Table of Contents

** Minutes

What are inventory allocation methods?

Why do ecommerce businesses need an inventory allocation strategy?

Factors to consider when allocating inventory

How can a 3PL like ShipBob improve inventory allocation for ecommerce businesses?

One of the greatest benefits of starting an ecommerce business is the endless opportunity for growth. If you’re selling a high-demand product, chances are you can easily expand into new markets.

But as your order volume increases, how will you track and manage inventory levels across your sales and distribution network?

To avoid struggles with cash flow and stocking issues, you will need to find a way to maintain control over inventory. This can be done by implementing a data-driven approach to how inventory is allocated.

In this article, you will learn what inventory allocation entails, the factors to consider when making inventory-related decisions, and how you can get smarter about how you approach inventory management.

What is inventory allocation?

Inventory allocation refers to the process of strategically tracking inventory levels across a distribution network. Proper inventory allocation helps ensure stock levels and storage costs are optimized to meet customer demand efficiently.

What are inventory allocation methods?

Inventory allocation is a critical component of logistics, as it can help you save on costs while helping you consistently meet customer demand — even during peak seasons or as you expand into new markets.

There are two main inventory allocations methods: manual or tech-enabled. Here is an overview of the difference between these two approaches:

Manual inventory allocation

Let’s say you are seeing shifts in your customers’ shipping destinations over time. You may encounter questions like these:

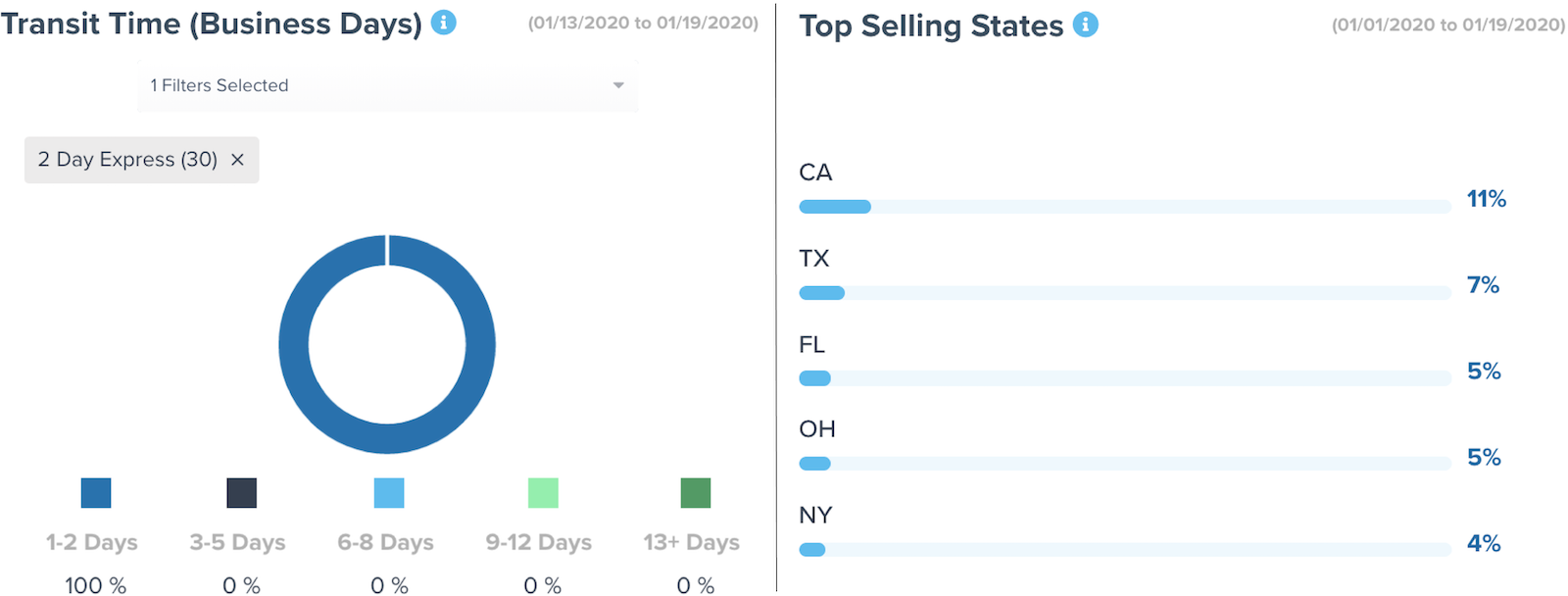

- Should I allocate more units of inventory or a greater percentage of my total inventory to my California warehouse, since there has been a growing demand in that region of the West Coast part of the US?

- Should the additional stock be sourced from my New York warehouse, since my sales have been lower on the Ease Coast? Or should I change up the reorder quantities the next time I order more from my manufacturer?

To make these types of decisions around inventory, some businesses choose to manually manage and track inventory levels. Manually managing inventory involves the use of physical inventory ledgers or spreadsheets, and using the manual data to make decisions on physical distribution.

Obviously, the manual method can be inefficient and prone to error and slower to understand and glean insights from. As your business grows, it also becomes unsustainable and hard to scale.

Tech-enabled inventory allocation

Managing SKUs that sell at different velocities across a distribution network can be a challenge without processes and technology to support the effort.

That’s why many brands invest in technology to easily track inventory across a network in real time, and aggregate the data to make accurate, informed decisions.

There are several options to enable a technology-based approach to inventory allocation. Established brands often invest in ERP inventory software, which is robust but costly. There are plenty of tools and inventory apps designed for small to mid-size online stores to make inventory allocation decision-making much easier.

Why do ecommerce businesses need an inventory allocation strategy?

Knowledge is power. Knowing how much ecommerce inventory you need in each warehouse location (and how much you can store based on space and cost) is a surefire way to optimize your supply chain.

Proper inventory allocation can save you significantly on storage costs by optimizing inventory levels without overstocking or not stocking enough to meet demand.

In ecommerce, inventory levels constantly fluctuate — especially if you sell through more than one channel — which is why most brands use technology and automation to track inventory in real time, so they can stay informed while spending less time manually tracking inventory.

A solid inventory allocation strategy that’s tech-enabled and offers valuable insights can help you reduce a number of risks and streamline your distribution network. Here is an overview:

The risk of overstocking

The easy route to meeting customer demand is to simply order more stock than you should need. But “easy” isn’t always the most cost-effective. In fact, overstocking can quickly increase carrying costs associated with warehousing, labor, insurance and rent.

Additionally, the lost value of damaged, expired or out-of-date products, known as dead stock, accumulates when inventory remains on the shelf too long. And if you allow the warehouse to store dead stock for too long, you risk paying too much in holding costs.

To avoid overstocking, you want to be strategic in how you optimize inventory levels by looking at historical order data, inventory turnover, and other inventory trends.

The risk of overselling

Imagine that a celebrity or influencer promotes one of your products on Instagram, and overnight, you see an influx in sales. Unfortunately, you didn’t have enough inventory in stock to fulfill orders right away, resulting in a high volume of backorders.

Unsurprisingly, backorders don’t typically make for a great customer experience. It forces the shopper to decide if they’re willing to pay upfront and wait longer for their product to arrive.

If the shopper wants to buy the product along with other items that are in stock, and you want them to get the part of the order that is available now, it can cause a split shipment. This is not the worst thing in the world if it’s a rare occurrence, but it can lead to higher shipping costs and packaging waste.

It’s important to make notes of any potential influx in orders, based on factors such as seasonality and promotional campaigns, to ensure you’re prepared with the right amount of safety stock based on previous order trends and future plans.

More streamlined multichannel management

Inventory allocation becomes more complex as you expand into new sales channels, which is known as multichannel inventory management or the oversight of stock levels, reorders, and inventory forecasting across different sources.

Implementing inventory management software to track inventory in real time across a multichannel sales network can help alleviate headaches. Many popular sales channels, including Amazon, Walmart, and Facebook offer direct integrations to your existing tech stack, so you can track inventory from one dashboard. Tech-enabled fulfillment companies like ShipBob can even help fulfill orders across these channels.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

Build a foundation to scale

Implementing technology and processes to help you make better decisions on inventory allocation that save on costs and time can create a solid foundation for your business to scale.

But investing in the logistics infrastructure and technology can be challenging, time-consuming, and costly for growing brands (and even established ones).

That’s why many ecommerce brands partner with a third-party logistics (3PL) company that can offer a growing fulfillment network, retail fulfillment capabilities, and inventory management tools to help them save time and money as they scale their business.

For instance, ShipBob is a best-in-class 3PL with fulfillment center locations across the globe.

Since ShipBob’s entire network is powered by its proprietary logistics technology, merchants can easily track orders across sales channels and manage inventory allocation throughout the entire fulfillment network — all from one dashboard.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Factors to consider when allocating inventory

Not every business sells on multiple sales channels, uses more than one warehouse to store inventory in, or has the same number of SKUs. This means every business has a unique set of needs when it comes to managing inventory.

No matter how small or established your business is, or how many orders are placed each month, getting smart about inventory allocation will help you maintain supply chain efficiency, including how much inventory to order and when, where to store inventory geographically, and the cost-savings it can result in.

In this section, we’ll walk you through some factors related to inventory allocation to keep in mind.

Inventory demand

Demand forecasting is one of the most powerful tools for an ecommerce business. Although you will likely never be able to 100% accurately predict demand, implementing tools to help you collect, analyze, and predict future sales patterns over time can help you make decisions around marketing spend, production, labor, and more.

With proper demand forecasting, businesses are able to take a data-driven approach to product allocation and better predict how much inventory they need stored at each location or allocated towards each sales channel.

At some point, you will also likely want to run promotions such as flash sales, and forecasting demand can help prepare for marketing initiatives that may cause a significant (but temporary) shift in demand.

Inventory availability

A big part of streamlining order fulfillment is ensuring that items are in stock at the locations closest to your customers’ shipping destinations. Without a proper way to track inventory availability, you risk running into issues during the fulfillment process.

To avoid fulfillment issues, you can easily implement an inventory tracking system that directly connects to your online store(s) and lets you sync SKUs and orders to view all inventory counts, fulfillment centers, sales channels, and customers in one place.

Being able to aggregate inventory availability insights will let you decide when it’s time to purchase more inventory for each location before inventory runs out, taking manufacturing leads times, transportation timelines, and receiving turnarounds into account. It can also help you avoid the need to fulfill the order from a warehouse that’s further from the order’s destination.

Implementing an inventory tracking software ensures greater visibility and accuracy. Many 3PL companies like ShipBob help ecommerce brands that use sophisticated software, so merchants can easily track inventory levels across any of ShipBob’s fulfillment center network in real time.

Warehouse space availability

Another key factor to consider is how much warehouse space is available and how much it will cost you. Many brands store inventory and fulfill orders in their home until they run out of space. From there, they have the option to manage a warehouse or send inventory to a 3PL to store in one or more fulfillment center locations.

Based on the type of warehousing solution you choose, storage fees can range from per-SKU or per-unit, to a fixed fee for each bin, shelf, or pallet used, or even be based on square footage allocated.

ShipBob charges for warehousing monthly on a per-shelf, bin, and pallet basis for each SKU, so you only pay for the space you use.

Ease of order fulfillment

Proper inventory allocation impacts the speed of order fulfillment and costs associated with shipping orders. For instance, if you notice that sales of laptop sleeves are through the roof in San Francisco and Chicago, then warehouses located in or near those cities is where you should aim to allocate more inventory, as compared to storing units in facilities in the middle of nowhere.

Where you ship from is an important aspect of inventory allocation. Customers are used to fast and affordable delivery, and if a brand can’t deliver, then it can result in a higher cart abandonment rate.

To make sure you can deliver on customer expectations, try to minimize the number of shipping zones your average package travels, which can in turn reduce shipping costs and last-mile delivery times.

You can do this by storing inventory across different geographic locations based on where your customers live. This allows you to offer more shipping options and incentives to keep your customers happy. You can also check this list of the best distribution kpis if you want to know other factors that will make your customers delighted.

How can a 3PL like ShipBob improve inventory allocation for ecommerce businesses?

It can be a challenge to expand into new locations and sales channels without proper inventory allocation systems and technology in place. To expand your retail supply chain, you need access to real-time inventory tracking and data to make informed decisions. Without it, a lack of oversight can cause a number of issues.

ShipBob is a best-in-class 3PL that offers a global fulfillment network powered by proprietary warehouse management system and built-in inventory management tools.

This allows growing merchants to outsource fulfillment and logistics to a 3PL, but still obtain control and visibility into the entire inventory and order management process.

ShipBob makes it easy to optimize inventory levels across a distribution network. Here are some of the benefits of partnering with ShipBob to improve logistics operations, including inventory allocation.

Automate your inventory allocation

Inventory automation can provide valuable data that can influence your inventory allocation strategy. Whether you store inventory in one ShipBob location or multiple, you can view inventory levels in real time all from the ShipBob dashboard.

This way, you can create, manage, and merge SKUs, easily forecast demand, set automatic reorder points, view which items are fast-selling or slow-moving, and much more.

“My end goal when I started my business was to create something that was fully automated, so I could focus on driving sales. I didn’t want to have to worry about inventory and distribution as much.

I was looking for someone who would automate fulfillment for us. I chose ShipBob, and it turned out to be a very easy and scalable solution.

Everything was automated, from setting up my store, to sending product, to fulfilling orders.

It was pretty remarkable how a 24-year-old like me with very little money and no prior logistics experience could launch a product and have distribution be automated.”

Josh Hollings, Founder & CEO of Drop FX

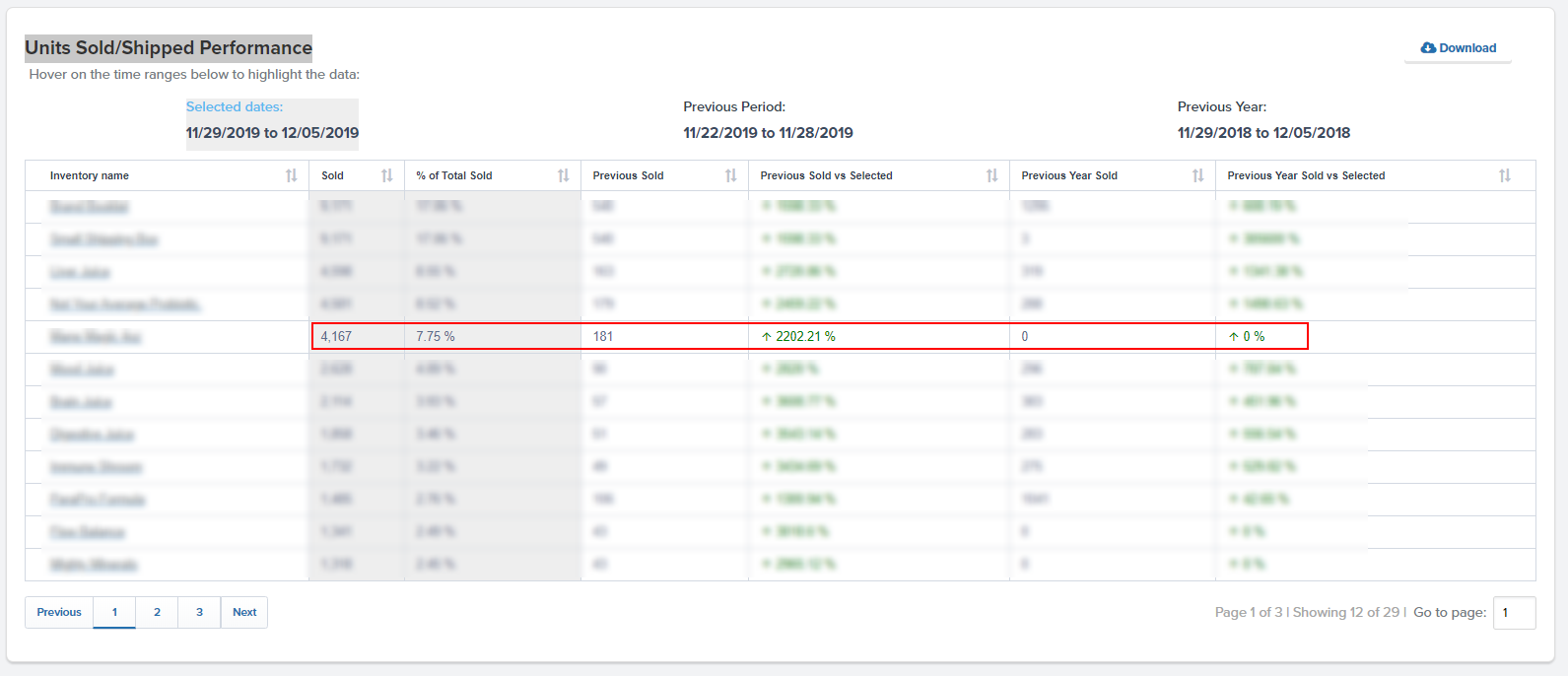

Track and forecast inventory trends

Before you can determine when to reorder inventory, you need to be able to analyze inventory trends. Your past sales and inventory data should guide future decisions and help you be proactive, rather than reactive.

Because ShipBob’s fulfillment network is powered by a centralized tech stack, you’re given access to an advanced data and analytics tool that help you make better decisions related to stock, including inventory forecasting functionality.

Tracking and forecasting inventory trends can help you plan your repurchase lifecycle to ensure that only the requisite stock is held at warehouses.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO Shorts

As a result, you’re able to meet demand by optimizing the amount of inventory needed on hand, avoid stockouts, and reduce manual work.

Have a pulse on your inventory levels

Tracking inventory levels, also known as stock control, is one of the most important aspects of inventory management, from optimizing stock levels in a warehouse(s) to stabilizing inventory storage costs, and maintaining enough stock to meet customer demand.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours. For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

By keeping track of your inventory levels across a distribution network, you’re able to optimize your inventory replenishment process. Having full visibility into inventory levels at all times can optimize logistics costs while ensuring you have just enough stock stored at all times.

From the ShipBob dashboard, you get answers to questions like:

- How much stock do I currently have on hand?

- What were my historical stock levels at any point in time in any location?

- How many days do I have left until a SKU will be out of stock?

- By when do I need to reorder inventory for each product?

- If I run a flash sale on my site, how will this affect my available stock levels?

- How does product demand compare to previous periods?

- How are my sales affected by different seasons and months?

- What are my best-selling items?

- Which items are not generating sales?

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We can generate custom reports to tie this inventory data into our accounting platforms.”

Leverage an international fulfillment network

As your business grows, you might find opportunity in expanding into international markets. This can be challenge if you’re only distributing inventory domestically.

ShipBob makes it easy to expand into new markets across the world, thanks to our growing international fulfillment network. Our fulfillment center locations are located across the US, as well as in Canada, the EU, and the UK (with more locations continuously being added!).

With ShipBob, you can ship internationally using discounted shipping rates from our carrier partners, as well as have the option to ship inventory to other countries, so you can pick, pack, and kit orders domestically for more customers.

No matter if you’re looking to grow domestically or internationally, shipping from multiple locations near your customers can drive down shipping costs and speed up transit times. This helps you leverage ground shipping more often, which is significantly cheaper than expedited shipping.

Partner with ShipBob

ShipBob is a leading 3PL that offers accurate fulfillment services, an expansive international network, and inventory allocation tools for growing direct-to-consumer (DTC) brands.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

With ShipBob, you’re able to save time, money and energy while gaining access to a robust fulfillment infrastructure, data and analytics, logistics expertise, and a great support team to help you strategically expand your distribution network, track and optimize inventory, and meet customer expectations.

To learn more about how ShipBob works, click the button below.

Inventory allocation FAQs

Here are some of the most common answers to questions related to inventory allocation:

What is inventory allocation?

Inventory allocation refers to the process of strategically tracking and optimizing inventory inventory levels across a brand’s distribution network. If executed properly, using automation and technology, it helps to ensure that you have an optimal amount of stock at each distribution location to meet demand.

What is allocated inventory?

Allocated inventory refers to the amount of stock stored in each warehouse location to meet demand in a certain region.

What is allocation planning?

Allocation planning in ecommerce refers to the process of tracking inventory levels, forecasting future demand, and aggregating historical order data to make informed decisions on how much stock should be ordered and stored in every warehouse location.