Table of Contents

** Minutes

Downsides of having too much stock

5 reasons businesses overstock inventory

As an ecommerce business, customers will expect their orders to be fulfilled efficiently and delivered on time. When you experience stockouts, you can’t fulfill orders which is harmful to your business. As such, you end up paying for canceled orders and even risk losing your customers to the competition.

To avoid the high cost of stockouts, you have to ensure that you’re replenishing your inventory on time and efficiently restocking your best-selling SKUs. However, many businesses fail to plan their replenishment strategically and end up overstocking inventory in a bid to prevent stockouts. This too can be extremely expensive and mustn’t be left unchecked.

In this guide, we’ll find out what overstocking is, what causes it, how it affects your business, and how you can prevent it. Let’s get started.

What is overstocking?

Overstocking is when you order more inventory than you can sell. Thus, you end up with excess stock sitting in your warehouse with no prospect of getting sold any time soon. This not only racks up your inventory storage costs but could potentially leave you with expired or obsolete inventory, which can hurt your bottom line.

Overstocking vs. understocking

In overstocking, you purchase too much inventory and end up with excess stock that you can’t sell. Meanwhile, in understocking, you purchase too little inventory that you end up with stockouts. Both of these scenarios result in serious losses for a business.

For instance, when you understock, you don’t have the inventory you need to fulfill customer orders. That means your customers will cancel their orders and possibly even go to your competitors to buy the product. Moreover, you risk being viewed as unreliable, resulting in reputational damage that’s hard to recover from.

Downsides of having too much stock

Overstocks cost retailers billions of dollars in lost revenue each year. In fact, a study from Tyco Retail Solutions found that retailers worldwide lose $362.1 billion annually. So how exactly does having too much stock impact your business? Let’s take a look at the biggest downsides to overstock.

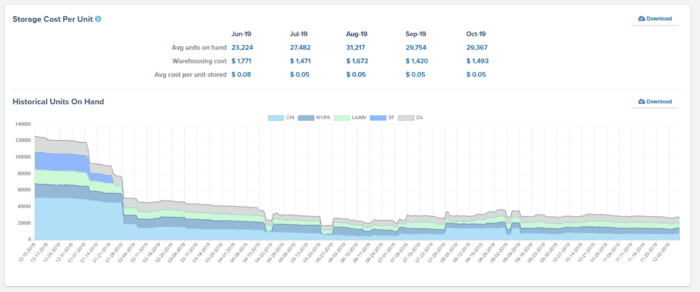

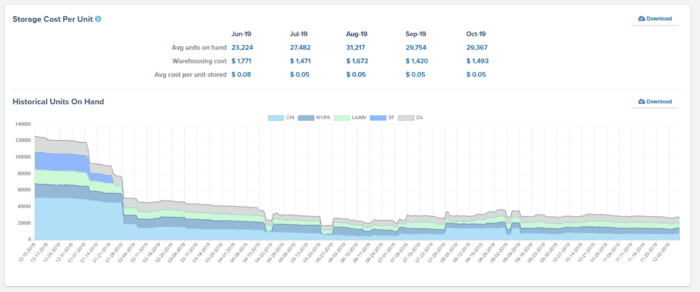

Increased storage costs

The cost to store surplus stock is one of the most prominent downsides of overstocking. Warehousing costs are not cheap, and they don’t just include the cost to rent a warehouse or storage space but also the cost of labor to manage your warehousing operations. McKinsey reports that companies are spending about $300 billion every year on warehousing operations alone.

In addition, your surplus inventory is also costing you in terms of space. Not only are you spending money to stock the excess inventory but you’re also losing money because they take up valuable storage space that could be used for storing products that sell well.

Less working capital

When you spend money to purchase inventory, you won’t recover that investment unless you sell the product. That means your money gets tied up in excess inventory when you overstock. As such, you have less working capital to operate your business, which can snowball and turn into more serious problems for your business.

For starters, you won’t have the funds needed to restock inventory that’s selling well, resulting in lost sales. Moreover, you won’t be able to introduce new products into your assortment that could be profitable for your business, resulting in missed opportunities. This is particularly harmful to small businesses that have thin margins and are likely in lots of debt, making it difficult for them to recover.

Loss of products

Many products come with an expiration date, which means that being unable to sell them for long periods of time will result in loss of inventory and ultimately, loss of money. When you overstock, there’s a significant risk that you’ll end up with dead stock. This is particularly true for perishable and time-sensitive goods, which are at a higher risk of expiration or obsolescence.

How much stock is “too much?”

Now the big question is: When are you considered “overstocked?” How much stock is considered “too much?” The answer varies for each business. There’s no one-size-fits-all number for the right inventory amount, even within the same company. Certain SKUs may sell well and therefore, require more units in stock. Meanwhile, other SKUs may be slow to sell and quickly build up over time, resulting in overstocking.

So, the best way to determine whether you’re overstocked is by looking at your inventory turnover rate at the SKU level. A low inventory turnover rate is a sign that you’re overstocking. This would often call for SKU rationalization so you can quickly discontinue items that aren’t selling all too well.

5 reasons businesses overstock inventory

Since overstocking is such a serious issue for businesses, it’s important to get to the root of the problem and address the reasons why businesses overstock inventory.

The fear of stockouts

Of course, the biggest reason why businesses overstock inventory is because they don’t want to experience stockouts. Considering the high cost of stockouts, many businesses overreact and end up over-ordering inventory. This is a perfectly reasonable reaction because according to the Tyco Retail Solutions study highlighted earlier, stockouts are costing global retailers $456.3 billion annually.

The solution

While stockouts can be harmful and expensive, they don’t necessarily have to result in overstocking. Businesses need to replenish their stock in a timely manner by setting up reorder notifications, which will allow them to place inventory reorders before stock runs out. Additionally, they can also keep some safety stock to tide them over in case of unexpected surges in demand or disruptions in the supply chain. You can use the safety stock formula to accurately calculate how much safety stock you need for your business.

Improper inventory management

Proper inventory management helps to ensure that companies always maintain sufficient stock levels while balancing their inventory holding costs and purchasing costs. However, manmade errors resulting from a lack of visibility or expertise can lead to overstocking. If you don’t have sufficient insight into your inventory costs, you could be acquiring new inventory without properly factoring in your cost of goods sold and your profit margins.

The solution

Invest in ecommerce inventory management software that gives you full visibility into your inventory levels and performance. This will also help you keep track of different costs associated with procuring and storing inventory, which will make it easier to properly manage your stock and acquire more inventory accordingly.

Seasonal demands

As sales volumes change with seasonal demand, many businesses struggle to accurately plan their procurement and may end up purchasing too much inventory. This is exacerbated by a failure to strategically price your products or properly promote your brand to take advantage of seasonal buying windows.

The solution

Companies need to know exactly how seasonality affects demand for their business. This will allow them to be strategic with their assortment planning, which will make it easier to accurately plan their procurement to avoid overstocking.

Lack of demand forecasting

When businesses don’t have insight into future demand, it prevents them from planning their inventory procurement accurately. They may not be able to tell when sales for a particular SKU are slowing down, which may warrant a reduction in the number of units to reorder. So, they could end up ordering more inventory than their customers need.

The solution

Investing in proper demand forecasting tools is crucial as it allows businesses to get an accurate idea of how much inventory they can expect to sell in the future. As such, they will be able to tell if demand is slowing down so they can reduce the number of units they reorder. Alternatively, it even helps them to avoid stockouts as it could predict future demand surges, which might call for an increase in the number of reordered units.

Overcompensating for supply chain issues

Finally, businesses have been dealing with stockouts resulting from recent supply chain issues such as the Panama Canal incident, the war in Ukraine, the COVID-19 pandemic, and the mass resignations. As such, they’ve been trying to change their ordering tactics by overcompensating and overstocking inventory to avoid disruptions.

The solution

Instead, businesses should work toward building supply chain resilience so they can quickly pick back up even in case of unexpected supply chain disruptions. This could involve working with multiple suppliers, leveraging multiple carriers, distributing your inventory across multiple locations, and relying on logistics experts.

How to avoid overstocking with ShipBob

ShipBob offers a one-stop shop for eliminating overstocking issues by providing efficient fulfillment services and tech-enabled features. Using the ShipBob software, you can get real-time visibility into your inventory movement and advanced SKU tracking, which makes room for improved inventory management, stock control, and inventory optimization.

Forecast demand with ease

The ShipBob software helps with demand planning by keeping track of historical sales data and current inventory performance at the SKU level. This allows you to accurately forecast future demand so you can procure the right amount of inventory to avoid overstocking and understocking.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours. For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Keep track of your inventory levels in real-time

ShipBob offers real-time inventory tracking so you can always get an accurate view of your inventory level. You’ll be able to see how much inventory is being received, how many of them are being prepped to ship, and how many units are ready to sell. This allows you to make inventory reorders accordingly and avoid ordering more inventory than you really need.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Calculate your optimal inventory levels

In addition to inventory levels and demand predictions, ShipBob provides comprehensive reports on your inventory costs and performance. As such, you’ll be able to precisely calculate your safety stock availability and determine optimal inventory levels while factoring in production lead times.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

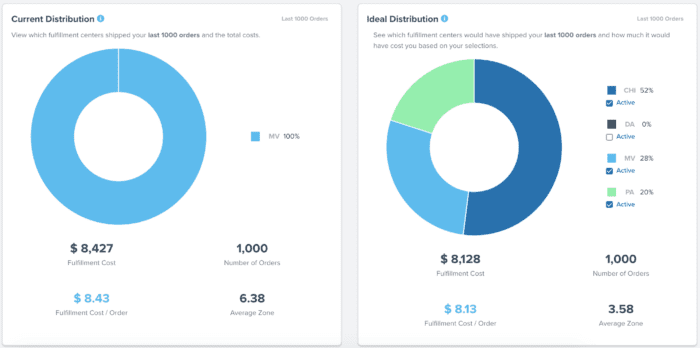

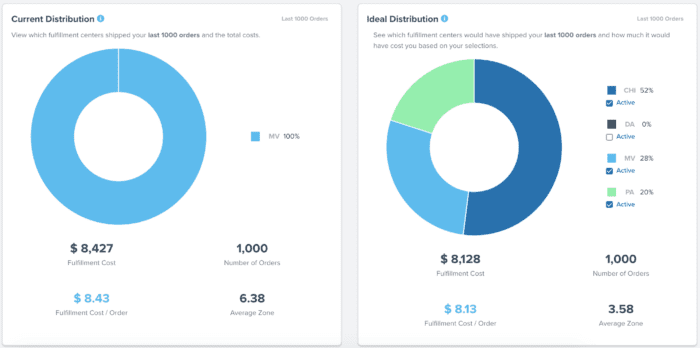

Distribute your inventory to any of our global fulfillment centers

With ShipBob, you can utilize a distributed global network of fulfillment centers to store your inventory. Using more than one fulfillment center allows you to quickly fulfill your orders to your customers across multiple locations, which not only improves your turnaround time but could potentially increase your sales.

“The more fulfillment centers we have inventory in, the more potential shipping addresses we can offer 2-day shipping to. And the more people that we offer the benefit of free 2-day shipping to, the more conversions we get. With ShipBob’s 2-Day Express Program, we’ve seen an 18% reduction in cart abandonment.”

Founder of My Calm Blanket

The software then allows you to calculate the optimal inventory distribution across different locations. It lets you keep track of real-time inventory levels across all these fulfillment centers, so you know exactly when and how much to reorder, which makes it easier to prevent overstocking.

Get Started with ShipBob

If you’re interested in working with ShipBob, request a quote to connect with our team.

FAQs

Overstocking FAQs

Here are answers to the most common questions about overstocking.

What causes overstocking?

The fear of stockouts, improper inventory management, lack of demand forecasting, changes in seasonal demands, and overcompensation for supply chain disruptions are the most common causes of overstocking.

What are the disadvantages of overstocking?

Overstocking leads to higher storage costs, limited working capital, and loss of products due to expiration or obsolescence.

How to avoid overstocking?

Proper SKU management, accurate demand forecasting, and real-time inventory visibility are some effective ways to avoid overstocking.

How does ShipBob help avoid overstocking inventory?

ShipBob offers robust software to help you keep track of different aspects of your inventory such as SKU performance, inventory on-hand, and daily history, using which you can improve your inventory planning and avoid overstocking.