Table of Contents

** Minutes

What is supply chain transformation?

Why supply chains are going digital

8 ways you can transform your supply chain

4 signs your supply chain is ready for a digital transformation

How ShipBob’s tech-enabled 3PLs help you create a consistent customer experience

Walmart founder, Sam Walton, once famously said, “Many of our best opportunities were created out of necessity.”

Online retailers who have embraced digital supply chain transformation try to stay ahead of supply chain disruptions (and even did so to combat common logistics challenges that came under the limelight during the pandemic).

Though the COVID-19 pandemic isn’t forever, the push towards digital logistics transformation will continue to support retailers as they buildsupply chain resilience and get prepared for almost anything — e.g., a sudden influx in demand,logistics procurement disruptions, natural disasters, a warehouse closure, etc.

Supply chain digitization not only builds a more agile supply chain, but it also allows brands to grow faster by automating processes, reducing human error, and gaining full visibility to understand how to best optimize their supply chain.

Transforming a traditional supply chain into a tech-enabled, on-demand logistics operation is one of the best ways to stay competitive and meet customer expectations around fast, accurate, and affordable delivery.

This article offers a roadmap on how to move forward with supply chain digital transformation and how partnering with a 3PL like ShipBob can help.

What is supply chain transformation?

Digital supply chain transformation refers to the overhaul of a traditional supply chain management process into one that is technology-enabled.

This includes the implementation of the latestlogistics innovations, such as automation, data and analytics, robotics, and AI learning.

The goal is to create a moreefficient supply chain that is fast, resilient, and more sustainable.

Why supply chains are going digital

TheCOVID-19 pandemic has brought many supply chain challenges to the surface.

From rising customer expectations to the need for higher visibility across a distributed supply chain, online brands that want to be around long-term have no choice but to invest in the latest technology and automation solutions to build a strongerretail supply chain.

Here is an overview of why supply chains are going digital.

Meet customer expectations

What customers want, customers get — be it faster delivery,free shipping, or hassle-free returns. If you can’t offer it, they will look elsewhere.

Embracing the latest insupply chain technology to meet customer expectations is the one of the best ways to stay competitive. With online giants like Amazon andWalmart Marketplace setting high standards, technology can help a small to mid-size online brand create a Prime-like experience.

By automating time-consuming and error-prone tasks throughout your supply chain, you and your logistics team can focus on expanding coverage, improving workflows, and determining how to optimize logistics to get products to where they need to be in the most affordable and fastest way possible.

Reduce labor costs

Manual warehouse management processes only slow down your supply chain velocity, lead to higher costs, and are also more prone to human error.

Warehouse automation can reduce the man-hours spent on repetitive, time-consuming tasks, such asorder processing,warehouse picking, and shipping. Once your supply chain labor costs drop drastically, you can pass on the savings to customers (such as offering free or affordable 2-day shipping).

With automation, your warehouse team can also free up time to focus on accurately packing orders and enhancing the customer experience.

Access to data that helps uncover areas for improvement

As you expand your operations, you will need accurate data that gives you insights into how operations are performing, so you can make informed decisions and measurable improvements.

Supply chain forecasting technology is an essential if you want to better manage performance, optimize operations, and prepare for the unexpected.

For instance, by implementingreal-time inventory management software, changes in inventory levels are automatically updated.

This way, you can view accurate inventory accounts at any time, have a better understanding on when it’s time toreplenish inventory based on historical data, and better manage SKUs by understanding which products are in high demand.

Real-time supply chain visibility

Technology provides business owners and logistics managers the ability to oversee operations without needing to involved in the day to day, so they can track performance and make improvements to their ecommerce supply chain.

From warehouse receiving processes to last-mile delivery times, having insights into how your supply chain is performing can help you optimize operations, make improvements, and easily expand your supply chain by having the right data at your fingertips.

8 ways you can transform your supply chain

There has never been a better time for online retailers to switch from a traditional to a digital supply chain.

There are several digital transformation solutions on the market that make it easy for online brands of all sizes to adapt a digital supply chain transformation, from inventory management solutions to automated shipping.

Here are the eight ways on how you can transform and digitize your supply chain.

1. Predict future demand

Intelligentdemand forecasting enables you to better predict customer demand and future trends, so you can prepare for slower or faster seasons, an influx in sales, and other predictions that makesupply chain planning much more effective.

The best way to forecast demand is by cutting out the guesswork by implementing technology that collects, records, and tracks real-time inventory and sales data to analyze inventory turnover performance over time.

For instance, ShipBob’s3PL software offers built-in inventory management software, so merchants can view historical sales data to make decisions on budget, production lead times, storage, andproduct pricing.

2. Implement an inventory management system

No more counting SKUs physically or recording inventory into Excel or ledgers.

One of the most accessible technology solutions on the market is an inventory management system, which gives you the ability to track inventory in real time, and across sales channels anddistribution centers.

Whether you decide to invest in a robustERP inventory system or a more simple and affordableinventory app, the ability to view, track, and manage inventory while measuring performance over time is an essential part of running an effective and lean supply chain.

Accurate inventory levels and reporting can ensure you’re not overpaying in storage while also avoidingstockouts and the accumulation ofdead stock.

It also makes it much easier during tax season, since you can easily generate inventory reports without the need for frequent, time-intensive inventory audits.

3. Explore warehouse robotics

Digital warehousing, which involves using high-tech equipment and labor-focused processes, helps improve workflows, reduce warehouse costs, improve warehouse safety, and maintain a high order accuracy rate.

Warehouse robotics that automate processes such aswarehouse picking, packing, and shipping are not uncommon, and more logistics operators are investing in robotics to save on time and costs in the long run.

This way, logistics teams can concentrate on more complicated processes, such as packaging innovations, workflows, and more.

Aside from robotics, digital supply chains are also being powered by automated guided vehicles, aerial drones, and automated storage and retrieval systems.

4. Opt for integrated technology

To achievesupply chain optimization, especially at a time when order loads are increasing exponentially, it’s important to choose technology that easily integrates with your supply chain.

When implementing technology, make sure it seamlessly fits into your existing or desired tech stack. A well-connected tech stack can include everything from inventory planning toreturns management, tofreight shipping solutions.

For instance, ShipBob’sorder fulfillment technology offers direct integrations with dozes of ecommerce solutions, creating anend-to-end ecommerce solution.

“With our old fulfillment solution, because of a lack of ownership of the entire fulfillment stack, it was difficult to rectify, unlike with ShipBob who owns the entire stack: inventory and order management system, warehouse management system, and their fulfillment centers.”

Gerard Ecker, Founder & CEO of Ocean & Co.

5. Invest in IoT

If you’re unfamiliar with the acronym, IoT is short for “Internet of Things,” referring to the online networks of devices and objects that communicate with other devices in the same network through their connection to data centers.

Using a network of RFID chips, smart devices, and mobile sensors, you can collect and exchange real-time data about your inventory, location, storage conditions, as well as handling and speed of movement of inventory.

Ultimately, IoT can help improve internal communication transparency and increase supply chain planning precision.

6. Increase cybersecurity

The downside to implementing new technologic systems is that your supply chain is more at risk of data breaches, identity theft, ransomware, and other cyberattacks.

Modern security technology reduces risk and enhances protection. Encryption, tokenization, on-demand access, and automatic alerts are all security enhancements that should be used within a tech-enabled supply chain.

Regardless of whose information is being exposed, cyberattacks can cause major security breaches throughout the supply chain, which can also put customer data at risk.

7. Install a warehouse management system

If youmanage a warehouse, awarehouse management system (WMS) is a must. A WMS monitors and controls daily operations in a warehouse, ensuring inventory is received, stored, picked, packed, shipped, and replenished in an efficient way.

Warehousing involves a lot of moving parts, including the constant flow of inventory, from receiving and picking, to packing orders and preparing them for shipment.

Without insight intostock availability and where items are located, it can slow down the fulfillment process, resulting inbackorders andsplit shipments.

With a WMS, you can optimize yourecommerce warehouse by reducing inefficiencies and enabling more visibility.

8. Expand through cloud computing

Thanks to cloud computing, the ability to communicate and share data can be done quickly and cost-efficiently.

The benefit of ecommerce is not only can you sell to anyone directly from your online store, but you can also establish amultichannel retailing strategy by expanding into different sales channels.

Expanding an ecommerce business is made possible partly by usingcloud-based computing solutions, which provide the logistics industry with low-capital technology advancements that easily record and aggregate data, and provide full visibility into an entire supply in real time.

This allows merchants to outsource fulfillment to a provider like ShipBob while still having access to data in real time to maintain control and oversight.

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

4 signs your supply chain is ready for a digital transformation

Due to high standards and expectations around accurate, fast, and reliable delivery, the entire logistics industry is already making changes and investing in the latest technology to stay competitive and meet demand.

Here are the four major signs it’s time to put your supply chain through a digital transformation.

1. You fail to meet customer delivery deadlines

Are you regularly unable to meet customer expectations around fast shipping? If yes, it might be time to find ways in which technology can help you speed up the process.

For instance, if orders are taking too long to process or fulfillment is being delayed due to inaccurate inventory counts, implementing technology to automate inventory tracking can free up time and provide insights into how to improve.

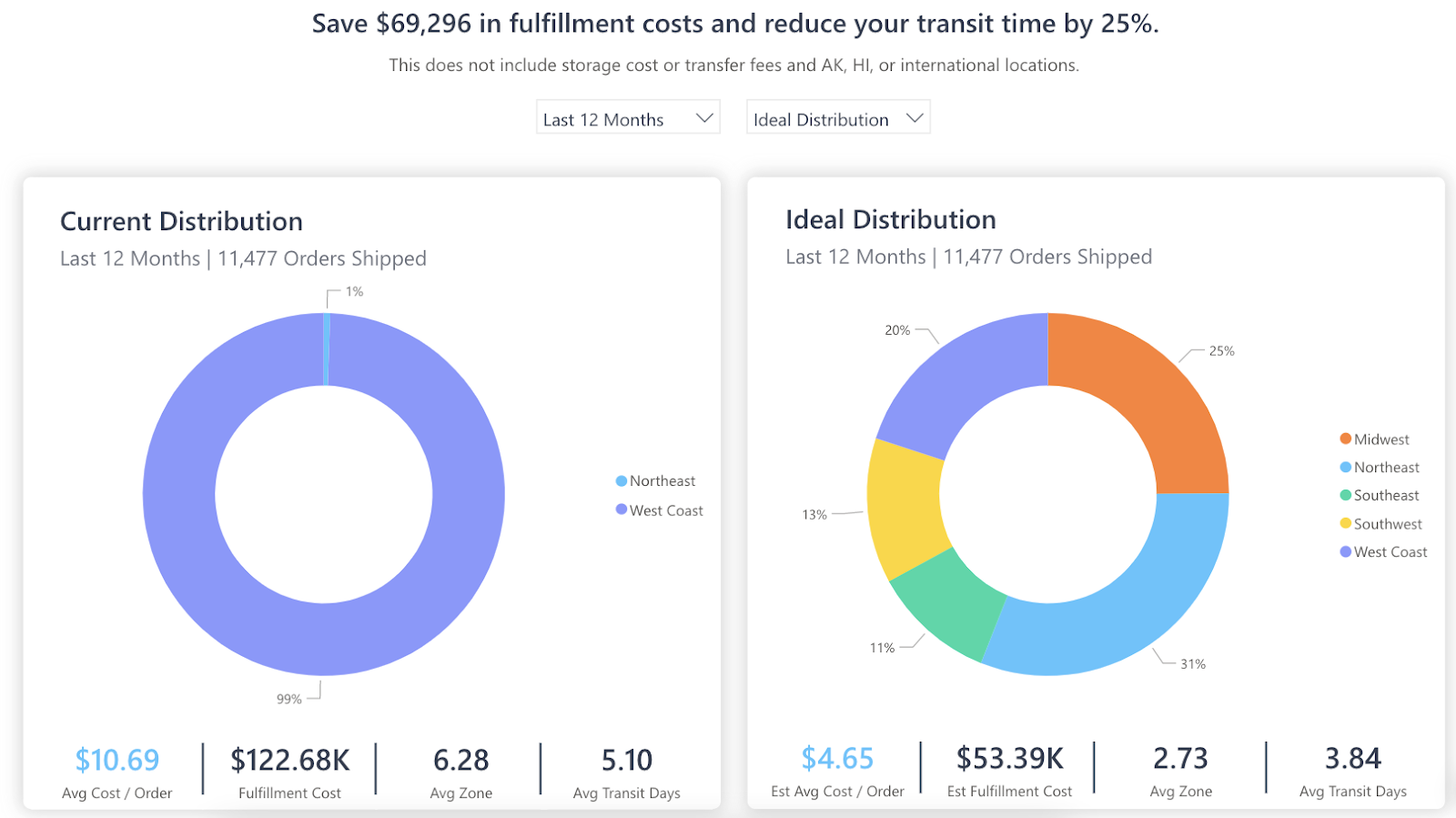

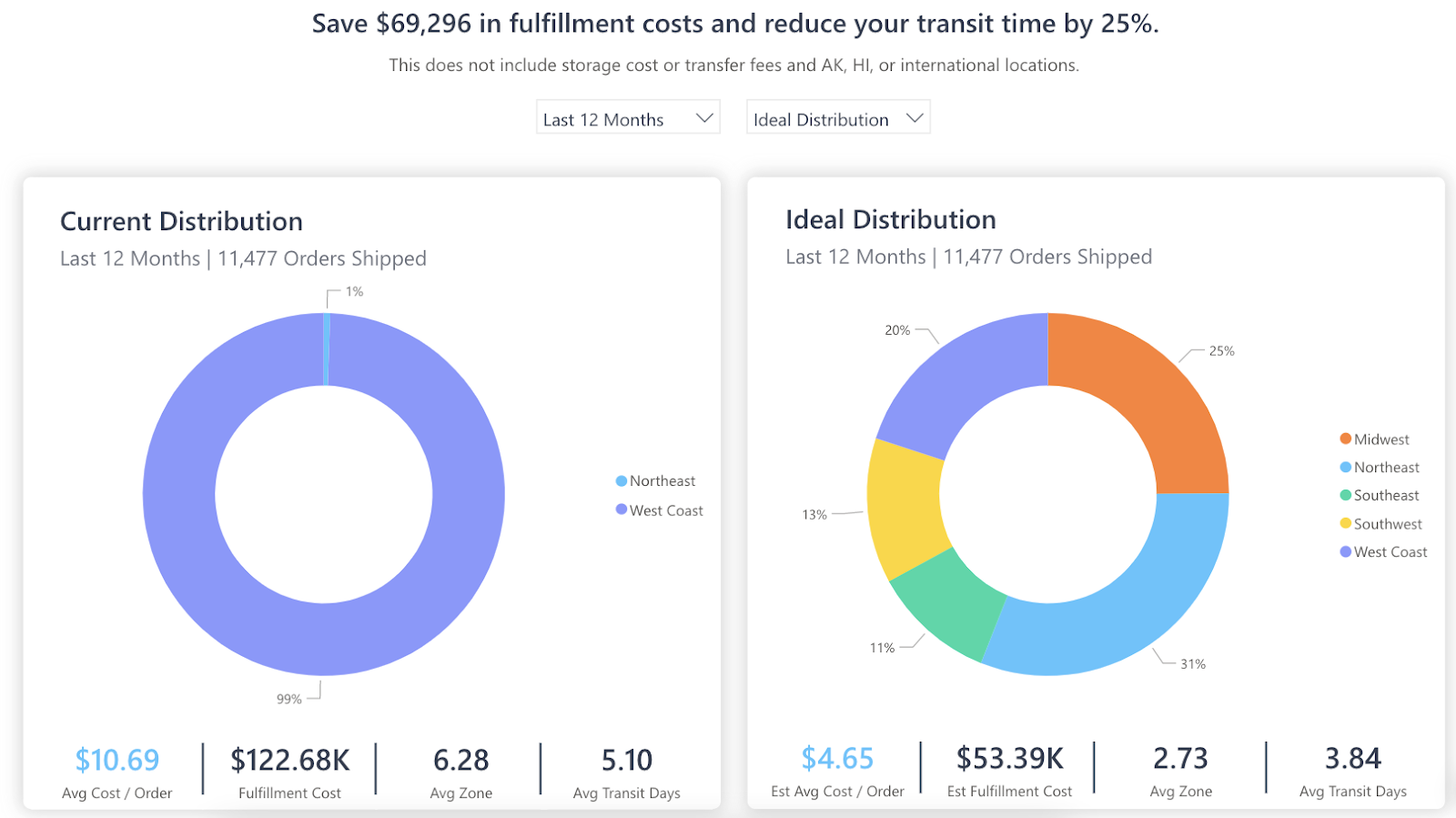

For instance, ShipBob’s fulfillment technology enables faster shipping and delivery by analyzing your customer data to optimize where your orders ship to. From there, inventory can be strategically split across different fulfillment centers of your choice (e.g., reaching different regions of a country) and then sent from the warehouse that is located closest to the customer.

When your orders travel less distance, you reduce both shipping costs and time in transit.

“ShipBob has been a great ally as they have fulfillment centers all over the US, facilitating a 2-3 day delivery time for any customer in the US.”

Andrea Lisbona, Founder & CEO ofTouchland

2. You have a high order return rate

When the supply chain processes are not optimized, you often encounter higherecommerce returns rates due to inaccurate picking and packing (AKA mis-picks and damages).

To reduce customer disappointment and high inventory return costs, adopting a digital solution can provide more visibility into the fulfillment process, therefore detecting any inefficiencies.

From there, you can work on improving processes to reduce the number of returns due to mis-picks and other errors.

For instance, ShipBob provides access to a wide range ofdistribution metrics that can help merchant calculate a perfect order metric, as well as other KPIs to easily monitor performance.

3. Siloed supply chain communication

Traditional inventory management lacks the ability to trackinbound and outbound logistics operations (and sometimes even within a warehouse), which hinders communication between teams and third-party logistics companies.

When all parties that are involved in operating a single supply chain don’t communicate efficiently, it can be almost impossible to expand due to a lack of timely information being shared.

Let’s say you sell across multiple sales channels. Without proper inventory counts being tracked across channels, it can lead to inaccuracies, higher costs, and lower customer satisfaction, whereasdigital inventory management can track inventory levels in real time across a distribution network.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations. It’s really nice to not have to operate three 3PLs.

ShipBob lets you manage your inventory while providing important data in a very digestible way. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

4. Poor inventory visibility

If you don’t know what and how many units of each SKU you have on hand and where, it will be hard to make data-backed decisions that can improve your bottom line.

Inventory visibility is, therefore, a non-negotiable aspect ofsupply chain management.

Digital supply chain management systems that track and record inventory in real time increase overall efficiency,maintain optimal inventory levels, improve forecasting, and reduce supply chain costs.

“Now we’re at two ShipBob fulfillment centers, and being able to have the analytics and see how everything is working together has been extremely helpful for me on the operations end.

It definitely helps me with inventory management and seeing what’s going on. Even though we’ve grown, I haven’t spent more time on the business from an operations standpoint.”

Dana Varrone, Director of Operations at Organic Olivia

How ShipBob’s tech-enabled 3PLs help you create a consistent customer experience

ShipBob is a technology-first 3PL with aninternational fulfillment network. ShipBob helps fast-growing direct-to-consumer brands stay competitive and grow their business faster by providing the infrastructure, technology, and resources necessary to build a successful online brand.

ShipBob’s entirelogistics network is powered by a proprietary tech stack, which allows merchants to track fulfillment activity and performance in real time all from one dashboard.

To get a glimpse into our operations, check out ShipBob’s 3Dfulfillment center tour:

Here is an overview of how ShipBob uses technology to optimize yourecommerce fulfillment strategy via supply chain transformations, including faster delivery and lowerfulfillment costs.

Real-time data and analytics

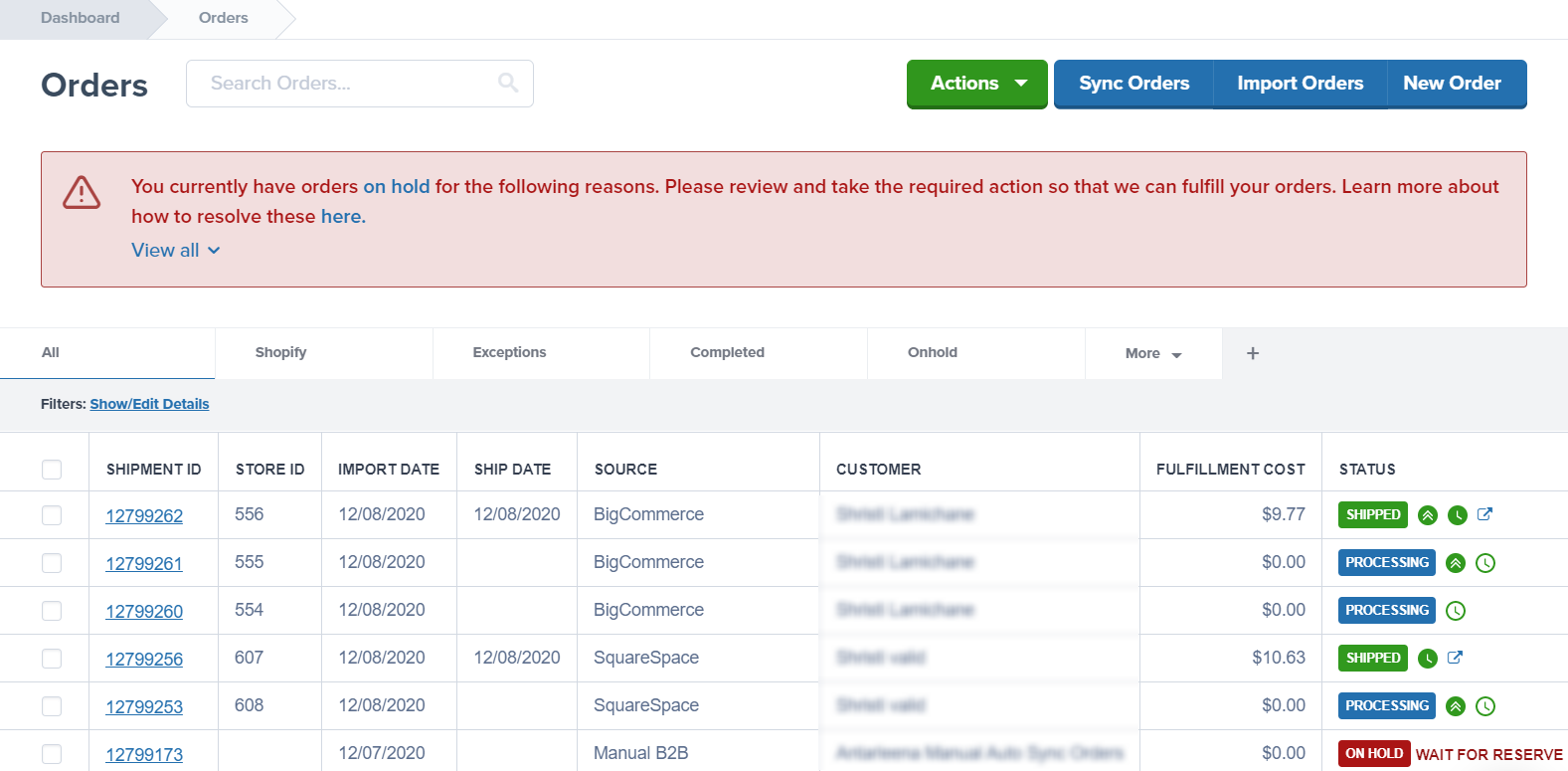

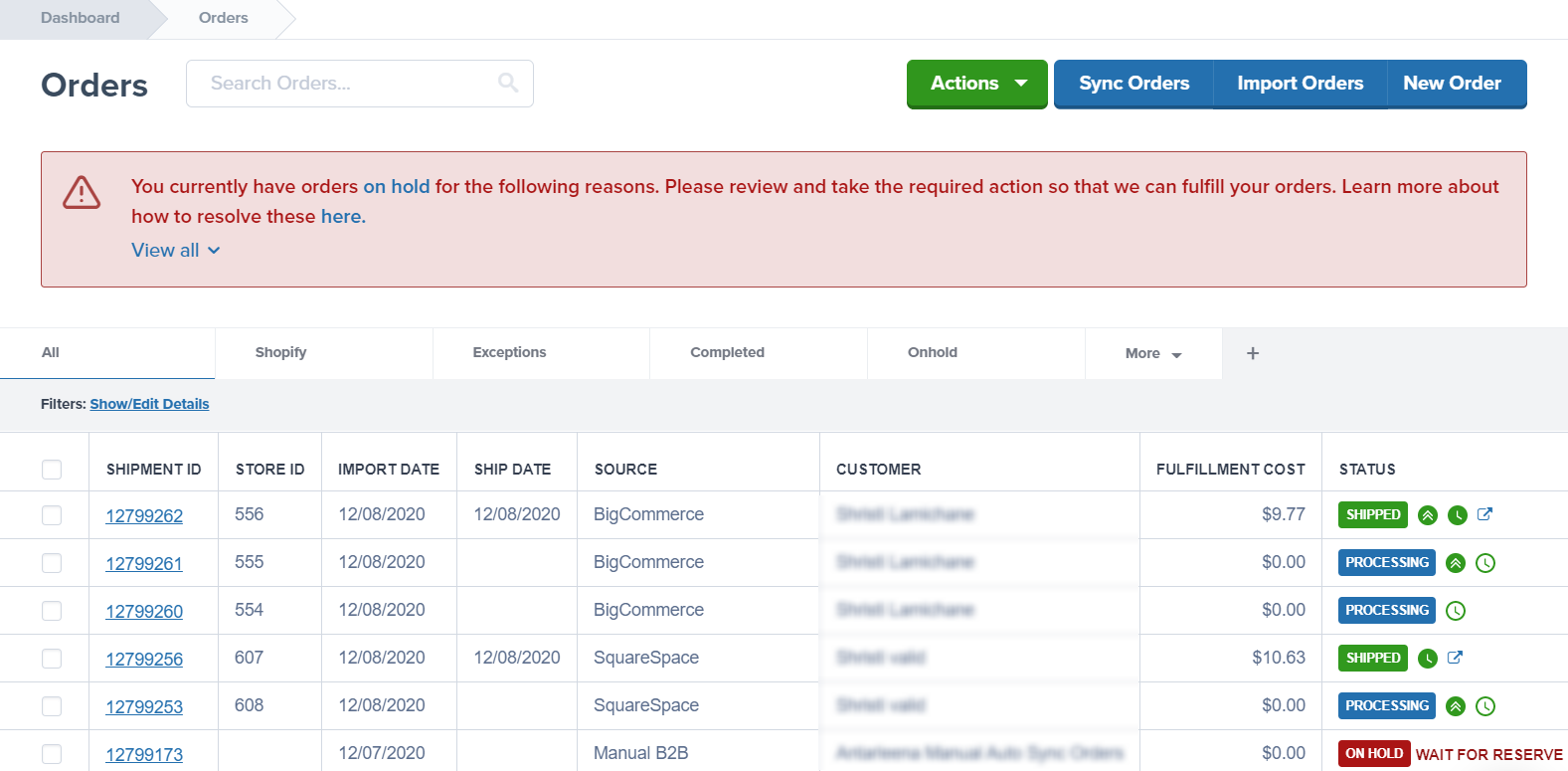

With ShipBob, merchants have access to a user-friendly dashboard, which is connected to our WMS to supply real-time insights.

Our data and analytics help you track and analyze fulfillment and shipping performance with full visibility into operations.

This allows you to track whether or not we’re hitting our SLAs, how the carriers are performing, filter orders, track inventory counts, and much more.

Rather than requesting someone to create a report for you, you can automatically pull them on-demand, eliminating back and forth while increasing transparency, makinginventory reporting and tracking operational costs (including warehousing and fulfillment) much easier.

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder ofMDacne

Accurate inventory tracking

ShipBob’s real-time inventory tracking system makes it easy to:

- Monitor inventory across your distribution network.

- Manage SKUs and view SKU velocity.

- Optimize product allocation.

- Forecast demand.

- Replenish inventory efficiently by setting reorder point notifications.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

High order accuracy rates

ShipBob’s fulfillment technology is designed to eliminate fulfillment errors to maintain a high order accuracy. Merchants are also provided with deep insights into fulfillment performance to keep us fully accountable.

We are constantly revising our operating procedures and implementing best practices, technology, and automation to stay at the cutting edge of supply chain transformations including order fulfillment, warehousing, and inventory management.

In addition to maintaining a high order accuracy rate, the ShipBob team closely measures ‘support cases per order,’ which is a big indicator of how well we’re performing as your logistics partner.

“The old 3PL charged for each pick and pack, wouldn’t take responsibility for any errors they made, and getting orders fulfilled would take up to 20 days in some cases.”

Torii Rowe, COO & Co-Founder of MANSSION, a ShipBob merchant

Fast delivery options

Amazon Prime pioneered 2-day shipping. And less than a decade later, customers have started to expect similar service levels from every retailer.

ShipBob’s distributed inventory model allows merchants to strategically split products across different fulfillment center locations. Once an orders is placed, it is routed to the nearest fulfillment center. When your orders travel less distance, you save both money and time in transit.

ShipBob continues to add more locations to its US network, as well as global fulfillment locations.

We also provide insights into inventory allocation based on historical order data, which allows merchants to determine their ideal distribution strategy in order to reduce shipping costs and speed up transit times.

“ShipBob has been a great ally as they have fulfillment centers all over the US, facilitating a 2-3 day delivery time for any customer in the US.”

Andrea Lisbona, Founder & CEO ofTouchland

Omnichannel retail support

Today’s fast-growing retailers sell via multiple sales channels, rather than relying on just one (e.g,, their online store) to attract sales, which is key to growth.

To efficiently manage and fulfill orders from different sources, ShipBob makes it easy to integrate multiple channels with our technology, including major ecommerce platforms, marketplaces, and even social media platforms.

Our highly integrated technology makes it possible for retailers to adopt an omnichannel retail approach with the ability to pull all your historical order data in one place and pull reports on sales trends to determine which products are fast-selling vs. slow-moving, see where there is the most demand geographically, and more.

“We want to continue to become a more multichannel brand and work with bigger retailers. We’ve done some B2B orders with ShipBob, including Urban Outfitters, and now we’re in talks with some larger wholesale accounts. We’re also testing subscription box partnerships.”

Manuel de la Cruz, CEO atBoie

Ready to get started with ShipBob?Click here to get pricing and more information on how ShipBob works.

Supply chain transformation FAQs

Here are answers to the top supply chain transformation questions.

How has digital transformation changed the ecommerce supply chain?

Digital transformation allows ecommerce supply chains to stay competitive, meet customer expectations around fast, affordable shipping, and automate processes to save time and money, all while tracking data-to-day operations in real time.

Can you outsource supply chain transformation?

Yes! In fact, the best way to enable a modern-day supply chain is by outsourcing logistics to a third-party, such as a 3PL like ShipBob. ShipBob is a fulfillment company that provides the infrastructure, technology, and resources necessary to scale a successful online brand without the need to invest in your own technology to enable a supply chain transformation. ShipBob’s entirefulfillment network is powered by a proprietary tech stack, which allows merchants to track fulfillment activity and performance in real time all from one dashboard.

What are the current supply chain transformation challenges?

TheCOVID-19 pandemic has brought many challenges that the logistics industry has been facing on to the surface. From rising customer expectations to the need for higher visibility across a distributed supply chain to reduce risk, online brands have no choice but to make an investment in the latest technology and automation solutions to build a stronger supply chain.