Table of Contents

** Minutes

What is supply chain forecasting?

Why is supply chain forecasting important?

5 quantitative forecasting methods

4 qualitative forecasting methods

If only there was a crystal ball that could foresee unexpected events like manufacturing delays and fluctuations in customer demand!

Supply chain planning is almost impossible without having an understanding of the future. And since an ecommerce supply chain consists of several moving parts, how does an online brand go about supply chain forecasting, so they can make better predictions and decisions?

There are several supply chain forecasting methods that businesses of all sizes can use that don’t involve hiring a psychic.

Depending on the size of your business, the products you sell, and how long you’ve been in business — there is sure to be a forecasting method that meets your needs.

In this article, you will learn the importance of supply chain forecasting and the most common qualitative and quantitative forecasting methods used in ecommerce.

What is supply chain forecasting?

Supply chain forecasting involves using data and research to make predictions on all aspects of the supply chain to ensure a business runs smoothly and continues to grow.

Though supply chain forecasting often relates to demand forecasting and sales projections, forecasting can also be used to determine production lead times, product pricing, labor needs, and more.

Quantitative vs. qualitative forecasting methods

There are two types of data used in supply chain forecasting methods: quantitative and qualitative. Here is a quick comparison:

- Quantitative forecasting uses historical data to determine the future, including sales projections. Based on the assumption that the future will largely mimic the past, it involves the use of formulas to calculate a predetermined forecasting measurement.

- Qualitative forecasting data is often used for new product lines or when a business first launches, since historical data doesn’t exist yet. Common types of qualitative data include surveys and interviews, industry benchmarks, competitive analyses, and more.

Why is supply chain forecasting important?

Supply chain forecasting is essential in ecommerce and a major component of supply chain management. Without forecasting abilities, it is hard to run a smooth ecommerce supply chain without any predictions on future demand, pricing trends, and even supply availability.

Forecasting enables brands to make better decisions based on both data and research, from conducting a competitive analysis to predicting future demand based on historical order data, trends, and patterns.

5 quantitative forecasting methods

When most people think of forecasting, they think of quantitative methods and the use of historical data, time series, or correlation information.

Using data-driven insights offers an analytical approach to making better decisions on how to plan for the future, both short- and long-term.

There are several quantitative forecasting methods to use in ecommerce logistics. Here is an overview of the most common methods, how to use them and when.

1. Exponential smoothing

Exponential smoothing is a sophisticated approach to supply chain forecasting. It uses weighted averages with the assumption that past trends and events will mirror the future.

When compared to other quantitative methods, it makes it easier to come up with data-driven predictions without the need to analyze multiple data sets.

With the right tools, the exponential smoothing method can be easy to use and is ideal for short-term forecasting.

2. Adaptive smoothing

The adaptive smoothing method uses a variety of variables to make a prediction. It provides a deeper look into changes from period to period and identifies specific patterns.

This method allows businesses to focus in on a specific variables to make better decisions, and it requires automation tools that record, collect, and aggregate data in real time.

With automation, a business can use adaptive smoothing to make accurate predictions across a large product catalog.

3. Moving average

The moving average is one of the simplest methods for supply chain forecasting. It examines data points by creating an average series of subsets from complete data. The average is used to make a prediction on the upcoming time period and is then recalculated every month, quarter, or year.

For instance, if you started your business in the beginning of Q1 and want to make a sales prediction for Q4, you can take the sales average of the prior three quarters combined to determine the next quarter’s sales projections (though you may want to consider major promotions like Black Friday/Cyber Monday and the holidays).

The moving average method doesn’t take into account that recent data may be a better indicator of the future and should be given more weight. It also doesn’t allow for seasonality or trends. As a result, this supply chain forecasting method is best for inventory control for low order volume.

4. Regression analysis

Regression analysis works by examining the relationship between two or more specific variables. While there are variations in how a regression analysis is conducted, they all examine the influence of one or more independent variables on a dependent variable.

This is a simple supply chain forecasting method used to measure some determinations using existing assumptions, such as seasonality. When compared to other methods, it offers a fast and easy way to make predictions.

5. Life cycle modeling

Life cycle modeling is a supply chain forecasting method that analyzes the growth and development of a new product. It requires data across different market groups such as creators, early and late adopters, and the early and late majority.

The data then determines the future performance and demand of a specific product across multiple markets, which helps brands determine how to distribute and market products, and how long the product will be in demand.

4 qualitative forecasting methods

Data-driven forecasting provides more accurate predictions, but qualitative data also plays a significant role in supply chain forecasting and has proven to be just as effective.

In many cases, ecommerce brands use a combination of both quantitative and qualitative forecasting methods to get as close to accurate predictions as possible.

However, qualitative forecasting methods come in handy when there is a lack of data. Oftentimes, new businesses or innovative products rely on qualitative forecasting methods to make predictions.

Here are the most common qualitative forecasting methods used in ecommerce supply chain forecasting.

1. Market research

Market research is a best practice for any business, whether it’s selling a product or even a service.

For ecommerce sales, market research can be used to predict supply and demand, and help determine whether or a not there is strong demand for a product that will support profit goals.

Market research can be executed internally by marketing or sales experts, or businesses can hire a third-party that specialize in market research.

There are different tactics used, from developing stakeholder surveys, conducting a thorough competitive analysis, or even interviewing experts in a specific field or industry.

2. Delphi method

The Delphi method consists of market orientation and judgments within a small group of experts or advisors, which is then sorted, grouped, and analyzed by third-party experts.

The opinions of the experts are gathered individually to avoid the influence of others’ options, which differs from a panel discussion or focus group. The gathering of opinions is outsourced to a third-party, which analyzes the opinions and information shared.

Once reviewed closely, the information is then summarized with an emphasis on different patterns or trends before handing the findings over to the business to review.

This method has proved effective and dependable for long-term forecasting.

3. Historical analysis

Historical analysis uses sales history of a product having a parallel relationship with a present product to predict future sales.

It can be utilized to predict the market’s response to a new product or product line. For instance, if you sell vacuums, you would look at past performance on your highest selling vacuum models. Then, you would compare whether or not the features for the new vacuum are similar yet offer something new and improved in terms of settings and options.

Historical data can also be collected by looking at your competition’s high-selling products and compare similar products in your line to determine demand when possible.

4. Panel consensus

The panel consensus method brings together members of a business across all levels to establish its forecast. It is an open process that allows all the participants to express their opinions and predictions based on what they know.

For example, you could work with your ecommerce customer service team to identify which products are being returned most often and why, or work with your sales team to get insights on what customers are asking for.

Building resilient supply chains isn’t challenging

Being able to predict the future and make better business decisions is key to building supply chain resilience.

But without the right tools and technology in place, it can be a challenge to oversee logistics operations, record and collect data, and analyze different sets of information to make accurate predictions.

As a business owner, your time should be spent on initiatives with higher opportunity costs, like marketing and product development. That’s where ShipBob comes in.

ShipBob is a best-in-class fulfillment provider that offers full visibility into your supply chain. We make it easy for brands to expand their distribution network and track inventory and orders in real time all from one dashboard.

Our entire international fulfillment network is operated by the same warehouse management system (WSM) that records and aggregates inventory and order data, as well as provides insights into fulfillment and shipping performance.

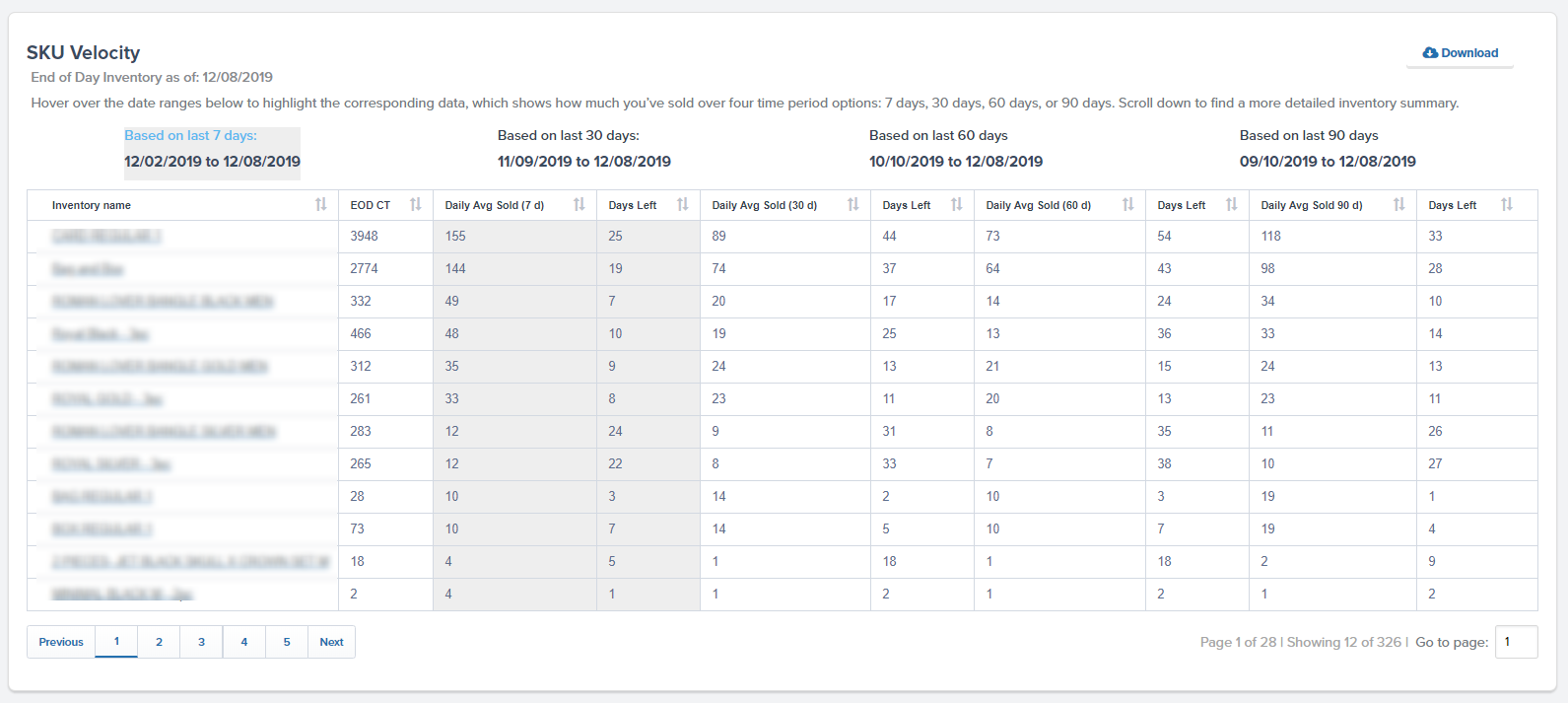

With ShipBob, you can access our data and analytics reporting tool to view inventory levels in real time, manage SKUs and track performance across distribution centers, understand SKU velocity, and make better inventory forecasting predictions.

With ShipBob, you can grow your business using data-driven decisions and optimize your supply chain without being involved in day-to-day operations.

To learn more about how ShipBob can grow your business and save you time and money in the long run, click the button below to start a conversation.

Supply chain forecasting FAQs

Here are some of the most commonly asked questions related to supply chain forecasting.

What are forecasting methods used in supply chains?

There are several different forecasting methods used in supply chain management. Depending on the amount of data you have to work with, you can choose between qualitative and quantitative forecasting methods, or a combination of both.

Qualitative forecasting methods use market research and other industry analyses to make predictions when there is a lack of data. Qualitative data is more accurate as it uses historical data and trends to make a prediction on future outcomes.

How does supply chain forecasting work?

Supply chain forecasting works by taking past data and trends, plus qualitative research to make predictions on everything from production timelines to customer demand. There are several ways to make forecasting predictions, from using historical order data to conducting market research, to identify whether or not certain products are in high demand.

How does supply chain forecasting improve operations?

Supply chain forecasting improves operations by preparing for unexpected events, delays, and fluctuations in the demand. By using data and other insights to make better decisions, you can optimize costs, meet demand, and keep your supply chain running.