Inventory Control Guide

Ecommerce businesses that take advantage of real-time supply chain data will reduce costs, improve customer satisfaction, and ultimately take a proactive approach to inventory control.

Learn how inventory control can help your ecommerce business flourish.

So, what do you want to learn?

Request Fulfillment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfillment expert will get back to you shortly. Privacy Policy

What is inventory control?

Inventory control is the process of optimizing inventory storage to ensure a business has the ideal inventory levels needed to fulfill customer orders on time. The goal of inventory control is for brands to keep only the necessary units on hand without spending too much money upfront or sacrificing customer satisfaction.

Inventory control vs. inventory management

Though very similar, inventory control is one part of inventory management.

Inventory control is focused more at the operations-level and very involved in warehouse system management, from scanning in new items in real-time on the warehouse floor to preparing units for kitting and assembly.

Inventory management is the high level oversight of inventory, from raw materials to stocked goods. It includes ordering and restocking inventory, strategically selecting locations and facilities to store product, inventory forecasting, and more.

Inventory management software generates inventory reports, automates tracking, and helps to identify areas of improvement. An inventory solution management system helps with inventory control across stores and warehouses.

4 reasons why inventory control is important

When you get inventory control right, you reduce costs, free up capital, improve warehousing, and keep customers happy. Here are a few ways inventory control helps ecommerce businesses.

1. Keeps counts accurate

Inventory control provides an accurate reflection of all units on hand. The best way to do this is by using a digital inventory system that electronically scans in barcodes of both new inventory and the retrieval of each unit picked in an order. This way, real-time inventory stock levels can be reported on at any time.

2. Helps you make the right inventory management decisions

Inventory control is more than just tracking inventory. It also takes inventory turnover into account, or how quickly inventory is sold and replaced in a specific time period. Sales are never going to be 100% linear, so you must continuously measure changes over time to adjust the rate and quantities at which you replenish.

Inventory control helps connect the upstream activities of purchasing and manufacturing to the downstream activities of sales and product demand to prevent bottlenecks, speed up processes, identify slow-moving or obsolete items, and even help evaluate suppliers.

3. Eliminates write-offs

Inventory control directly affects inventory accounting, which measures the changes in the value of physical inventory and costs of goods sold over time. Proper inventory control prevents inventory write-offs for inventory that no longer has value by reducing waste, making it easy to calculate inventory value, and helping your bottom line by only carrying inventory that you need.

“We utilize ShipBob’s Inventory API, which allows us to programmatically retrieve real-time data on how many units of each product are currently stored at ShipBob’s warehouses. We currently use this API to generate custom reports to tie this inventory data into our accounting platforms.”

Waveform Lighting Team

4. Ensures you have enough units to fulfill orders

Proper inventory stock control aims to let you hold the least amount of inventory in your warehouse(s), yet enough to keep up with demand. This accounts for safety stock, as the last thing you want to do is fulfill orders late or keep customers waiting.

Inventory control and demand forecasting go hand in hand — you won’t be stuck paying high storage or inventory carrying costs, but you also won’t add the dreaded “out-of-stock” message to your product page.

6 essential inventory control methods and best practices

Inventory control impacts your inbound and outbound logistics processes, sales, operations, customer satisfaction, and bottom line. Having an inventory control system in place helps refine your operations and understand the best cadence for purchase orders. Here are the best practices for efficient inventory control.

1. Incorporate real-time inventory tracking

Inventory tracking refers to monitoring stock levels and knowing where individual products are stored in a warehouse. Inventory tracking must be done in real time so that you know how much product can be shipped if a customer ordered an item now, make fast decisions if you need to send units elsewhere, and communicate any delays if items are out-of-stock.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours. For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

2. Set reorder points

Reorder points establish the stock level at which you need to order more inventory to prevent stockouts. This is done for each individual SKU since some products will be hot sellers and others will rarely sell. Automated re-ordering means less manual monitoring and more timely ordering.

3. Issue quality control

Order quality control helps you stay on top of suppliers, monitor each batch of inventory, make better decisions around future sales orders, keep customers happy, and meet any regulatory requirements. Inventory control makes quality control a lot easier. When you know exactly how many units you have and where each unit of inventory is located, you can react in the event of a product recall. You can also cross-reference that your records match up to actuals.

4. Designate stocked and non-stocked items

Whether you run a seasonal business or a high-growth brand, inventory optimization is important as your inventory needs will change throughout the year. For example, an apparel company will likely not stock winter coats in early summer since it wouldn’t be cost-effective. However, some clothing items will need to be stocked year round like jeans or t-shirts. Non-stocked items, or those that will be sold on an inconsistent basis, will require a different process of inventory control.

Not all SKUs are the same and won’t need to be ordered in the same quantities or replenished as quickly as others. You may even find you should discontinue certain SKUs that are costing you a lot of money throughout the supply chain but bringing in very little revenue.

5. Enact zoning

If you keep order fulfillment in-house (and don’t outsource fulfillment), you will have to invest in the infrastructure to scale your warehouse for greater efficiencies. For businesses that have a high SKU count and diverse product catalog, zoning can be critical to keeping your products organized and easy-to-find.

How you store items, the layout of the warehouse, and the proximity of certain items will impact operations, picking lists, and productivity. Zoning helps designated spaces for specific areas, such as those requiring refrigeration, storing hazardous materials or dangerous goods, separating out the same product by lot number or expiration date, or simply keeping SKUs that are bundled or ordered often close to one another.

6. Perform regular audits

Inventory control provides the ability to audit inventory in a streamlined way, so you can discover potential issues quicker or before they arise. With a well-organized space, stringent record-keeping, and inventory management software, you can regularly audit and automate stock levels for better inventory control.

3 common inventory control challenges

Like anything in life that lacks control, chaos can ensue. Below are the most common inventory control challenges to look out for.

1. Lack of visibility

Not knowing or being able to see at a glance where inventory physically is, how many units you have on hand, and what you’ve sold across each online and offline channel can cause major bottlenecks across your supply chain.

Without real-time unit counts, integrated systems, and an organized management system, many brands manage inventory blindly, which leads to over-selling and stockouts. This can also prevent you from reordering inventory in time from your manufacturer or supplier, and even knowing when inventory will arrive from them.

2. Lack of traceability

Not only does poor inventory control reduce the transparency of stock, it also may pose more serious risks to health and product safety. Without control measures like lot numbers for products that can harm people (especially those that can be eaten or ingested), products may not easily be able to be tracked down in the event of a product recall or contamination issue.

This can have serious repercussions for consumers and legal ramifications for your business. Inventory control through lot tracking also helps you stay organized with identifying which products you want to ship out first — for example, those with the closest expiration date or with the oldest branding.

3. The more you have, the harder it is to control

Small businesses that can fit inventory in their own homes often lack the right inventory control tools, but as a business grows and acquires more inventory, the harder it may actually become to manage it.

- The more you grow, the faster you turn around inventory and more units you need and more frequently you replenish it.

- The more you expand your product line and higher SKU count you have, the harder it is to stay on top of everything.

Of course, more inventory does not always lead to higher sales, more profit, or a greater return on investment. Each SKU needs proper, individual storage, and they don’t all turn over at the same rate. Being able to track basic inventory KPIs can help you gain more control over your inventory, leading to new insights you may not have realized.

Inventory control systems you need to know

There are many inventory control systems ecommerce brands can implement, but the two main inventory control systems or methods include perpetual and periodic inventory, which also have inventory accounting implications.

A perpetual inventory system records when stock is sold or received in real-time through the use of an inventory management system that automates the process. A perpetual inventory system will record changes in inventory at the time of the transaction.

A periodic inventory system on the other hand is when the business’s inventory and cost of goods sold (COGS) are not updated in the accounting records after each sale and/or inventory purchase — but rather the income statement is updated after a designated accounting period has passed.

Your inventory strategy will vary depending on your unique needs, but to meet today’s ecommerce workflow, you’ll want a dependable way to track inventory.

Managing inventory with ShipBob’s easy inventory control software

ShipBob is a third-party logistics (3PL) company that provides integrated inventory management software in addition to a network of fulfillment centers where ecommerce brands can connect their online store(s) and send their inventory for ShipBob to store, pick, pack, and ship orders.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

From the ShipBob dashboard, you can view SKU velocity and get an overview of performance over time and calculate the days of inventory on hand remaining, so you can better forecast demand and set proper reorder notification points based on historical data.

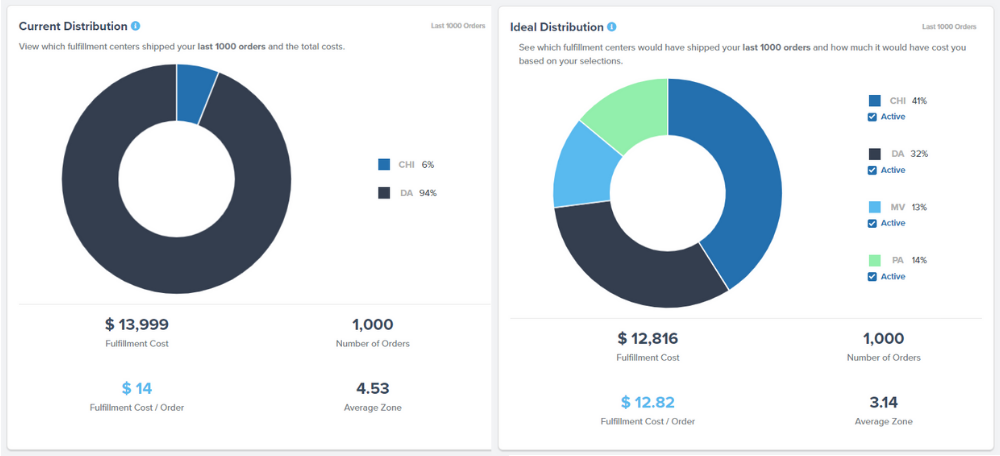

ShipBob also makes it easy to take a data-driven approach to inventory distribution. By aggregating historical order data, you get an analysis of which fulfillment centers you should stock to best leverage ShipBob’s network of fulfillment centers for the most cost-effective and fast deliveries.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

ShipBob’s inventory control system lets you set up reorder points to ensure you reorder in time, putting real-time customer demand and inventory replenishment parameters into place. As an end-to-end fulfillment provider, ShipBob handles every step of the ecommerce fulfillment process.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

Conclusion

Inventory control is no easy task. Too much inventory and you lack funds to invest in other areas of the business or risk dead stock; too little inventory and you lose potential sales, cause massive delays, and customer satisfaction levels plummet.

Inventory control requires input and output from operations that lines up with demand, promotions, and finances. You can bring in tons of sales, but without inventory control, your business’s profitability will take a hit and likely be unsustainable. To be more efficient, you need to invest in the processes and tools that improve inventory control.