Table of Contents

** Minutes

Why should ecommerce businesses care about SKU rationalization?

Ever felt the disappointment when you learn that a product you love has been discontinued?

Whether it’s your favourite ice cream flavour, a candle scent, a makeup item, or a unique tea blend, products come and go.

That’s because brands are always reevaluating their product line and optimising inventory based on profitability.

SKU rationalization, also known as “inventory optimisation,” is a key process designed to help increase profits and optimise costs.

This article provides a deep dive into SKU rationalization, including why it’s important, what it entails, plus what businesses can do to improve their overall SKU management process.

What is SKU rationalization?

SKU rationalization is the process of identifying whether a product on the SKU level should be discontinued due to declining sales and overall profitability.

By properly tracking SKU performance over time, businesses can decide whether or not to continue selling a specific SKU by putting systems in place to automatically track ecommerce KPIs specific to a SKU, including procurement costs, customer acquisition costs, storage costs, inventory turnover rate, fulfilment costs, and more.

By understanding a product’s profitability in addition to having the ability to track inventory performance, you can improve the SKU rationalization process and optimise inventory control.

Why should ecommerce businesses care about SKU rationalization?

The more inventory you have on hand, the more capital you have tied to inventory.

And the more SKUs you have, the more complex your inventory management process is. You will need to make more time or hire employees to help with tracking performance for each item, optimising space and tracking the costs associated with each SKU.

Most ecommerce businesses that have been around for a bit can benefit from reevaluating their current product line on a consistent basis. Taking the time do so allows better decision-making.

While reevaluating, they can decide whether or not to discontinue items or even introduce items to meet customer demand, resulting in what’s known as SKU proliferation (i.e., the addition of new SKUs).

As businesses look to improve and refresh their product catalogueueue, SKU rationalization helps cut costs, streamline inventory processes, and ultimately improve profit margins.

Taking the time to determine which SKUs should be discontinued and when results in:

- Optimised storage costs

- Reduced inventory shrinkage

- Less dead stock

- Improved inventory records

- Less capital tied up in inventory

Let’s take a closer look at how SKU rationalization impacts a business’s bottom line.

Reduces inventory carrying costs

Carrying costs include storage fees, insurance, and labour costs, which all accounts for 30% of your inventory costs.

Once you purchase inventory, you have to pay to have it stored and cared for until items are ready to picked, packed, and shipped.

When looking into past sales trends, you can decide how much of each SKU to reorder and when. An automated inventory tracking system can provide the necessary data and analytics needed to calculate inventory turnover rate, which shows how many times inventory is sold and then replaced in a specific time period.

For instance, ShipBob makes it easy to track storage, fulfilment, and other costs across their fulfilment network by tracking inventory activity (what’s incoming and what’s leaving) in real time through a centralised, user-friendly dashboard:

With this information, you can reduce the risk of overstocking and overpaying on any product that’s slow-moving or is on the verge of becoming obsolete inventory.

Streamline inventory management processes

Inventory management is more than tracking inventory on hand; it involves making decisions on individual SKUs, including how to reorder and when (if at all).

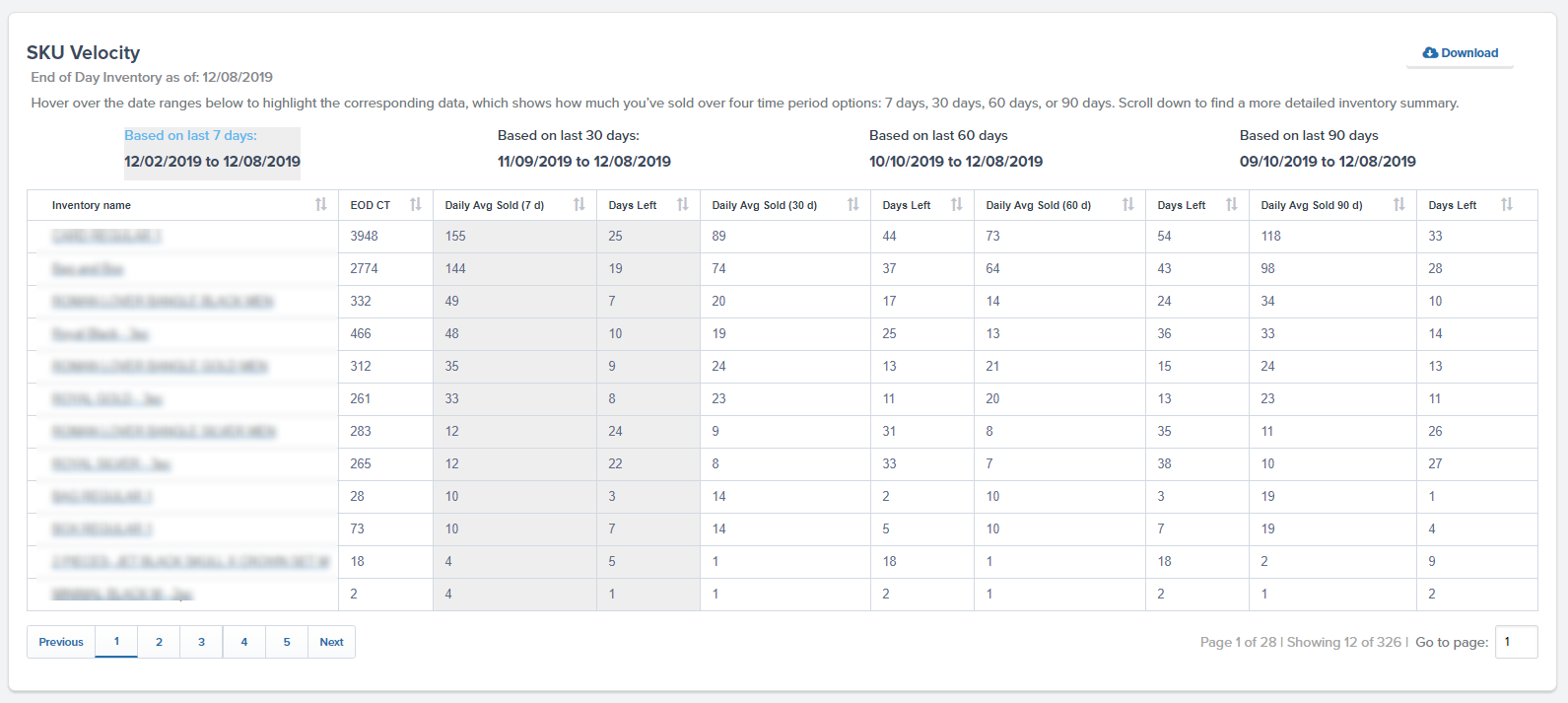

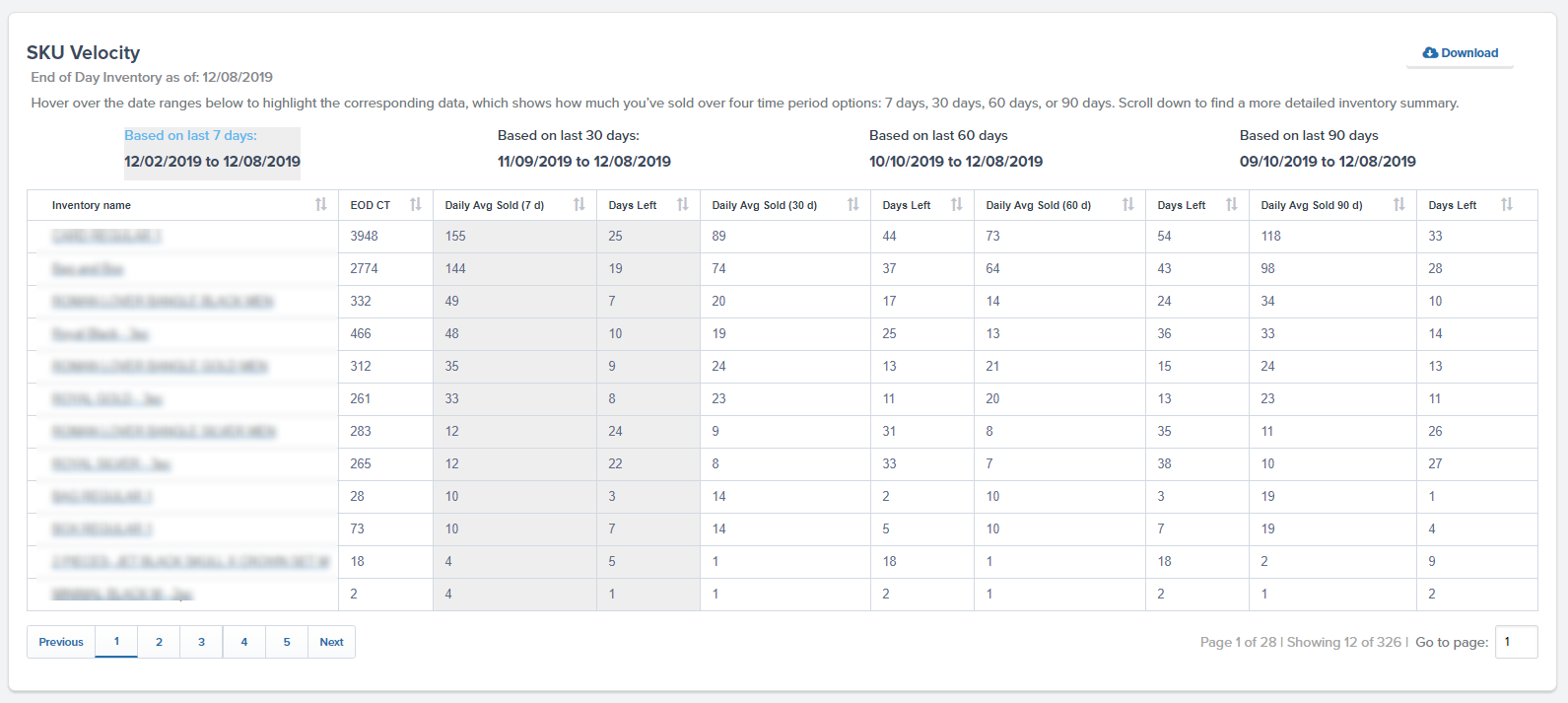

Inventory management software can help you make better decisions by tracking SKU performance over time and providing key inventory analytics, including inventory turnover rate, SKU velocity, demand forecasting, and more.

For instance, ShipBob’s centralised technology makes it easy to track SKUs through its digital inventory system, so you view, manage, and make changes to SKUs at any time. You can even easily set up product bundles.

“I used to have to pull inventory numbers from three places everyday and move all the disparate data into a spreadsheet.

ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations.

It’s really nice to not have to operate three 3PLs.

For inventory planning, I love the SKU velocity report, daily average products sold, and knowing how much inventory we have left and how long it will last. The enhanced visibility is great.”

Wes Brown, Head of Operations at Black Claw LLC

Having this level of inventory visibility enables you to track inventory in real time in a less time-consuming manner and collect data automatically, so you can make decisions effectively.

Increases profitability

Inventory is considered an asset on a business’s balance sheet. Any costs associated with holding unsold inventory is working capital with the assumption that a profit will be made at the end of a fiscal year or accounting period.

But as any business owner should know, sales can decline or inventory can lose value.

In this case, unsold items can be counted for as an inventory write-off, which might benefit your business in the short term, but having too much capital tie up in unsellable inventory in the long term can be harmful.

How to rationalize SKUs

Managing a high number of SKUs is not always a cost-effective option for ecommerce retailers. Though it might provide more options for customers, it can cause a decrease in inventory turnover even if items still hold value.

To justify a larger product catalogueueue, you will need to consider the cost of more space, labour, and intensive inventory tracking in order to maintain optimal inventory levels to meet demand while also keeping costs to a minimum.

But even if you have the resources to manage a high volume of inventory, discontinuing SKUs is a common practice in a growing business.

Here are some steps you can take to rationalize your SKU count and focus on inventory that drives the most revenue.

Consider your target market and any other variables

Product assortment should typically be based on the needs of your target market. And to understand your business’s inventory requirements a bit better, ask yourself some of these customer-focused questions:

- Who is my target audience?

- What are their needs and pain points?

- What products do they purchase the most?

- What is their purchase frequency?

The answers to these questions can help you understand if your current inventory replenishment cycle is optimised enough.

Before performing the SKU analysis, you must also consider other factors that might affect the outcome of the profitability of your SKUs such as:

- Can you bundle products?

- Do you offer free shipping thresholds to increase average order value (AOV)?

- Can you run a seasonal promotion or a flash sale to deplete less popular inventory?

Before introducing or discontinuing a SKU, make sure to weigh all your options before you move forward with a decision.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week.

It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO

Perform a detailed SKU analysis

Sometimes, sales might be steady but the costs associated with a specific SKU is too high. When analising SKU performance, you’ll have to dig in to different factors of your business that might be impacting a SKU’s profitability.

Other factors besides low inventory turnover include:

- High storage costs (e.g., large items that take up a lot of room, or having too many units of a certain product on hand)

- Future sales projections and seasonality

- Your return rate

- Longer production lead times

- High use of labour for picking and packing

Be sure to look beyond historical and current sales to get a holistic view of a SKU’s profitability before discontinuing it — especially if you have a high volume of inventory on hand.

Organise your product catalogueueue

Keeping a product catalogueueue that is up-to-date and accurate is a vital component of building an online brand because it helps customers find what they’re looking for and feel comfortable making a purchase based on the information provided.

Any time you discontinue or introduce a new item, make sure updating your product catalogueueue across all sales channels is part of the SKU rationalization process.

In terms of auditing inventory, proper catalogueueue management can also deliver more clarity around any repetitive items that could be grouped, bundled, or discontinued since it lacks in variation.

Having this clarity around what you offer makes it much easier to see what updates you need to make to meet customer demand and increase sales.

Review the results

Once you have catalogueueueued and rationalized the existing SKU assortment, the next step is to check if it has helped to optimise storage, reduce costs, and lower your risk of accumulating dead stock.

Be sure to repeat this SKU rationalization at least once every six months to keep your inventory optimised and business profitable.

Note: More SKUs does not always mean more success. It’s easy to overestimate the use of new colours and slight variations. Just because other companies expand their SKU count and product line, doesn’t mean it’s the best decision for all direct-to-consumer (DTC) brands.

SKU rationalization is easy with ShipBob

If you’re ready to expand your operations to drive more sales and offer more for your customers, ShipBob can help.

ShipBob is a premium fulfilment provider that simplifies logistics operations by taking warehousing, fulfilment, and shipping off your plate.

ShipBob’s entire international fulfilment network is powered by the same warehouse management system (WMS) with built-in inventory management.

This enables fast-growing brands in both the B2B and DTC space to monitor SKU velocity across multiple fulfilment centre locations and manage stock availability in real time.

“Our store is on WooCommerce, which integrates well with ShipBob. I loved how easy it was to set up my products in the dashboard for all SKUs (our box, pouch, marketing insert, etc.).

I’ve already referred a friend and fellow founder to ShipBob, who already loves how easy the dashboard is to use, since he was using a 3PL’s technology that was less than ideal and very manual.”

Leonie Lynch, Founder & CEO of Juspy

From the ShipBob dashboard, you can quickly view SKU performance at a glance, get a real-time view of all inventory, and update and manage SKUs efficiently.

What’s more, ShipBob’s analytics reporting tool, you’re also given the data and insights needed to identify slow-moving and fast-moving inventory, forecast demand, and make decisions on inventory reconciliation.

To learn more about how ShipBob can optimise your ecommerce supply chain, get the conversation started by requesting a quote below.

SKU rationalization FAQs

Here are answers to the top questions about SKU rationalization.

Is it bad to have a lot of SKUs?

An ideal SKU count will vary across brands and will depend on a variety of factors, but we can learn a thing or two from successful brands to help us make better decisions on how we manage SKUs. Ryan Treft, the founder and partner of Coalatree and Peejamas, believes in keeping his SKU count simple, which helps improve forecasting initiatives.

He says it’s easy to overestimate the use of new colours and slight variations. And it can also negatively impact customer buying behaviour.

Why? The paradox of choice. If you see 900 cereal brands in the grocery store aisle, you’re more likely to leave with zero. A lot of the time, having more than three options is too much to think about.

For every product, consider featuring only three options, and know that a lot of the time consumers will choose the middle option.

When is SKU rationalization needed?

SKU rationalization is helpful process any time a business wants to reevaluate their product catalogueueue and optimise for profitability. Increasing sales sometimes requires product discontinuation, especially if an item is projected to lose value or continues to have a low inventory turnover rate.

How can I rationalize SKUs with ShipBob?

ShipBob automatically tracks every SKU in your inventory, helps forecasts demand, and analyses your sales performance and carrying costs. By providing data upfront, you can decide which SKUs to discontinue.

What metrics are used for SKU rationalization?

The SKU rationalization process requires evaluating different supply chain analytics — from inventory turnover rate and SKU velocity, to warehousing costs and projected sales — to gain a holistic view of all the factors associated with a SKU’s profitability. These inventory metrics all play a role in deciding whether a not a product should be discontinued.