Table of Contents

** Minutes

How does smart warehousing benefit retailers?

7 smart warehousing techniques & technologies to implement

Smart warehousing best practices

ShipBob’s tech-enabled smart warehousing solutions

If you think about a traditional warehouse, you’re likely imagining a wide-open building with ample space to receive and store inventory.

However, with recent technological advancements, warehouses have become more automated. Now you’ll find that ecommerce warehousing is equipped a variety of tools like robotics, logistics automation, IoT technology, and real-time inventory management software. This is known as smart warehousing.

Smart warehousing contributes significant value by integrating technology and automation that enable both efficiency and cost savings.

With smart warehousing, you can automate several internal warehouse processes, track operations in real time, and analyse warehouse performance to make more informed supply chain decisions.

If you’re an online retailer looking to improve warehousing operations, this article focuses on what smart warehousing is, its benefits, and industry best practices.

What is smart warehousing?

Smart warehousing refers to a warehouse or fulfilment centre that is powered by supply chain technology and automation to simplify, accelerate, and improve logistics operations.

By investing in technology and automation to improve warehousing, online retailers are able to grow their business by meeting customer expectations and optimising logistics costs.

The goal of smart warehousing is to improve speed, accuracy, visibility, and transparency within the warehouse, so they can stay competitive and build a more resilient supply chain.

Where did smart warehousing come from?

Smart warehousing, also referred to as ‘warehouse digitization,’ was established in response to the rise of ecommerce and the demand for on-demand logistics.

Supply chain snafus brought on by the pandemic, primarily to companies that had embraced just-in-time logistics, forced companies to invest in the latest supply chain technology sooner than later.

As peak-pandemic supply chain obstacles have been resolved, smart warehousing is becoming more of a standard practice. Now online retailers that are looking to expand their businesses are looking for solutions to cost-effectively move away from traditional warehousing to smart warehousing.

The smart warehousing market is currently valued at $20.4B USD and is growing rapidly at an annual growth rate (CAGR) of 14.6%. This means the smart warehousing industry is expected to reach $40.5B USD by 2028. The growth of the market can, in part, be attributed to growing numbers of ecommerce businesses adopting multichannel sales strategies and improved technology.

How does smart warehousing benefit retailers?

Smart warehousing improves logistics operations so online retailers can grow their business while maintaining transparency and warehouse control. The more visibility an online retailer has into warehouse performance enables smarter decisions and the ability to establish a more agile supply chain.

Here are a few of the benefits of investing in smart warehousing to grow an online brand.

Reduces human errors

Warehousing is a complex and volume-driven process with many moving parts. When executed manually, human errors in the warehousing picking, packing and shipping process are likely to creep in.

However, with the right smart warehouse systems, you can significantly reduce human error while also saving on labour costs.

Whether it’s as simple as implementing an inventory scanner system, integrating an automated order processing, or investing in an automated guided vehicles (AGVs) to receive, pick, and ship orders, digitizing warehouse processes improves order accuracy, so you can further enhance the customer experience.

Improves inventory management

Not only is order accuracy important, but so is accurate inventory tracking. With proper inventory management, you can keep track of the flow of inventory throughout a supply chain in real time to improve inventory accuracy.

For example, tech-enabled 3PLs integrate inventory tracking systems with a warehouse inventory management solution. This allows merchants to track their inventory from the receiving stage to shipping, as well as returns.

Additionally, managing or fulfilling from a single warehouse is no longer an option if you’re looking to offer affordable 2-day shipping to your customers while also expanding into new markets across the globe.

Successful online brands operate out of multiple warehouse networks, also referred to as fulfilment centres, to improve shipping and last-mile delivery.

By centralising inventory tracking into one system, you get accurate inventory data across your logistics network. Over time, you can analyse warehouse performance and get answers to questions like:

- How many units of each SKU is available in each warehouse location?

- What is my ideal product allocation strategy?

- How many of my orders are fulfilled on time?

- How many and which orders can’t be fulfilled because of inadequate stock levels?

- Which items are not generating sales and incurring high holding costs?

- And more.

“Now we’re at two ShipBob fulfilment centres, and being able to have the analytics and see how everything is working together has been extremely helpful for me on the operations end.

It definitely helps me with inventory management and seeing what’s going on. It truly helped us on a day-to-day basis. Even though we’ve grown, I haven’t spent more time on the business from an operations standpoint.”

Dana Varrone, Director of Operations at Organic Olivia

Provides faster order fulfilment

Retail fulfilment is often slowed down due to a lack of technology and logistics automation, inventory distribution, and inventory allocation, all of which play a role in optimising the fulfilment process.

Not to mention, as your order volume grows, you and your team will have to spend more time on logistics operations, rather than focusing on other important business tasks.

Smart warehousing processes, technology, and automation collects and aggregates data, which delivers insights on how to improve the fulfilment process. The result? An accurate, efficient, and fast fulfilment process that meets customer expectations.

For instance, ShipBob is a 3PL that operates a robust retail fulfilment infrastructure powered by the latest in digital logistics technology.

As soon as an order is created or imported into your ShipBob dashboard, it is automatically sent to one of our fulfilment centres that’s holding your inventory to be fulfilled. Our tech assigns orders to our picking team, who receives a picking list of the items, quantities, and storage locations at our facility to procure and complete their pick(s).

“Since partnering with ShipBob, we now have an automated system for shipping and can focus our time on new product launches.

We continually are able to reliably and quickly fulfil thousands of orders during a single apparel drop. This partly has to do with ShipBob saving us time by automating the order fulfilment process.”

Jason Ton, CFO of 100 Thieves

Leads to fewer order returns

Returns cost businesses around 66% of the items original price. That’s thousands of dollars (or likely much more) lost every year on order returns.

When items are picked and packed correctly, your online store will experience fewer ecommerce returns from customers. This is because there will be fewer instances of mispicks (where customers receive the wrong item due to shipping errors) and less damage during transit (proper packing ensures items are protected, reducing the likelihood of breakage).

Smart warehousing can reduce the amount of returns simply by improving processes and workflows to ensure accuracy and consistency across operations.

However, returns are sometimes inevitable, so it’s important to establish a returns management process as part of your overall warehouse strategy.

With access to the right data and analytics, you can find insights to improve the returns process and further enhance the customer experience by quickly and effectively processing returns and getting products back on the shelves.

“For reverse logistics, we have also been leveraging ShipBob’s Returns API to automate and streamline our routine RMA processes. Having ShipBob handle our returns has been a huge help in reducing our daily workload, and the ability to drive this process via API is wonderful.”

Waveform Lighting Team

Procures real-time data reports

With the growing number of orders and the rise of omnichannel retailing, conducting physical inventory counts using spreadsheets or ledgers is an outdated, ineffective process.

As you expand operations, manual work will only lead to inaccuracies that cause bad decisions, money left on the table, and poor customer experiences.

One of the biggest benefits of smart warehouse technology is the ability to automatically collect and aggregate data from across your logistics network to gain insights on performance and track inventory levels at any given period.

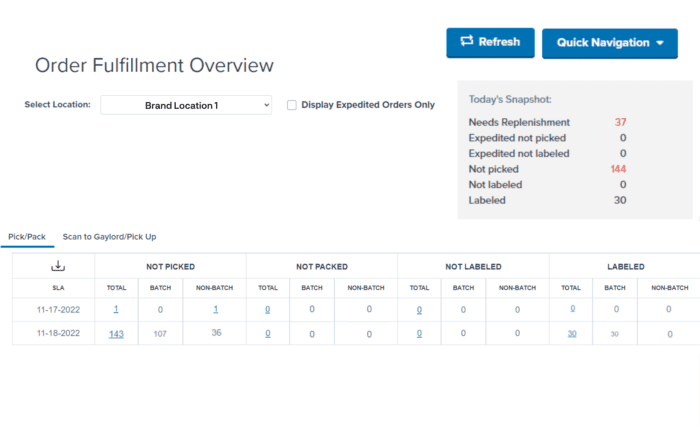

For instance, having access to data from real-time inventory records can help you make better business decisions on everything from receiving processes to allocating inventory effectively to improve your shipping strategy and optimise costs.

“At my previous 3PL, nothing seemed to come easy. Even getting a reshipment was nearly impossible. I felt like I had to babysit them. Everything was done on spreadsheets and it was very difficult to get the fulfilment data I needed.

Now, we’re working with a tech-enabled 3PL that seamlessly provides data to help us make business decisions.

ShipBob’s analytics tool is a game-changer and it’s helped me grow my business tremendously. With ShipBob’s free analytics tool, it’s so easy for any of my team members to pull data in real-time.”

Courtney Lee, founder of Prymal

Decreases order fulfilment costs

A major component of smart warehouse management is the time, effort, and money that go into order fulfilment. When added up, fulfilment costs include:

- Receiving, storing and managing inventory

- Picking, packing, and shipping orders

- Packing and shipping materials

- Shipping costs

- Processing and managing returns

Arguably, one of the biggest benefits of implementing smart warehousing is that it significantly lowers fulfilment costs.

When you’re able to successfully integrate smart warehousing and fulfilment processes into a centralised technology and automation system, you not only speed up the fulfilment process but you also reduce costs.

However, if you partner with a 3PL like ShipBob, the standard pick and pack fees are built into the overall fulfilment cost, which also includes shipping.

Since ShipBob take scare of everything, from receiving to automated shipping, you save both time and money by focusing your attention on revenue-generating initiatives.

“We need to deliver quickly and inexpensively. Since switching to ShipBob from our previous 3PL, our fulfilment cost on comparable orders went down by 25%.”

Michael Peters, VP of E-Commerce Operations at TB12

7 smart warehousing techniques & technologies to implement

Fast-growing online brands that manage their own warehouse(s) and wish to get smart warehousing right need to be willing to experiment with new-age technologies such as AI, robotics, and automated guided vehicles.

Read on as we elaborate on smart warehousing tips, tricks, and technologies that are here to stay within the ecommerce industry.

1. Warehouse robotics

When we think of logistics innovation, warehouse robotics is what usually first comes to mind. They not only improve order accuracy but also improve productivity while lowering labour costs.

The biggest benefit is to allow your team to focus on how to improve and optimise operations rather than being bogged down by time-consuming tasks.

Warehouse robotics in action:

- Automates picking: The best kind of automated picking tools are robotics that ensure the orders are picked two to three times faster than usual. These mobile robots work in collaboration with the picker to help them pick orders off the shelves faster, with fewer inaccuracies.

- Improves inventory visibility: While they may look like they are straight out of a sci-fi movie, drones add immense value to your warehouse operations by improving inventory visibility. These devices can autonomously move throughout your warehouse to conduct inventory audits, cycle counting, item searches, and more.

2. Artificial intelligence

Artificial intelligence (AI) analyses and learns from supply chain data to help you stay one step ahead of every potential crisis. Integrating AI can transform your warehouse operations by predicting the future and helping you make intelligent business decisions.

Artificial intelligence in action:

- Optimizes storage: Whenever you are about to run out of storage space, your AI-powered system can alert you. This enables you to plan for ways to increase storage space or reduce inventory volumes.

- Averts risks: By analising historical sales data, real-time market fluctuations, current inventory levels, and other data points, AI can help you predict potential crises such as overstocking, understocking, delays in shipping, etc. Armed with such insights, you can work towards avoiding such situations.

3. Warehouse management systems

Inventory distribution refers to storing inventory in multiple locations to strategically reduce shipping costs and speed up transit times.

In order for a distributed inventory model to be effective, a warehouse management system (WMS) is needed, which centralises logistics operations under one roof.

A WMS is key to help you effortlessly track inventory and ensure that goods are stored, picked, packed, and shipped properly.

WMS systems in action:

- Decreases fulfilment time: A WMS provides visibility into inventory and order activity to ensure an effective fulfilment process.

- Improves order accuracy: By improving inventory visibility and automating the order picking, packing and shipping, a WMS can significantly reduce errors.

4. Setting reorder points

Storing too much inventory can lead to higher carrying costs, but not storing enough inventory can lead to stockouts. Therefore, in the face of unexpected demand, supplier deliveries, and logistics issues, it is important to get smart on how you restock inventory.

One of the easiest ways to stay on top of reordering is to use an inventory tracking system that allows you to set up automatic reorder point notifications to optimise inventory levels and restock accordingly.

By analising first-mile delivery timelines and your inventory turnover rate, you make better decisions on when it’s time to restock inventory using the reorder point formula.

If you work with a fulfilment provider like ShipBob whose built-in inventory management system collects insights related to first-mile delivery timelines and inventory turnover rate, you get the information you need to set and adjust reorder points.

Reorder point automation in action:

- Sends reminders when units for each SKU are low or hit their threshold: You want to replenish inventory to meet demand while optimising storage, so the moment the inventory hits the reorder point, an alert is automatically sent so you can reorder stock from your supplier.

- Inventory forecasting: The reorder point needs to change with the fluctuating demand and other factors like manufacturer or transportation lead times. By analising inventory trends, you can make adjustment to your reorder point based on the data, so you’re notified on time.

5. Automated guided vehicles

Automated guided vehicles (AGVs), such as forklift AGVs, towing AGVs, and unit load handlers, help accelerate internal processes like storing, lifting, stocktaking, etc. These autonomous vehicles follow guide paths or sensors to optimise warehousing.

When implemented correctly, it can increase warehouse efficiency, improve material handling, and reduce costs, which is why many retailers are designing their digitized warehouses around this new technology.

Automated guided vehicles in action:

- Automates inventory receiving, storage, and shipping: By integrating AGVs into your warehouse processes, you get to take a hands-off approach when it comes to everything from inventory receiving to storage and retrieval.

- Automates unloading/loading pallets: AGVs also ensure smoother operations by automating the loading and unloading semi-trailers and picking and stacking pallets accurately. This reduces pallet carrying, loading, and unloading time.

6. Inventory management system

An inventory management system helps you gain control over these variations in inventory, across multiple storage centres. It also offers better inventory data management by tracking and recording real-time SKU quantities, inventory turnover, SKU performance, and much more.

Inventory management in action:

- Improves inventory management and visibility: There are peaks and troughs to inventory levels at every warehouse and channel, across your supply chain network. This helps to understand that at a glance, while centralising operations.

- Improves inventory efficiency: Inventory tracking systems improve visibility, so you can efficiently allocate inventory across your distribution network, assign pickers to optimised routes, and improve warehouse picking and packing processes.

When it’s time to invest in real-time inventory tracking and automation, many online retailers often turn to a fulfilment partner like ShipBob so they can hand off order fulfilment and smart warehousing, without having to invest in the infrastructure themselves.

ShipBob operates global fulfilment centres powered by fulfilment software with built-in inventory management tools. A 3PL partnership allows you to outsource fulfilment while also gaining access to advanced inventory tracking systems with visual data and analytics reporting.

7. Internet of Things (IoT)

IoT is short for “Internet of Things,” referring to the online networks of devices and objects that communicate with other devices in the same network through their connection to data centres.

Synchronizing and connecting smart warehouse technologies (such as WMS, sensors, conveyors, RFID tags, and AGVs) to each other, and to the internet allows you to collect and share that information amongst these devices.

By collecting operational data in a single connected technology, you gain deep visibility and avoid silos in your business.

Thus, democratizing information within your organisation makes it possible to improve or make more convenient warehouse tasks such as lighting management, environmental controls, and data monitoring.

Internet of things in action:

- Locates items: A smart warehouse with a networked set of security devices can help you constantly monitor each products’ location, so you can prevent errors, theft, and item misplacement.

- Offers state-of-the-art predictive analytics solutions: Supply chain analytics is what makes your business function at its very best. Data collected by the network of devices helps accurately predict the time of arrival of goods from the supplier, when you will run out of inventory, when warehouse machinery needs maintenance, etc.

Smart warehousing best practices

Smart warehousing helps to avoid empty shelves and costly bottlenecks. Here is a list of smart warehousing best practices to help supply chain decision-makers gain the most from smart warehouse technology and automation solutions.

Optimise your warehouse regularly

The ecommerce industry is very demanding and requires warehouses to use the latest technology and processes.

To keep up with the ever-changing customer demands and supply chain dynamics, it’s important to optimise warehouse layouts, warehouse slotting, and inventory movement.

Smart warehouse optimisation involves conducting regular warehouse audits and acting on the insights. Managing all of this in-house can get overwhelming. But, it can be made easy if you partner with a logistics platform like ShipBob.

Partner with a tech-enabled 3PL

As a full-stack, tech-enabled fulfilment solution, ShipBob offers state-of-the-art smart warehousing solutions. Partnering with a tech-enabled 3PL like ShipBob that offers the latest smart warehousing solutions will help you remain competitive.

Whether you are a startup or a quickly growing retail business, you can leverage our latest technologies to improve cost-effectiveness and efficiency of operations, ranging from warehouse receiving to optimised shipping.

ShipBob merchants also gain access to a robust fulfilment network that enables affordable 2-day shipping and the ability to further expand into fulfilment centres in other countries.

“ShipBob is a tech company first, unlike other 3PLs who are trying to add tech to their existing business. We love ShipBob’s software. Other 3PLs have tech that is so antiquated and old, it looks like an AOL compact disk that used to come in the mail.

ShipBob is very forward-thinking and leaps and bounds ahead of reporting in other systems. Overall, there is more transparency with ShipBob that even helps our team manage customer service better.”

Wes Brown, Head of Operations at Black Claw LLC

Implement demand forecasting

If you wish to predict which products your customers want at different times of the year, ShipBob’s fully connected fulfilment network provides the data and analytics needed to help withdemand forecasting.

Intelligent inventory forecasting using past order data and details of upcoming events can help you optimise inventory, minimise inventory shrinkage, lower storage costs, and ensure customer satisfaction.

With the right data at your fingertips, you can decide the best time to run a flash sale, discontinue a slow-selling item, or know how much inventory to order based on seasonality.

Rethink your warehouse layout

Smart warehousing requires more space and organised areas to deliver the best results. Therefore to become smart technology-ready, it’s important to first start withwarehouse setup.

Optimising your warehouse space involves identifying which areas of your warehouse operations need support from technology. For instance, though a WMS may not directly impact the warehouse layout design, it can impact the way you lay out equipment, as well as your workstations.

Before you invest in technology to improve warehouse operations, take time to plan your warehouse layout design, which can decrease storage costs and speed up the fulfilment process without the need for technology.

From there, you can determine how you can use technology to further enhance your warehouse operations.

A ShipBob warehouse, as seen here, has been optimised to ensure a smooth flow of operations all the way from receiving to picking and packing to shipping out customer orders.

ShipBob’s tech-enabled smart warehousing solutions

ShipBob is a global fulfilment provider with best-in-class technology that provides online retailers with a modern, end-to-end supply chain solution.

By automating warehousing tasks, such as picking, packing, shipping, inventory management, and more, ShipBob can help you improve transit times, reduce shipping costs, and provide more value for your customers.

To get a glimpse inside how our operations works, check out the 3D experience below:

ShipBob, with its reliable fulfilment technology and growing network, is the perfect smart warehousing solution that will take your business to the next level.

To learn more about our fulfilment solution, click the button below for more information and custom pricing.

ShipBob’s WMS for smart warehousing

ShipBob has a best-in-class warehouse management system (WMS) for brands that fulfil orders from their own warehouse and need help managing inventory, reducing picking, packing, and shipping errors, and scaling with ease.

With powerful technology and best-in-class analytics and reporting, ShipBob’s WMS can help your brand achieve smart warehousing in your own facility.

When brands use ShipBob’s WMS, they can leverage a hybrid fulfilment solution ShipBob’s fulfilment services in any of ShipBob’s fulfilment centres across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Get a glimpse of how ShipBob merchant, Bunker Branding, uses ShipBob’s WMS to streamline their warehouse operations and order fulfilment.

Request a quote to connect with a ShipBob team member about how you can start using ShipBob’s WMS in your own warehouse.

Smart warehousing FAQs

Here are answers to the top questions people have about smart warehousing.

Why is smart warehousing important?

Customers expect reliable, fast, and affordable shipping. Smart warehousing powers logistics teams to improve performance with technology and automation solutions to meet such customer expectations.

How does smart warehousing benefit ecommerce?

Smart warehousing helps ecommerce businesses improve their operations in the following ways:

- Reduces manual labour, human errors, damage, and inaccuracies

- Improves inventor visibility and transparency

- Improves warehousing speed and accuracy

- Offers real-time data tracking, analytics, reporting

How can you switch to smart warehousing solutions?

Smart warehousing is like adding a brain to a storage facility that thinks up better and more efficient ways of replenishment, receiving, storing, picking, packing, and shipping of inventory. To do this on your own, you’ll need to be running a large enough warehouse or network for the costs to be justified and the investments worthwhile.

That’s why many fast-growing online brands partner with third-parties like ShipBob that offer fulfilment centres across the globe that are tech-enabled. This allows online brands to outsource logistics while also gaining visibility and optimising costs.

What are the components of smart warehouse systems?

There are various components of smart warehouse, including warehouse robotics, artificial intelligence (AI), automated guided vehicles (AGVs), inventory management systems, warehouse management systems, and Internet of Things (IoT). Integrating these components creates a smart warehouse system that improves accuracy, efficiency, and warehouse operations.

How does RFID work in smart warehousing?

RFID (or Radio Frequency Identification) is used in smart warehousing to track and identify inventory in real-time. This way, the location of inventory within the supply chain is always known. There are several benefits of using RFID in smart warehousing including greater warehouse efficiency and employee productivity, as well as accurate documentation of movement throughout the supply chain.