Table of Contents

** Minutes

What is distribution logistics?

Direct vs. indirect distribution

How COVID-19 has changed the game

Tips for improving your distribution logistics

Between making a sale and delivering a customer order, distribution logistics play a critical role in the ecommerce supply chain. Distribution is the heart of an online business. Without it, it would be hard to consistently delivery and meet customer expectations.

But to get distribution right, it’s oftentimes a balancing act. For one, you need enough inventory to meet demand while also optimizing storage space to keep costs low.

There’s an art and science to establishing a physical distribution process. And, as we’ve learned from the pandemic, you can’t predict the future, which makes optimizing distribution logistics based on demand challenging.

A major component of distribution logistics is to reduce risk, as well as costs, to create a more resilient supply chain — no matter what challenges come your way.

Let’s take a deeper dive into what distribution logistics involve, how to optimize it, and what to consider as the supply chain continues to struggle with delays and disruptions.

What is distribution logistics?

Distribution logistics can mean a lot of things depending on the industry.

For direct-to-consumer (DTC) brands, it refers to the entire process of getting finished goods delivered from a manufacturer or supplier directly to the retailer or distribution centers where the fulfillment process takes place.

From there, orders are prepared for last-mile delivery. During distribution phase, online brands will work with various carrier partnerships to ensure shipments are delivered on time and at the most affordable rate.

What is a sales logistician?

A sales logistician is the person in charge of logistics sales. This role is responsible for the order-to-cash process and ensures that orders placed are accurately fulfilled and shipped on time.

The role also involves the process of forecasting demand so online retailers and their logistics directors can accurately plan logistics processes like product procurement, warehouse receiving time lines, and inventory replenishment to ensure there is enough stock to meet demand.

Lastly, a sale logistician works and maintains relationships with third-party logistics to ensure that distribution is being done in the most efficient, cost-effective way possible.

Direct vs. indirect distribution

A distribution logistics method can include various channels, depending on the needs of the business.

For ecommerce, there are two distribution logistics approaches that ecommerce businesses can choose from: direct and indirect.

Direct distribution

Direct distribution involves cutting out the middleman entirely by taking on distribution management in-house.

Once inventory is purchased, it is delivered directly to the online retailer who either rents a warehouse or fulfills orders from an office or at home.

For direct distribution, an online retail is also responsible for the fulfillment process. They will need to invest in their own inventory management software, so they can efficiently track inventory, from pipeline inventory to items being fulfilled.

The online retailer is also responsible in developing a shipping strategy by choosing shipping methods and carrier partners based on their profit margins and average shipping costs.

Brands that take care of their own distribution logistics are required to invest in their own storage needs, fulfill orders in-house, and maintain carrier partnerships for their shipping needs.

Indirect distribution

With indirect distribution, DTC brands have the flexibility to outsource fulfillment to a third-party logistics (3PL) provider.

Indirect distribution involves sending inventory to a 3PL provider that takes care of warehousing, picking and packing, and shipping on behalf of the online retailer.

Depending on the 3PL’s capabilities, a 3PL provides the resources, tools, expertise, and customer support needed to optimize logistics operations without the need to invest for merchants to invest in their own fulfillment infrastructure and warehouse management system (WMS).

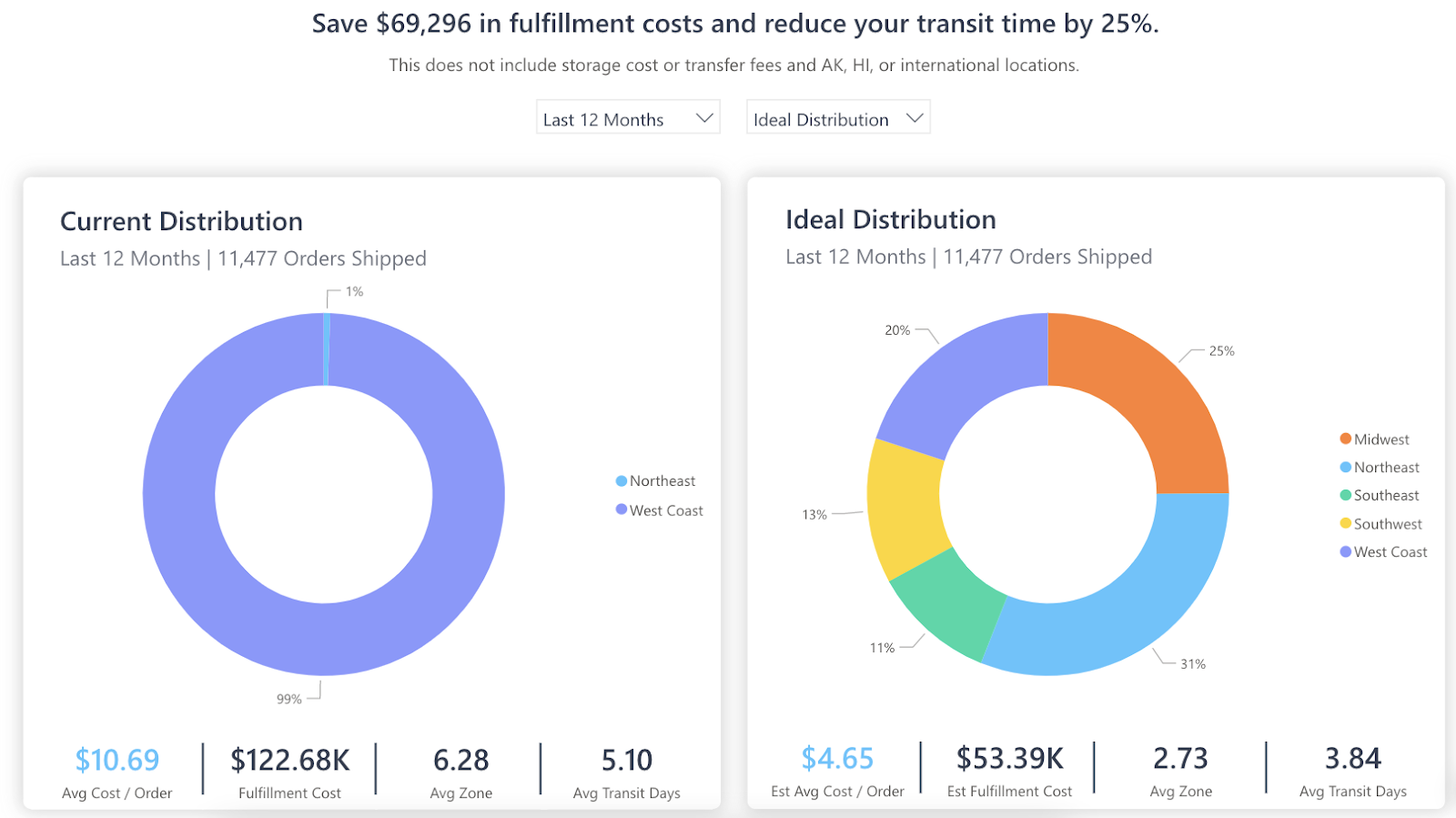

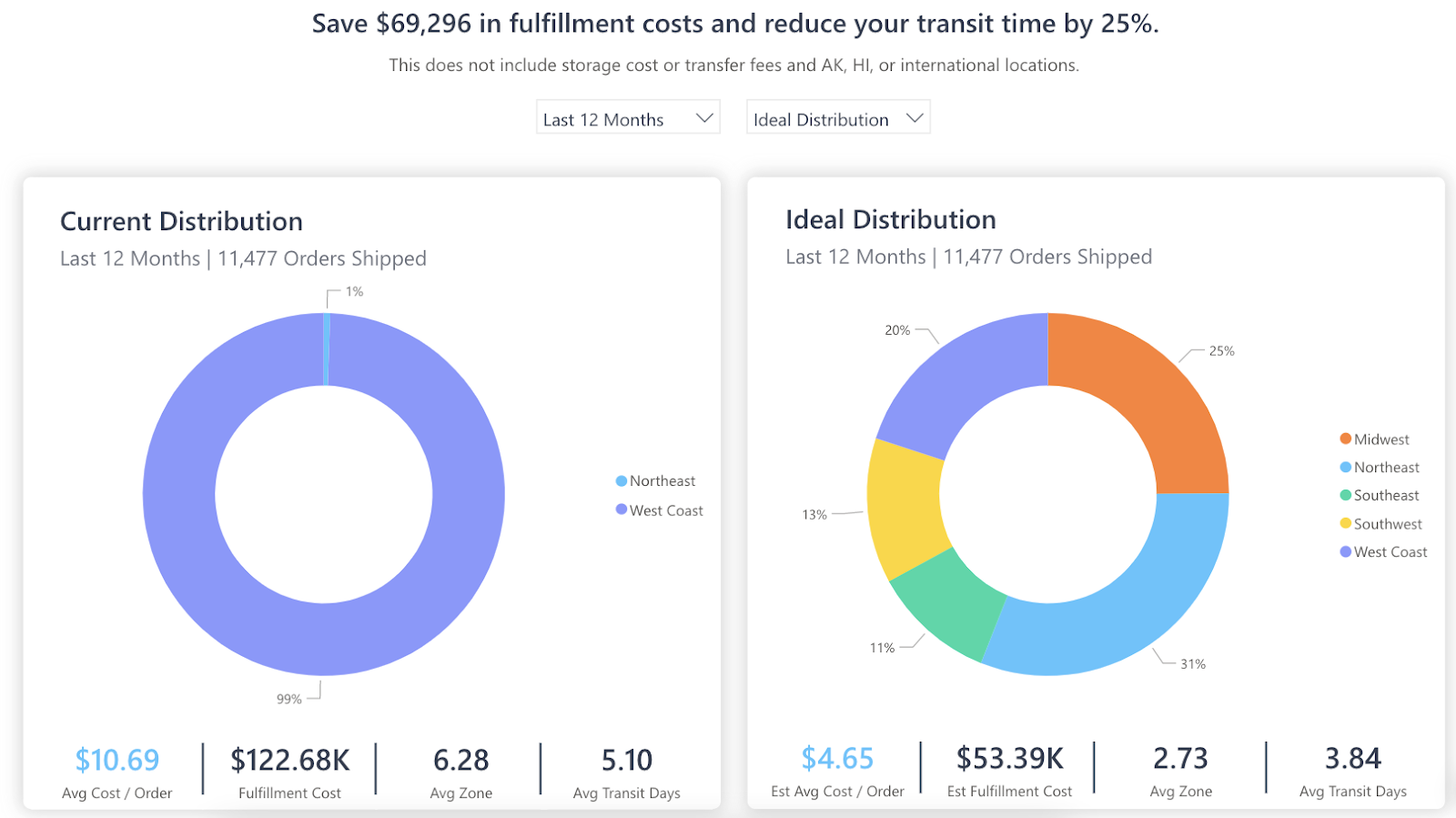

For instance, with ShipBob, you can connect multiple sales channels, including an online store, to ShipBob’s fulfillment software. From there, you’re able to choose one or more fulfillment center locations to store inventory in, which has the potential to reduce shipping zones, therefore reducing costs, when shipping orders across the US.

Once orders are placed, they are routed to the nearest fulfillment center location to be shipped via the most optimized shipping route.

“Compared to other warehouses we’ve worked with, ShipBob processes orders so quickly to get them out the door faster. It’s fun to see orders shipping out instantaneously. I love how fast and efficient ShipBob is.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

How COVID-19 has changed the game

When the COVID-19 pandemic hit, it caused massive disruptions to the supply chain, with closing borders and travel restrictions significantly affecting distribution and logistics.

As the pandemic continues, supply chain delays and disruptions continue to make headlines. To thrive during these times, online retailers are working towards building more agile supply chains and implementing new digital logistics systems throughout their network to continue to meet customer expectations.

On the manufacturing side, there has been sudden scarcity of raw materials, which has caused delays in work-in-process phase. This has impacted the ability for online retailers to restock on time to meet demand.

To ensure that inventory shortages don’t reach early-COVID levels, manufacturers are resolving to keep more inventory on hand so they can prevent production shutdowns. And to tackle the warehousing and capacity issues that could result from this change, they’ve even started to adopt automated storage and retrieval systems (ASRS), which can save up to 85% of the floor space taken up by standard shelving.

Many brands are also considering partnering with more local supplier and manufacturers, making product procurement less susceptible to supply chain disruptions. This not only gives them more control over the supply chain but also significantly reduces logistics costs in first-mile delivery.

Many online brands are also seeking to utilize 3PLs like ShipBob to take advantage of a robust 3PL distribution network. This has made it possible for brands to store inventory in multiple locations to help reduce costs and transit times despite ongoing delays (especially when dealing with cross-border shipping).

Overall, diversifying your distribution strategy is important, especially when it comes to location. Not only does inventory distribution save on shipping costs and speed up delivery times, but it also keep your supply chain running in case one location must shut down for any reason.

“I was about ready to launch SubSubmarine, and then COVID-19 hit. Shipping methods suddenly became more limited and expensive to the point where it would not be feasible to ship through the Australian Post to fans in America (costing about 20 USD or 28 Australian dollars per package and getting stuck in transit).

Learning from that experience, I needed to find a viable solution to both of these issues, which is where ShipBob came in.”

Lee Nania, Founder of SubSubmarine

Tips for improving your distribution logistics

Despite ongoing distribution challenges, here are some tips on how you can optimize your own distribution logistics strategy to reduce risk, save costs, and continue to meet customer expectations.

Leverage software

Implementing the right supply chain technology stack has the potential to improve how you manage different aspects of your distribution logistics, from first-mile freight delivery to tracking inventory in real time, to monitoring fulfillment and shipping performance.

When implementing the right software, make sure it seamlessly fits into your existing or desired tech stack. A well-connected tech stack can include everything from inventory planning to returns management, to freight shipping solutions.

For instance, ShipBob’s order fulfillment and digital logistics technology offers direct integrations with dozes of ecommerce solutions, creating an end-to-end ecommerce solution.

“Since using ShipBob, we realized it’s so helpful having such a clear software and online platform. I haven’t had experience with other 3PL warehouses, but I imagine that some of the smaller, more traditional ones in Sydney would not have that, and it would be much more annoying to see what’s going on inside the warehouse.”

Nakisah Williams, founder of Craft Club Co.

Partner with a 3PL

The best option to delegate distribution to the experts by partnering with a tech-enabled 3PL or distribution partner like ShipBob.

ShipBob not only takes care of fulfillment but also warehousing and distribution, ensuring that your inventory is managed efficiently and stored strategically across different fulfillment centers. This helps you reduce costs while ensuring faster, more accurate fulfillment to improve customer satisfaction.

From the ShipBob dashboard, you can monitor, manage, and optimize your supply chain with access to to shipping and fulfillment insights, as well as demand forecasting and other key supply chain analytics.

This insight can help you allocate inventory in distribution centers that are closest to where your customers lives to reduce shipping costs and transit times.

“ShipBob has been a great ally as they have fulfillment centers all over the US, facilitating a 2-3 day delivery time for any customer in the US.”

Andrea Lisbona, Founder & CEO of Touchland

Forecast demand

Accurately forecasting demand is essential to make informed decisions on distribution. Having the right tools and metrics in place to strategically plan for demand and replenish inventory on time is essential.

Intelligent inventory forecasting uses past order data and details of upcoming events, which can help you optimize inventory, minimize inventory shrinkage, lower storage costs, and keep your customers happy.

With the right data at your fingertips, you can decide the best time to run a flash sale, discontinue a slow-selling item, or know how much inventory to order based on seasonality.

ShipBob helps DTC brands grow

ShipBob partners with fast-growing DTC brands to help streamline their distribution and fulfillment strategy.

From operating a global logistics network to reducing fulfillment costs, ShipBob can help you meet customer expectations without the headaches and constant growing pains.

Here is an overview of how ShipBob helps DTC brands grow through strategic distribution.

Multiple fulfillment centers for faster shipping

ShipBob continues to add more locations to its US network, as well as global fulfillment locations, which enables you to strategically store inventory across multiple locations to speed up transit times.

To help you identify your ideal distribution method, ShipBob’s dashboard aggregates historical order data, which allows merchants to determine their ideal distribution strategy to optimize average delivery timelines.

“It’s so helpful knowing that we have the options to expand so easily. We know that we can compare the markets simply, and because ShipBob [has] already set up [multiple fulfillment centers in various countries], it’s a simple choice. We don’t need to compare the logistics as intensely.”

Nakisah Williams, founder of Craft Club Co.

Reduced shipping costs

Having a proper shipping strategy ensures that you can provide competitive, cost-effective shipping options for your customers.

Along with the ability to speed up shipping, ShipBob can also help you optimize and reduce shipping costs while also offering shipping incentives, such as affordable 2-day shipping or free shipping (with a minimum cart value threshold that’s higher than your average order value).

ShipBob partners with leading domestic and international carriers, as well as regional parcel carriers, and negotiates bulk shipping discounts to pass on to you and your customers.

“When I was shipping orders myself, what I paid per order is the same price now to pick, pack, and ship orders through ShipBob. It’s even much cheaper to ship to certain countries, which used to take ages and often got lost with localised post here.

Now, I have very transparent pricing, and I can easily run and plan my business. I also like that I’m billed right away. My old carrier billed monthly, which would drain a huge sum of Euros from my account at once. My cash flow has improved.”

Leonie Lynch, Founder & CEO of Juspy

Robust and streamlined analytics

ShipBob offers a powerful data and analytics reporting tool that makes it easy for merchants to analyze distribution metrics, monitor fulfillment and shipping performance, and manage their supply chain operations without being involved in the day-to-day operations.

Through ShipBob’s dashboard, you can:

- View, track, and manage inventory across sales channels and your distribution network

- Manage SKUs and product bundles.

- Monitor SKU velocity, inventory days on hand, and more.

- Forecast demand by viewing historical trends.

- Filter all orders by status.

- And much more!

“I felt like I couldn’t grow until I moved to ShipBob. Our old 3PL was slowing us down. Now I am encouraged to sell more with them. My CPA even said to me, ‘thank god you switched to ShipBob. ShipBob provides me clarity and insight to help me make business decisions when I need it, along with responsive customer support.”

Courtney Lee, founder of Prymal

For a behind the scenes look at how ShipBob operates, check out the 3D experience below:

By partnering with ShipBob, you can easily streamline fulfillment across multiple sales channels, track inventory in real time from a single dashboard, and save time and money by leaving logistics up to the experts.

Get the process started by requesting custom pricing, or read this review to learn more about ShipBob’s logistics capabilities.

Tips for improving your distribution logistics FAQs

Here are answers to the most common questions about distribution logistics.

Can you outsource distribution logistics?

Yes! ShipBob is 3PL that offers access to a growing network of fulfillment center locations. With ShipBob, you can choose which locations to store inventory in. This way, orders are picked, packed, and shipped from the nearest fulfillment center location, rather than having all customer orders shipped from one location. By outsourcing fulfillment to a 3PL that can help you manage distribution, you can save time and money as you scale your business.

What is the difference between logistics and distribution?

Logistics management refers to supply chain planning, whereas distribution management focuses on the movement of good from supplier to distribution location(s), and routing orders from the nearest distribution center to the final destination for faster delivery.