Table of Contents

** Minutes

What is supply chain performance?

Why is supply chain performance important?

Supply chain performance KPIs to track

Measuring supply chain performance

What affects supply chain performance?

3 ways to improve supply chain performance

How ShipBob can help you improve your supply chain performance

Like the old adage goes: a chain is as strong as the weakest link. A business’s supply chain is no different.

Whether there’s a manufacturing delay or inaccuracies in fulfilment, every stage of an ecommerce operation impacts the next.

This is why proper supply chain management is vital for the smooth functioning of an ecommerce business. But how exactly do you know if a supply chain is performing well? And how do you decide what areas of improvement are worth investing in?

To effectively manage your business, you need to keep a close eye on your supply chain performance.

In this article, we take a closer look at what supply chain performance is, why it matters, which KPIs to track, and how to improve it.

What is supply chain performance?

Supply chain performance refers to how effective each stage of the ecommerce supply chain is in optimising costs, reducing inefficiencies, improving speed, and meeting customer expectations.

Different aspects of the supply chain such as on-time delivery, stock availability, order accuracy, and production lead times all play a role in ensuring that its performance is seamless and responsive.

Why is supply chain performance important?

Supply chain performance goes beyond immediate organisational boundaries; it plays a crucial role in multiple aspects of your business, including accounting, sales, and employee and customer satisfaction.

Setting and tracking specific KPIs throughout the supply chain gives businesses the insights and data needed to make improvements and establish a strong logistics system. But it also helps to keep your business healthy across departments, so you can reach revenue and growth goals.

It affects both short-term and long-term goals

Supply chain performance influences whether or not you meet your business goals — both in the long and short term.

How your supply chain activities are functioning right now will determine if you’re operating at a level that’s necessary to achieve those goals, such as expanding into international markets while sustaining a healthy profit margin.

For example, you may have a goal to increase sales by X%. But if your supply chain performance indicates that fulfilment rate is slowing down due to a high monthly order volume, chances are you won’t be able to fulfil orders on time to meet customer expectations.

Tracking specific KPIs based on past and current performance data can can result in better supply chain planning so you can prepare for future production, inventory replenishment, and faster fulfilment.

It helps with reducing operating costs

Supply chain performance offers a comprehensive look at how logistics operations are functioning at every stage. This allows businesses to identify opportunities for improvement.

Once you have an understanding of what needs to be improved, you can implement systems, processes, and workflows to optimise costs.

And since measuring performance enhances supply chain visibility, it mitigates costly mistakes such as failing to reorder at the right time or overstocking on slow-moving items.

It improves the financial performance of the company

Consistently measuring supply chain performance is essential for building a lean supply chain. Not only is it way to make improvements, it’s an opportunity to eliminate inefficiencies within the supply chain to reduce lead times and costs

As a result, orders can be fulfiled quickly without compromising accuracy which greatly improves brand loyalty.

Supply chain performance KPIs to track

Businesses need to keep a close eye on their supply chain KPIs and consistently to identify areas of improvement.

The supply chain analytics and distribution metrics you track can greatly improve your operations so you can worry less about logistics and spend more time and energy on delivering a great product.

Here are some of the most common supply chain performance KPIs to track.

Perfect order rate

What exactly constitutes as a perfect order?

- Accuracy

- On-time delivery

- Damage-free

Overall, perfect order metrics track supply chain efficiency.

Tracking perfect order rate indicates how many orders are filled accurately, packed with all the necessary documentation, and delivered on time without any damages.

Supply chain costs

When it comes down to it, optimising costs is everything.

Supply chain costs, also known as logistics costs, refer to all expenses associated with moving product from procurement to the end user.

These costs can include:

- Transportation and shipping costs — both first-mile delivery and last-mile delivery

- Warehousing and storage costs

- Labour

- Fulfilment costs

There are plenty of ways to reduce supply chain costs, but one of the most common ways to cut costs is to implement the latest in logistics automation. Another common option is to partner with a 3PL that provides the necessary fulfilment infrastructure without investing in building it from scratch.

Order fill rate

Order fill rate is the percentage of orders you can ship from your available stock without any lost sales, backorders, or stockouts.

Tracking order fill rate is beneficial because it reflects your company’s ability to meet customer expectations around fast and accurate delivery.

Internally, it helps to measure how often stockouts and backorders occur so you can make improvements accordingly.

Cash-to-cash cycle time

Cash-to-cash cycle time indicates how long it takes to generate revenue to make up for costs of goods sold.

You should keep a close eye on how quickly you’re able to turn cash into cash, so you can forecast sales and understand how profitable your business is after selling finished goods and before you replenish inventory.

For instance, a short cash-to-cash cycle time is a sign that your supply chain is lean and you’re quickly turning purchased inventory into profit.

Measuring supply chain performance

Once you have a clear idea of the KPIs that you need to be tracking, you can start to measure your overall supply chain performance.

Regular supply chain performance measurement is an essential step to supply chain transformationas it helps you identify where to eliminate waste, implement technology, or use automation to reduce time-consuming tasks.

Start with measuring inventory investment & efficiency

A majority of your KPIs will be based on inventory management.

That’s because your inventory investment has a direct impact on your cash flow. Positive inventory investment is when production exceeds sales within a given timeframe, whereas the reverse is true in the case of negative inventory investment.

On its own, positive inventory investment doesn’t indicate a problem in your supply chain because you may be increasing production based on predicted or current demand.

Inventory efficiency is an indicator of how effectively you’re using available inventory to meet consumer demand while maintaining optimal stock levels. To measure inventory efficiency, you will need to track inventory turnover within a given period.

Having an accurate picture of your inventory investment and efficiency will help you identify opportunities for supply chain optimisation.

Get a clear idea of your lead times

Lead time, or the time taken to complete specific processes or tasks, is a major driver within your supply chain.

It determines how much time is spent on different supply chain operations, such as order cycle time (i.e., the average time it takes to process, fulfil and ship out an order).

Having a clear understanding of the individual lead time through the supply chain can help you pinpoint areas where there are inefficiencies and backlogs so you can streamline your operations.

Don’t forget about on-time supplier delivery

Tracking lead times start before you even receive inventory.

Understanding how long it takes for the supplier to deliver inventory is important because it highly impacts your ability to meet demand. From there, you’ll need to track warehouse receiving, fulfilment, and average delivery timelines.

Measuring on-time supply delivery is crucial because late deliveries can significantly set back the rest of your ecommerce schedule and result in longer lead times.

You should be able to identify whether certain suppliers are prone to late deliveries and which ones have performed exceptionally well so you can review your partnerships.

Many ecommerce business diversify their supplier needs to create a more agile supply chainin case of manufacturing delays or disruptions.

What affects supply chain performance?

With the ecommerce supply chain involving a number of moving parts, your performance is influenced every stage of the supply chain.

Having a clear idea of the factors that affect supply chain performance will help you improve supply chain execution.

Relationships

Your relationships with different third parties such as manufacturers and suppliers, distributors and retailers, and shipping and logistics partners all play a crucial role in your supply chain performance.

Communication issues and lack of visibility can often result in longer production lead times, higher costs, and other delays.

Environment uncertainty

There are many external environmental factors that can cause unpredicted disruptions to the supply chain, which affects your overall supply chain performance. The supply chain changes caused by COVID are a testament to this.

Businesses may be able to mitigate the impact of environmental uncertainties by focusing on supply chain velocity and building agile and sustainable supply chain.

Bad weather, pandemics, and raw supplies shortage can all impact your supply chain. Many businesses calculate how much buffer inventory it makes sense to have on hold in case of interruptions.

Another way businesses mitigate risk from environment uncertainty is by storing inventory in multiple fulfilment centres. If, for any reason, a fulfilment centre needs to close down, orders can be fulfiled from a secondary location.

“We sell flammable goods that need to be shipped via ground, so ShipBob has been a great ally as they have fulfilment centres all over the US, facilitating a 2-3 day delivery time for any customer in the US. This is helpful especially when weather challenges happen; being able to have different locations to ship from allows for a more seamless supply chain.”

Andrea Lisbona, Founder & CEO of Touchland

3 ways to improve supply chain performance

So you want to improve your supply chain performance. Where do you start?

Here is a high-level overview on how to identify opportunities and make improvements.

1. Expand the visibility of your supply chain

A high degree of supply chain visibility is crucial for seamless communication between different parties involved throughout the chain. As such, it helps to improve relationships and encourage better collabouration.

When you know exactly how products are moving throughout the supply chain, you can anticipate possible disruptions and make proactive decisions about what to do next to mitigate them.

For example, if a supplier notifies you early about possible production delays, you might be able to look for alternative suppliers before you experience further disruptions, or prepare to utilise safety stock to meet demand.

With increased visibility, you can also quickly identify any bottlenecks and pinpoint opportunities for improvement. This makes it easier to streamline your operations and improve your supply chain performance.

For example, if you notice regular delays in warehouse receiving, you can discuss with your team how to speed up the process, so inventory gets on the shelves sooner.

2. Automate your supply chain process

Automation is the key to saving time and improving the efficiency of your supply chain. Look for tasks and processes that can be automated so you can focus on things that require human involvement.

Supply chain technology solutions to support direct-to-consumer brands are more accessible now than ever before.

For example, cloud shipping software can provide you with faster shipping times by analising optimal delivery routes and ensuring that orders are fulfiled from the most efficient locations.

An automated fulfilment solution like ShipBob allows you to delegate the time-consuming processes of picking, packing, and shipping out orders.

With ShipBob, you can sell on multiple channels, store inventory in fulfilment centres across the globe, and track supply chain performance from one dashboard.

“We realised that this time, we had to find a global fulfilment provider with expertise in US fulfilment — which led us back to ShipBob. ShipBob’s software was much easier to use than our previous local provider’s, and gave us a better picture of what was going on with our orders. Even from overseas, it gave us the visibility and control we would expect from a provider in our backyard.”

John Greenhalgh, Co-Founder of A Year of Dates

3. Nurture good relationships with suppliers

Supplier relationships play an important role in your supply chain performance. That’s why this is another area that you should focus on to optimise your procurement and logistics.

Nurturing good relationships with your suppliers is essential for speeding up your procurement and ensuring cost-effectiveness.

Additionally, it gives you better visibility that will help you anticipate any potential changes in the procurement stage such as increased raw material pricing or higher production lead times.

This way you can plan ahead and make necessary adjustments before those changes impact your supply chain performance.

How ShipBob can help you improve your supply chain performance

Outsourcing different aspects of your supply chain to a global omnifulfilment partner like ShipBob can significantly improve your supply chain performance.

ShipBob can take care of the entire fulfilment process on your behalf, while providing you with better supply chain visibility using proprietary software.

Outsourced supply chain

When you outsource supply chain management to ShipBob, you can delegate all the time-consuming, but necessary, logistics tasks, including:

- Warehouse receiving and storage

- Omnichannel order management

- DTC, B2B, and multichannel retail fulfilment

- Shipping and courier relationships (plus access to discounted rates)

- Returns management

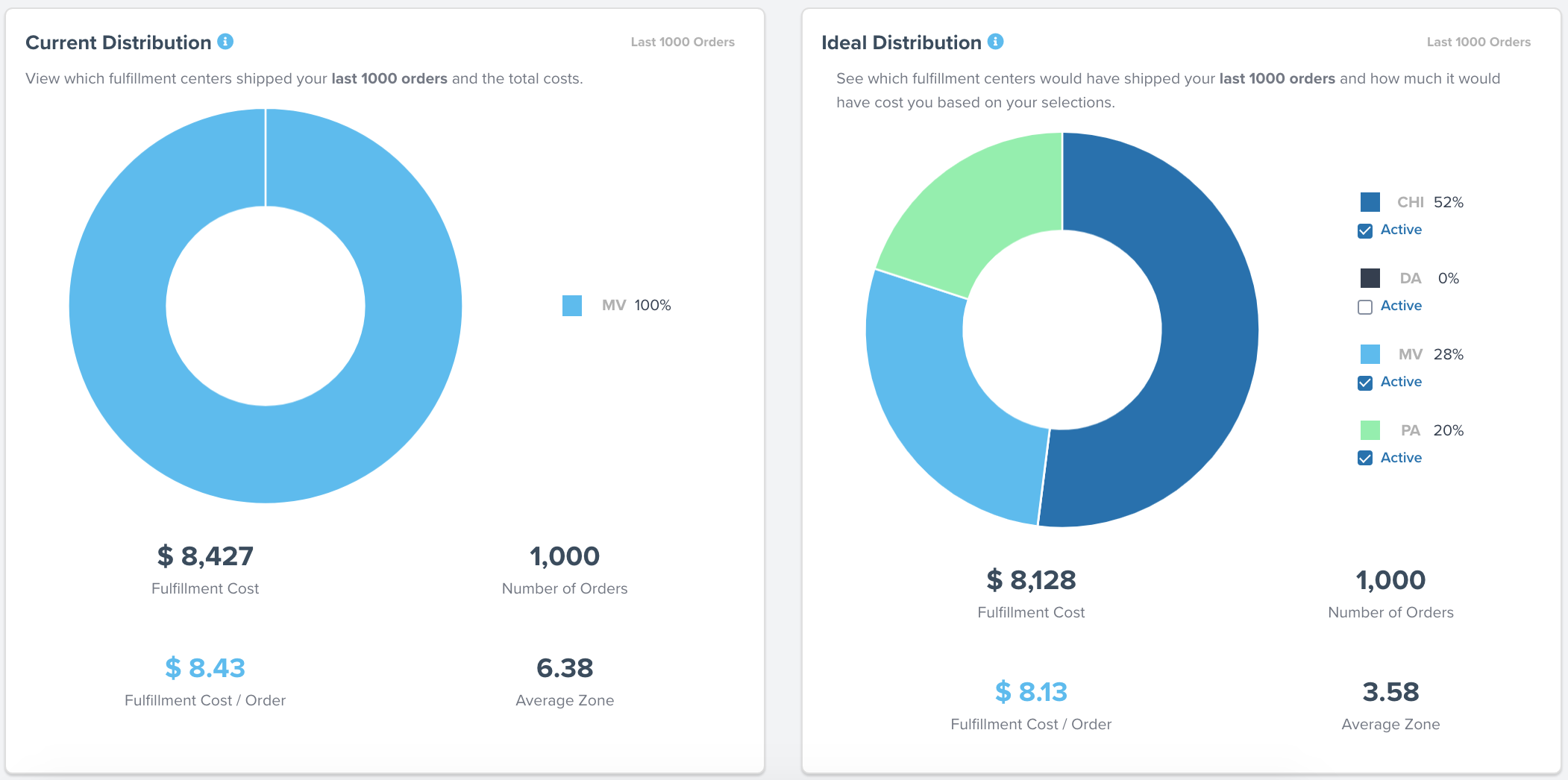

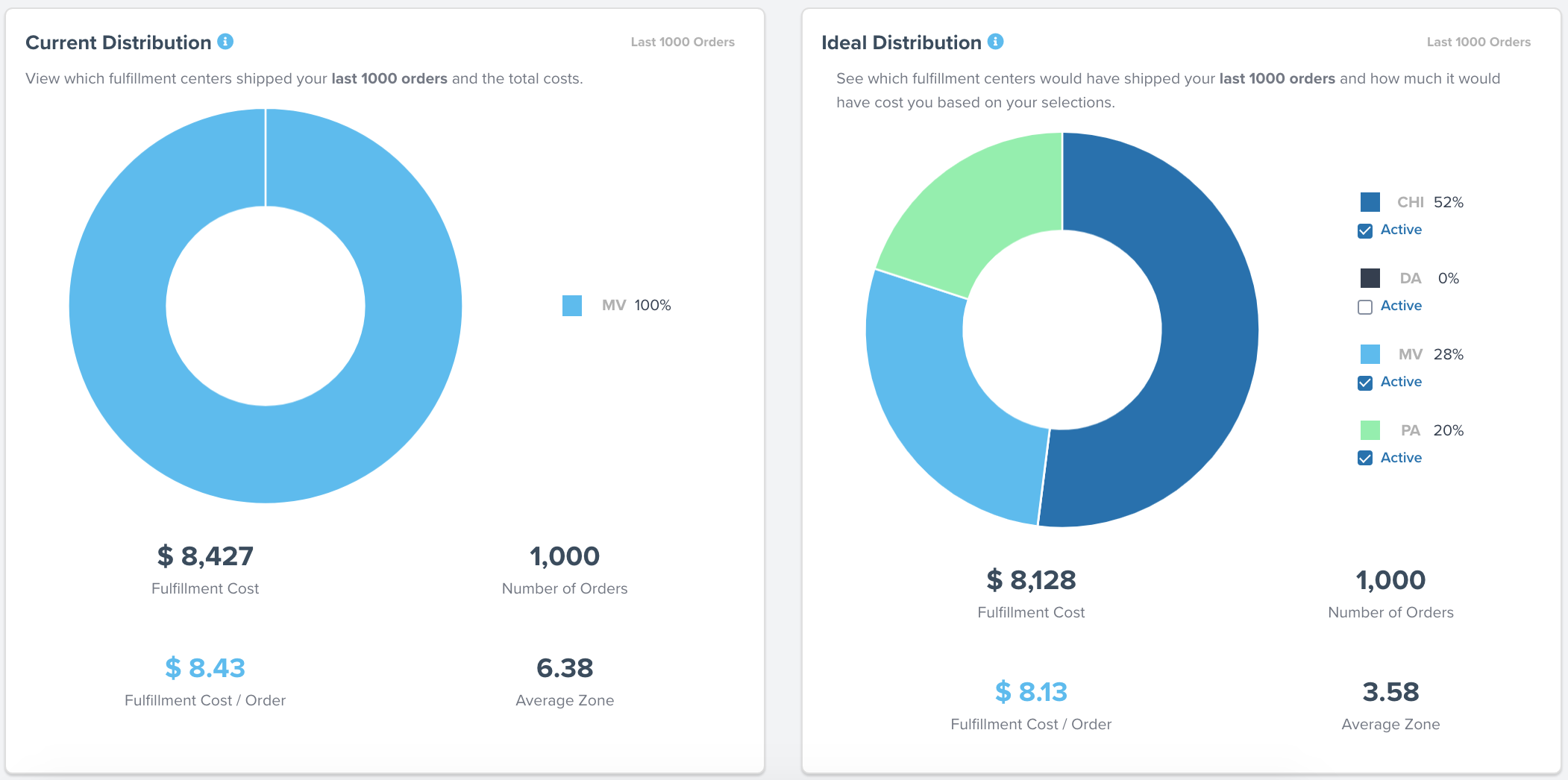

Best of all, with our global fulfilment network we provide access to expertise, resources, and data to help you decide how to strategically distribute inventory to improve delivery speeds and reduce shipping costs.

For U.S. orders, you can even use one fulfilment centre and obtain 100% 2-day shipping coverage across the continental US.

For international orders, you can store inventory in Canada, Europe, and Australia to offer faster and affordable shipping.

“If it weren’t for ShipBob, we wouldn’t have the resources to offer the Foundations collection at scale. The resources provided, the time and cost savings, and the shipping speeds that ShipBob provides has been a game-changer for 100 Thieves.”

Jasmine Ortega, Apparel Operations Manager at 100 Thieves

Decentralised supply chain

ShipBob allows you to maintain a decentralised supply chain, so you can focus on other aspects of your operation such as marketing and sales.

With a decentralised supply chain system, you’re given flexibility, visibility, and the opportunity to cut down on logistics costs significantly.

By outsourcing fulfilment to ShipBob, while also managing relationships with suppliers and other vendors, you’re still in the decision-making seat as you expand into new sales channels and geographical locations.

Here are some advantages of partnering with ShipBob to decentralise your supply chain:

- Outsource fulfilment and track inventory in real time by using ShipBob’s built-in inventory management tools.

- Leverage a global network of fulfilment centres to store inventory, so orders are shipped out from the most efficient location.

- View inventory levels by location, oversee SKU management, and forecast demand.

- Take advantage of 30+ integrations to create an end-to-end supply chain solution.

“Outsourcing both retail and DTC order fulfilment to ShipBob really just gave us the flexibility that we needed to effectively grow our business — not just the DTC segment, but the retail segment also. Honestly, it changed the game for us. So we were just thrilled that ShipBob has come to lead the way in providing fulfilment solutions for small to medium sized businesses like ours.”

Nathan Garrison, Co-Founder and CEO of Sharkbanz

Advanced supply chain technology

ShipBob provides you with robust technology that gives you full visibility into your supply chain along with advanced analytics and forecasting capabilities.

At no extra cost, ShipBob’s web-based platform saves you time with reliable and transparent insights to help you with decision-making process, including:

- How to optimally distribute your inventory between different locations.

- When to reorder more inventory to meet future demand.

- When to discontinue slow-moving items.

- And much more.

“We are very impressed by ShipBob’s transparency, simplicity, and intuitive dashboard. ShipBob’s front-end software was the primary decision-making factor for me in choosing them over other fulfilment solutions. Their software is so simple and intuitive, especially as so many 3PLs have either bad or no front-facing software, making it impossible to enter orders, keep track of what’s leaving or entering the warehouse.

It’s fun to see orders shipping out instantaneously. I love how fast and efficient ShipBob is. Their shipping costs are very reasonable, and their platform makes fulfilment feel so easy.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

To learn more about how ShipBob can help you improve your supply chain, request a quote today.

Supply chain performance FAQs

Here are answers to the top questions about supply chain performance.

What are the five measures of supply chain performance?

Every business has its own set of measurements for tracking supply chain performance. However, the five most common measures are perfect order rate, supply chain costs, order fill rate, cash-to-cash cycle time, and inventory turnover.

How do we measure supply chain performance?

You can measure supply chain performance using data and analytics tools, such as an inventory management system, to track KPIs related to supply chain efficiency, inventory turnover, costs, and more. Many 3PLs, like ShipBob, offer data and analytics tools, as well as software integrations, to track supply chain analytics all in one place.

Why is supply chain performance important?

Supply chain performance is important because it can influence your business goals, reduce operating costs, and improve your financial performance.

What factors affect the supply chain?

An ecommerce supply chain is dealing with a constant flow of inventory, from supplier to customer. There are many factors that can affect that supply chain, such as manufacturing delays, warehouse closures, extreme weather and natural disasters, and more.