Inventory Management & Maintenance Guide

Everything you need to know to stay on top of the inventory management process.

Managing inventory strategically has never been more important, and it only gets more challenging as you grow in both product development and units sold.

So, what do you want to learn?

Request Fulfillment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfillment expert will get back to you shortly. Privacy Policy

What is inventory management?

Inventory management is the management and monitoring process of a company’s stocked goods (inventory). Inventory management is vital for supply chain management in online, omnichannel, and brick-and-mortar businesses, and includes ordering and restocking inventory, storing inventory, adjusting frequency, order quantity, and inventory forecasting for the final point of sale.

Why is inventory management important?

Managing inventory the right way is crucial, especially for growing ecommerce businesses. Here’s why.

1. It ensures you never run out of stock

Part of inventory management is figuring out how much inventory you should have on hand at all times. Too much inventory, and you risk ‘dead stock’: inventory that can no longer be sold due to being outdated. Too little, and you’ll run out of stock, fail to meet customer demands, and miss out on potential sales.

By using a reorder point formula, you can ensure that you keep an eye on your inventory so that it doesn’t dip below a critical level. (More on this later.)

2. It helps you save money on storage

Too much inventory can result in too much money spent on storage space. Storing inventory is a variable cost — it’s based on how much space your beginning inventory takes up at any given time. When you have more product on hand than you need, you end up paying more for inventory storage. Being smart about inventory levels can help you reallocate those funds.

3. It prepares you for the unexpected

It pays to be prepared. Do you know what you’d do if any of the following supply chain mishaps took place tomorrow?

- You unexpectedly sell out of a product

- You miscalculate your storage needs and run out of space

- Incoming inventory from the manufacturer is delayed

- You run into a cash flow issue and can’t purchase more inventory

Strategic inventory solutions can help you get out of these sticky situations. Tracking inventory over time and having contingency plans in place for potential inventory problems will prepare you for situations that would otherwise seriously impact your business.

4. It shows trends in customer behavior

Keeping track of what inventory sells like hotcakes versus what ends up covered in metaphorical cobwebs can share some important insight about what your customers are — and aren’t — into. You can also gauge the success of prior promotions or product launches by assessing inventory levels before and after those events.

5. It predicts the future

Well, kind of. Good inventory management lends itself to good inventory forecasting, which can help you predict and plan for demand. You can leverage past inventory trends on a monthly, seasonal, or SKU-by-SKU level to better prepare for future levels of sales and demand. Make sure to keep any planned marketing promotions or new product launches in mind, too.

6. It helps you track costs of goods sold

Inventory accounting is when you track and account for changes in the value of inventory over time as it relates to manufacturing and costs of goods sold. If you don’t have an accurate method for keeping track of the value of your inventory, you can’t properly value your assets or goods sold and budget for the inventory you need to buy for your business.

10 crucial inventory maintenance techniques

There are countless inventory management techniques to employ, but here are some of the basics that ecommerce teams need to get right in today’s world.

1. Set reorder points

Also called par levels, reorder points are the minimum quantity of each product that must be on hand that signals it’s time to order more inventory in order to prevent stockouts. When your inventory level hit the reorder point, it’s time to order more products from your manufacturer.

To calculate reorder points for your products, add up the following (in days):

- Your manufacturer’s lead time for sending inventory to your fulfillment center

- Your retail fulfillment provider’s receiving turnaround time (if applicable)

- A recommended “safety stock” of at least 14 days in case of a sudden demand spike

Then, multiply the sum of 1, 2, and 3 by your average units of the product sold per day. This number is your reorder point.

Although it requires some math upfront, setting reorder points will help streamline and take the guess out of restocking inventory.

Make sure that you check your reorder points over time and adjust as necessary, especially before peak times like the holidays when you’re likely to need more holiday inventory on hand. At this time, you might need to increase both your reorder points and reorder quantity.

2. Use the FIFO approach

“First-in, first-out,” aka FIFO, is an inventory management principle that means that your oldest inventory (first-in) gets sold and shipped out first (first-out). This is especially important if you’re selling perishable products or those with expiration dates.

Even if your goods are shelf-stable, FIFO can still be a good strategy. Because packaging, design and branding, and product features tend to change over time, it’s important to change out inventory so you don’t end up with obsolete products.

If you’re storing inventory and fulfilling purchase orders in-house, you’ll have to monitor this manually. If you’re outsourcing to a third-party logistics (3PL) provider, they’ll likely be able to implement a FIFO system for you.

3. Regularly audit your inventory

While auditing physical inventory is often tedious, it’s important to check actual inventory levels against the amount of inventory you have listed electronically. If you work with a third-party provider, you’ll probably be relying on their software system and reporting to keep track of inventory levels. However, it’s important to make sure that the system’s numbers match up with your physical stock.

Spot checking can be a more manageable way to keep inventory audits under control in between full physical inventory audits. This means choosing a specific product, counting the number of units on hand, and comparing it to the number of units listed in the system or inventory sheet.

This is especially helpful if you have a large product catalog with lots of different SKUs. Inventory management technology can help simplify this process by prompting a spot check when the system marks the product stock as zero.

After checking your inventory levels, it’s important to have regularly updated backups of this data. This can be as simple as exporting the data from your inventory management software to a CSV file at least once per week. Additionally, you can set up automatic backups of the inventory levels provided in your ecommerce platform using apps like this one.

4. Maintain a relationship with your suppliers

Choosing the right manufacturer is a huge step for growing businesses to find the most cost-effective and efficient partner that can help elevate growth. But finding the right supplier for your business is just the beginning. Maintaining a good relationship with your manufacturer will ensure they’re a partner in inventory management rather than an obstacle.

Make sure to communicate frequently with your manufacturer, especially when you’re anticipating an increase in sales or they’re running behind schedule on production.

If you have inventory quality issues, a product that won’t sell, a product that sells out more quickly than anticipated, or any other situation that calls for production adjustments, having a good relationship with your supplier will help your retail supply chain run more smoothly.

5. Use inventory management software

Software that is specifically designed to help you manage your inventory, whether in-house or in a 3PL’s warehouse, can help avoid losing money from unsold products, inventory reports on stock levels and trends in real-time, and offer suggestions for inventory distribution. It can also help automate several of the techniques above, saving time and potential human errors for your business.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

There are countless inventory management techniques to employ, but here are some of the basics that ecommerce teams need to get right in today’s world.

6. Inventory tracking

Knowing which SKUs you have in your possession, their locations in storage, and the quantities available at each location is mission critical for ecommerce brands. Real-time inventory management involves implementing technology that enables the ability to track inventory flow, and view and manage inventory levels throughout the ecommerce supply chain on demand.

This level of inventory visibility is the first inventory management technique to nail, as without it, you can’t measure efficiency and improvements, know when to order more products, or refine your strategy as you grow.

7. Inventory optimization

The right tools, technology, processes, and infrastructure can help you not only forecast demand and optimize storage but also understand when you should expand into another fulfillment center, or even in new markets.

Inventory allocation involves strategically tracking inventory levels across a distribution network to meet customer demand efficiently, while accounting for each unit sold across each channel and fulfilled from each location.

With global supply chain shortages, manufacturer shutdowns due to COVID outbreaks, and rising costs, diversifying your supplier or manufacturer mix is another great way to optimize inventory control and reduce risk.

8. Add items to your product range

Once you’ve optimized your inventory, you should be able to understand whether it makes sense to expand your product line by selling complementary or supplemental products. Common examples include introducing a best-selling item in a variety of new colors, or expanding from selling just peanut butter, to a variety of jellies and jams.

SKU proliferation refers to the process of adding more products to your inventory based on changes in the market and to attract more buyers to increase your sales.

9. Reduce the number of products you sell

One of the best things some brands can do to optimize inventory management is to cut back on the products they sell (yes, you read that correctly!).

SKU rationalization is the process of identifying whether a product at the SKU level should be discontinued due to declining sales and overall profitability.

By understanding this, in addition to having the ability to track inventory performance, you can focus on your fastest-moving products and double down on profitability.

10. Measure everything

Inventory analytics are metrics that gauge the movement and performance of your physical products. The ongoing assessment and evaluation of inventory provides:

- The insights needed to optimize stock availability to meet demand while keeping storage costs to a minimum (including COGS, inventory turnover, revenue, internal processes, and more)

- The ability to help reduce risks and common challenges related to inventory, such as stockouts or accumulating dead stock

- Data to operate more efficiently, optimize cash flow, and increase profitability

- Information on whether your operations are improving or getting worse

Check out our 15 most valuable inventory KPIs to keep track of and example Inventory reports.

Why do I need an inventory management system?

An inventory management system is a necessity for growing ecommerce businesses. Here’s why.

View real-time inventory counts at the SKU level

With inventory tracking software in place, your orders and inventory are synced in real-time. At any given time, you can view the status of inventory you send to various partners, the quantity on hand at your storage facility, and total units sold per day. This provides reassurance and visibility into what is available to ship to your customers, as well as the real-time impact of promotions and product launches.

Automate reorder notifications to prevent stockouts

Using historical data, inventory management software can help project when you should order more inventory to prevent stockouts. This helps take the guesswork out of reorder points. Some inventory systems also allow you to set reorder notification points that automatically alert you to restock.

Run reporting on inventory trends and forecasting

Inventory software can automate reporting on product trends and inventory forecasting for your retail business.

An inventory management solution can help you better predict future demand and sales. Monitoring which products are purchased together can help you understand your customers’ behavior and help you decide how to group your products for new offers or promotions. You may find patterns of how one SKU drives demand for another.

You can also monitor the inventory you have on hand and units sold per day, run reports to see which SKUs and sales channels are your highest sellers, and see which products aren’t as popular, costing you higher warehousing fees. This can save business owners money in the long-run and keep inventory carrying costs down.

Best inventory management software

There’s no one-size-fits-all inventory management system; every small business or large corporation has different needs, especially when it comes to ecommerce. Here are some of the most popular inventory management software for online stores.

ShipBob

ShipBob is not a standalone inventory management system, but rather an order fulfillment solution that has inventory management software built in. Merchants get the tools, guidance, and reporting necessary to efficiently manage their inventory across multiple stores and ShipBob’s fulfillment centers.https://www.youtube.com/embed/YdTbM4XlizY?feature=oembed

Inventory tracking tools are included at no extra cost for merchants who use ShipBob to fulfill orders. Having order fulfillment synced up with inventory management helps optimize your supply chain and keep data and reporting in one place.

SAP

Some businesses — especially enterprise retailers who have been operating for many years — choose legacy providers like SAP to track inventory. These include warehouse management and enterprise resource planning systems (WMS and ERP respectively).

Many WMS and ERP systems use legacy technology. While these systems record and manage stock levels, there is not always an automation or optimization component. These options also tend to be expensive, incurring significant overhead in exchange for limited functionality, thus geared toward very large companies.

The different types of inventory

There are many statuses or types of inventory depending on the phase of the lifecycle it’s in. Below is a breakdown of a few common types of inventory throughout the supply chain.

Raw materials

These are your materials or ingredients that come together to eventually make up a product you sell. Also known as production inventory, or manufacturing inventory, they get transformed into end products during the manufacturing process. These are different from partially-finished and finished goods.

Work in process (WIP) inventory

Work in process inventory refers to partly finished materials within any production round, or the total cost of unfinished goods currently in production. WIP inventory is considered an asset on a company’s balance sheet. They are different from finished goods.

Finished goods

These are your final products that are done being manufactured and are ready to be sold to your customers as-is.

Supplies or MRO goods

The difference between supplies and inventory is:

- Supplies or MRO goods (maintenance, repair and operation supplies) are the items that you use to run your daily operations. They aren’t necessarily a component of the finished products that are sold to customers, but they play an essential role in your business function (e.g., cleaning supplies, office equipment, etc.).

- Inventory, on the other hand, refers to the raw materials that will be transformed into finished goods, and the finished goods themselves that are sold to the end customer.

Why outsource inventory management to a 3PL?

You may think that outsourcing inventory storage and ecommerce order fulfillment to a 3PL provider means turning inventory management over to them. In reality, a good 3PL partner provides merchants the tools, data, and transparency they need to manage their inventory efficiently and cost-effectively.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

Inventory management involves much more than just warehousing your products. Fulfillment and inventory management go hand in hand. Here’s how a 3PL helps you manage your inventory.

Sync SKUs and orders from your store

A tech-enabled 3PL’s software seamlessly integrates with all major ecommerce platforms and marketplaces. This enables merchants to connect their store in just a few clicks without needing a developer.

Connecting these channels provides a cohesive view of all orders, inventory, fulfillment centers, sales channels, and customers in one place. You can easily pull over all of your SKUs from your store into your 3PL’s system. And as you add new products, you can easily sync your new SKUs.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO Shorts

View real-time inventory counts

Once your 3PL has your inventory at their fulfillment centers, you can check the quantity on hand and units sold per day at any given time for direct visibility into what is available to ship to your customers.

For instance, from the ShipBob dashboard, you can:

- Visualize SKU velocity and days of inventory remaining on hand.

- Input changes in projected order volume or scenarios to calculate changes in inventory turnover.

This type of real-time visibility allows you to view historical inventory levels and how much inventory is remaining at each distribution center:

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Proactively reorder inventory

Tech-based fulfillment uses historical data to help project when you should reorder inventory to prevent stockouts and backorders. You can set reorder notification points for the stock levels at which you want to be automatically reminded to restock.

For instance, SHipBob provides access to daily inventory history data at any point in time. You can search by item, filter by specific lot number, and account for inventory in transit:

This helps you connect the upstream activities of purchasing and manufacturing to the downstream activities of sales and product demand, ultimately helping you make more accurate purchasing and production decisions to save on inventory and logistics costs.

Store inventory in strategic locations

If your 3PL has multiple fulfillment centers, they should be able to help you determine the optimal fulfillment center locations based on your customers’ shipping destinations.

Your customers most likely don’t all reside in one geographic area. Using one fulfillment center can make it difficult to efficiently reach the majority of people who buy from you. Instead, distributing your inventory to major hubs or cities can ensure you ship to lower shipping zones, delivering orders more quickly and at a reduced shipping cost.

Each time an order is placed on your online store, the 3PL’s order management system will automatically choose the fulfillment center closest to the end customer to draw inventory and ship the order. Additionally, if you run out of inventory at one fulfillment center, you’ll have backup at another.

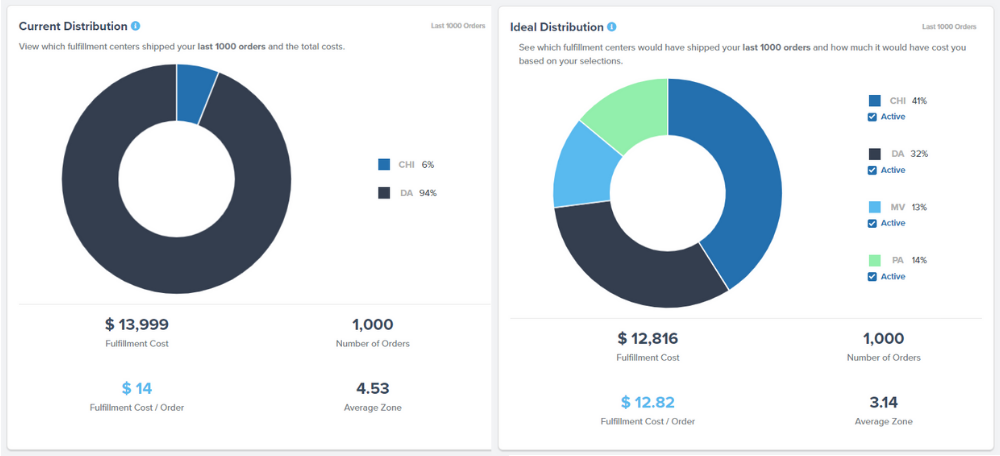

For instance, ShipBob makes it easy to optimize inventory distribution. By aggregating historical order data, you get an analysis of which fulfillment centers you should stock to best leverage ShipBob’s network of fulfillment centers for the most cost-effective and fast deliveries (see example below).

Discover trends to drive growth

As we mentioned above, having accurate insights about your customers’ purchasing trends can help you figure out the optimal inventory levels for your products.

For example, understanding which products aren’t selling but instead incurring storage costs — as well as those that are selling more quickly than you can keep them in stock — can empower you to make better supply chain decisions.

Some 3PLs provide built-in reports that let you view a trend analysis of your products and give you more control of your inventory and the key metrics that drive business growth. These include peak fulfillment times, revenue of orders shipped by day, sales by channel, and sales and quantity of orders by USPS shipping zone.

Control how products are grouped

A 3PL’s technology gives you the power to select how you group your warehouse inventory. This includes:

- Bundling your products for promotions

- Merging the same product across multiple sales channels

- Separating inventory by lot numbers and expiration dates to comply with regulations and be able to act promptly and effectively in the event of a recall. (This also helps with the FIFO technique we talked about earlier.)

- Kitting items to assemble them a certain way before they are shipped to customers

- Preparing orders to send in bulk or transfer inventory

Today, outsourced order fulfillment often means receiving the tools needed to manage inventory from within their warehouse(s). A good 3PL shouldn’t be a cost center but rather a partner that helps prevent stockouts and can accurately forecast demand to increase sales and reduce storage costs.

Request a fulfillment quote from ShipBob to learn how we manage your inventory and order fulfillment for you.

Inventory management and maintenance glossary

Below is a handy table summarizing several basic inventory management terms you’ll come across.

| Inventory Term | Definition |

| Cost of goods sold (COGS) | The direct costs of producing your sellable inventory, including labor, materials, and other direct costs |

| Economic order quantity (EOQ) | A calculation used to figure out the optimal order quantity you should have with the goal to minimize logistics costs, warehousing space, and stockouts |

| Minimum order quantity (MOQ) | The fewest number of units that are required to be purchased at one time |

| Reorder quantity | The total number of units you request from a manufacturer or supplier on an inventory replenishment purchase order |

| Lead time | The amount of time it takes for an order to be completed, whether it be a production lead time, a shipping carrier transit time, or other turnaround time that involves inventory |

| Pipeline inventory | The value of finished goods ordered from a supplier or manufacturer that is currently in transit and has yet to reach a physical store or distribution center (also known as goods in transit) |

| Inventory position | Where a business’s inventory is held — both its physical location in a storage space, and its position in the overall supply chain |

| Inventory levels | The quantities of products that you have in a fulfillment center(s) or store at any given time |

| Dead stock | Inventory that is obsolete and no longer sellable |

| Safety stock | The excess product you keep on hand in case of an emergency (also known as buffer inventory) |

| Inventory forecasting | The process of calculating the inventory needed to fulfill future customer orders based on how much product you predict you will sell over a specific period of time |

| Stockout | When inventory is unavailable, preventing an item from being purchased or shipped |

| Just in time (JIT) inventory | A method designed to cut costs, increase efficiency, and decrease waste by receiving goods just when they are needed |

| Restocking | The process of replenishing products at the right time and at the right place based on demand and projected sales |

| Lot tracking | A system used to trace parts or ingredients associated with a group of products back to a manufacturer or supplier, or organize inventory by production batch or expiration date |

| Reorder points | The minimum unit count or stock level for a specific product that triggers the reordering of more inventory when reached |

| Inventory turnover | A ratio that measures how many times inventory is sold and then replaced in a specific time period |

Below are some inventory accounting and inventory valuation terms as well:

| Inventory Term | Definition |

| Inventory discrepancy | When the amount of inventory on hand is different from current inventory records (can also be expressed as inventory accuracy) |

| Inventory shrinkage | When actual inventory levels are less than accounting has them recorded as |

| Inventory write-off | The process of removing or reducing the value of inventory that has no value from accounting records |

| Inventory write-down | When your inventory’s market value falls below the book value, but it still considered sellable (also known as inventory impairment) |

| Inventory reconciliation | The process of comparing physical inventory counts with records of inventory on hand (e.g., during an inventory audit) |

| Inventory carrying cost | The total cost of all expenses related to storing unsold goods (also known as inventory holding cost) |

| Inventory weighted average | An inventory valuation method that uses a weighted average to determine the amount of money that goes into COGS and inventory |

| Beginning Inventory | The total value of a business’s current inventory in stock at the beginning of an accounting period |

| Perpetual inventory | An inventory valuation method that records when stock is sold or received in real-time |

| Periodic inventory | An inventory valuation system where the business’s inventory and COGS are not updated in the accounting records after each sale and/or inventory purchase, but instead when a designated accounting period has passed |

| First-in, first-out (FIFO) | An inventory valuation method that assumes goods purchased or produced first are sold first (this also means the oldest inventory gets shipped out to customers before newer inventory) |

Conclusion

Inventory management affects every aspect of a business’s operations. Choosing the right inventory management system and techniques can help your business save money, meet customer demand, and stay efficient and effective in the fast-moving ecommerce landscape.

If you’re in need of a 3PL that will help you manage your inventory in real-time, check out ShipBob. With ShipBob’s technology and network of fulfillment centers, you can manage inventory and order fulfillment efficiently and effectively from one central platform.

Inventory management FAQs

Now that you’ve gotten more familiar with managing inventory for an ecommerce business, here are some frequently asked questions you may want to know.

How do I know when to reorder inventory?

Calculate reorder points either manually or through your inventory management system’s software. Some inventory management software allows you to enable automatic reorder notifications when stock drops below the designated reorder point.

How do I know how much inventory to order?

Stocking the right amount of inventory is a delicate balance you have to strike. If you order too much inventory, you’ll end up with extra stock for which you have to pay for storage; too little, and your customers will look elsewhere.Analyzing historical data and trends from previous months will help you determine how much stock you’ll need moving forward. If you’re launching a new product, make sure to clear storage space for excess inventory before it arrives.

How do I deal with stockouts on my store?

If you frequently find your products selling out, make sure that you order a higher quantity of inventory the next time you restock. If you’re in the situation where you’ve run out, keep customers in the loop on when they can expect your product to be back in stock by displaying inventory restock dates on the product page and offer them the option to be notified when it’s back in stock.

How do I plan for seasonality?

Seasonal variations in supply and demand can put a lot of pressure on a growing business. If your business has been around for over a year, analyzing previous years’ seasonal trends can help you plan properly for upcoming seasonality.If your business is brand new, you can research seasonal trends in your industry to help you form predictions. For example, if your product is meant for winter use only, you’re likely to find that demand is highest just before and during the winter months, while you’ll want to have less stock on hand in the summer.

How do I manage inventory in multiple warehouses?

If you are operating several of your own warehouses or inventory storage locations, make sure to set up a WMS and inventory management system that allows you to keep track of inventory across locations. Having the right technology in place can streamline in-house inventory management.

If you outsource supply chain management and the warehouses are all owned and operated by the same 3PL, they should be able to provide visibility into all of your orders, stock levels across fulfillment centers, and shipments in one place.

If your inventory is stored in warehouses operated by several different fulfillment providers (e.g., in different countries), an inventory management system can help you manage all sales channels, locations, and currencies to streamline inventory control from a single dashboard.

What is a SKU?

A SKU, or Stock Keeping Unit, is an alphanumeric code number assigned used to identify a product. The code represents different product characteristics, such as color, size, and brand. Each product variation is assigned a SKU, and the SKU is used to keep track of inventory (e.g., a Large red shirt is a different SKU than a Medium red shirt, and thus, should be stored in a separate location).

What is inventory turnover?

An inventory turnover ratio measures how quickly your company is selling inventory. It can be a useful comparison to industry averages to measure the strength of your company’s sales volume and performance. Knowing your inventory turnover rate can provide valuable insight into how your company manages inventory, sales, and costs.