Table of Contents

** Minutes

What is distributed inventory?

3 reasons to distribute your inventory across multiple fulfillment centers

ShipBob’s technology provides data-driven inventory location recommendations

What do you want to learn?

When outsourcing order fulfillment to a 3PL, you may think the more warehouses you use, the more complexities you encounter. The reality is using a single 3PL with multiple locations offers many advantages.

When it comes to fulfillment center location, one of the most important considerations is if it’s near your customers. Since your customers likely don’t all reside in a single geographic region, using one fulfillment center can make it nearly impossible to efficiently reach the majority of people who buy from you.

Instead, using distributed inventory means each time an order is placed on your store, the distribution center closest to that customer will automatically fulfill the order.

What is distributed inventory?

Distributed inventory is the splitting of physical goods across different fulfillment centers that are strategically chosen to keep inventory closer to the end customer. This way, it is nearby when it’s ready to be shipped to achieve a lower transit time and cheaper shipping costs.

Instead of using a single fulfillment center and centralizing inventory, distributed inventory lets a merchant leverage the locations that are most optimal for the business, enabling each order to be routed to and shipped from the closest fulfillment center.

3 reasons to distribute your inventory across multiple fulfillment centers

Learn the top benefits of splitting your product quantities into fulfillment warehouses in different regions (and how to know which locations are the best for your brand). Note: While you can do this with an on-demand warehousing solution, there are many risks. A professional fulfillment company that actually runs their own fulfillment centers is best.

1. Spread risk in case of emergencies

Splitting inventory across warehouses helps you be prepared and have options in the event that your orders can’t leave a particular fulfillment center. A common example of a delivery exception is bad weather that delays an order.

There are many catastrophes and natural disasters that prevent shipping carriers from making it to the fulfillment center or cause delays while in transit. At some point, a flood, wildfire, hurricane, earthquake, snow storm, or other force in nature will likely impact some of your orders.

Though much less likely, there are possibilities of other disasters that affect what’s inside a warehouse, such as an electrical fire. When you split your inventory across geographic areas, you will have backup inventory in other locations. Whether to prevent delays or lost stock, it can be better to be safe than sorry.

“ShipBob has been a great ally as they have fulfillment centers all over the US, facilitating a 2-3 day delivery time for any customer in the US. This is helpful especially when weather challenges happen; being able to have different locations to ship from allows for a more seamless supply chain.”

Andrea Lisbona, Founder & CEO of Touchland

2. Drive down shipping costs

While you may need to make a greater initial investment to purchase more inventory or ship units to additional locations than you would with only one fulfillment center, there are cost savings to be realized elsewhere.

When you ship from only one warehouse, it can take a long time to reach your end customer. With today’s standard and expectation of two-day shipping, a longer time in transit can prevent your customers from buying from you in the first place or making a repeat purchase. Additionally, high shipping costs are one of the top reasons for shopping cart abandonment.

Storing inventory closer to your customers helps lower shipping costs, because orders will travel a shorter distance. It is almost always less expensive to ship an order 30 miles than 3,000 miles. Of course, having access to a 3PL’s network of ecommerce fulfillment centers lets you use multiple facilities without paying for the infrastructure, staff, and equipment yourself.

“With ShipBob, we have the option to use more of their warehouses to further reduce shipping costs. Because they have a lot of people to handle our orders and additional warehouses we can expand into, we can scale up with ease as we continue to grow quickly. If we ran our own warehouse, it would be much harder to hire people and we’d inevitably outgrow the space.”

Oded Harth, CEO & Co-Founder of MDacne

Of course, if your order volume is on the low side, it may not make sense for you to distribute your inventory. You must consider whether ecommerce warehousing costs, transportation costs to logistics centers, and the number of SKUs you have would be offset by the reduced shipping costs and potential additional revenue made by offering better shipping options for more addresses.

3. Get your orders shipped to customers faster

With customers today expecting a two-day turnaround for their orders (and many accepting nothing longer), using multiple warehousing and storage locations lets you significantly reduce delivery times.

I’m most impressed with ShipBob’s commitment to driving improvement and technology, which drives reductions in delivery time. I knew a shorter transit time was going to become more and more important. Customers get accustomed to a certain service level at a low price — often free — and want it faster over time.Michael Peters, VP of E-Commerce Operations at TB12

If you use fulfillment centers in hubs like Chicago or Los Angeles, you can reach a large amount of the population in different areas of the country. It is easy to get the package delivered the same day to people who live in these cities, because the inventory is already close by. If your inventory is only in one of those cities, say, Los Angeles, then imagine how long it will take a package to arrive to your customers who live on the East Coast.

Ultimately, the quicker a customer gets their order, the happier they are. If you can offer a quick turnaround time – without using expedited shipping and it costing an arm and leg – you will likely see a surge in sales.

“The more fulfillment centers we have inventory in, the more potential shipping addresses we can offer 2-day shipping to. And the more people that we offer the benefit of free 2-day shipping to, the more conversions we get. With ShipBob’s 2-Day Express Program, we’ve seen an 18% reduction in cart abandonment.”

Founder of My Calm Blanket

[Download: ShipBob’s 2-Day Express Shipping: How to Drive Revenue Through Ecommerce Fulfillment]

ShipBob’s technology provides data-driven inventory location recommendations

If you partner with ShipBob for fulfillment and distribution, our free proprietary technology and analytics tool use your historical order data to display your current shipping speeds and costs, and compare those to what they would be if you used different fulfillment centers in ShipBob’s network.

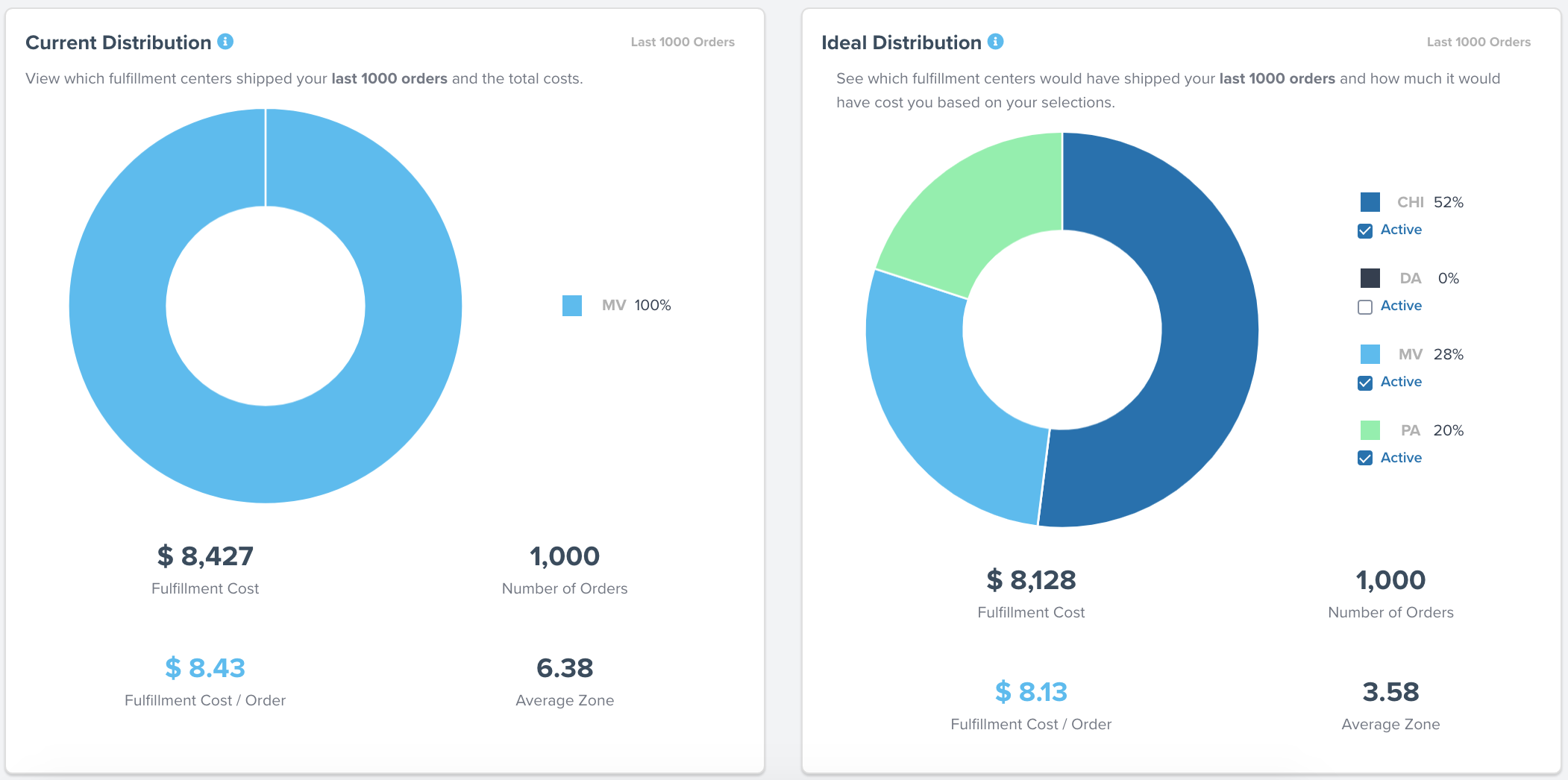

In the example below, a merchant is storing inventory and shipping orders exclusively out of our Moreno Valley, California fulfillment center (MV) just outside of Los Angeles. This location is great for local customers, but the average shipping zone is on the high side at 6.38 as seen on the chart to the left.

If the merchant instead stored inventory in additional locations of Chicago, Illinois (CHI) and Bethlehem, Pennsylvania (PA) for a total of three locations, the average shipping zone would be reduced to 3.58 as seen on the chart to the right. Instead of 100% of orders being fulfilled out of Moreno Valley, California, only 28% would be, as the remaining 72% of orders would be fulfilled from the other locations that are closer to the end customer.

Additionally, the average fulfillment or shipping cost would go from $8.43 per order to $8.13 per order. While $0.30 may not sound like a lot, for a merchant with an average order volume of 5,000 orders per month, that is an extra $1,5000 they are paying per month, or $18,000 per year. And if they continue to grow, that number will only go up.

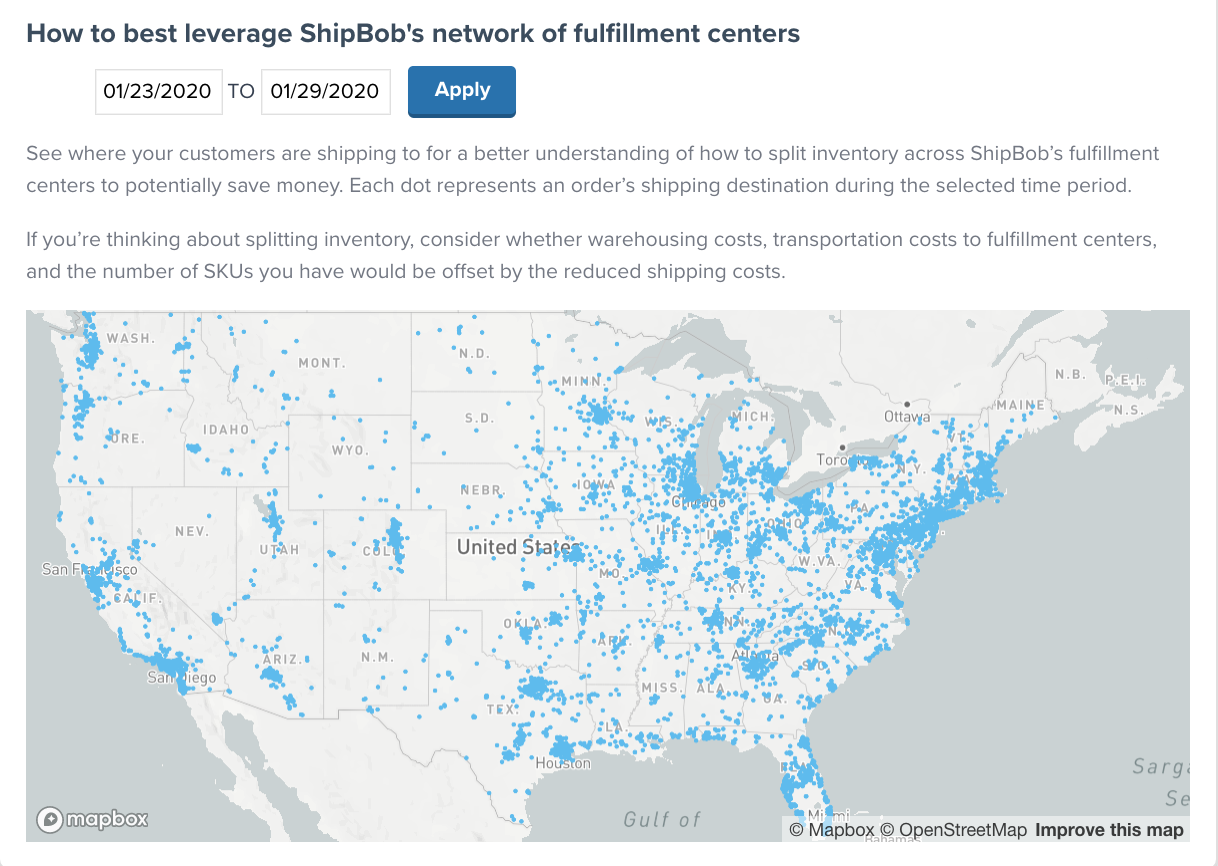

With this tool, you can visualize your ideal inventory distribution and toggle between different locations to see which make the most sense for your business. As you can see on the map below (using the same example from above), the majority of orders are actually on the East Coast and not on the West Coast of the United States, which explains why costs and transit times are higher than they could be.

“Storing inventory in different regions is key to reducing costs and transit times. From expanding into a second ShipBob fulfillment center, we are excited to be able to offer 65% of our customers with 2-day ground shipping, up from 32% by only having a single West Coast facility. Soon, this will be 100%. Not only is this better for our customers but we also gain a 13% savings to our bottom line.”

Pablo Gabatto, Business Operations Manager at Ample Foods

ShipBob helps brands at every stage of growth. Many get started in just one fulfillment center and revaluate their strategy as they grow. They can continue to expand into additional locations as they please, always choosing which ones they prefer. The distribution metrics ShipBob provides are always up-to-date to help you make the most intelligent decisions.

Conclusion

To be successful in the competitive ecommerce space, many online brands distribute their inventory to multiple warehouses. A good outsourced order fulfillment provider can help you determine the optimal fulfillment center locations for your business based on your customers’ addresses. Want a deep dive on distributed inventory? Watch a video recording of the webinar, “How to Transform Your Logistics Using Distributed Inventory.”

Talk to a fulfillment expert

ShipBob is the premier retail fulfillment partner for direct-to-consumer brands. With a robust network of fulfillment centers, best-in-class technology, and advanced analytics that help you make better decisions, we help you optimize your supply chain while providing the best customer experience. Learn why thousands of ecommerce brands work with ShipBob today.