, ShipBob has 2-Day Express Shipping that provides 100% coverage in the continental US from even just one fulfillment center.

You can also distribute your inventory across ShipBob’s fulfillment centers across all regions of the United States. We leave it up to you to decide where you want us to store your inventory.

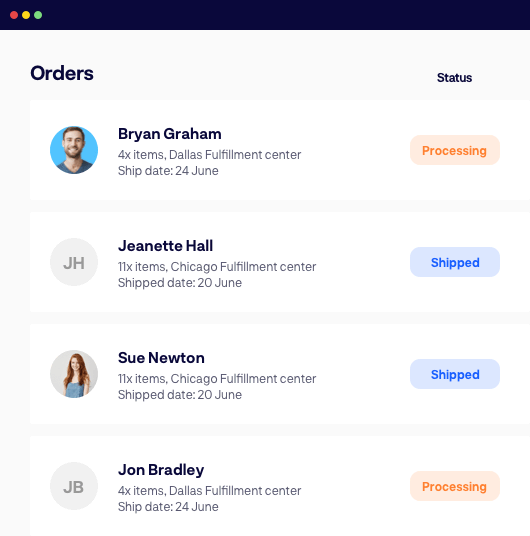

Order management

At ShipBob, we track your orders from A to Z. Filter orders by status, search for specific orders, see a quick timeline view of where your order is in the fulfillment process (e.g. when an order is picked, packed, or shipped), easily find shipping-related information (e.g., weights, dimensions, or carrier service), and get a quick snapshot of any orders that require action.

With order management software for your direct-to-consumer and wholesale shipments, you can manage subscriptions, make changes to your orders post-purchase, map your store’s shipping options to ShipBob, and automatically share tracking information with your customers.

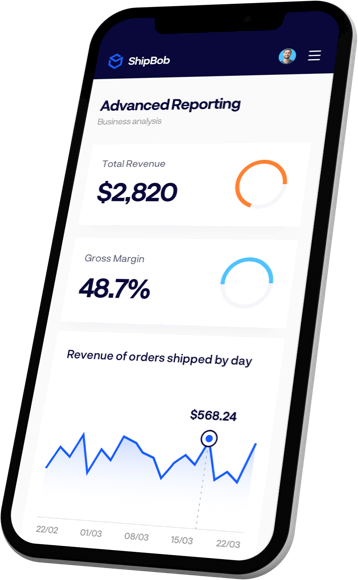

Reporting and analytics

To provide you with visibility into our operations and performance, and also hold ourselves accountable, ShipBob’s free analytics tool is packed with charts to help you with everything from year-end reporting, to better supply chain decision-making.

Data can be a competitive advantage, and our reports show an analysis of which fulfillment centers you should stock, days of inventory left before you run out, impact of promotions on stock levels, each shipping method’s average cart value, shipping cost, and days in transit, your fulfillment cost per order, storage cost per unit, and much more.

End-to-end customer experience

We care about the customer experience as much as you and strive to be an extension of your team. From custom branded boxes to free plain packaging, ShipBob works with you to provide the unboxing experience you want. We also help you offer the fastest, most cost-effective shipping options to meet your customers’ expectations.

As soon as an order ships, tracking is pushed back to your store. We also offer return management services, allowing customers to generate return shipping labels and track returns, while getting your products processed and back into your available inventory as efficiently as possible.