Table of Contents

** Minutes

What is distribution management?

4 distribution management channels

Benefits of distribution management systems

Top 5 distribution management softwares

Distribution management challenges & disruptions to prepare for

How ShipBob’s distribution management system works for ecommerce retailers

Key Takeaways

1

Distribution management involves overseeing the movement of finished goods from manufacturers to end users, encompassing activities like warehousing, inventory management, and last-mile delivery.

2

Effective distribution management enhances order fulfillment, inventory turnover, profit margins, and customer satisfaction by ensuring efficient inventory movement through the supply chain.

3

Distribution management systems help businesses fulfill orders quickly, meet customer expectations, respond to market seasonality, and analyze distribution data to optimize operations.

4

Challenges in distribution management include lack of visibility into operations, unpredictable weather, pandemics, and shipment delays, which can be mitigated by diversifying distribution strategies and utilizing multiple suppliers and locations.

Supply chain managers, across industries, will agree that nothing is more frustrating than:

- Manufacturing delays

- Delivery of wrong or damaged products

- Falling behind on fulfilling orders

- Unexpected supply chain disruptions

Though many unexpected events or mishaps are uncontrollable, common supply chain issues can be traced back to poor supply chain management and how efficient inventory moves from manufacturer to retailer to the end user.

Especially with the growing popularity of omnichannel retailing, absolute control over your layered, dynamic, and complex distribution ecosystem has become a must.

This article provides an overview of what distribution management is, how it works, and how you can leverage a 3PL partner to improve distribution.

What is distribution management?

Distribution management refers to overseeing the movement of finished goods from a manufacture or supplier to the end user.

Throughout this process, there are several activities and processes that take place, including warehousing, inventory management, warehouse picking and packing, and last-mile delivery.

Well-executed distribution management can help to improve the order fulfillment process, inventory turnover rate, profit margins, supply chain agility, and ultimately higher customer satisfaction.

Why is distribution management important for ecommerce?

The goal of distribution management is to keep inventory moving through the supply chain. How well distribution management is executed impacts profit margins and how fast a brand can grow.

For instance, if you’re overspending on storage, then you might have accumulated too much deadstock. Or, if you’re not replenishing inventory fast enough, then it can lead to lost sales, backorders, and stockouts.

When done right, distribution management is one of the smartest ways to ensure that:

- Inventory is distributed efficiently to reach customers in the fastest, most efficient manner.

- There is enough inventory to meet demand while optimizing storage costs.

- Business owners have enough visibility into operations to make improvements and informed decisions.

4 distribution management channels

Overseeing physical distribution of inventory is a major component of supply chain management.

But to understand distribution logistics, it’s important to understand the different types of distribution channels and how inventory moves through the supply chain.

1. Wholesaler

Wholesalers offer either raw materials or finished goods in bulk at a low price and can be sold to manufacturers, distributors, or retailers.

Wholesalers are oftentimes involved in the distribution of raw materials that are used to make a finished product. For instance, fabric wholesalers provide materials to clothing manufactures, so they produce finished garments.

2. Retailer

A retailer has the option to work directly with a wholesaler, manufacturer, or supplier. Major retailers often distribute products from different suppliers across different sales channels to reach their end customers.

For instance, Walmart and Target work purchase from different brands that offer a variety of products, so they can be sold online or in their brick-and-mortar locations.

3. Distributor

Distributors act as the intermediary between the manufacturer and the wholesaler or retailer. When manufacturers want to increase their regional distribution, they authorize distributors (who know the local market) to sell the products.

Many a time, distributors also offer logistical and storage support in their specific location. For instance, car brands distribute the latest car models to dealerships across multiple regions, so they can be sold locally to the end user.

4. Ecommerce

Ecommerce has paved the way for direct-to-consumer (DTC) brands in modern times, which delivers products directly to the end user (often, at their homes). Online retailers work with manufacturers and suppliers to order inventory and have it stored in an ecommerce warehouse.

Once inventory is received and orders are placed online, items are picked, packed, and shipped directly from the business. Ecommerce fulfillment has taken the middleman out of distribution, providing faster delivery, affordable prices, and better customer service.

Benefits of distribution management systems

Now that you understand how distribution management works and can identify the key activities throughout the process, let’s dive deeper into the benefits of adopting a comprehensive distribution management system.

1. Fulfill order as quickly as possible

When you first start out, in-house fulfillment might be manageable as there is a smaller volume of orders to fulfill.

But to stay competitive and reach more customers, many brands expand into a multichannel distribution operations, which leads to a higher volume of orders when done right.

There are two components that are highly effective in speeding up the fulfillment process: technology and location(s).

Technology can help improve the fulfillment process, starting with automatic order processing to helping warehouse pickers easily locate items within the warehouse in a timely manner.

Having the right tech stack in place can also enhance inventory visibility throughout your distribution network, so you are better prepared for the unexpected and can make better business decisions.

Location is also key. For instance, by splitting inventory across multiple fulfillment centers that are closer to your end customers, you rely less on a single warehouse to fulfill orders. That way, you can optimize shipping by reducing costs and speeding up transit times.

Additionally, if an item is unavailable at one location, it can be fulfilled at another. Ultimately, both supply chain technology and optimized distribution work together to enable faster retail fulfillment.

“Compared to other warehouses we’ve worked with, ShipBob processes orders so quickly to get them out the door faster.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

2. Consistently meet customer expectations

Distribution management is central to consistently meeting customer expectations.

With distribution management systems you won’t ever drop the ball again on getting the goods from the manufacturer to the end customer. The technology can be harnessed to ensure that orders are reliably and quickly delivered, time and time again, at the right cost.

It also ensures the availability of SKUs for each sales channel and when the customer wants it. At the same time, it keeps order fulfillment costs low so that the retailer may pass the savings on to their customers.

3. Respond to market seasonality

Depending on the type products you sell, seasonality can play a major role in distribution.

A ‘seasonal’ brand offers products that are relevant during a specific time period, event, or season, leading to different demand levels depending on the time of year (e.g., a swimsuit brand shines in the spring and summer but not as much in the winter).

Though many brands experience sales fluctuation, especially during the holiday season, some brands are more vulnerable to seasonality.

Proper distribution management can support seasonal brands by collecting historical sales data and determining how much inventory to have on hand at specific periods of time, known as demand forecasting.

By predicting market changes, such as fluctuations in seasonal sales order volume, you can adjust inventory levels and allocate inventory accordingly.

4. Analyze distribution management data

To improve and optimize your distribution network, you need the right systems in place to collect and analyze supply chain data.

By optimizing everything from inventory turnover rate, warehouse allocation, and how much inventory on the SKU level is currently available at each location, you can gain insights into how to best distribute product and optimize inventory throughout your network.

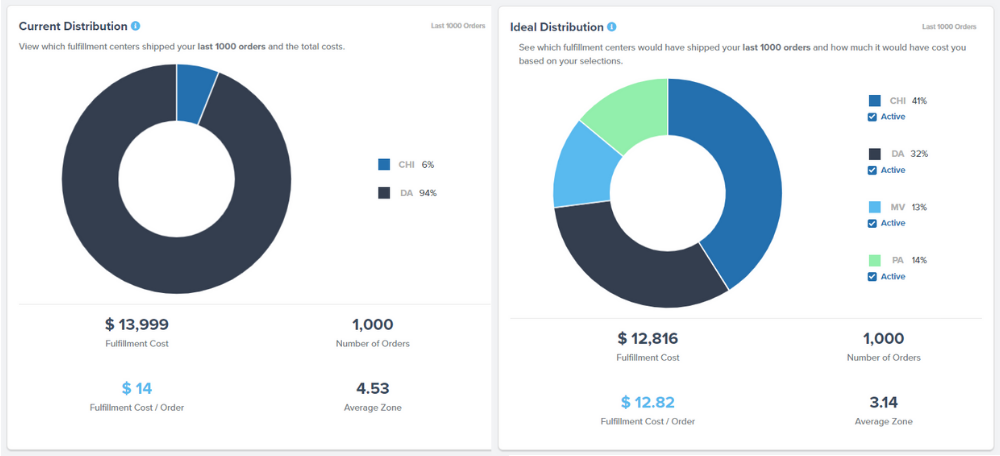

For instance, ShipBob’s merchant dashboard offers insights into various distribution metrics, including how much you can save on shipping costs if orders were fulfilled at a different location within ShipBob’s network.

This insight can help you allocate inventory in distribution centers that are closest to where your customers lives to reduce shipping costs and transit times.

“We love that ShipBob actually operates its fulfillment centers — they know their operations and they are very clear about it. ShipBob having multiple locations was also huge for us. Keeping our inventory in Chicago and Los Angeles has brought cost savings since we ship from the locations that are closest to the customer.”

Courtney Lee, founder of Prymal

5. Increase profit margins

To scale back on operational expenses, having enough visibility into operations (so you can optimize your distribution strategy) can significantly save on costs. By simply utilizing more locations (most likely, of a 3PL’s) to store inventory can help you save on shipping while meeting customer expectations.

For instance, optimized inventory distribution has proven to help online retailers:

- Save $2 per order on fulfillment costs.

- Bring 13% cost savings to your bottom line.

Other ways you can improve profit margins through optimized distribution is by partnering with a 3PL like ShipBob that offers multiple locations across the globe and fulfillment services. That way, you can spend less time on logistics while reducing fulfillment costs.

“ShipBob has been the perfect partner. Their speed to scale and fast pick, pack, and ship process has been seamless, as our business grew 1,200% in a couple of weeks.”

Andrea Lisbona, Founder & CEO of Touchland

6. Faster delivery options

70% of US customers will choose a brand over a competitor if they provide more delivery options.

With an established distribution strategy, you’re able to offer better shipping incentives for your customers.

For instance, storing inventory closer to your customers saves on shipping costs while speeding up transit times. Therefore, you can offer customers incentives like 2-day shipping or free shipping with a required minimum cart value.

Top 5 distribution management softwares

As ecommerce continues to grow, the standards set on fast, affordable delivery and customer expectations become higher.

There has never been a greater need for supply chain agility, which means developing a flexible distribution strategy is key.

Fortunately, there are several distribution management solutions on the market to help online brands optimize distribution, so they can save on costs while meeting customer expectations..

Some of the best distribution management software include:

- Brightpearl

- ShipBob

- Infor M3

- DEAR Systems

- Sage 100 Cloud

Below provides a high-level overview of the different solutions and the features they offer:

Distribution Management Software | Overview of Features |

| Brightpearl |

|

| ShipBob |

|

| Infor M3 |

|

| DEAR Systems |

|

| Sage 100 Cloud |

|

Distribution management challenges & disruptions to prepare for

Supply chain planning and designing can be considered a success only if it includes contingency plans to combat unexpected situations.

Product and buyer disruptions, and economic and environmental challenges can impact distribution at any time.

Below offers an overview of common distribution management challenges and how to better prepare for the unexpected.

Unpredictable weather conditions

Be it devastating floods or forest fires, to torrential rain and heavy snowstorms, climate change is causing a lot of unpredictable weather incidents across the globe. This can affect your inventory stocking and delay your delivery services.

One way to reduce the risk of bad weather conditions is to utilize multiple locations to store inventory in. That way, if one warehouse or fulfillment center must close down due to bad weather, then items can be fulfilled at a different locations.

Pandemics

The COVID-19 pandemic resulted in:

- A sudden scarcity of raw materials, which delayed the work-in-process phase

- An influx in demand, causing stockouts of essential items

- Warehouse closures

- Shipping delays

- Several other issues that caused supply chains to slow down or halt all together

What the pandemic taught the ecommerce industry is that building a resilient supply chain should always be a number one priority. To build resilience, visibility and transparency are key.

The more insights you have on day-to-day operations, the more proactive you can be to respond to disruptions and keep your supply chain running.

Diversifying your distribution strategy is also important, especially when it comes to location. Not only does inventory distribution save on shipping costs and speed up delivery times, but it also can be saving grace in case one location must shut down for any reason.

Shipment issues or delays

During the pandemic, many major carriers were at full capacity and struggled to deliver a higher than usual volume of packages on time.

Through shipping issues and delays can occur at any time, it can be wise to diversify your carrier partners and work with a mix of both major and regional carriers. That way, you have more shipping options in case a carrier is suffering from delays.

For instance, since the beginning of the pandemic, ShipBob continues to share weekly shipping carrier data, so online brands have more visibility into how major carriers are performing to proactively communicate any potential delivery delays with their customers.

Supply chain shortages

Raw material shortages or manufacturing delays can cause major disruptions in your supply chain. The best way to combat supply chain shortages or delays is to partner with multiple suppliers or manufacturing options.

This ensures that you are not left at risk or without replenishment when your primary supplier is unable to deliver during shortages, shutdowns, or trade restrictions.

How ShipBob’s distribution management system works for ecommerce retailers

ShipBob is a best-in-class 3PL that provides the infrastructure and technology to enhance your distribution management strategy.

ShipBob’s warehousing and distribution services improve the ecommerce distribution process, including receiving inventory, real-time inventory tracking, fast fulfillment, and automated shipping.

By partnering with ShipBob, you get access to a global fulfillment network, technology, and premium customer support to help you optimize your supply chain and improve your logistics operations. Some supply chain initiatives that ShipBob can help you improve include:

1. Inventory receiving

When ecommerce inventory arrives at a warehouse or fulfillment center like ShipBob, it is unloaded, processed, and stored.

A proper inventory receiving process (also known as ‘warehouse receiving‘) is important as it sets your supply chain up for efficient, cost-effective inventory management and fulfillment later on in the fulfillment experience. With ShipBob’s technology-enabled fulfillment network, inventory is accurately received and scanned into the system, ensuring real-time visibility for merchants.

2. Warehouse management

Once the inventory is received, it needs to be monitored to ensure there is enough inventory to meet demand. The rise of digital warehousing has made it a standard to implement a warehouse management system (WMS), a software designed specifically to optimize warehouse processes, including warehouse inventory management. That way, the need for manual work is reduced, allowing warehouse staff to focus on speed without compromising accuracy.

ShipBob’s proprietary WMS, for example, ensures that inventory is tracked in real-time, reducing the need for manual processes and allowing you to monitor stock levels, velocity, and replenishment needs from a single dashboard.

3. Packing orders

The packing process begins once all items for a single order have been picked from the shelves. ShipBob optimizes packing by using the right-sized boxes and protective materials to ensure orders arrive in perfect condition.

To reduce shipping costs and maintain order accuracy, packing should always keep an order within the smallest number of boxes (avoiding split shipments) and use the right type of packing material(s) for each product in your assortment.

4. Shipping

In this final step, the packed orders are sent out to their final destinations. For direct-to-consumer (DTC) brands, it is often the end user, but some brands also offer B2B ecommerce services. In that case, some order (often larger packages with many units) are delivered to another company.

ShipBob’s extensive carrier partnerships, including major and regional parcel carriers, enable brands to provide fast and reliable shipping options. With ShipBob’s network of fulfillment centers, you can store inventory in multiple locations, making affordable 2-day shipping available to your customers, which is a key driver of customer satisfaction.

Ecommerce shipping is a vital stage in the distribution process as it plays a key role in customer satisfaction. In fact, 43% of online shoppers view fast and reliable delivery as the most important factor when shopping online.

Having a proper shipping strategy ensures that you can provide competitive, cost-effective shipping options for your customers.

There are several ways to approach delivery management and how efficient you ship orders, such as:

- Storing inventory in multiple locations to enable affordable 2-day shipping

- Partnering with a mix of major and regional parcel carriers

- Offering free shipping with a minimum cart value threshold that’s higher than your average order value

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

To learn more about how ShipBob can improve your distribution strategy, click the button below to start a conversation with our team.

Distribution management FAQs

Here are the top asked distribution management questions:

What are the objectives of distribution management?

Ever since the pandemic, customer expectations of ecommerce have gone through the roof. Effective distribution management can help you consistently meet such expectations by fast-tracking distribution and order fulfillment. And it helps save costs and energy spent by responding quickly to market seasonality and increasing profit margins by analyzing distribution management data.

What are the major issues in distribution management?

A major issue in distribution management includes not having enough visibility into day-to-day operations. Without the necessary data and information to forecast demand, understand where sales are coming from, or know how to optimize inventory storage, it can be a challenge to make informed decisions that optimize distribution.

Can distribution management be outsourced?

Yes! An outsourced supply chain tends to be much more effective and efficient, which ultimately leads to a better customer experience and profitability. For instance, many fast-growing brands work with a distribution partner like ShipBob, so they optimize distribution, reduce risk, save on costs, and speed up transit times. This also saves ecommerce businesses time by outsourcing fulfillment, so they can spend more time revenue-driving initiatives.

What does a distribution manager do?

A distribution manager oversees the entire process of moving products from the manufacturer to the final customer. This includes managing inventory, coordinating warehouse activities, selecting carriers, optimizing transportation routes, and ensuring on-time deliveries. Their goal is to ensure that the right products are delivered to the right places in the most efficient and cost-effective manner.

What’s the difference between direct and indirect distribution channels?

Direct distribution channels involve selling products directly from the manufacturer to the customer, bypassing retailers or wholesalers. Indirect distribution channels, on the other hand, involve third parties—like distributors, retailers, or wholesalers—who act as intermediaries between the manufacturer and the end customer.