Table of Contents

** Minutes

Why SKU tracking is important for ecommerce businesses

Benefits of properly tracking SKUs

Tips for improving your SKU tracking efforts

How ShipBob makes tracking SKUs easy

What’s the difference between a red shirt and a black shirt? To the human eye, quite a bit.

How about the same black shirt in 2 different sizes? A little harder to tell, right?

Or what about the difference between 2 units and 20 units of the same product? It’s pretty obvious to see there is a difference of about 10x in those amounts, but it’s maybe not as obvious to see a difference of 18 units when deciphering between 100 and 118 units.

That said, eyeballing or guessing doesn’t cut it when it comes inventory tracking.

And the more extensive your product line becomes and the more options you offer will require a more comprehensive approach to inventory management that goes beyond basic physical inventory counts.

Organizing inventory using stock keeping units (SKU) is a best practice for managing stock availability based on characteristics and key differences in products.

In this post, we dive deep into how to track different SKUs, why it’s important, and how it can benefit your business.

What is SKU tracking?

SKU tracking is an essential part of the overall SKU management process of assigning a unique alphanumerical code to a product and using that code to track variations in product that are available in stock or out of stock.

Though it involves more time invested in inventory planning upfront, SKU tracking makes inventory management much easier in the long run and enables you to expand your distribution strategy as you expand your business.

How to track SKUs by use case

With the ability to monitor inventory at multiple stages of the retail fulfillment process, SKU tracking plays a crucial role in inventory management as it enables more visibility into inventory flow throughout the entire ecommerce supply chain.

Here are a few different use cases to highlight how SKU tracking is used by ecommerce businesses.

Tracking orders being delivered to end customers

Depending on the shipping carrier, you can use SKU tracking to monitor items currently in transit to the end customer (easiest when single items are shipped in a package).

Some carriers offer order tracking at the product SKU level, which gives you enhanced inventory visibility even when items leave the warehouse and enter the last-mile delivery stage.

Informed order tracking gives you insight into what exactly is in transit, which provides a more holistic view of how many items are in each stage of the supply chain, including which items have been ordered and are in transit.

Tracking SKUs in transit in your supply chain

Ecommerce businesses can also track goods in transit, which can help provide more visibility over the first-mile delivery process.

An accurate understanding of your pipeline inventory at the SKU level gives you insight into when you can expect more inventory to be received and ensure that future orders can be fulfilled on time (or understand if they will need to be backordered).

For instance, when forecasting inventory to meet incoming orders, you will need to look at how much of each item has been purchased and when it will arrive at the warehouse.

Tracking SKUs in warehouses

Proper warehouse inventory management can optimize warehouse performance by collecting insights you can use to improve warehouse processes.

If you manage or rent a warehouse, it’s important to also implement an inventory management software, which helps you view real-time inventory levels and locate items at the SKU level throughout a warehouse.

Digital warehousing tools not only help to organize a variety of SKUs throughout your warehouse, they also enable faster fulfillment, making it much easier for your picking team to locate the right items to fulfill orders.

Additionally, with a SKU tracking system paired with inventory scanners, you can monitor inventory levels and properly account for physical inventory at the SKU level.

When it’s time to expand, you will have already established a foundation for building a multi-channel distribution system to store inventory in multiple warehouse locations while optimizing your distribution logistics strategy.

Being able to manage SKUs that are in stock further enhances inventory control and can help to prevent inventory shrinkage.

By scanning items during the warehouse receiving stage and again when items are picked, you can automatically collect warehouse activity, providing more accurate inventory records.

Why SKU tracking is important for ecommerce businesses

SKUs can assist a number of activities for ecommerce businesses, such as providing accurate data that gives insights into profitability, sales trends, and future demand.

This, in turn, makes the inventory management process more efficient as it allows you to make smarter inventory replenishment decisions to avoid overstocking and understocking inventory.

Overall, it helps with stock control by providing the insights needed to make informed decisions on how much of each SKU to reorder, when to reorder, and where to store it (if you utilize multiple warehouses) to keep storage costs at a minimum while still meeting demand.

Benefits of properly tracking SKUs

Here is an overview of just a few benefits of proper SKU tracking.

Tracking inventory accurately

By enabling you to track variations in the products you offer, SKU tracking more accurately tracks inventory availability to ensure future orders are fulfilled accordingly.

Proper SKU tracking enables you to improve inventory accuracy and also makes it easier to account for inventory at the end of the year.

So when it’s time to account for your ending inventory balance and its value, you’re given exact numbers of how much of each SKU you have left over and the cost of goods sold (COGS) for each.

This makes inventory accounting much easier and more accurate at the end of the year.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet.

ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations. It’s really nice to not have to operate three 3PLs.”

Wes Brown, Head of Operations at Black Claw LLC

Forecasting sales

SKU tracking is a great way to monitor how well a particular product sells and your current inventory levels, which enables you to forecast sales more accurately.

With accurate inventory forecasting, you can also make smart decisions on how and when to restock inventory.

For example, if you operate an online fashion brand, the data might tell you that certain colors of a pair of pants might sell more during the winter compared to summer months in the US, for example.

Or, you can use the data to determine any variations of a product that are undersold. If you sell the same sweater in multiple colors, you might find the mustard yellow one isn’t selling and is taking up room in your warehouse. This may enable you to put it on sale to get rid of the excess inventory.

Overall, being able to identify fast-selling or slow-selling products at the SKU level can help you forecast demand and improve your product catalog to increase sales based on what your customers want.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week.

It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

Prevent dead stock

Along with measuring SKU performance, SKU tracking can be used to identify which products are slow-selling and are at risk of going obsolete and becoming unsellable.

With full visibility on slower-moving items, you can proactively decide to discontinue items or put certain SKUs on hold until items on hand are sold.

It’s easy for dead stock to accumulate over time, which can quickly increase carrying costs — so the more proactive you can identify slow-moving SKUs, the better.

By preventing dead stock from building up, you can lower logistics costs, making SKU tracking worth the investment and time.

Prevent stockouts

Not only does SKU tracking help prevent overstocking but it also helps to avoid understocking.

With real-time updates of inventory levels, tracking SKUs will also show you which items are selling fast and will need to be repurchased more frequently than others.

With a proper SKU tracking system, you can decide whether or not the blue shirts are at risk of stocking out faster than the purple shirts.

In combination with the right supply chain forecasting method, SKU tracking can help support the prevention of stockouts, which can optimize storage costs while ensuring future demand is met.

“ShipBob’s Inventory Planner integration allows us to have all of our warehouse forecasting and inventory numbers in one platform.

We can create ShipBob WROs directly in Inventory Planner and have the inventory levels be reflected in our local shipping warehouse and ShipBob immediately.

It also provides forecasting for each individual ShipBob warehouse, so we know how many units we need to ship each week to cover a certain period and also to not run out of stock.”

Marc Fontanetta, Director of Operations at BAKblade

Tips for improving your SKU tracking efforts

If you run an ecommerce businesses, chances are you already have a system to track inventory at the SKU level.

As you expand your business — whether that’s expanding into new sales channels or launching a new product line — the following tips can help you improve your SKU tracking efforts.

Set up a standardized method for tracking SKUs

The first step is to establish a standardized naming convention for all your SKUs. If this already exists, it’s worth revisiting to ensure everything is up-to-date and accurate.

Codes following a consistent framework will be easier for internal teams and third-party partners to work with.

For instance, if you depend on a fulfillment company like ShipBob for high-volume order fulfillment, accurate SKU data ensures that the right items match what is being ordered using SKUs to easily pull up product details. This results in a much high order accuracy rate.

Ideally, the code should be short (between 8 and 12 characters). It should also be simple so your warehouse picking team can quickly identify it.

Avoid confusing characters

Since the goal is to simplify things, make sure you avoid any characters that could cause confusion.

For example, since the number “0” (zero) could be confused for the letter “O,” avoid beginning your codes with a zero. Spaces and special characters should also be avoided as they can be difficult to decipher.

Sort products by similarities on your site

SKUs should also be grouped by a similar characteristic such as size or color on your ecommerce website.

This makes it easier to display similar products that the customer might be interested in and different variations of the same product.

For example, someone who first looks at a pair of shoes in red can easily see that they also come in black — which might be the color they really wanted.

This establishes a more accurate product catalog for your website. So if you offer the same pair of shoes in different sizes and colors, shoppers can see exactly what options are in stock.

Sometimes, products have a less visible difference between relatable items, such as ingredients.

For internal purposes, it might be worth using SKUs to organize inventory in groups or implement a lot tracking system to distinguish less visible differences between items (e.g., such as ingredients).

“We also have easy ways to manage subscription orders as well as expiration dates and lot numbers, so inventory goes in First In, First Out (FIFO).”

Leonie Lynch, Founder & CEO of Juspy

How ShipBob makes tracking SKUs easy

ShipBob simplifies both fulfillment and SKU tracking for you with a robust digital inventory system that lets you track inventory at the SKU level, including product bundles.

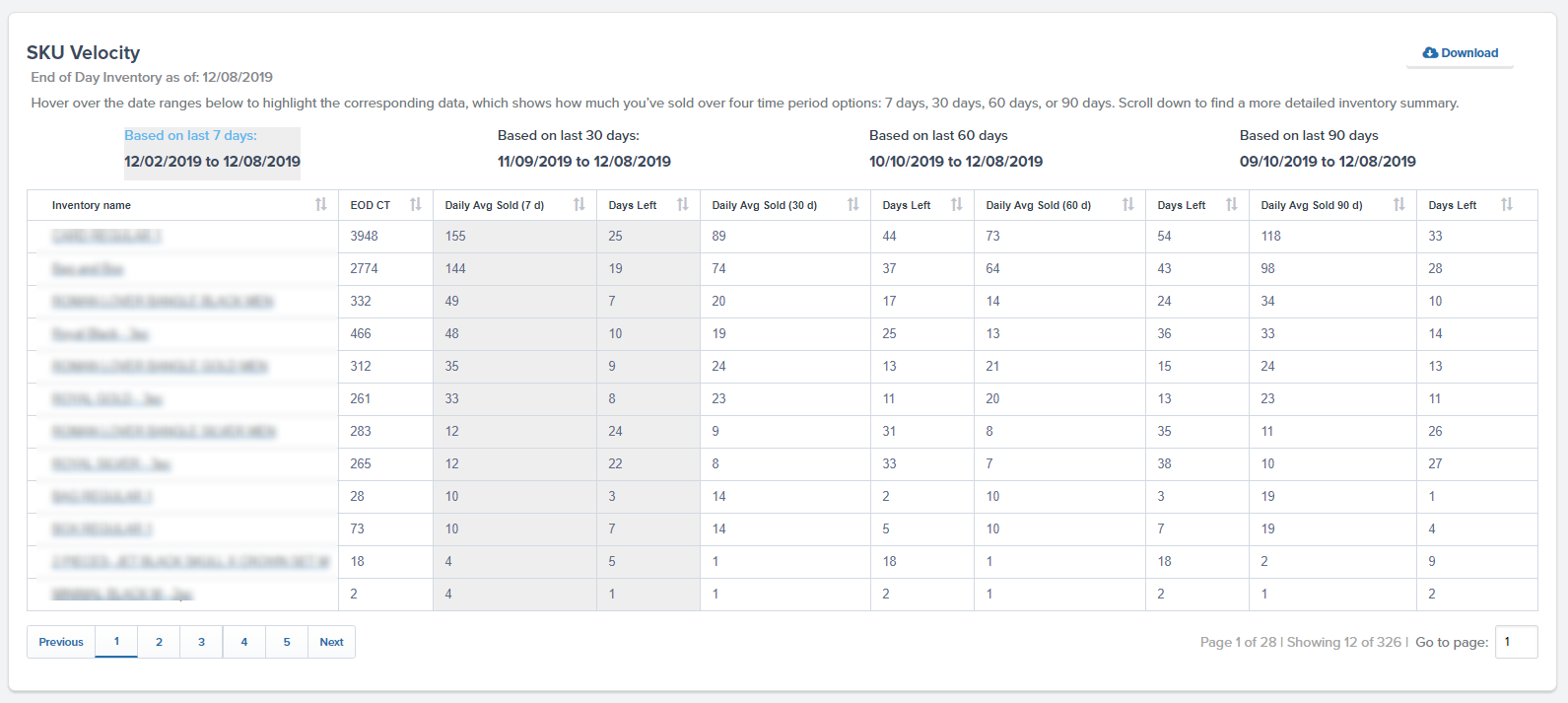

The built-in inventory tracking tool automatically tracks performance of each SKU that enters and exits our distribution centers, which allows you to monitor SKU velocity and manage stock availability in real time.

From the ShipBob dashboard, you can quickly view SKU performance at a glance, get a real-time view of all inventory, and update and manage SKUs efficiently.

You can also input changes in order volume or scenarios to calculate changes in inventory turnover.

This enables you to enhance inventory planning with the ability to forecast demand based on historical SKU performance.

These insights help you make strategic decisions on inventory replenishment, as well as provide tools to keep you on top of it all.

For example, ShipBob makes it easy calculate reorder points and set up notifications when it’s time to order more inventory to prevent stockouts.

ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left.

There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

Interested to see our fulfillment solution in action? Check out a 3D behind the scenes look at how ShipBob operates:

Outsource fulfillment to ShipBob and simplify the inventory management process.Request pricing to get started.

Improve SKU tracking with ShipBob’s WMS

For brands looking to improve inventory visibility and tracking within their own warehouses, look no further than ShipBob’s warehouse management system (WMS).

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfillment network) to streamline in-house inventory management and fulfillment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

SKU tracking FAQs

Here are the answers to the most popular SKU tracking questions.

How do you track a SKU?

SKU tracking is done by using an inventory scanner or implementing inventory management software with the ability to scan SKUs that enter and exit a warehouse. The first step is to decide how to best categorize inventory based on characteristics (e.g., color, size, etc.) and set up an alphanumerical code structure. Once your SKUs are set, you can attach barcodes to your products so they can be scanned and identified.

How do you track inventory with SKUs?

You can track inventory with SKUs by using an inventory tracking tool that integrates with your ecommerce platform and/or point-of-sale (POS) system and warehouse management system. This way, you can expand into different sales channels and distribution locations and still be able to track inventory throughout your supply chain using a centralized system.

How do you set up SKUs?

To set up SKUs, start by creating a standard framework or naming convention to follow. You can then use tools (like an ecommerce platform) and integrations (like fulfillment and inventory software) to generate SKU codes following this framework.

What is the easiest way to track inventory?

The easiest way to track inventory is by using a robust inventory management tool that integrates with your supply chain technology stack, including a warehouse management system. This way, you can track inventory flow based on warehouse activity.