Table of Contents

** Minutes

What are the different stock controlling methods?

How to improve stock control for your ecommerce business?

What to look for in a stock control system?

How to optimize stock control with ShipBob’s inventory management software

It can be tempting to fill a warehouse with as much stock as there is space to ensure you meet customer demand. But it goes without saying that taking the easy route is not always the most efficient and cost-effective.

Having an optimal amount of stock on hand can be challenging, especially if you have a lot to keep track of. And stock shouldn’t just sit still — it’s constantly moving throughout the retail supply chain.

Fortunately, there are several ways to make informed decisions on controlling stock to better manage your ecommerce supply chain and continuously meet demand.

In this article, you will learn the importance of stock control, different methods that are common in ecommerce, and tips on how to better control stock levels.

What is stock control?

Stock control, also known as inventory control, is the process of optimizing stock levels in a warehouse(s) to stabilize inventory storage costs while maintaining enough stock to meet customer demand.

If done right, proper stock control can optimize logistics costs while ensuring you have just enough stock stored at all times. In order to control stock, you will need access to tools and data to make better predictions on supply and demand.

What are the different stock controlling methods?

Though it is impossible to accurately predict future demand, there are common methods you can use to help make better predictions on how much stock to have on hand and when the right time is to reorder. These methods are designed to optimize stock levels, improve inventory accuracy, and provide flexibility.

Here are some of the most common stock controlling methods used in ecommerce:

Economic order quantity (EOQ)

The economic order quantity (EOQ) method is designed to find the optimal order quantity to get from your manufacturer in order to minimize costs and optimize warehousing space.

Also referred to as “optimum lot size,” this method can help you make better decisions on how to avoid stockouts, how much safety stock to have on hand, and when it makes the most sense to order more inventory.

The EOQ calculation is based on the following three variables: holdings costs, annual demand, and order cost. To give it a test run, try using our simple EOQ calculator.

Vendor-managed inventory (VMI)

The VMI method consists of delegating the process of ordering and restocking inventory to a third party. Managing and owning ecommerce inventory and the associated risks in managing it all are taken care of by the vendor.

By using this method, you pay for the stock only after it has been sold, while unsold stock is returned to the vendor. This allows businesses to worry less about controlling inventory by having it be handled by someone else.

Just-in-time (JIT)

The JIT inventory method refers to ordering as much stock required to meet customer demand, but it also requires the ability to order quickly soon after to meet the next batch of orders.

This stock control method is designed specifically to reduce inventory carrying costs, increase efficiency, and decrease waste by only purchasing stock that’s sure to sell sooner than later.

Although this method comes with several benefits, there are some big downfalls. In order to implement the JIT method, ecommerce business must be able to accurately forecast demand, as well as have the ability to access real-time stock levels, or risk a high volume of stockouts.

FIFO (first in, first out)

The FIFO method requires the first batch of inventory that arrived in the warehouse to be sold first and shipped out first. This makes it easy to calculate costs and value of inventory despite any changes in supplier pricing.

Using this method, batches with the oldest manufacturing or receiving date will be picked and sold first.

By using FIFO, any inventory left during the end of the financial year does not affect cost of goods sold (COGS), but it can cause some inaccuracies, which can impact inventory accounting. It also does not offer any tax advantages.

How to improve stock control for your ecommerce business?

Order too much stock and you end up overpaying for warehouse space, and worse — accumulating dead stock (i.e., inventory that becomes unsellable over time).

But not ordering enough stock can cause items to be out of stock, can lead to backorders, and cause a decline in customer satisfaction.

Obviously, each scenario is less than ideal. Therefore, exercising better stock control is the best way to help your business stay afloat. Here are some best practices to help you improve and optimize stock control for your ecommerce business.

Understand your stock levels

To better control stock, you need to pay close attention to stock trends over time. Having a better sense of which items are slow-moving versus fast-moving and replaced in a specific time period can help you make better decisions on when to restock.

The inventory turnover ratio is a great tool to help you determine the best time to order new stock and at what quantity per SKU. The inventory turnover ratio formula is simple:

Inventory Turnover = COGS / Average Inventory Value

To calculate, you will first need to identify COGS and your average inventory value (beginning inventory + ending inventory / 2). Once you have those numbers, you can easily calculate inventory turnover rate using our inventory turnover ratio calculator.

Determine how much to reorder

Once you have a better sense of stock trends, you will then have to figure out how much to reorder from your supplier or manufacturer. Before you submit an inventory replenishment purchase order, calculating the reorder quantity can help you decide on the optimal amount to reorder.

The reorder quantity formula is calculated by multiplying average daily units sold by the average lead time:

Optimal Reorder Quantity for a SKU = Avg. Daily Units Sold x Avg. Lead Time

If you see your order volume start to increase, it’s important to calculate reorder quantity often as sales trends can change quickly.

Find opportunities to optimize your supply chain

Controlling stock is just one aspect of supply chain planning. To manage logistics costs and efficiency, it’s always important to seek opportunities to optimize your supply chain.

One of the best ways to create an efficient supply chain is to implement technology and automation tools.

Many direct-to-consumer (DTC) brands invest in an inventory management system to access data and analytics that help:

- Keep track of stock levels in real time.

- Set automatic reorder notifications to make sure you never run out of inventory or wait too long to reorder (factoring in lead times from the manufacturer, receiving turnaround times in the warehouse, and so on).

- Make better inventory forecasting predictions.

What to look for in a stock control system?

Stock control systems are designed to help automate stock control, which can help improve the overall inventory management process.

As long as orders are coming in, stock levels will constantly shift. That’s why tracking in real time is so important; it allows you to accurately view stock levels at any given time, even across warehouse locations.

Here is an overview of how a stock control system works:

Track inventory levels in real time

Knowing what (and how much) you have in stock and where it is stored can go a long way toward ensuring on-time order fulfillment.

Since inventory is constantly moving and orders are continuously processed, real-time inventory tracking helps to ensure you have an accurate sense of how much inventory you have on hand and whether or not you’ll have enough to fulfill orders.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours. For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Though tracking inventory levels can be done using a manual system or spreadsheets, there are several inventory apps and other types of tools available that are worth the investment.

These tools are designed specifically to help you track stock in real time while saving you time and reducing human error.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Data and analytics reporting capabilities

To make better decisions and forecast demand, you need access to a data and analytics reporting tool. Without data, you will have to guess on how much stock to order and when, which is not enough insight to control stock levels.

A good stock control system should provide you with insights that help you connect your supply chain activity with sales data so you’re better informed. With the right technology, you can get answers to questions such as:

- How much stock do I currently have on hand?

- What were my historical stock levels at any point in time in any location?

- How many days do I have left until a SKU will be out of stock?

- By when do I need to reorder inventory for each product?

- If I run a flash sale on my site, how will this affect my available stock levels?

- How does product demand compare to previous periods?

- How are my sales affected by different seasons and months?

- What are my best-selling items?

- Which items are not generating sales?

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

How to optimize stock control with ShipBob’s inventory management software

By outsourcing logistics operations and fulfillment to ShipBob, you’re given the tools necessary to help you optimize stock levels while minimizing warehousing and other costs.

We offer best-in-class logistics capabilities with a global fulfillment network powered by technology with built-in inventory management tools.

With ShipBob, you can automate inventory tracking and view stock levels in real time across ShipBob’s fulfillment center locations all from one dashboard.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Here is an overview on how ShipBob’s software can help you optimize stock control.

Automate the stock control process

With ShipBob, you can automate inventory tasks, such as setting up reorder notification points when inventory levels fall below a certain threshold.

This way, you can reduce manual inventory tracking and optimize stock levels. The notification points you set can be based on the insights you have using ShipBob’s free analytics and reporting tool that provides insights and visualizations using historical order data to help with demand forecasting.

“I wanted to create something that was fully automated, so I could focus on driving sales. I didn’t want to have to worry about inventory and distribution as much.

When I was gearing up to launch the business, I was looking for someone who would automate fulfillment for us. I chose ShipBob, and it turned out to be a very easy and scalable solution.”

Josh Hollings, Founder & CEO of Drop FX

Leverage distribution fulfillment networks and stay competitive

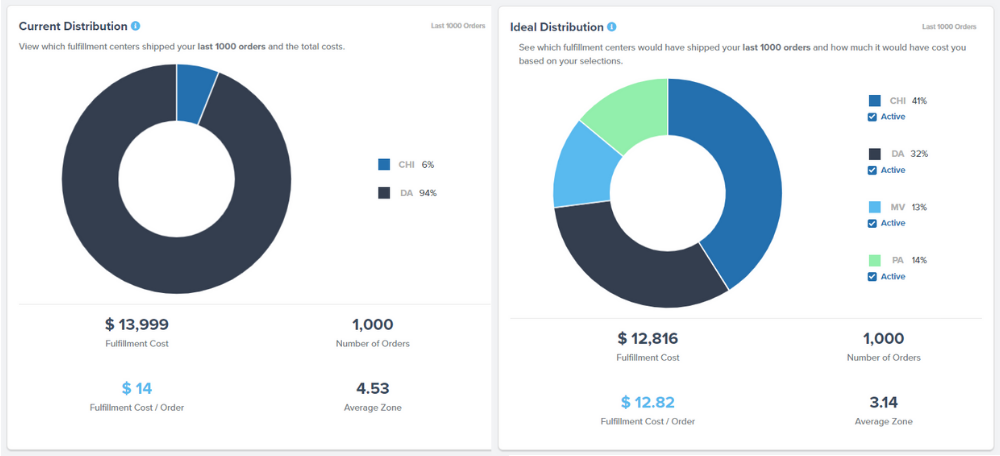

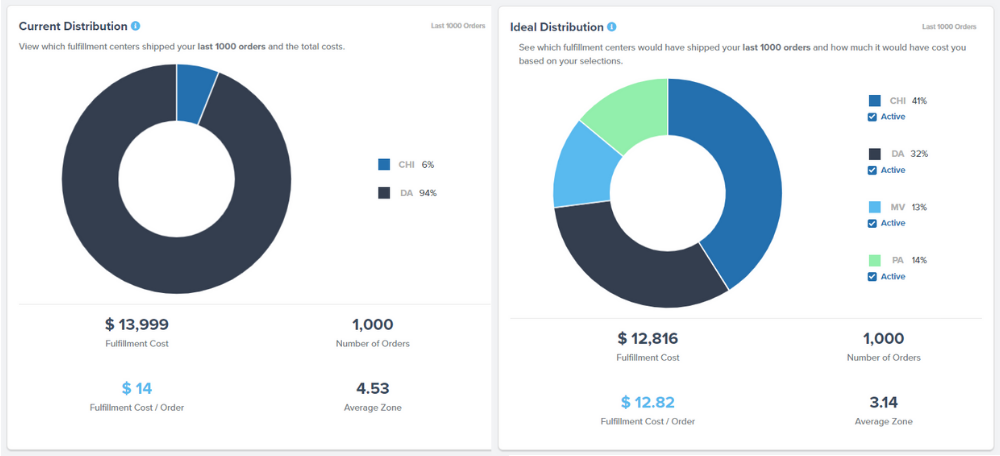

Optimizing stock levels isn’t the only way to reduce logistics costs. Along with our inventory management tools, ShipBob offers the ability to split inventory across multiple fulfillment center locations to reduce shipping costs and speed up last-mile delivery.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

Since ShipBob’s entire distribution network is powered by proprietary technology, merchants are able to track inventory across multiple locations all from one dashboard, making it easy to optimize stock levels per location.

You can easily visualize where your customers are, and compare your current and ideal distribution to optimize product allocation:

Another benefit of storing inventory across locations is that it allows you to have backup stock in case of emergency (e.g., unexpected warehouse closure due to bad weather).

“We love that ShipBob actually operates its fulfillment centers — they know their operations and they are very clear about it.

ShipBob having multiple locations was also huge for us. Keeping our inventory in Chicago and Los Angeles has brought cost savings since we ship from the locations that are closest to the customer.”

Courtney Lee, founder of Prymal

Easily integrate with existing ecommerce platforms

By connecting ShipBob’s technology to your ecommerce platform, you can manage all your fulfillment and logistics needs all from a single dashboard:

- View the status of inventory and quantity on hand across locations at any point in time.

- Identify slow-moving inventory with high storage costs

- Gain insights into the performance of units sold over time by channel.

- And much more.

“ShipBob’s technology integrates with Shopify and Bold Subscriptions, and it is so cool to see how all the shipments move through the process so quickly and how fast the whole fulfillment process happens.”

Andrea Hamilton, founder of The Finer Things 1920

Improve inventory management with ShipBob’s WMS

For brands looking to store inventory and fulfill orders within their own warehouses, ShipBob’s warehouse management system (WMS) can provide better visibility and organization.

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfillment network) to streamline in-house inventory management and fulfillment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

For brands looking to scale internationally, ShipBob even offers a hybrid solution where merchants can employ ShipBob’s WMS technology in their own warehouses while simultaneously leveraging ShipBob’s fulfillment services in any of ShipBob’s fulfillment centers across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Conclusion

Controlling stock can seem like a moving target, but that’s not to say that having the right support, technology, and resources can help you make better decisions when it comes to ordering and stocking inventory.

ShipBob is a third-party logistics (3PL) provider that offers a full suite of fulfillment solutions to help you scale your business while saving money and time.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

To learn more about how ShipBob can help you with warehousing, inventory control, and retail fulfillment, click the button below to speak with a fulfillment expert.

Stock control FAQs

Here are some answers to common questions about stock control and managing inventory levels.

What are the methods of stock control?

To optimize stock control, there are several methods to choose from, including the following: economic order quantity (EOQ), vendor-managed inventory (VMI), just-in-time (JIT), and first in first out (FIFO).

Why is stock control important?

Stock control is a key part of inventory management that helps to maximize and regulate stock levels to meet customer demand while keeping warehouse costs to a minimum. Stock control also helps eliminate common inventory issues such backorders, stockouts, and dead stock.

What are stock control systems?

Stock control systems are designed to help ecommerce businesses automatically track stock levels in real time, especially across multiple warehouse locations. These types of systems also provide insights and data to help with demand forecasting.

What is the golden rule of stock control?

Ecommerce businesses should always strive to keep maximum inventory of the best-sellers and reduce the volume of slow-selling stock. Historical order data helps with forecasting demand, which can also help to provide insights into which items you need to reorder at the SKU level in given time period.