Table of Contents

** Minutes

First-mile vs. last-mile delivery: what’s the difference?

Why first-mile delivery is important for ecommerce

First-mile delivery best practices to optimize your supply chain

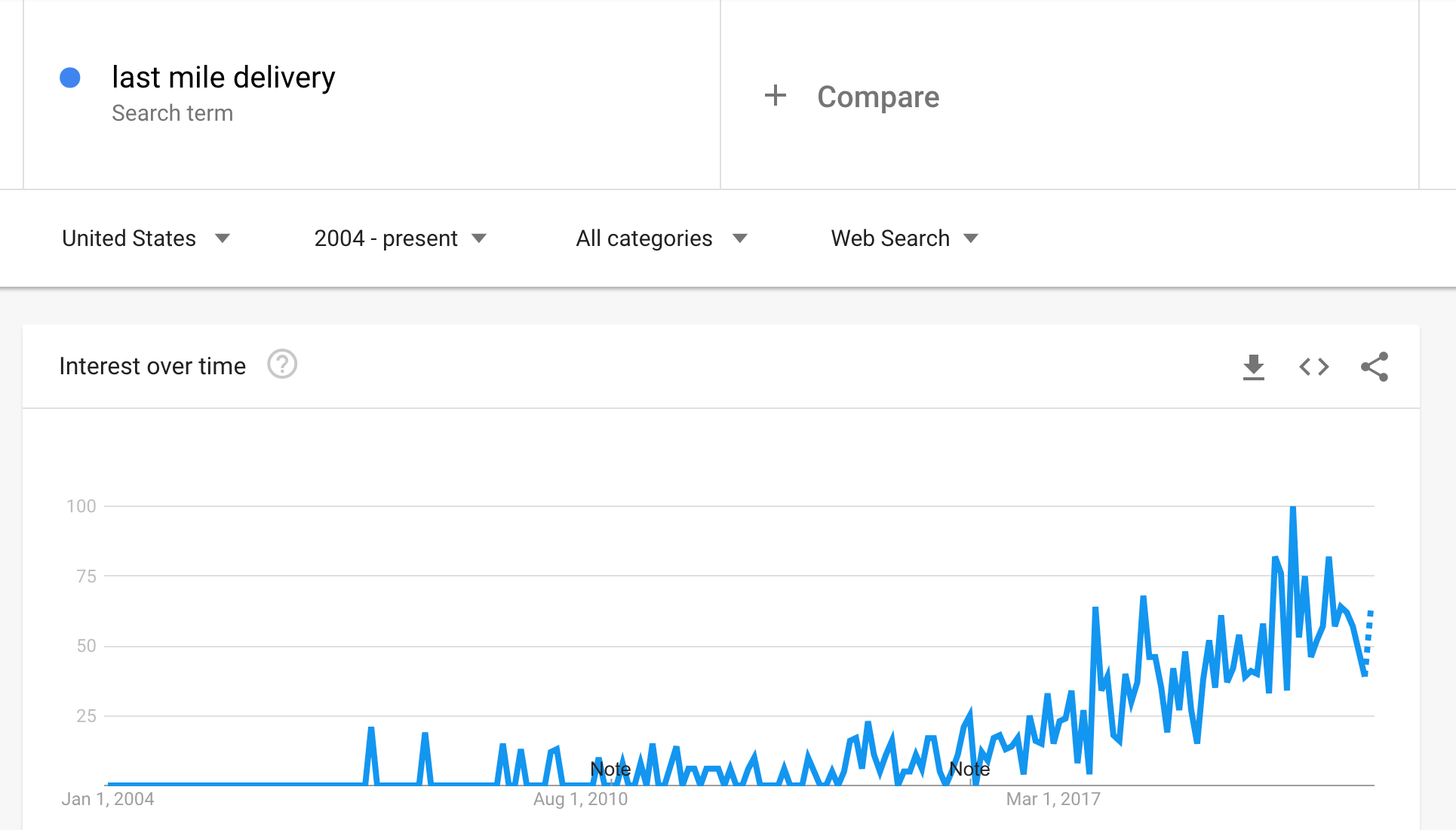

In ecommerce logistics, there’s been a lot of buzz on the topic of last-mile delivery.

Take a look at how ‘last-mile delivery’ Google searches have grown over the last four years:

It’s understandable — efficient last-mile delivery has a direct impact on customer loyalty and profitability. If a shipment is delayed or a customer receives the wrong item, it can significantly reduce customer satisfaction.

And if a business is paying too much in shipping costs, it can majorly reduce profit margins.

Providing an exceptional delivery experience for customers is a constant balancing act that many fast-growing online retailers struggle with. But what if there was a way to improve last-mile delivery earlier on in theecommerce supply chain?

It turns out the first-mile delivery stage has a direct impact on your shipping experience, and improving it will deliver substantial downstream gains.

In this article, we’ll break down what first-mile delivery is, why it’s important, and six best practices you can use to improve your first-mile delivery process.

What is first-mile delivery?

First-mile delivery refers to the process of transporting finished goods from a manufacturer or supplier’s facility to an online retailer’s warehouse or multiple distribution centers — the last destination before products are delivered to the end user.

It’s typically the first step of order fulfillment and requires thorough supply chain planning, from understanding production lead times to developing a warehouse receiving process.

First-mile delivery also relies strongly on an optimal location. For instance, choosing between a domestic or overseas supplier will impact how quickly you can receive new inventory and where you story inventory based on customer location and demand can impact shipping costs and timelines.

First-mile vs. last-mile delivery: what’s the difference?

When looking at the direct-to-consumer (DTC) model, first-mile deliveries refer to the movement of products from supplier to a retailer, and last-mile deliveries rely on shipping carriers to move packages from the shipper to the end customer.

Another key differentiator is size of shipments. First-mile deliveries typically transport large pallet-sized shipments with unbranded packaging since goods are ordered and transported in bulk or through freight.

Once inventory is delivered to where fulfillment will take place, it’s up to the retail business owner to double check the delivery and ensure what was shipped matches what was ordered. This process is crucial as it ensures there are no inaccuracies in physical inventory counts and helps to avoid inventory shrinkage.

Last-mile deliveries involve smaller, sometimes branded shipments because they mostly transport individual orders to end customers. These orders can also be packaged to emphasize the unboxing experience, which can include custom packaging, marketing inserts, and more.

Why first-mile delivery is important for ecommerce

As the first stage in the supply chain, first-mile delivery has a major impact on a business’s retail fulfillment process.

As 2021 ecommerce sales are set to hit $4.48 trillion in the US alone, it’s becoming more evident that the “first mile” is still inefficient and lacks transparency in many ways.

Inefficient first-mile delivery can have a trickle down effect that will impact supply chain efficiency throughout the fulfillment stage, which can then slow down last-mile delivery.

Some of these inefficiencies often start with improper purchase ordering. For instance, if there is a delay in production or the wrong inventory is delivered, it’s enough to disrupt the rest of your supply chain, especially if you have orders coming in that depend on the next shipment of inventory.

Fortunately, many issues that occur during first-mile delivery can be solved by finding ways to enable more visibility, diversify your supplier network, and execute a thorough warehouse receiving process.

First-mile delivery best practices to optimize your supply chain

Now that you understand the importance of first-mile delivery, here are some best practices that can help optimize first-mile delivery for a more resilient supply chain.

1. Partner with a tech-enabled 3PL

It’s always an option to manage logistics yourself, but if you’re ordering large volumes of inventory and dealing with a high order volume, you’re going to need the space and the support from an expert.

A technology-enabled 3PL like ShipBob handles all the logistics associated with warehousing, fulfillment, and shipping.

When you first get started with a 3PL, you can determine which locations within their logistics network you’d like to store inventory in.

From there, you can have inventory delivered from your supplier directly to the fulfillment center, where logistics experts will conduct a thorough inventory receiving check to ensure what was ordered matches the paperwork.

For instance, ShipBob’s global fulfillment network makes it easy for brands to allocate inventory based on where their customers are located.

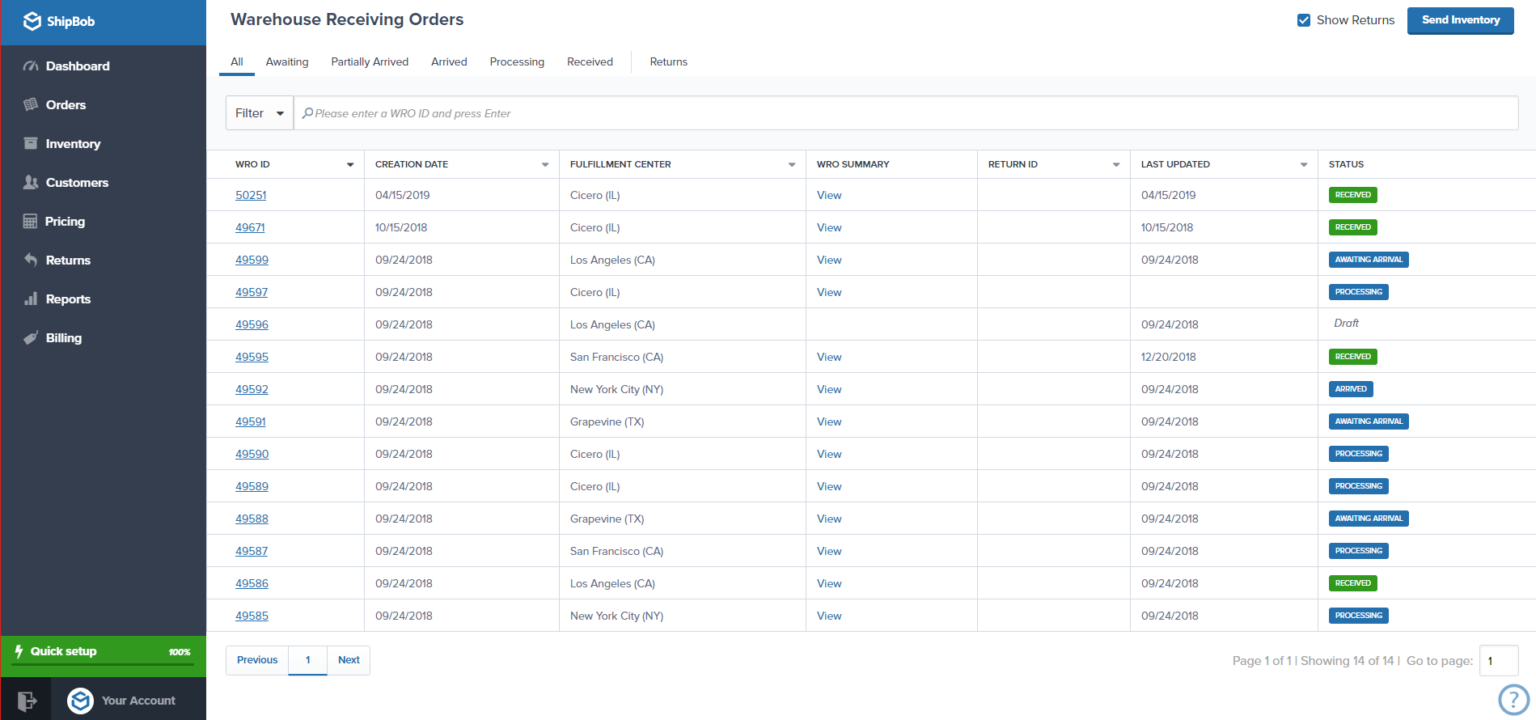

To ensure the completion of a smooth first-mile delivery, ShipBob’s WRO system (for warehouse receiving orders) is designed to make sure you have the information you need to send us your inventory, so everything is accounted for and stowed away properly.

Once inventory is received, you can track real-time inventory flow from your ShipBob dashboard. Since all inventory and order data is aggregated in one place, you can pull inventory records and determine the optimal time to replenish inventory and set automation reorder notifications when inventory is running low.

“In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order. The analytics are super helpful.

We download Excel files from the ShipBob dashboard all the time and use them to analyze everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time.

Even the way their warehouse receiving orders (WROs) work for sending inventory is very straightforward.”

Ines Guien, Vice President of Operations at Dossier

2. Map out your supply chain process

One of the ways you can optimize your supply chain is by mapping it out, starting with first-mile delivery.

By going through each step of your existing supply chain closely, you’ll be able to identify where the inefficiencies lie and the steps needed to optimize and improve processes.

For example, let’s say that your warehouse team contacts your supplier when your stock is running low to restock inventory, but it’s all done manually.

Since the manual process is time-consuming, it’s prone to human error. At this point, you might want to consider automation and other types of supply chain technology to reduce the manual work associated with reordering inventory and also cut down on human error.

3. Create a clear warehouse receiving process

Another first-mile delivery optimization best practice is to a develop a thorough warehouse receiving process, which is important for accurate inventory tracking; it outlines how you or your warehouse team will receive inventory shipments sent by your supplier.

Here is an overview of the basics steps:

- Complete pre-receiving tasks: Determine how much of each item will be shipped in how many containers, as well as packaging requirements for each item (e.g., labeling criteria, the number of packages loaded per pallet, and acceptable package sizes and weights).

- Receive and unload stock: Meet with the shipper and unload the necessary cargo; double check inventory received against paperwork.

- Organize and store new inventory: Store inventory in a way that will help speed up warehouse picking.

4. Collect the right data

To optimize your first-mile delivery process effectively, you will need a system in place to collect data and report on key distribution metrics.

There are several ways to digest supply chain data and information. Here are a few metrics you can use to evaluate how well first-mile delivery process is performing:

- Time to ship: The number of days it takes for your supplier to ship stock after an order is placed.

- Time to stock: The time it takes to break down pallet loads and stock inventory that’s ready to be shipped.

- Transit damage rate: The number of products shipped by your supplier that are damaged in transit.

Much of this can be tracked by implementing an inventory management software or a warehouse management system (WMS).

Or, you can simply outsource fulfillment to gain more visibility. For instance, ShipBob offers merchants access to data and analytics reporting that provides insights into their operations without needing to be involved in the day-to-day.

“Now we’re at two ShipBob fulfillment centers, and being able to have the analytics and see how everything is working together has been extremely helpful for me on the operations end. It definitely helps me with inventory management and seeing what’s going on.

It truly helped us on a day-to-day basis. Even though we’ve grown, I haven’t spent more time on the business from an operations standpoint.”

Dana Varrone, Director of Operations at Organic Olivia

5. Select the right packaging

If your inventory isn’t packaged properly for shipping, it doesn’t matter how quickly it arrives at your warehouse since most of it will be damaged. One way to evaluate which supplier to contract for your business is their quality of packaging for your inventory.

Some guidelines that carriers like UPS recommend for freight shipping include:

- Using ample dunnage in each box included in the shipment to prevent breakage.

- Using top and bottom load protectors for your shipments “to evenly distribute the weight of shipments when they are stacked one on top of another.”

- Using corner/edge boards to “increase vertical stacking strength, prevent damage to corner edges, and stabilize the load.”

- Using stretch wrapping to prevent load shifting and stabilize the shipment in transit.

As you build relationships with suppliers, be sure to keep them accountable on their performance and quality of delivery.

6. Create a labeling system

Consistent labeling of your shipments is key to keeping track of all your inventory.

If your supplier labels your products differently from your warehouse or your distribution center, then it will cause problems in identifying how many available SKUs you have of each product and which SKUs you need to reorder when your inventory runs low.

If you work with a 3PL, you might also be required to display labels on your shipments in a certain way to streamline the warehouse receiving process.

For instance, ShipBob requires placement of a WRO label to ensure that labels are visible and don’t obstruct the box flaps to prevent opening the shipment.

Streamlining first-mile & last-mile delivery with ShipBob

One of the biggest challenges of managing logistics systems on your own is that you end up having to deal with different stakeholders, ordering inventory on time, and fulfilling and shipping orders quickly and accurately.

Managing a growing supply chain can be time-consuming, costly, and can pull you away from revenue-driving initiatives.

ShipBob can help.

From receiving inventory to shipping customer orders, ShipBob handles the entire fulfillment process while providing you with full visibility over your logistics operations. Get a glimpse into how ShipBob works with a virtual tour of one of our fulfillment centers:

From the ShipBob dashboard, you easily create a WRO with information on where you’re sending inventory to, the quantities of each SKU being sent, how it will be shipped to ShipBob (e.g., parcel, palletized container, or floor loaded container), and create a box label for each shipment.

You can also track the status of all WROs and check if a WRO was received on time based on our service level agreements (SLA).

“Touchland has been working with ShipBob since 2018 and there are several reasons why ShipBob has been the perfect partner. Overall, we have had a great experience having a ShipBob as a partner that can scale fast with us.”

Andrea Lisbona, Founder & CEO of Touchland

Fast-growing direct-to-consumer brands like Touchland, and Drop FX partner with ShipBob to ship hundreds of thousands of orders across the globe.

Ready to jump on board?

Contact the ShipBob team by clicking the button below and receive more information on how to get started.

First-mile delivery FAQs

Here are answers to some common questions related to first-mile delivery:

What is first-mile delivery?

First-mile delivery refers to the process of moving inventory from a production facility to a warehouse or distribution center. The first-mile delivery relies on effective communication between the supplier and retailer, as well as efficient inventory receiving processes that ensure all inventory that was ordered is accounted for.

Can you outsource first-mile delivery?

Transportation of goods at the first mile is typically handled by suppliers and production facilities through external carriers. Depending on your contract with your supplier, you might have to bear the cost of your first mile shipments.

How long does first-mile delivery take?

It depends on how far your supplier is to your warehouse or fulfillment center(s) and the shipping method they use to transport their shipments. For instance, partnering with suppliers overseas will increase production lead times and the time it takes to receive inventory (or you will have to pay more for expedited shipments).

How much does first-mile delivery cost?

Your first mile delivery costs will depend on how much inventory you choose to order from your supplier and the shipping method used to transport your inventory. It’s cost-effective to order only as much inventory as you need based on forecasted demand to ensure there isn’t too much capital associated with inventory.