Dead stock, spoilage, and obsolete inventory are a regular part of running an ecommerce operation. A little is fine – the trick is keeping them in check.

Without proper inventory control and stock management practices, outdated inventory can quickly get out of hand and cause problems for your brand. Too much unsellable inventory can sit on shelves, rack up high storage costs that eat away at profit margins, and take up valuable shelf space.

This is why many ecommerce warehouses implement stock rotation to ensure that they don’t end up with too much expired or obsolete inventory. In this guide, we take a closer look at what stock rotation means, its impact on fulfilment and shipping, and the best practices to implement it for your ecommerce business.

What is stock rotation?

Stock rotation is the process of reorganizing the goods in your warehouse so certain units of inventory are sold before others. Through stock rotation, a business prioritizes selling older, slower-selling, or perishable units of inventory to keep stock moving through the supply chain and prevent stock losing its viability or going obsolete.

Stock rotation typically follows the First In, First Out (FIFO) principle, where the oldest inventory is shipped out first before you start to ship out newer products. This ensures that perishables and products with an expiration date get sold before they lose their quality.

Some businesses may also implement the Last In, First Out (LIFO) principle of stock rotation. This involves using the newest products first, which is ideal for businesses that handle non-perishable goods and want to maximise operating capacity.

The role of stock rotation in managing inventory levels

Practicing stock rotation forces brands to closely monitor inventory movement through their warehouses. By doing so, brands naturally achieve deeper visibility into their inventory levels, which makes it easier to maintain optimal stock levels.

For example, through rotating your stock, you may discover that you have a lot more of a particular SKU than you thought, or that a certain SKU is selling very slowly. This insight helps prevent you from reordering more of that SKU too soon and accidentally overstocking.

Similarly, you may discover that a lot of inventory currently taking up shelf space is about to expire. By selling those units before any other units of that SKU, you free up space – space which you can use to store more of your best-selling items. That way, you have more of your best-sellers on hand, and can avoid accidental stockouts.

In both these scenarios, and many more, stock rotation enables your brand to optimise your inventory levels and meet customer demand more easily.

How can rotating stock affect fulfilment and shipping?

In warehouses, stock rotation is often a physical task – for instance, workers must move older stock to the front of the shelf or closer to the fulfilment bay. These small rearrangements can have big impacts on warehouse efficiency, as it helps pickers locate and retrieve the correct items on their picking lists, and do so quickly (rather than hunting for the oldest SKU at every pick). allowing for a speedy fulfilment process.

This speeds up the fulfilment process – and with a faster picking process, you can ensure that orders are fulfilled and out the door as quickly as possible. In turn, customers can get their orders on time, which boosts customer satisfaction and encourages repeat purchasing.

Stock rotation best practices for ecommerce

While stock rotation can be highly beneficial for ecommerce businesses, it needs to be implemented and managed correctly. Here are some best practices that can help you get the most out of your stock rotations.

Choose the right stock rotation methods for your business

Stock rotation isn’t a one-way-fits-all game. There are different methods of circulating stock, and depending on your brand’s products, size, and goals, one stock rotation approach may work better than others. For example, a grocery store may not rotate stock in the same way as a business selling landscaping products.

It’s important to figure out the stock rotation tactic that works best for your business. Here are some of the main stock rotation methods that you could consider.

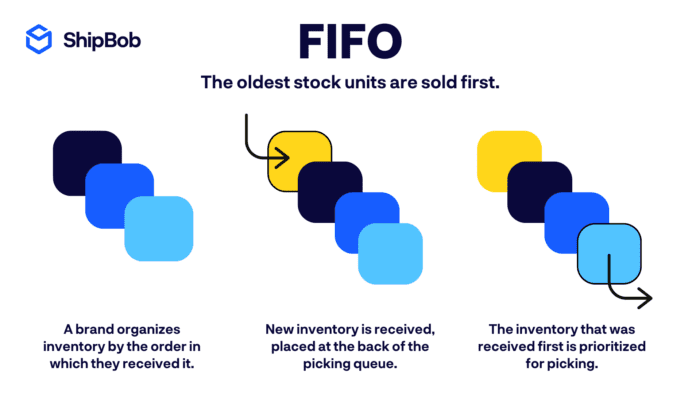

FIFO

As discussed earlier, FIFO (or First In, First Out) involves rotating stock so that the first inventory to come into the warehouse is also the first to get shipped out. Within FIFO, new products that warehouse workers receive are stored at the back of the shelf, which means that older products are pushed forward to be picked and sold first.

FIFO is one of the most common stock rotation methods for most ecommerce retailers – particularly those that sell perishable goods such as food and beverages. FIFO is also ideal for rotating products that aren’t necessarily perishable, but may go out of style or lose value over time. For example, retailers may want to prioritise the sale of certain clothing items before trends shift.

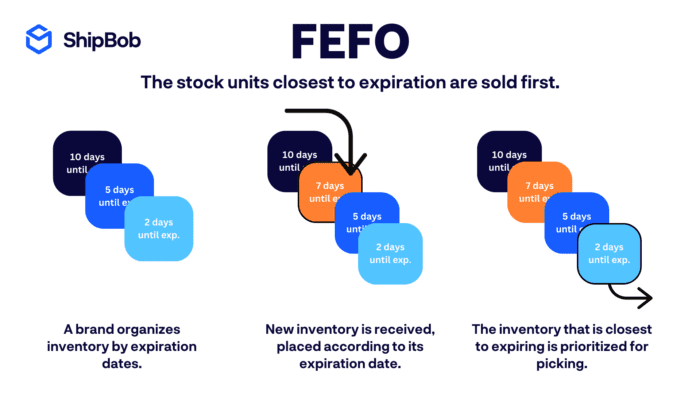

FEFO

FEFO (or First Expired, First Out) involves prioritising the sale of products with impending expiration dates, regardless of when they arrived at the warehouse.

This method assumes that retailers may not be receiving the freshest products every time. As a result, workers check expiration dates to ensure that the freshest goods are stored at the back.

Although this method may be more time-consuming, it’s highly effective for moving perishable products out before they go out-of-date, especially if they have a shorter shelf-life. FEFO is often necessary for food safety, and to maintain product quality.

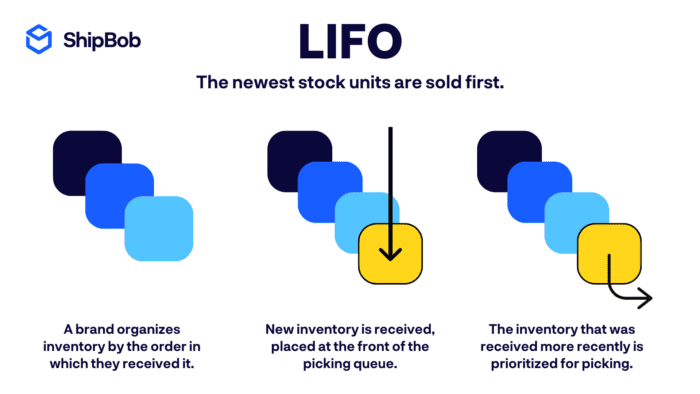

LIFO

If it’s not efficient or necessary for you to rotate inventory, you could use the LIFO (or Last In, First Out) method. Within LIFO, a brand prioritizes selling the last products received in the warehouse – in other words, the newer stock received most recently.

LIFO is most used in warehouses that store fast-moving and/or non-perishable products, as well as items that are heavy and inconvenient to move.

Leverage technology to automate and perfect stock rotation

The right technology can help you streamline your stock rotation system by automating certain aspects of the process. This not only increases your warehouse’s efficiency, but can also improve operational and order accuracy.

Some of the best tools to facilitate stock rotation include:

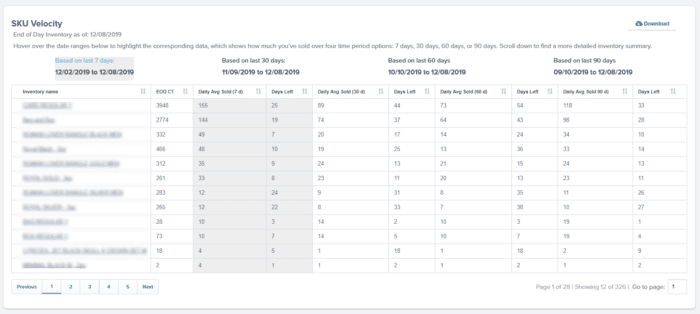

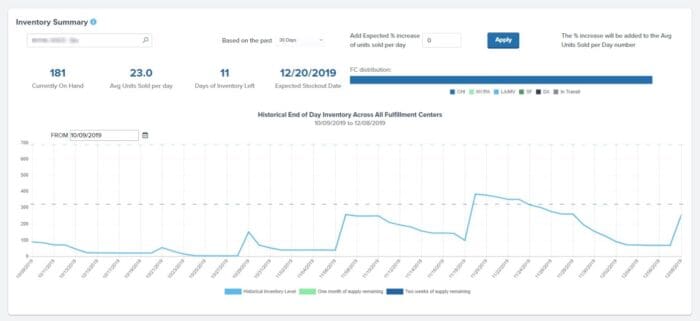

- Inventory management software, which provides SKU-level visibility, perpetual real-time inventory counts, and insight into inventory turnover to prevent stockouts and overstocking.

- Barcode scanning, which helps identify and keep track of all your products as they move through your supply chain.

- Lot numbers, which organise inventory by production or expiration date.

- A warehouse management system (WMS), which powers warehouse operations like picking, packing, and shipping.

Measure the impact of stock rotation regularly

It’s important to constantly measure the impact of stock rotation to ensure that your approach is working. This will allow you to understand whether you need to adjust your approach and keep making improvements to your stock rotation strategy.

A great way to measure stock rotation’s efficacy is to track cost savings. Reducing spoilage and inventory obsolescence by rotating your stock minimises waste and maximises ROI for your stock – so when properly implemented, stock rotation should boost your bottom line.

Tracking other relevant inventory KPIs will also help you measure the impact of stock rotation, including:

- Inventory turnover ratio

- Holding costs

- Stockouts

- Stock to sales ratio

If your rotation strategy is working, you should essentially see a drop in dead stock over time, along with lower holding costs and improved inventory turnover. While some brands track these metrics manually, others leverage expert partners like ShipBob that will automatically record data on storage costs and SKU velocity through a dashboard.

Stock rotation in ShipBob’s fulfilment centres

Stock rotation is easiest when your warehouse operations are primed for it. ShipBob’s tech-enabled, logistics-powered warehouses are designed to optimise inventory management processes like stock rotation, as well as picking, packing, shipping, and other daily tasks for ecommerce brands.

Explore some of the ways that ShipBob’s software delivers better inventory visibility and control to streamline rotation below.

An inventory management dashboard to power stock rotation

ShipBob’s inventory management dashboard supports real-time inventory tracking to facilitate stock rotations. You can use the dashboard to view how many units you have on hand, how many are incoming, and how many are at various stages of fulfilment – all with just a glance. With this visibility, you’ll be able to determine which products to rotate and prioritise.

Moreover, you can use the same dashboard to view inventory status across all the ShipBob fulfilment centres where you have distributed inventory. This will allow you to reallocate some of your older inventory to fulfilment centres that are running low on stock instead of simply reordering new inventory.

“I don’t want to have to ask multiple people for information or wait for reports on stock levels at various locations. Now, I can literally go into my ShipBob dashboard and see exactly what I want to see with a few clicks. I

love that it’s a quick snapshot of everything that’s going on. I can literally not look at the ShipBob platform for 3 weeks, and then log in and within 10 minutes of analising the data, I know exactly where we stand in the business.

Even if I had to crunch some numbers, it would be just pulling a couple of reports and putting that data together – it’s so much easier than other solutions. As a person who relies on data analytics to run my business, I want to see my analytics exactly how ShipBob displays them to me.”

Mithu Kuna, Co-Founder and CEO of Baby Doppler

ShipBob’s lot feature adds another layer of organisation to your stock management efforts, as it allows you to separate lot items according to their expiration date or use-by dates. That way, you can ensure that items with the closest expiration date are shipped out first.

Optimising fulfilment with smart stock rotation

At ShipBob, we leverage technology to automate and streamline order processing and speed up fulfilment.

Once orders are imported from your ecommerce store to ShipBob’s software, inventory is automatically assigned to those orders based on stock availability. Businesses that want to use FIFO have the option to create a customised order processing logic that prioritizes the oldest orders first.

ShipBob’s fulfilment centres also leverage a lot tracking system. Once we receive your warehouse receiving order (WRO), you can assign lot numbers to specific items, and our team will store those items in separate, distinct locations.

Inventory is organised based on production or expiration date, so that items with the closest expiration date are prioritized during fulfilment. That way, you can prevent outdated or expired inventory from piling up and inflating storage costs.

To further help you avoid deadstock, ShipBob can strategically distribute your inventory across our fulfilment centre network. This places your inventory closer to the customers that are ordering those items, enabling you to meet demand more efficiently. You can even reallocate older inventory from one fulfilment centre to another to make sure it gets sold right away.

“ShipBob’s software helped us better understand where we should grow next. In the beginning, it was difficult to easily calculate how much we were selling in each region. ShipBob’s ideal distribution algorithm enabled us to see not only where our customers were based, but where we should allocate inventory to best meet demand.”

Natalia Lara, CMO of Oxford Healthspan

Handling returns

ShipBob’s returns management process also contributes to improved stock rotation. We implement these best practices to respect each brand’s preferences, and prioritise the right items in the picking pool:

- When a customer returns an item to a ShipBob fulfilment centre, you can decide whether you want our team to restock, quarantine, or discard that item.

- For return to sender (RTS) shipments resulting from a carrier delivery failure, ShipBob will automatically restock the items unless instructed otherwise.

- Perishable goods such as food products are disposed of upon receipt.

- To avoid restocking expired or damaged products, we ensure that the package is unopened and undamaged on arrival.

- Returns for items that have expired are processed by either quarantining or disposing of them (depending on your preference).

ShipBob also supports restocking returned to sender lot products. Our team carefully reviews the lot numbers and expiration dates printed on lot products, and ensures that they match the information in the ShipBob dashboard before they restock the item.

Wave goodbye to stale inventory with ShipBob

At ShipBob, you can find fulfilment and inventory management solutions that enable you to rotate stock and minimise dead stock with ease. From enhanced inventory visibility to express shipping, you can get better control over your inventory and how it moves across the supply chain.

Run a tight ship with industry-leading warehouse management software

Brands that run their own warehouses can leverage ShipBob’s proprietary warehouse management software (WMS) to enhance inventory visibility.

The software allows you to see exactly how many units you have for each SKU at various stages of your supply chain, as well as accurate order counts at the picked, packed, and labelled statuses. This level of visibility gives you better control over your inventory, so you’ll be able to effectively plan your procurement, avoid stockouts, and prevent overstocking. Moreover, you can also identify orders that need fulfilment prioritized to keep your stock on the move.

“When we were small, everyone knew what products were called and where they were in the warehouse. But now we have over 200,000 SKUs on our website, 190,000 of which are stowed in our warehouse. It became difficult to make sure everyone was doing fulfilment in the right way. ShipBob’s WMS makes it almost impossible to do things wrong. Eliminating the potential for human error during picking and packing has been great. That was our biggest problem before. Last time I checked, our error rate was less than 1%. We’re shipping out over 10,000 orders per month.”

Clint Sanders, VP of Operations of Bunker Branding

See the wheels in motion using ShipBob’s inventory dashboards

ShipBob’s software features a built-in inventory management system, which delivers key analytics and data through one easy-to-navigate dashboard. Besides location-specific inventory visibility, the dashboard delivers real-time inventory tracking and intelligent cycle counts to improve inventory accuracy and support your stock rotation efforts.

For more information on how ShipBob’s solutions can help you manage your inventory, click the button below.

Stock rotation FAQs

Below are answers to common questions about stock rotation.

How does ShipBob’s fulfilment process ensure effective stock rotation?

At ShipBob, lot items are organised based on expiration date. When fulfilling orders, items with the nearest expiration date are prioritized to ensure effective stock rotation.

Can stock rotation impact the speed of my order fulfilment?

When you organise inventory to support effective stock rotation, you make it easier for pickers to retrieve the prioritized inventory units. This speeds up order fulfilment, as pickers can quickly find and pick the right items, rather than sifting through many different units to find one that’s prioritized.

What stock rotation methods does ShipBob recommend for perishable goods?

Although ShipBob doesn’t fulfil orders for perishable goods, we help ecommerce businesses to manage products with expiration dates using lot tracking. We generally recommend the FIFO method for handling these types of goods.