Table of Contents

** Minutes

Why is SKU proliferation important?

What can retailers do to keep SKU proliferation in check?

Jackie operates an online store selling hair care products, including shampoo and conditioner.

After seeing more and more hair lovers dying their hair and posting on Instagram, she decided to offer a new product: DIY hair dying kits in multiple shades.

The new product line ended up being a huge hit. But at the same time, Jackie’s business ran into into some logistics challenges.

There wasn’t enough storage space to hold all of her SKUs and units needed to meet demand.

This is a prime example of SKU proliferation.

To keep up with the changing market, businesses are always introducing new items or variations of a similar product.

But introducing new inventory involves reevaluating your current logistics operations —whether it’s expanding storage space, making changes to your restocking process, or optimizing the fulfillment process.

In this article, we will discuss how ecommerce businesses can approach SKU proliferation, why it’s important, plus strategies on how to optimize the SKU proliferation process.

What is SKU proliferation?

SKU proliferation refers to the process of adding more products to your inventory based on changes in the market, thus increasing the number of stock keeping units (SKUs).

For example, you may decide to introduce your best-selling item in a variety of new colors, which will result in several new SKUs to keep track of.

While SKU proliferation helps you attract more buyers and increase your sales, it can lead to some challenges if new SKUs are not strategically introduced into your ecommerce supply chain.

Otherwise, you may find yourself way in over your head with too many SKUs to keep track of, reducing inventory visibility, increasing carrying costs, and potentially impacting profitability.

Why is SKU proliferation important?

To stay agile and scale, ecommerce businesses have to keep up with their customers’ desires and keep products relevant. This is the primary reason why businesses introduce new products, even if they slightly differ from their existing inventory.

For example, a popular razor brand might decide to introduce a new product that boasts a closer shave than their existing product.

This gives customers an option to buy a premium version of the original if they choose. It’s not uncommon for businesses to offer a ‘good,’ ‘better,’ and ‘best’ option for their customers.

Technology also plays a role as some products can be manufactured fast and enter the market quickly to keep up with the latest trends (e.g., remember fidget spinners?).

But like many trends, they come and go, which leaves behind a high volume of unsellable inventory.

With all this in mind, adding new SKUs to your existing inventory requires a proper inventory managementprocess, including:

- Tracking inventory in real-time

- Making updates across all sales channels

- Optimizing warehouse capacity

- Ensuring full inventory visibility

- Managing old inventory and dead stock

How does SKU growth affect SKU proliferation?

SKU growth directly results in SKU proliferation. In many cases, the two terms are also used interchangeably due to this close relationship.

In terms of SKU growth, any time you introduce new products, it will add a layer of complexity to the logistics side of your business.

For instance, as the number of SKUs in your inventory increases, unsold and slow-moving items will accumulate, therefore increasing carrying costs.

Introducing new SKUs will require you to make decisions on how to manage slow-moving items, so you can make room for newer inventory.

In some cases, older inventory is still sellable even if sales slow down, which requires strategic marketing and sales tactics to speed up these sales to make room for more inventory.

No matter how many SKUs you offer, as you grow your business, the types and quantities of SKUs will change. As you introduce new SKUs, proper SKU management allows you to:

- Monitor inventory flow

- Keep costs to a minimum

- Ensure that your product catalog is up-to-date

Why SKU proliferation can be a real problem

If left unchecked, SKU proliferation can negatively impact not only the your supply chain but revenue as well. Here is an overview of how SKU proliferation can cause major disruptions if not monitored and managed well.

Inefficient supply chains

If you’re constantly adding new SKUs, it can cause slowdowns and inefficiencies in your overall retail fulfillment process (unless you offer popular limited drops that sell out quickly and fulfilling them fast).

Finding the space to adequately store both new and existing inventory can quickly increase logistics costs, especially if you’re not selling through all product fast.

And not only will you run into warehousing challenges, but with the more SKUs you have on hand, the harder it is to ensure picking and packing workflows are optimized for accurate, fast fulfillment.

Without access to inventory forecasting data, it can also be hard to decide how many units of each SKU you will need to reorder and when based on demand.

Overall, introducing new SKUs at a rapid rate can slow down supply chain efficiency unless the right systems, workflows, and processes are in place.

High cost of storage

Like mentioned earlier, one of the biggest challenges in adding more SKUs is minimizing logistics costs, especially storage needs.

The more inventory you have, the higher your storage costs will be. You may reach a point of maximizing existing storage space, needing to invest in another warehouse or outsourcing fulfillment altogether.

Accommodating new inventory while also holding onto older items that have the potential to sell but at a slower rate can be a tricky balance.

Of course, renting additional ecommerce warehouse space can get costly, not to mention you will need to hire more labor to manage it all.

That’s why many brands outsource warehousing and distribution needs to a 3PL like ShipBob that has a global network of warehouses around the world, so they don’t have to worry about running out of space.

Inventory obsoletion

The biggest challenge in holding on to inventory is that it may go obsolete quickly (via expirations, outdated packaging, and more). Though inventory obsoletion can occur for several reasons, having more SKUs increases the likelihood of older items selling at a slower rate.

Some products are also trendy or seasonal, which requires you to sell a high volume of inventory at once since it’s time-sensitive (e.g., swimwear or winter sports gear).

Even if you made decisions based on historical sales data, there is always a chance you’ll end up with a surplus of inventory.

Let’s say you sell coffee and offer a holiday blend (whether it’s pumpkin spice or gingerbread). As a seasonal product, the holiday blend will see a quick spike sales but will eventually die down after the holidays when people don’t associate those flavors as much with or in the new year.

In these cases, a significant amount of inventory might need to be ordered and stored at once to ensure fast fulfillment based on high demand, but the you’re at a higher risk of accumulating leftover, unsellable inventory.

You can always run a flash sale or donate unsold inventory, but your bottom line takes a hit.

Inefficient capital allocation

With SKU proliferation, some of your capital is tied up in slow-moving items (AKA you had to pay for inventory upfront, but then you’re not selling it to make the money back).

As you introduce better SKUs, it’s possible the older items are are less likely to sell at the same rate (e.g., electronics), even if they still are considered in demand and valuable.

When you have too much capital tied up in inventory, it might make it harder to fund other areas of your business – whether it’s new equipment, better technology, marketing, or additional hires.

What is an ideal SKU count for your ecommerce store?

Ideal SKU count depends on a variety of factors, but we can learn a thing or two from successful brands to help us make better decisions on how we manage SKUs.

The argument for a larger SKU count is to get repeat purchases by offering those customers who already bought from you a greater variety (by selling complementary products, up-sells, or even different flavors, variations, etc.).

But Ryan Treft, the founder and partner of Coalatree and Peejamas, believes in keeping his SKU count simple, which helps improve forecasting initiatives.

Coalatree was insolvent when Ryan picked it up several years ago. This was because they pumped out too many SKUs too fast that didn’t make sense for their relative size.

This goes to show that selling more products does not always translate to more sales.

The difference between 20 and 40 SKUs can be hard enough, so having 40 to 400 SKUs can get overwhelming quickly.

It’s easy to overestimate the use of new colors and slight differences. And it can also negatively impact customer buying behavior.

Why? The paradox of choice. If you see 900 cereal brands in the grocery store aisle, you’re more likely to leave with zero. A lot of the time for ecommerce, having more than three options is too much to think about.

So Ryan’s recommends keeping it simple. For every product, consider featuring only three options, knowing that a lot of the time consumers will choose the middle option.

“Don’t go crazy with your SKU count. Focus on keeping a catalog small while still being able to increase lifetime value and new sales.

For a lot of brands, 3 SKUs make up 50% of sales.

You probably don’t need hundreds of products that aren’t driving revenue.”

Ryan Treft, Founder & Partner of Coalatree and Peejamas

Ryan also advises to go on pace with cash flow, margin, lead time, and MOQ, and to be sensible to what a customer really needs. Too much choice is overwhelming. Sometimes it’s better to pair it down to a simple message.

What can retailers do to keep SKU proliferation in check?

SKU proliferation doesn’t necessarily have to be a bad thing, especially for rapidly growing direct-to-consumer brands that want to scale their operations.

With accurate inventory planning and proper supply chain management, you can effectively manage a high order volume without throwing your entire supply chain for a loop.

Here are some best practices to keep SKU proliferation in check while scaling your business.

Identify and liquidate dead stock

As you introduce new variations of a SKU, you will need a game plan on how you will deal with older inventory, which is likely to accumulate and become dead stock.

Because of this, it’s important to quickly identify and liquidate dead stock to free up storage space and whatever capital you can salvage.

You could bundle a slow-moving item with a new or popular item, promote a flash sale, or donate inventory, so you can offset costs and make room in your warehouse.

In most cases, you may also be able to write off unsold inventory at the end of year or accounting period.

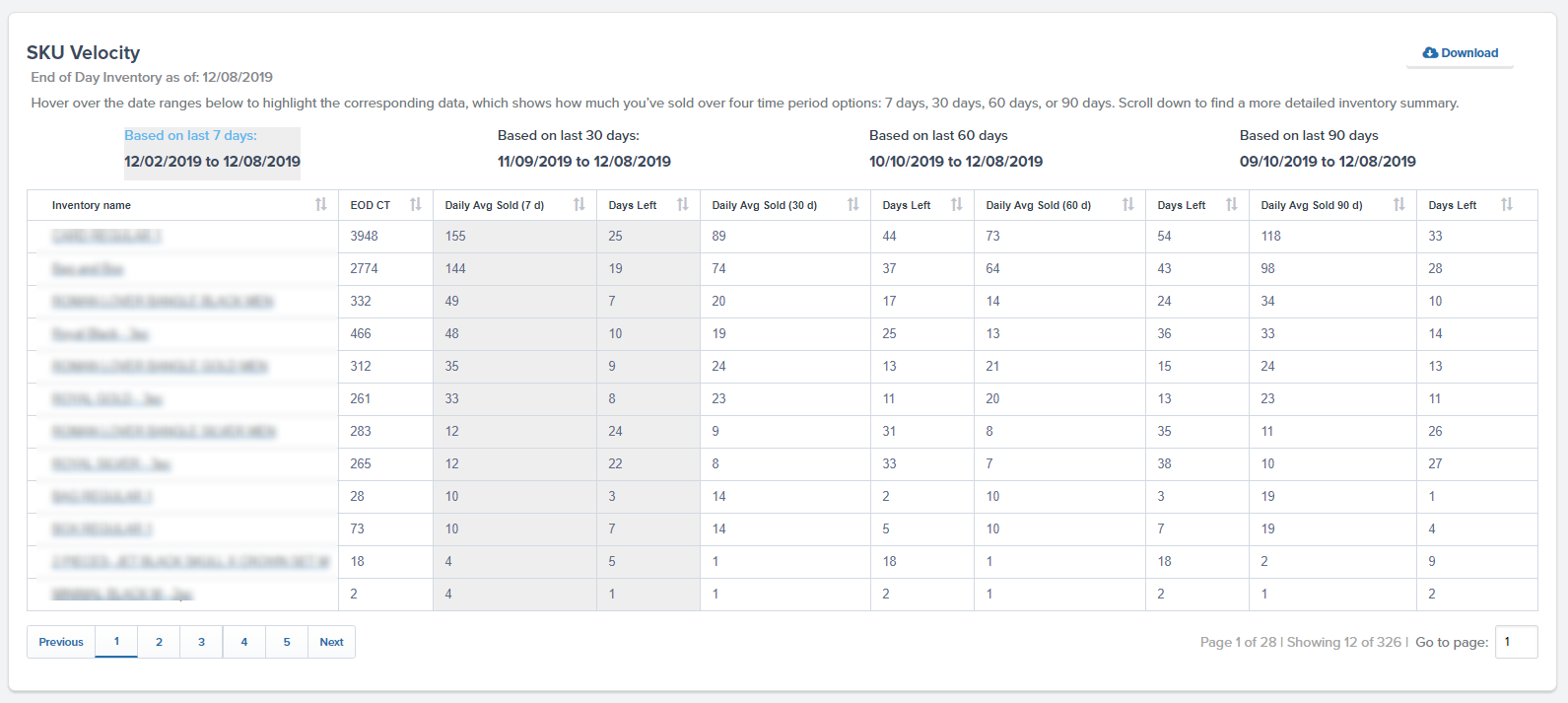

The right inventory management software can also help you track SKU velocity, so you can quickly identify slow-moving SKUs that are at risk of becoming dead stock.

This will allow you to proactively manage dead stock, so you don’t end up overpaying in storage.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week.

It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO Shorts

Forecast demand to keep healthy inventory levels

Accurate demand forecasting is key to preventing unchecked SKU proliferation and reducing the risk of dead stock from accumulating.

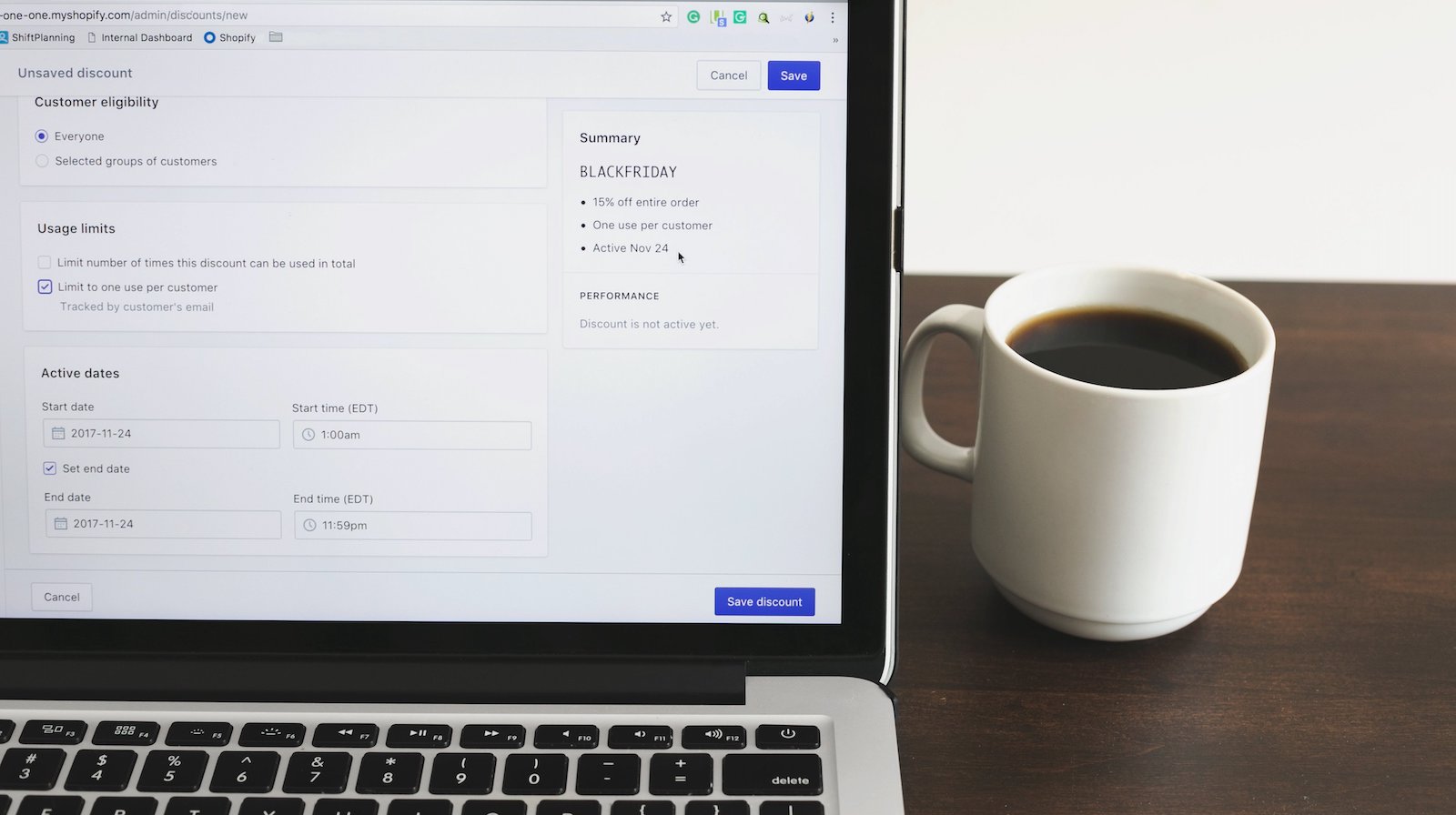

Forecasting demand uses historical sales data and evaluates it with other factors, such as planned promotions, to estimate how much product you will sell during a certain timeframe.

Coupled with real-time inventory tracking, you can use demand forecasting to maintain optimal inventory levels.

“We have access to live inventory management, knowing exactly how many units we have in Texas vs. Chicago vs. New York.

It not only helps with our overall process in managing and making sure our inventory levels are balanced but also for tax purposes at the end of the year.

ShipBob made that entire process very simplified for our accountants and us.”

Matt Dryfhout, Founder & CEO of BAKblade

Upgrade your inventory management system

If your current inventory management system doesn’t let you track inventory levels and movement in real time, it’s time for an upgrade.

Before you add new SKUs, consider investing in inventory management software that offers real-time tracking, so you can closely monitor the movement of inventory throughout your supply chain.

This will give you an idea of when and how much to reorder, preventing both stockouts and over-ordering. It will also help you understand which items are selling slowly, so you can make quick decisions on what to do next.

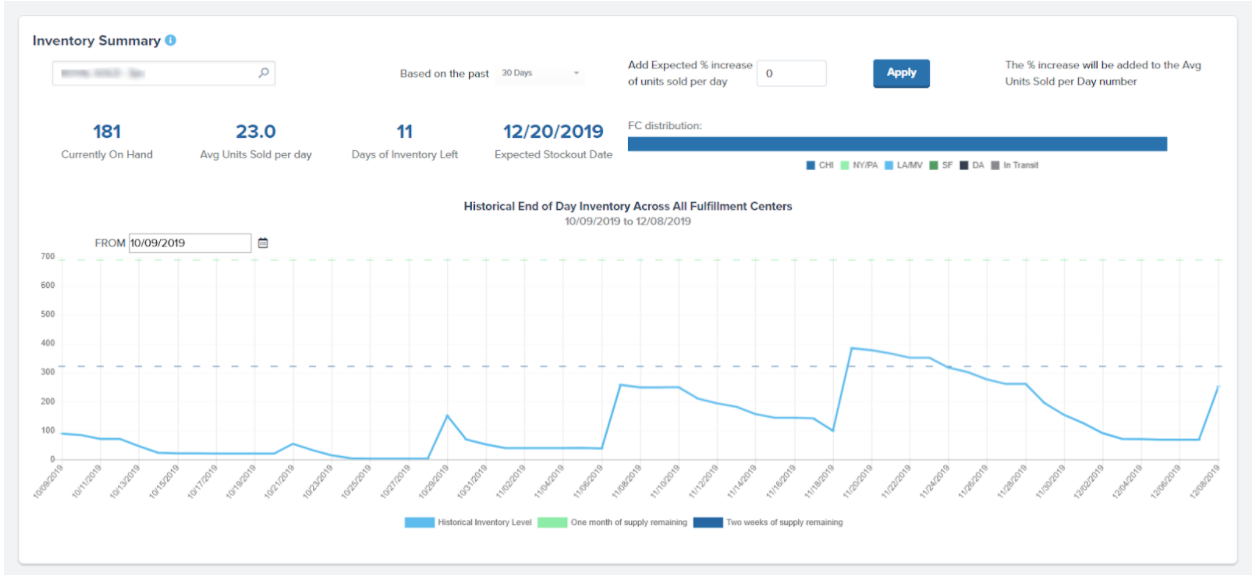

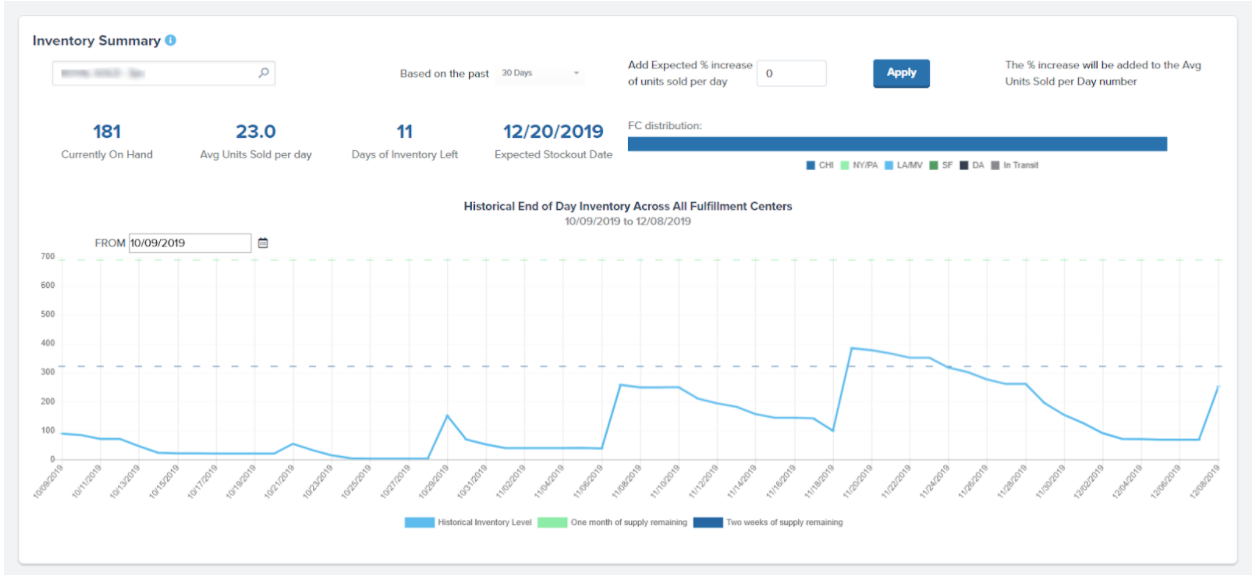

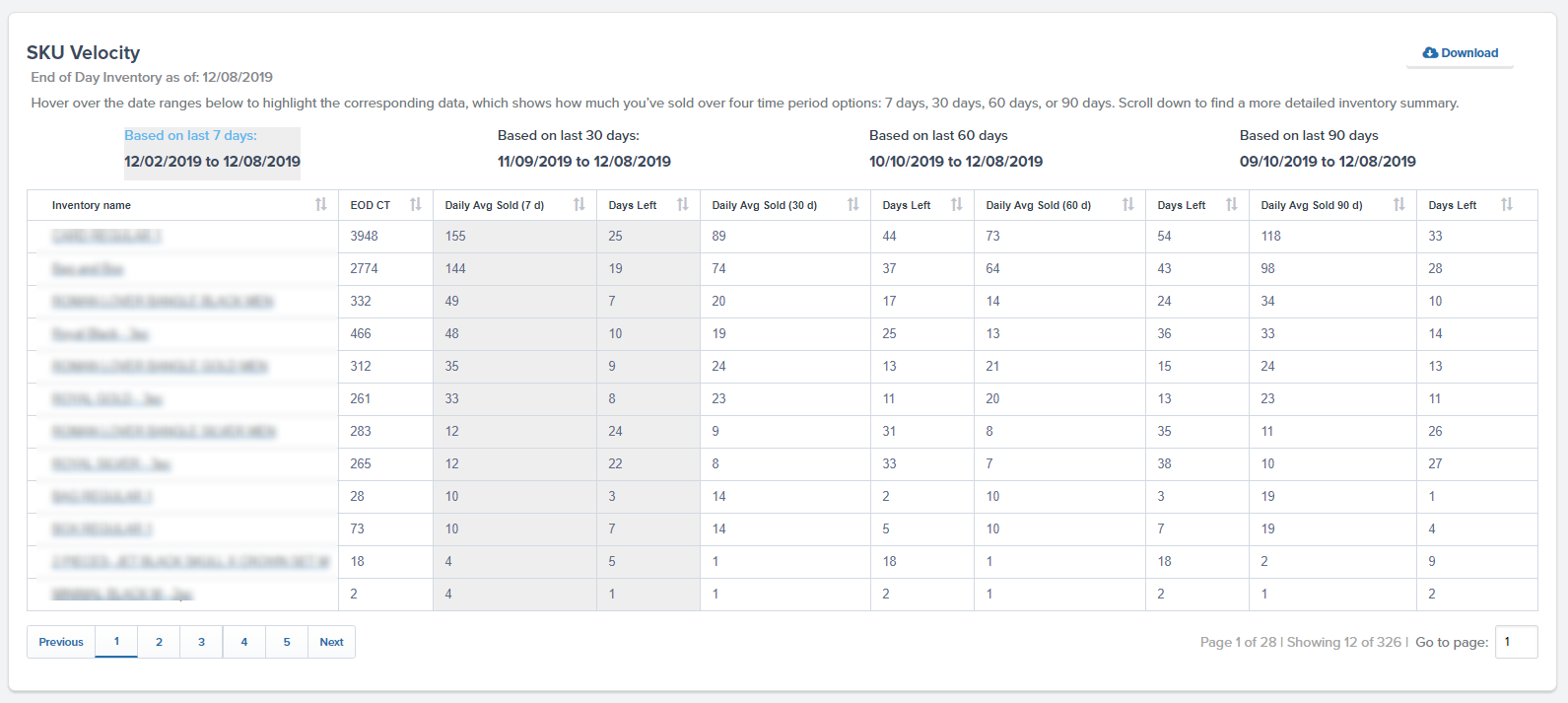

For instance, ShipBob’s dashboard makes it easy to quickly view SKU performance at a glance.

From the ShipBob dashboard, you get an on-demand view of all inventory at the SKU level and their performance, including unit sold per day.

You’re given visibility into what is available and where, as well as the real-time impact of potential changes in demand.

You can also input changes in order volume or scenarios to calculate changes in inventory turnover.

“Having ShipBob’s dashboard is so helpful, especially when you can look on there and see how many have been sold today and how many you can sell. It’s really helpful to know that it’s a trustworthy inventory source!

It’s really handy, and I love that it just automatically implements new changes.”

Nakisah Williams, founder of Craft Club Co.

Perform SKU rationalization

Known as SKU rationalization, another critical step is to perform an inventory audit and determine which SKUs should be discontinued or kept on the shelf depending on profitability.

Profitability is best achieved with SKUs that have a decent margin and high inventory turnover rate (coupled with low storage and fulfillment costs).

ShipBob’s analytics and reporting tool makes SKU rationalization easy by allowing you to track SKU velocity and how factors like promotions can impact stock levels.

“ShipBob is very forward-thinking and leaps and bounds ahead of reporting in other systems.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last.”

Wes Brown, Head of Operations at Black Claw LLC

Stop worrying about SKU proliferation and move to ShipBob

The best and easiest way to keep SKU proliferation in check is by partnering with ShipBob.

ShipBob is a best-in-class 3PL that takes care of all the warehousing and fulfillment needs required to run a successful ecommerce business.

With ShipBob’s ever-growing global fulfillment network, your inventory is strategically stored across multiple fulfillment centers. That means you won’t ever have to worry about getting more warehouse space to fit your growing product catalog.

ShipBob also provides industry-leading technology with access to advanced supply chain analytics and inventory tracking features, so you can get real-time updates on how your inventory is performing, and how much inventory you have left at each fulfillment center.

Having this level of visibility and insights can make inventory planning more efficient and more precise.

Moving forward, you can avoid over-ordering or reordering slow-moving SKUs to keep SKU proliferation in check.

And you can keep up with demand by ensuring that you always have your fastest-selling items in stock.

You don’t have to tackle the logistics side of ecommerce alone.

Get in touch with ShipBob today to learn how we can help support your online brand.

SKU proliferation FAQs

Here are answers to the most common asked questions about SKU proliferation.

How do you handle SKU proliferation?

Handling SKU proliferation requires a proper SKU management process, including full visibility over inventory to track performance, such as inventory turnover. Having full visibility over inventory levels in real time can help forecast demand so you can stock inventory at the SKU level accordingly, while also optimizing storage costs.

What causes SKU proliferation?

There are several causes of SKU proliferation. The two most common reasons are wanting to increase sales and acting on rapid market changes. The pressure of keeping up with competitors, product trends, and meeting the needs of customers also play a crucial role.

Is SKU proliferation a bad thing?

Not necessarily, as when done right, it can expand your audience, introduce new profitable products, and keep customers happy with more choices. But introducing new SKUs requires proper inventory management, including software and processes. Once a new SKU is introduced, you will need to make adjustments in your supply chain, from adding new product listings across all online channels, sending it to your distribution center(s), and ensuring there’s space to store it while keeping costs at a minimum.

How does SKU proliferation affect supply chain efficiency?

SKU proliferation affects the amount of storage space required, as well as fulfillment efficiency. Introducing new SKUs may require rearranging storage or investing in an additional warehouse. You will also need to make sure your warehouse management system is up to date to ensure fast and accurate fulfillment.

What kind of software helps with SKU proliferation?

To keep SKU proliferation in check, investing in an inventory management system allows for real-time inventory tracking, so you can quickly detect slow-moving SKUs and make room for newer SKUs.