Table of Contents

** Minutes

Why demand planning is important to ecommerce retailers

Step by step guide to demand planning strategy

Demand planning process best practices

Imagine this:

You’ve landed a feature in a reputable industry publication for one of your new products. It took you six months to get their attention, but you finally have! Once consumers read the feature, they arrive on your website in droves and want to buy your product. The only problem is, you’ve run out of stock for it.

By the time you get the inventory for the featured product back in stock, you might lose all the customers who were interested in it in the first place.

Demand planning helps you provide for your customers when they want to buy your products and helps you estimate how much inventory you need, when you need it.

Learn why demand planning is important and how you can build a demand planning strategy step by step.

What is demand planning?

Demand planning is the supply chain management process of predicting the future demand for a company’s products and using those predictions to organize its supply chain to meet that demand.

It uses supply chain forecasting, demand forecasting, operations planning, and inventory management models to accurately predict future demand and how much inventory will be needed to meet it.

Why demand planning is important to ecommerce retailers

Demand planning isn’t necessary for new ecommerce brands that are just getting started, but it’s absolutely critical for fast-growing retailers that need to keep up with their customers. Here are some ways to ensure you’re accurately planning for demand.

Meet growing customer demands

If you’re a high-growth DTC or ecommerce brand, demand planning helps you meet demand as it grows.

At ShipBob, we’ve seen examples of retailers that grow at different speeds.

In one case, a ShipBob retailer grew from 2,000 orders per month to 20,000+ orders per month in a single year. Another ShipBob merchant grew more slowly, from 2,000 orders per month to 6,000 orders per month in just one year.

Both of these retailers use ShipBob’s inventory forecasting tools in their demand planning process to make sure they’re fulfilling demand as it comes to them.

Maintain healthy inventory levels

Demand planning helps you identify exactly how much inventory you should be holding to meet your business’s demand.

By combining your safety stock availability with your demand forecasting models, you’ll ensure that none of your in-demand products drop below their required inventory levels at the wrong time.

Boost customer satisfaction

When retailers use demand planning, they’re able to ensure higher order fulfillment which, in turn, boosts customer satisfaction.

If you don’t execute demand planning consistently, you run the risk of mismatching your inventory with your demand and disappointing your customers.

Keeping customers happy is a key aspect of returning business. 91% of customers won’t engage with an online store after they’ve had a bad customer experience.

By practicing demand planning, you’re making an investment in your customer retention strategy too.

Step by step guide to demand planning strategy

Now that you know what demand planning is and why it’s important, here’s how you can implement demand planning for your business:

Step 1: Implement inventory technology

Demand planning starts with tracking your inventory’s performance. Inventory management software helps you track your inventory levels, orders sales, and shipments.

If you don’t already have an inventory management system in place, here are a few options we recommend:

- Inventory Planner

- ShipBob

All three of these options are web-based applications that either are mobile-friendly or have compatible mobile apps.

Step 2: Collect data

Once you’ve implemented your inventory management software, you’ll need to collect relevant internal data about your business’s order history and performance and external data about your business’s industry, market trends, and consumer behavior patterns.

For internal data, speak to your sales and marketing teams about successful promotions or moments when the business had a surge in demand. Map that qualitative information against the quantitative information around your business’s historical order data and inventory analytics.

For external data, gather industry briefings that document consumer behavior, news articles that share current market conditions, or celebrity social media mentions of your product. Are there any demand signals like market disruptions or natural disasters that might affect demand for your product lines? You’ll have to record them in this step of the process.

Step 3: Organize and analyze data

Now that you’ve collected your internal and external data, it’s time to organize and analyze it.

Some key metrics you should look out for in your data are sales numbers by channel, inventory turnover ratio, and backorder rate.

Is your business seasonal? If so, you should pay special attention to your inventory performance during peak and off-peak sales months.

Step 4: Select your demand forecasting method

Demand forecasting can be done through quantitative and qualitative methods. Here are a few different options to help you decide which method might work best for you:

Quantitative methods:

- Exponential smoothing: This method leverages historical data to make its forecast, but accounts for seasonal variations as well. It’s useful for smaller companies because it can use smaller datasets to make its predictions.

- Regression analysis: This method examines the relationship between two or more specific variables to make its forecast.

- Econometric forecasting: This method is a more complex way of forecasting demand that combines internal and external data to arrive at a forecast.

Qualitative methods:

- Delphi method: This method gathers the opinions and judgments of a small group of industry experts and advisors. These opinions and judgments are summarized by a third party before they’re shared with the business.

- Historical analysis: This method uses the sales history of a parallel product to evaluate future demand. For example, if you’re forecasting demand for a new body wash scent, you might look to past demand for existing body wash scents for your forecast.

- Panel consensus: This method brings internal stakeholders together to provide guidance on the demand forecast. For example, you can ask your customer service team which products are the highest rated by customers. You can also ask your sales team for insights on what customers are requesting from them.

Step 5: Forecast demand

With a mix of methods described above, you can now create your demand forecast.

Demand forecasts are prepared as spreadsheets and represented as trend charts.

Step 6: Make decisions & plans based on forecasted demand

Your demand forecast will help you plan your inventory, which is the last step in your demand planning strategy.

Inventory planning methods like the economic order quantity (EOQ) model use annual demand forecasts to arrive at an optimal inventory mix for your business.

Other factors that you should take into account include production lead times and supplier capacities since they will impact your ability to meet your forecasted demand.

Demand planning process best practices

Good demand planning requires the right software, data, models, and more. Here are a few best practices to ensure your demand planning process is on track:

Use the right software

Utilizing the right software will help you gather data when you need to plan your demand.

You can either choose an inventory management system that tracks your product performance, or you can go for an end-to-end fulfillment system like ShipBob, which tracks your orders from creation to delivery. ShipBob’s inventory management system even tracks returns when your customers need to send an order back to you.

Ensure you have accurate inventory data

Bad data leads to bad decisions in any organization, and the same is true of inventory data. Inaccurate inventory data is usually out-of-date, comes from unreliable sources within your operations, or is presented in confusing ways. It often has a negative impact on your forecast accuracy.

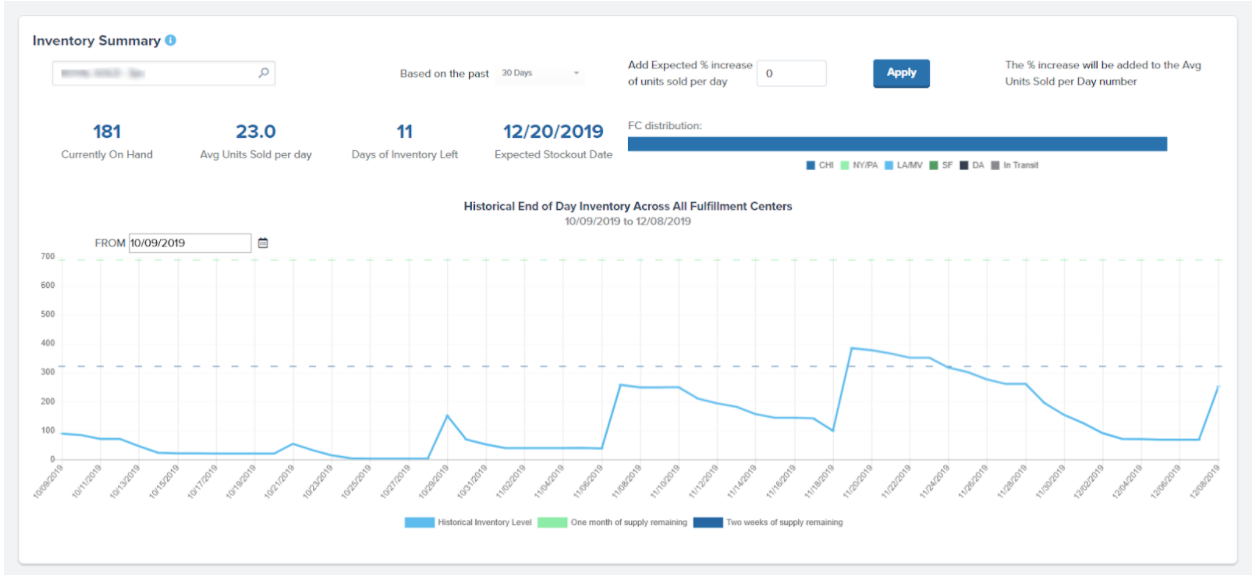

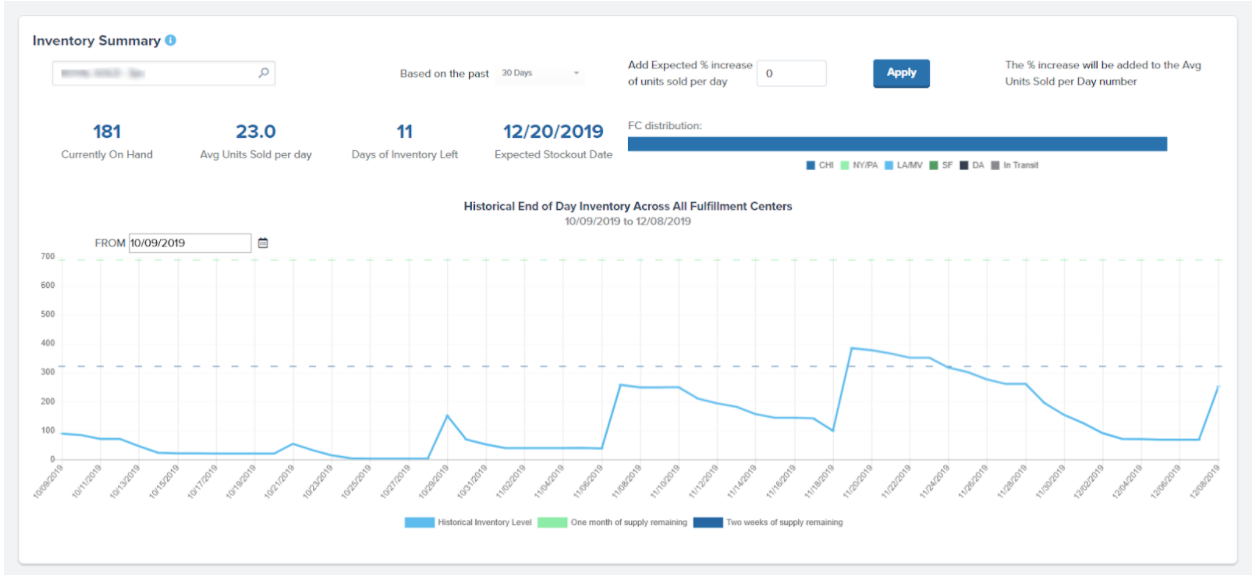

ShipBob’s inventory analytics give you a real-time view of your inventory, including metrics like:

- Fulfillment performance and SLAs

- Current inventory distribution vs ideal distribution

- Transit times, shipping methods, and destinations

- Historical stock levels

- Logistics costs associated with storage, fulfillment, and shipping

“Our favorite aspects of ShipBob’s fulfillment software are the algorithm and analytics. ShipBob’s analytics dashboard has a lot of valuable reports that show our top-selling states, order revenue and costs, units sold, sales by SKU, days of inventory, SKU velocity, sales vs. inventory distributions showing where our customers are and where we’re shipping from, and more.”

Andrew Hardy, COO of Nature’s Ultra

Prepare for holiday surges

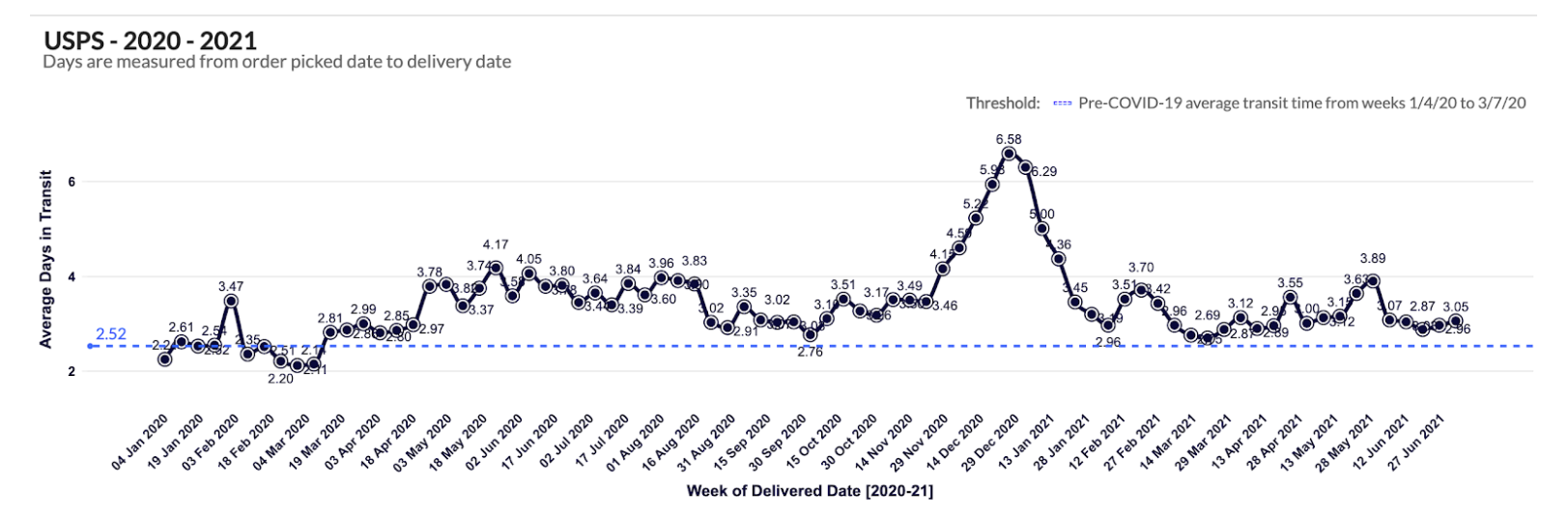

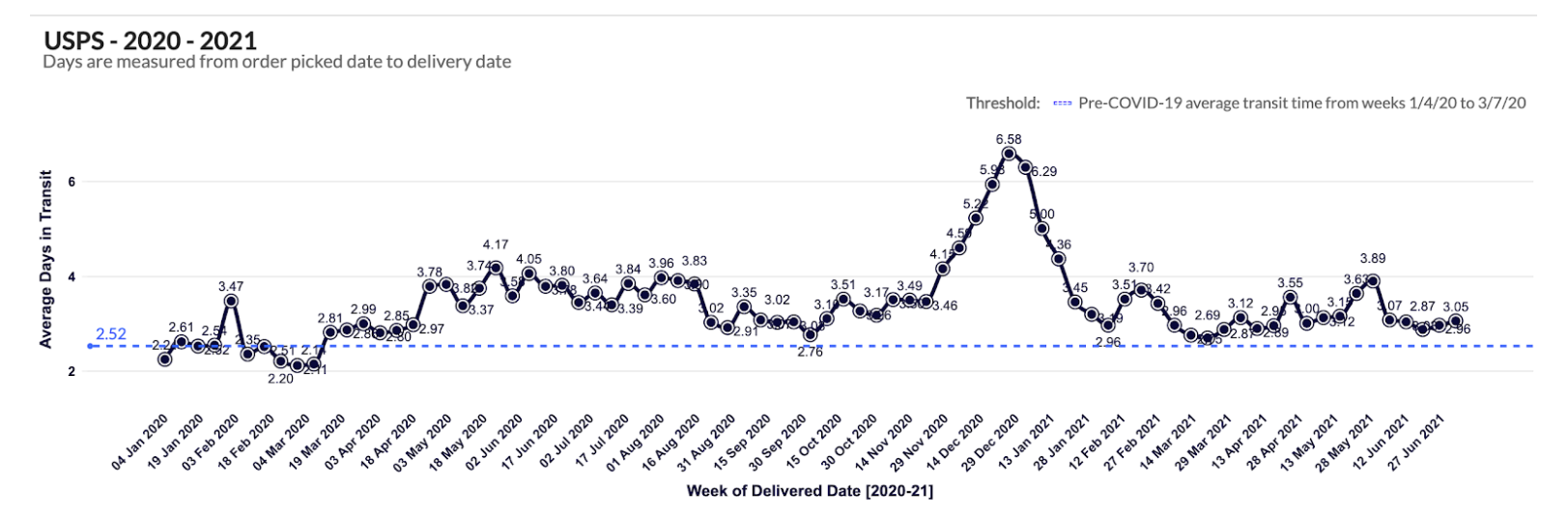

Holiday season brings about a surge in demand, especially around Thanksgiving, Black Friday and Christmas. This year will be especially difficult for retailers with ongoing supply chain delays across the world.

Most major carriers are facing delays in their shipping transit times (as documented here) and cross-border shipments are stuck at US ports due to congestion and labor shortages.

What does this mean for you? Place your inventory orders in advance and have enough safety stock to account for last-minute orders placed during the holiday season.

Create data process models

Having a process model for your demand planning strategy helps you create an accurate plan.

Go through the steps in your demand planning process and identify which steps apply to your business and can be executed at the right time.

For example, you may want to consider organizing your internal data and conducting an initial forecast before you combine it with external data. Similarly, you may want to think about reconciling bottom-up and top-down forecasts together before arriving at a final forecast, depending on how much data your company has access to.

Set demand planning goals

Goals can help your demand planners organize and streamline your demand planning process.

Is your goal with planning demand to reduce your stockouts? Or is it to prevent overstocking? Are there past scenarios in your business you’re looking to avoid with your latest demand planning exercise?

Knowing this beforehand will help you design a plan that best suits your business objectives.

Let ShipBob be the difference

Whether you’re an experienced ecommerce retailer, or you’re newer to the space, demand planning can take time to execute well.

ShipBob’s inventory management and inventory forecasting features reduce your data collection, organization, and implementation time, so that you can create your demand plan faster and execute on it for your customers.

Our inventory management system syncs with your store so that you know which SKUs are in stock across our fulfillment centers. You can also set reorder points to automate inventory procurement from your suppliers so that you never face stockouts for any of your products. You can also project how additional orders in the future might impact your existing inventory, which means you can plan ahead for any scenario in your demand planning strategy.

Integrations with apps like Inventory Planner offer even more assistance for retailers with their inventory management, with features like replenishment recommendations, purchase budgeting, and custom forecasts.

To assist with demand forecasting, our analytics dashboard provides insights into your inventory’s performance, answering questions like:

- How does seasonality affect sales?

- What are the historical stock levels at each fulfillment center?

- Which products are getting returned the most?

- When should I reorder stock for each SKU?

So when you’re planning your demand for next quarter and next year, let ShipBob’s data help you design a better plan to satisfy even more customers.

Get in touch with ShipBob to learn how our fulfillment services and technology can help your ecommerce business.

Demand planning FAQs

Here are answers to the most common questions about demand planning:

What is the difference between demand forecasting and demand planning?

Demand forecasting is one step in the overall demand planning process. Once an accurate forecast has been done, a business has to map that forecast against its inventory needs, which comprises the rest of the demand management and demand planning process.

How can 3PLs help with demand planning?

3PLs like ShipBob help retailers get access to real-time inventory data that they need to execute a demand planning strategy well. They provide granular information around key metrics like SKU velocity, inventory turnover rates, sales by SKU, and more, so that retailers can make better decisions during their demand planning process and meet customer expectations with a higher degree of optimization.

Can software help with demand planning?

Software is critical for executing demand planning today. It offers data-driven insights into a business’s performance that are essential to designing an accurate demand plan.