Real-Time Inventory Management Guide

For both supply and demand purposes, real-time inventory management is a critical component of running a successful business.

Read on to fully understand real-time inventory management, its benefits, and how ShipBob’s can help improve your logistics operations.

So, what do you want to learn?

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is real-time inventory?

Real-time inventory management involves implementing technology that enables the ability to track, view, and manage inventory levels throughout the ecommerce supply chain on demand.

This level of inventory control and visibility improves supply chain resilience, so you can respond to demand, restock inventory on time, prepare for unexpected events, and keep your business running smoothly.

How real-time inventory tracking can help you understand your supply chain & customers

With real-time inventory tracking, you’re able to collect and view up-to-date inventory data at any time across your distribution network.

To establish an on-demand logistics operation, you need an inventory management system that plugs into your supply chain, connects with all sales channels and distribution centres, so inventory can be recorded from all channels in one place.

Real-time inventory data that’s streamlined provides an accurate and transparent view of inventory levels at any given period of time.

Access to real-time inventory data provides unparalleled insights into past and future demand, as well as SKU and channel performance. Understanding historical inventory trends empowers you to optimise your supply chain, so you can expand your business effectively.

Lastly, harnessing real-time information adds a layer of transparency, so you can easily oversee operations without being involved in the day-to-day. It also makes supply chain planning much easier, since you have the data needed to support your decision-making.

6 ways real-time inventory management benefits ecommerce

Whether you sell directly from your online store and fulfil orders yourself, or you sell across different channels, your inventory is constantly moving throughout the supply chain.

Without real-time inventory management, it’s a challenge to stay on top of inventory levels and know when it’s time to replenish inventory to meet demand, without overstocking and increasing holding costs.

Here are the six benefits to real-time inventory management.

1. Inventory control in real time

When you have real-time inventory management procedures in place, you can easily track inventory at the operations-level.

From scanning inventory on the warehouse floor to preparing units for kitting and assembly, you know exactly how much inventory is being received, how much is ready to sell, how many items are being prepared to ship, etc.

When you know the real-time status of inventory and how much of it is at each location (if you use multiple warehouses), you can make business decisions quickly and restock accordingly.

For instance, ShipBob offers multiple fulfilment locations, which allows merchants to split inventory across locations. With inventory allocation data, merchants are able to expand into new locations and view which SKUs are performing the best in certain areas, so they can optimise inventory levels at each location based on demand.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

2. Accurate reporting using the most current data

Having access to real-time inventory data also helps ensure inventory accuracy.

Without the right technology in place to track real-time data (or needing to rely on inventory tracking using spreadsheets) can cause inventory shrinkage, mispicks, and inventory theft to be overlooked.

You also risk dealing with more stockouts and overstocking inventory, which both cause profit loss and lower customer satisfaction.

Having integrated technology helps keep inventory records up-to-date, so you have more visibility over your ecommerce inventory at all time.

ShipBob offers an advanced analytics reporting tool to help you gain insights from real-time inventory data. This way, you can outsource logistics, have ShipBob store inventory in locations of your choice, and fulfil orders on your behalf, while also maintaining full visibility into inventory levels.

“At my previous 3PL, nothing seemed to come easy. Even getting a reshipment was nearly impossible. I felt like I had to babysit them. Everything was done on spreadsheets and it was very difficult to get the fulfilment data I needed.

Now, we’re working with a tech-enabled 3PL that seamlessly provides data to help us make business decisions. ShipBob’s analytics tool is a game-changer and it’s helped me grow my business tremendously.

With ShipBob’s free analytics tool, it’s so easy for any of my team members to pull data in real-time.”

Courtney Lee, founder of Prymal

3. Keep the right inventory levels

Demand is always fluctuating, which makes it a challenge to optimise inventory levels. But with real-time inventory data, you can better plan inventory and store it accordingly at each warehouse based on historical data and trends.

You can also use such data to calculate the right amount of safety stock to help ensure there’s always enough inventory without overpaying on storage or having too much capital tied up in inventory.

Just think of how this can keep everything from stockout costs to substitution rates to holding costs under control.

Using real-time inventory levels is the most accurate and time-savings method of restocking inventory to always meet demand.

Many inventory apps for ecommerce stores provide the ability to set automatic reorder point notifications based on past inventory performance at the SKU level, so you can be notified when inventory is running low.

“ShipBob’s analytics tool is also really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

4. Improve supply chain workflows

One of the core benefits of having inventory data delivered in real time is you can quickly and easily spot points of concern within your supply chain, so you can make improvements accordingly.

Inventory management relies on other stages of the supply chain, from production lead times to warehouse receiving timelines. Real-time inventory data provides insights into or should at least factor in how how long inventory takes to get from the manufacturer to your warehouses, so you can better manage your supply chain.

Having access to inventory data helps to eliminate supply chain inefficiencies, improves logistics operations and workflows, and reduces logistics costs.

“Now we’re at two fulfilment centres, and being able to have the analytics and see how everything is working together has been extremely helpful for me on the operations end.”

Dana Varrone, Director of Operations at Organic Olivia

5. Easier inventory management across distributed warehouses

When you have customers located across the globe, it is recommended that you split inventory across multiple warehouses once your order volume warrants it. But establishing an international presence can make managing inventory even more challenging.

But with real-time inventory data, you can strategically store the right amount of SKUs at each location to meet demand, as well as reduce shipping costs and speed up transit times for orders that are placed by your customers.

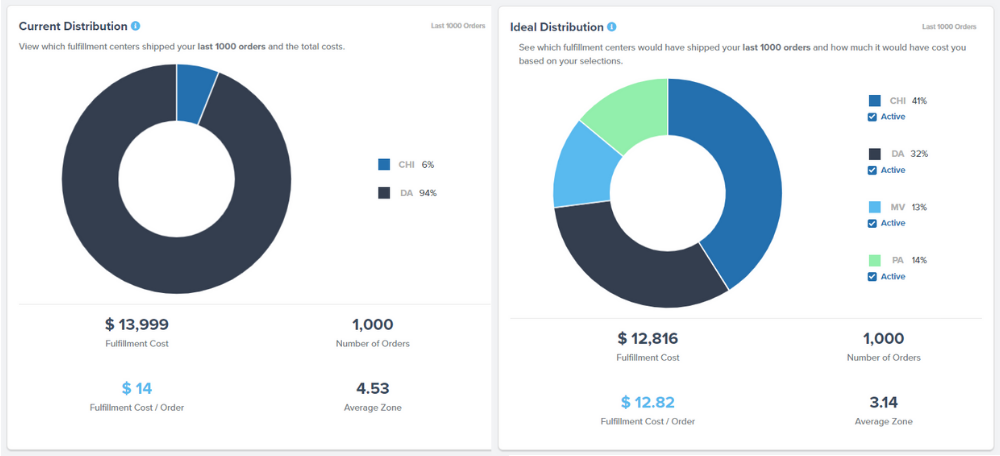

For instance, since ShipBob’s entire global fulfilment network is powered by the same technology, you’re given access to insights on SKU performance at each location, so you can determine the ideal distribution strategy and allocate product efficiently.

“We have access to live inventory management, knowing exactly how many units we have with ShipBob in each location.

It not only helps with our overall process in managing and making sure our inventory levels are balanced but also for tax purposes at the end of the year. ShipBob made that entire process very simplified for our accountants and us.”

Matt Dryfhout, Founder & CEO of BAKblade

6. Provide a better customer experience

There are several ways real-time inventory solutions improve the customer experience.

For one, it helps you decide which items are in high demand, so you can make sure you order enough to prevent stockouts (also taking supply chain disruptions into account).

With proper demand forecasting, you can take a more data-driven approach to making predictions, so you can strategically decide how much inventory you need stored at each location or allocated towards each sales channel.

You can also use inventory data to decide when is the best time to restock inventory, so you can avoid backorders and delayed deliveries.

“ShipBob’s technology provides cost savings. Other 3PLs pass fees onto the client for work they do related to manual processes because they lack the fulfilment technology needed to meet customer expectations.

ShipBob’s technology has effectively eliminated the work of a program manager at other 3PLs, while providing immediate visibility into inventory and the ability to respond and make changes myself.”

Carl Protsch, Co-Founder of FLEO

Real-time inventory management challenges

There are several challenges ecommerce operators will encounter when lacking real-time inventory management capabilities. Below we outline them and explain how to get it right from the start.

You’re manually tracking stock levels and/or your tech stack is not fully connected

Spreadsheets, paper, or even basic inventory apps are not going to cut it as a real-time inventory management solution. Any type of manual inventory work for you is going to cost time and money, and likely lead to a lot of errors.

From POs to sales channels, real-time inventory management must connect the upstream and downstream parts of the supply chain. Otherwise, you could face both over-selling and over-stocking.

With ShipBob you can connect to ecommerce platforms like Shopify to sync real-time stock levels back to your store and set thresholds for safety stock and have zero units left showing as available for Shopify.

ShipBob also integrates with other tools like Inventory Planner to connect your purchase orders and information with manufacturers to and from ShipBob, so it connects to your warehouse receiving orders (WROs) in ShipBob, automates the reordering process, and syncs the front end of the inventory lifecycle with the order fulfilment lifecycle for full traceability of real-time inventory management.

You’re not reserving stock for certain channels

When you’re selling on one channel like Shopify, BigCommerce, or Amazon, you’re usually managing one set of sales data and one location where you store inventory. As you grow and add new sales channels and fulfilment centres, you have to factor in various buying behaviours, turnover rates, return frequencies, shipping speeds, and demand across channels — in addition to the usual complexities of inventory management.

You not only have to rebalance inventory according to what’s in your warehouse, but also what’s concurrently listed on multiple channels. For example, if you sell the same products on multiple channels, you’ll need to manage and merge SKUs so you know which are identical products and manage the same pool(s) of inventory accordingly.

At any point, orders could be flying in from multiple channels at the same time. It’s easy to lose track of stock levels and rack up backorders. Without a system built specifically for multichannel inventory management, it’s nearly impossible to keep your head above water and prevent capital from getting tied up in inventory as you grow.

ShipBob is a fulfilment company that provides multichannel inventory management and tracking tools at no extra cost for merchants — e.g., to help minimise overselling on Shopify with the following tools:

- Shopify Real-Time Order Sync: Fast order import for fast fulfilment and inventory count accuracy.

- Inventory Quantity Sync: Compares inventory counts in ShipBob and Shopify every 15 minutes, and uses smart logic to only update the quantity in Shopify if ShipBob shows lower stock levels, or if ShipBob has a stock increase due to restocking, warehouse receiving orders, etc.

- Inventory Threshold: Creates a safety buffer to help you minimise overselling, keeping a set amount of inventory reserved. Once you specify the buffer quantity and your inventory count hits that threshold, ShipBob will post zero units available back to Shopify.

You don’t have the proper equipment in your warehouse

When you’re managing inventory and fulfilment yourself, it can be expensive to get the same equipment used in large warehouses. This can lead to errors throughout all inventory-related processes.

Fulfilment experts like ShipBob use inventory scanners and wearable devices that automatically update counts back to all the places that need to access that data. With barcodes on every SKU storage location, scanners are used across the fulfilment floor to push updates back in real time, giving each merchant visibility into when an order is being picked, packed, shipped, and so on.

You mix SKUs together in storage

This is a big no-no but common mistake brands make when fulfiling orders from home and need to save space. Each SKU needs a dedicated storage location so you are less likely to send the wrong item out — even if each item is barcoded.

Fulfilment companies like ShipBob store each item in a different location and scan each item during the picking process, and then again at the packing station as another QA method to double and triple check that the right items are being sent out to each end consumer. ShipBob also lets you upload product photos to each SKU in your dashboard as an additional visual cue to ensure we have the right item every time.

You lack traceability in case of emergency

Lot tracking is also used to organise inventory by production batch or expiration date, with a lot number, or identification number, getting assigned to a particular quantity or lot of material from a single manufacturer. This helps in potential contamination scares or product recalls, being able to separate out affected inventory from shippable inventory, and contact people who had an affected item sent to them.

Professional fulfilment companies like ShipBob can help you separate items based on their lot numbers by not storing them with other non-lot items, or other lots of the same item. ShipBob’s real-time inventory management system has logic designed to always ship items with the nearest expiration date.

Real-time inventory management solutions for ecommerce

As more ecommerce brands compete by establishing a multichannel retailing strategy along with the pressure to deliver to customers fast and affordably, real-time inventory solutions help brands of all sizes keep their supply chain running, despite uncontrollable delays, unexpected events, and ever-growing customer expectations.

Though there are several inventory management solutions on the market, there’s also the opportunity to partner with tech-enabled 3PL that offers outsourced fulfilment as well as real-time inventory tracking, along with a full suite of logistics solutions.

Let’s go over the benefits and limitations of using a standalone inventory management software versus outsourcing fulfilment to a 3PL.

Real-time inventory management & control software

For retailers, real-time inventory management software is maybe the greatest thing since sliced bread.

Designed to continuously track and manage your inventory at the store or warehouse level, these systems can help your business maintain a high inventory turnover ratio and low days sales in inventory, and always ensure that the products your customers need are in stock at every location.

Inventory management software is designed to record inventory data in real time. Here is a list of some of the top-ranked inventory automation and management solutions for ecommerce:

The only limitation with such standalone inventory management solutions is that they are mostly designed to manage inventory flowing in and out of the warehouse.

Fortunately, all the leading inventory management solutions listed above directly integrate with ShipBob’s order fulfilment technology, which streamline inventory data and ecommerce fulfilment insights all in one place.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Real-time inventory management with a 3PL

3PLs enable you to fully leverage the benefits of real-time inventory management by dealing with the physical aspects of tracking and managing inventory for you, without having to rely on spreadsheets or multiple dashboards.

With a 3PL like ShipBob, you don’t have to spend all your time managing inventory, as data is automatically recorded and available through a single dashboard. At any time, you can view inventory on hand, set automatic reorder points notifications, manage SKUs, and forecast demand.

Ultimately, this level of inventory automation can free up your time, so you can focus more on revenue-driving initiatives.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

Get real-time inventory management & control with ShipBob

ShipBob’s powerful software with built-in inventory management is just one part of our best-in-class retail fulfilment solution. Aside from the real-time tracking and management of inventory, the platform automatically tracks fulfilment metrics too.

Whether you store inventory in one of our locations or multiple fulfilment locations across the globe, ShipBob’s dashboard provides insights to help you improve last-mile delivery, reduce shipping costs, allocate inventory based on demand, and access data to help make better business decisions.

Our entire distribution network is operated by the same warehouse management system (WMS), which offers real-time data and insights into fulfilment and automated shipping performance. This also ensures consistency across our entire network, so as you expand as you please.

ShipBob’s ecosystem of partner apps for inventory management, returns management, inventory accounting, and more all offer the ability to easily plug ShipBob into your existing tech stack and enable a powerful logistics solution to meet customer expectations.

For a fully custom logistics solutions, ShipBob also offers an open Developer API, so you can make ShipBob work for your business, no matter what your needs are.

“We utilise ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

ShipBob is an international 3PL with the fulfilment infrastructure, technology, support, and expertise you need to stay competitive in an ever-changing industry.

Real-time inventory FAQs

Get answers to the most frequently asked questions related to real-time inventory management.

How do you keep track of inventory in real time?

There are several inventory management solutions on the market, from simple inventory apps to ERP inventory systems that provide real-time inventory tracking solutions. Another solution is partnering with a 3PL with fulfilment technology that enables real-time inventory tracking across distribution channels, so you can also remove fulfilment from your plate.

Why is real-time inventory management important?

Access to real-time inventory data provides important insights into demand, along with product and sales channel performance. Understanding historical inventory trends helps you plan for and optimise your supply chain over time so you don’t run out of stock, tie up too much capital in inventory, and misrepresent your inventory value for your accountants.

What’s the best way to keep track of inventory?

The best way to keep track of inventory is to ditch the spreadsheets and implement an inventory management system that records real-time inventory data automatically. By automating inventory tracking, you spend less time managing inventory while also improving accuracy and avoiding mistakes human errors, which can cause inventory shrinkage, stockouts, and more.