Table of Contents

** Minutes

What does inventory restocking consist of?

What happens when you don’t have a strong inventory restocking method

3 inventory restocking methods

3 tips for restocking inventory

Automate your inventory restocking with ShipBob

Imagine you run an online store for your premium roasted coffee. On average, you sell 3,000 units of coffee bags a month.

Out of the blue, your order volume doubles. You find yourself scrambling to restock inventory since your best-selling coffee flavours keep going out of stock, losing out on both sales and customer trust.

Being able to replenish stock to meet demand and keep costs low requires a well thought-out strategy.

If you’re struggling to optimise inventory levels, this article walks you through inventory restocking tips and best practices, so you can better manage your supply chain and consistently meet demand.

What is inventory restocking?

Inventory restocking refers to the process of replenishing products at the right time and at the right place based on demand and projected sales.

When done right, it leads to optimisation, ensuring that you don’t miss any sales opportunities without overstocking (which leads to higher carrying costs, dead stock, and other inventory issues).

When you are getting started, you may blindly order a seemingly random quantity of inventory and hope you sell through it. While this method can work for small businesses operating out of their own homes, as you grow you will need a more sophisticated model.

Restocking inventory is more than just ordering more product from a supplier and putting it on the shelves. It requires proper inventory allocation and insights into demand, as well as an understanding of production lead time and how long it takes to receive and store inventory to prepare for retail fulfilment.

What does inventory restocking consist of?

Restocking inventory is a critical cog in the inventory optimisation wheel, but it’s a challenge when you can’t predict the future.

Whether it’s leading up to the holiday shopping season, or an influencer shares your product with their followers, demand can shift at any time, making it hard to anticipate.

However, there are ways to strategically restock inventory based on what you know at the SKU level. Here is an overview of what inventory restocking consists of.

Knowing when to restock

Optimising your replenishment cycle is all about knowing when and how often you should restock inventory. To make a strategic decision, it’s important to implement tools and technology that help you track inventory in real time, especially since ecommerce inventory is constantly moving through the supply chain (and there are often delays along the way).

There are different inventory apps on the market that make it easy to forecast demand based on historical sales trends, so you can make a better judgement call on the best time to reorder at SKU level.

Keep in the mind that you will also have to think through timelines for different stages of the supply chain, from how long it takes to receive inventory from your supplier to how quickly your team can get inventory on the shelves.

Knowing what to restock

Depending on how many SKUs you sell, you might need to take the inventory restocking process a step further. Having an understanding of what items are selling faster than others can help you optimise and restock inventory based on demand.

This helps to avoid stocking the same amount of each product, even though one item might be a slower seller. You may also find certain SKUs rarely sell and may save you money to discontinue them.

Implementing ways to gain full visibility into inventory levels can also help you understand where there is most demand (especially if you store inventory across different locations).

Knowing how to restock

Knowing how to restock inventory efficiently and quickly requires the support of a team and technology. Inventory restocking is more than simply reordering stock — you have to consider your inventory storage and receiving processes and how quickly you can get inventory prepared to sell.

If you are going to ramp up, you may place a larger order of inventory. Will you have adequate space for it? Will you need to reorganise or re-rack your warehouse? Making changes to warehouse setup can take a long time and a lot of planning.

Another process that impacts inventory restocking is how efficiently you manage returns. Returns need to be processed quickly, so you understand how many items returned are sellable and can be placed back on the shelves for future sales.

What happens when you don’t have a strong inventory restocking method

Poor inventory restocking processes can negatively impact your store’s bottom line, from losing out on sales to overspending on logistics costs.

By failing to implement stock control processes and improving inventory accuracy, you will face several inventory management issues that can impact inventory restocking.

Here are the most common inventory restocking challenges.

Inventory stockouts

When you fail to order inventory on time, you risk dealing with stockouts. Stockout costs can be significant, especially when it happens on a regular basis, leading to lost customers, canceled orders, and sometimes even negative online customer reviews.

One of the many ways to avoid stockouts is to calculate how much safety stock makes sense to store. That way, if there is a sudden surge in demand, you have extra inventory to avoid any fulfilment delays. You should also take supply chain issues into account, knowing that shipping from overseas comes with its own set of challenges (e.g., delays at ports).

To accurately calculate safety stock, all you need is the following information:

- Maximum daily usage

- Maximum lead time

- Average daily usage

- Average lead time

From there, you can use this formula to get an accurate safety stock calculation:

(Maximum daily usage x maximum lead time) – (average daily usage x average lead time) = safety stock amount

Overstocking inventory

Inventory management is all about optimising inventory levels — which can be a constant balancing act.

Overstocking can be just as harmful as dealing with stockouts. Though you will be able to meet demand, it can cut into profit margins by draining resources and your budget. Not only are you overpaying for inventory storage, you risk accumulating dead stock, which refers to inventory that becomes unsellable (whether items exceed their expiration date or go out of season).

You will also have too much capital tied up to inventory, which impacts cash flow and how quickly your business can grow.

Increased order fulfilment costs

You might not realise it, but poor inventory management can also lead to higher fulfilment costs, as receiving, storing, picking, packing, and shipping are all impacted by how efficiently you restock inventory.

Let’s say a customer ordered a few items from your store, but one of the items is out of stock. This can lead to what’s known as a split shipment, which consists of one item being fulfiled before the other or from a different location. With a split shipment, you’re paying more for shipping as there are two separate packages (and it doesn’t make a great customer experience either).

If you store inventory in multiple locations, it’s important to know where to store certain SKUs, as well as how much. This helps to ensure you have the right inventory in the right place to meet demand.

When you have enough inventory to meet demand in key locations, you can optimise your shipping strategy by reducing shipping costs and transit times.

3 inventory restocking methods

Getting inventory restocked on time is important for all online retailers, big or small. As a general rule, the more data-driven your restocking method is, the better. But there are several ways to establish an inventory restocking method based on your brand’s resources and needs.

Periodic inventory restocking method

Small businesses with low order volumes often use a periodic inventory system. This inventory valuation method refers to when the business’s inventory and cost of goods sold (COGS) are not updated in the accounting records after each sale and/or inventory purchase.

This simple restocking method calls for inventory to be replenished regularly after a set period of time (e.g., each month, quarter, or year). This means, even if the inventory suddenly dips to dangerously low levels, the replenishment will not happen until the designated accounting period has passed.

Though this method is easy to implement and requires minimal data, it does not implement real-time inventory tracking, so it can be hard to pull data and make decisions when stock levels are not up to date.

Top-off restocking method

If you have a lot of fast-moving SKUs, the top-off strategy is likely to work well for your business. Also known as the “lean time replenishment” method, it ensures a high inventory turnover rate and low days sales in inventory while reducing the risk of stockouts.

Using this method, retailers replenish stock to acceptable levels at each storage location, every time there is a dip in demand. During the slow periods, the efforts of picking staff who will have less orders to fulfil can be can be redirected towards replenishment.

This method is also great for improving efficiency during busy holiday shopping season.

Profit-based restocking method

Using the profit-based restocking method, you decide whether to restock the inventory (or not) based on how profitable the SKU is.

If your inventory analysis shows that a certain SKU leads to more profit, then you will ensure that your storage facilities have enough stock at all times. For this method to work, you will need to be able to regularly track sales profitability by SKU.

Demand restocking method

The demand restocking method refers to restocking based on future demand predictions.

To be able to fill everyday orders and meet future demand fluctuations, it’s also recommended you maintain healthy levels of buffer inventory, which reduces the risk of a stockout in case of a sudden increase in demand.

3 tips for restocking inventory

Poor restocking processes can be harmful to retailers. When you fail to restock inventory accordingly, the risk of losing sales opportunities, diminishing customer loyalty, and increasing ecommerce warehousing costs is higher.

Here are some tips on how to optimise your inventory restocking processes to reduce risk and meet demand.

Implement an inventory management system

As you expand your supply chain with multiple warehouse locations and different sales channels, restocking accordingly becomes even more challenging. Most online brands implement inventory management software to streamline inventory, orders, and shipment processes.

Inventory management software also helps save time by automating inventory tracking, which also reduces human error by taking out manual work.

Overall, tools and technology can help you secure a broad view of the inventory at all stages of the supply chain, so you know what and when to restock.

Leverage inventory data

Having data at your fingertips is very important. Inventory data allows you to analyse past trends, predict future demand, and adjust your inventory levels accordingly.

For example, if you routinely face out-of-stock issues around the holidays, you can use data from last Q4 to determine how much more inventory you need to have on hand for the upcoming holiday season, while factoring in your current growth rate.

You can also use inventory data for other initiatives, including inventory reporting or deciding when to run your next promotion, such as a flash sale to deplete older products.

Carry out regular inventory audits

Inventory audits are the process of cross-checking your business’s financial and inventory records against actual inventory levels, so you can gain further inventory visibility.

Conducting inventory audits allows you to identify inefficiencies or inventory shrinkage, calculate profit, and reorder accordingly. It can be done by simply counting physical stock to see if it matches how much you believe you should have.

Automate your inventory restocking with ShipBob

ShipBob’s entire fulfilment network is operated by a proprietary tech stack that makes it easy track inventory in real time, view data and analytics, forecast demand, and restock inventory.

With ShipBob, you get access to inventory automation tools to save time and money while optimising healthy inventory levels across multiple fulfilment locations.

Here is an overview of how ShipBob automates parts of the inventory restocking process while fulfiling orders.

1. Full access to inventory analytics

Having full visibility into inventory data and analytics is key. Without taking a data-driven approach to inventory management, it can be challenging to make the right decisions to meet demand and optimise costs.

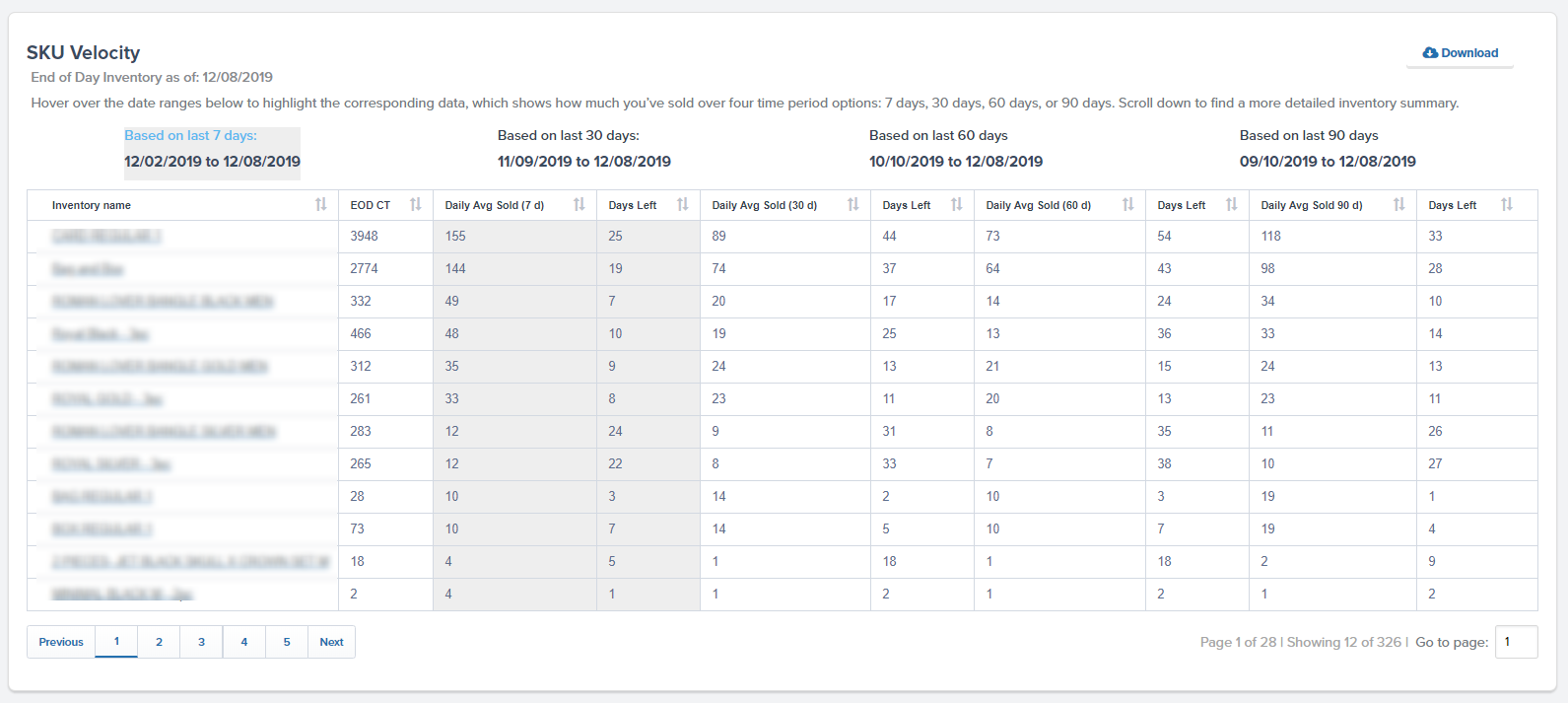

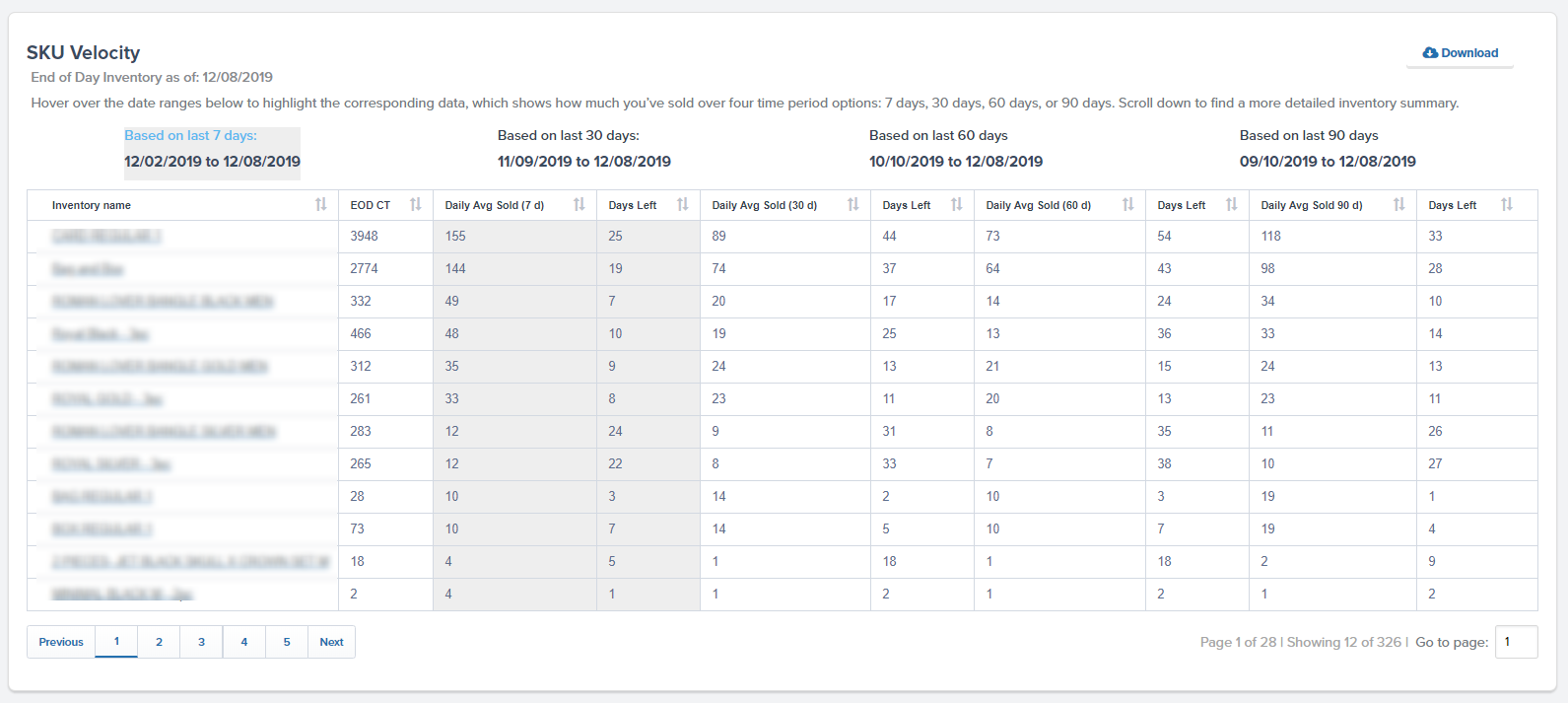

ShipBob allows you track inventory at every stage, so you know which inventory is in transit, how much is available per location, average units sold per days, days of inventory left, when it’s time to reorder, and much more.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

2. Use reorder notification points

When should you order the next batch of inventory? Order too soon and you are overstocked, too late and you stock out. Knowing when to restock inventory is key, but it can be a time-consuming process to keep up with, especially since inventory levels constantly change.

ShipBob makes it easy to monitor inventory levels in real time, all from one dashboard. With our built-in inventory management system, you can use historical data to determine the best time to restock and set automatic reorder notification points. Every time your inventory drops to the reorder point level, you will be notified and advised to restock.

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

3. Get demand forecasting data

With proper inventory forecastingtools, you can make data-driven decisions on how much stock to reorder and when. ShipBob makes it easier to forecast demand by aggregating historical order data and trends.

From the ShipBob dashboard, you can better understand SKU velocity, the impact of recent promotions on stock levels, how to prioritise which items to order next, and much more.

4. Leverage automatic safety stock settings

It’s never a good idea to wait until you run out of inventory before ordering more, because it can take days, weeks, and most recently months to acquire more product.

ShipBob offers real-time tracking of stock levels and the ability to access data needed to calculate your ideal reorder quantity. From there, you can determine the optimal amount of safety stock you need and set automatic reorder points to avoid stockouts.

5. Receiving new inventory

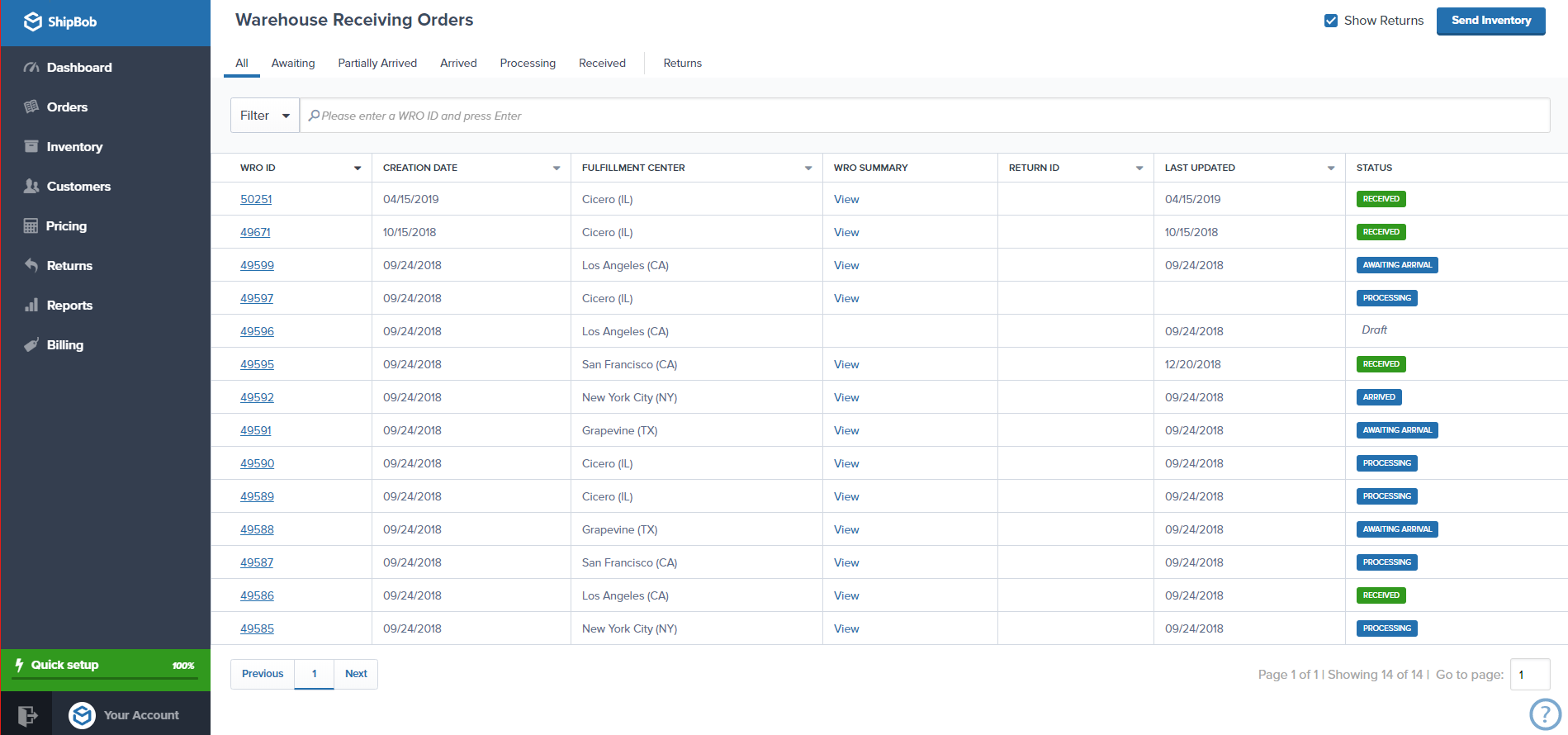

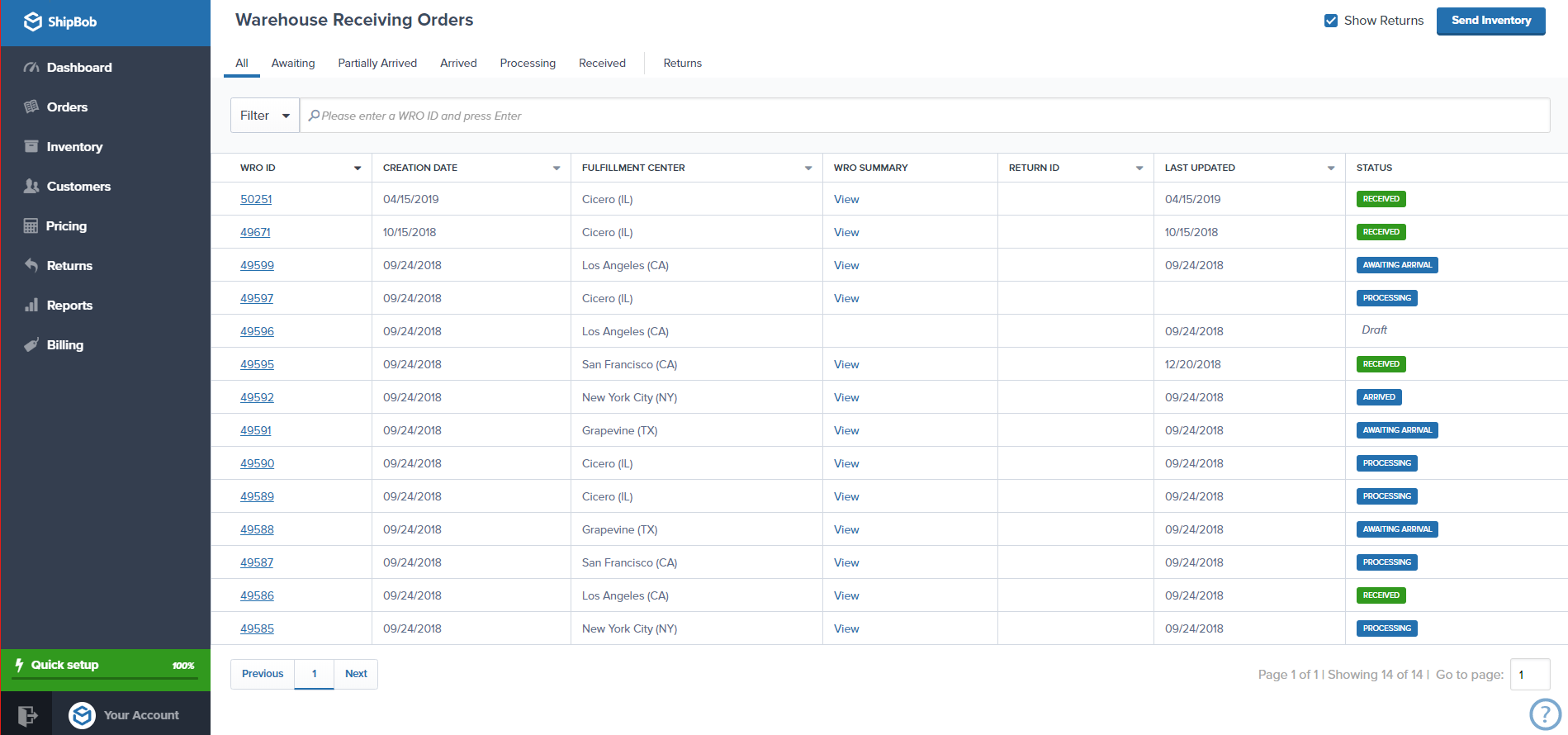

ShipBob takes the warehouse receiving process seriously so inventory is stocked and prepared for fulfilment quickly. ShipBob’s facilitates a proven warehouse receiving order (WRO) process designed to have your inventory sent efficiently to our fulfilment centres.

Once it arrives, your inventory is unloaded, checked, and unpacked by our fulfilment experts. Inventory is then stowed, and inventory levels are updated in the ShipBob dashboard. From there, you can track the status of all WROs and check if WRO was received on time based on our service level agreements (SLA).

“We download Excel files from the ShipBob dashboard all the time and use them to analyse everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time. Even the way their warehouse receiving orders (WROs) work for sending inventory is very straightforward.”

Ines Guien, Vice President of Operations at Dossier

Get started with ShipBob

If you’re spending a lot of time and resources trying to keep up with managing inventory, ShipBob can help.

By outsourcing fulfilment to ShipBob, you get access to best-in-class 3PL services beyond picking. packing, and kitting, including analytics to help you optimise inventory levels, keep logistics and storage costs low, and speed up fulfilment.

Since ShipBob’s entire fulfilment network is powered by the same proprietary technology, you can easily expand into new fulfilment locations and track all inventory from a single dashboard.

To learn more about how ShipBob can help you optimise your supply chain, click the button below for more information and custom pricing.

Improve inventory management with ShipBob’s WMS

For brands looking to store inventory and fulfil orders within their own warehouses, ShipBob’s warehouse management system (WMS) can provide better visibility and organisation.

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfilment network) to streamline in-house inventory management and fulfilment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

For brands looking to scale internationally, ShipBob even offers a hybrid solution where merchants can employ ShipBob’s WMS technology in their own warehouses while simultaneously leveraging ShipBob’s fulfilment services in any of ShipBob’s fulfilment centres across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Restocking inventory FAQs

It may seem fairly simple, but getting inventory restocked is more than just placing an order with your supplier. Here are responses to some of the commonly asked questions related to inventory restocking.

How often should you restock your inventory?

How often and how much inventory you restock is based on several factors, including your warehousing space and costs, typical and planned order volume, inventory days on hand, products themselves (e.g., if they have expiration dates), product profitability, supplier lead times, and available capital. Using an inventory management system provides you with the insights you need to determine how often you should restock inventory based on historical information.

How can you automate inventory restocking?

There are several ways to automate inventory restocking. One the most common ways is to determine inventory days on hand and forecast demand, then set automatic reorder points using an inventory management tool.

If you partner with a 3PL like ShipBob, automating inventory restocking is made much easier. For instance, ShipBob makes it easy to track inventory in real time, forecast demand, and set automatic reorder points, so you will be notified when it’s time to reorder more inventory.

What’s the best way to avoid stockouts?

To avoid stockouts, you need to make data-driven inventory restocking decisions. By using tools and technology to track inventory in real time and provide historical inventory insights, you can determine what products are in the highest demand.

From there, you can determine the best time to restock inventory at the SKU level. You can even determine which products and how much to store in different warehouse locations if you use a distributed inventory model. It’s always a good idea to calculate how much safety stock makes sense to have on hand in case of a sudden surge in demand.

What’s the best method for inventory restocking?

There are several great methods to help you restock inventory efficiently, and the method you choose depends on the size of your business. When businesses first start out, they often use a periodic inventory method. However, as your business grows, you will need technology and automation tools to optimise inventory and decide when to restock inventory based on real-time data.

Being able to track inventory in real time, access inventory forecasting insights, and set automatic reorder notifications using an inventory management software can help you further optimise inventory and ensure you restock on time.