Table of Contents

** Minutes

Why is OTIF important for ecommerce businesses?

OTIF impacts more than you might think

When it’s time to track OTIF as a KPI

Ways to improve your On Time & In Full score

How ShipBob can improve OTIF scores and make your business run more efficiently

There are many moving parts to an ecommerce business. Keeping track of the numerous factors across the supply chain can be a daunting but it’s necessary for optimal performance.

Ecommerce businesses need to closely monitor their performance across the supply chain so they can optimise their processes and increase efficiency. This involves keeping track of critical distribution metrics such as how many orders were shipped out on time because this is vital to determine how efficient their processes are, how satisfied customers will be, and whether they need to make improvements.

In this post, we take a closer look at the On-Time In-Full (OTIF) metric and why it’s important for ecommerce businesses. We also show you when and how to calculate your OTIF score as well as how to improve it.

What is OTIF?

OTIF or On-Time In-Full is a KPI used for measuring how many orders were delivered on time and in full. It helps to assess whether the business was able to deliver every item in the order on or before the expected date of delivery. This metric is mainly used as a delivery KPI, although it can also be applied throughout the supply chain. For instance, you may have OTIF picking or OTIF dispatch to assess different aspects of your fulfilment process.

Why is OTIF important for ecommerce businesses?

OTIF is an important metric to track because it helps ecommerce businesses understand the efficiency of their fulfilment and delivery process. OTIF keeps track of how a brand’s shipping partners are performing in terms of making on-time deliveries. It also means identifying whether fulfilment processes like receiving, picking, packing, and shipping are efficient enough to quickly deliver orders in full.

When aligned with other KPIs and reports, OTIF can be used to gain a bigger picture of how different processes in the supply chain are performing and what needs to be improved. For example, a low OTIF score may be a result of stockouts and supply chain disruptions. In this case, bad customer reviews about a product not being available or not delivered may occur. High stockout costs combined with low OTIF scores can also help to pinpoint the source.

OTIF impacts more than you might think

The OTIF metric isn’t just for measuring delivery performance. It’s strongly connected to other aspects of your supply chain and performance.

A good OTIF score starts from the supplier purchasing and procurement process. The items that your customers order should be in stock and ready to ship. Otherwise, there will be delivery delays, impacting your OTIF figure.

Even if you have enough inventory on hand, you could still struggle with a low OTIF score due to issues in your warehousing and storage. Inefficient picking processes and staff shortages could lead to delays. Moreover, how you store and organise inventory can also affect the speed of fulfilment, which eventually impacts your OTIF score.

OTIF is a crucial metric for gauging the shipping experience that your business offers. For this figure to be on the higher side, your carrier should be able to deliver the items on time and undamaged. Slow shipping speeds, damages in-transit, and lack of carrier order tracking can have an impact on your OTIF figure and subsequently, the overall shipping experience.

Customer satisfaction is one of the most significant areas connected to OTIF. Low OTIF scores typically translate to poor customer satisfaction scores because customers aren’t getting their full orders on time.

How to calculate OTIF

The process of calculating your OTIF rate is fairly simple. It involves counting the total number of deliveries that were made on time and complete and dividing the number by the total number of deliveries. The following formula can be used:

On-Time In-Full Rate = Total deliveries made on time and in full / Total deliveries made X 100

So let’s say out of 600 orders, 455 were delivered on time and complete. That means your On-Time In-Full rate would be:

On-Time In-Full Rate = 455/600 X 100 = 75.8%

This is a bit on the lower end. Although it’s virtually impossible and unrealistic to strive for an OTIF rate of 100%, ecommerce businesses should strive for a score that’s in the high 80%-90% range.

Additionally, ecommerce businesses may have different target scores for different product lines. Using the ABC classification, your target OTIF scores may look something like:

| Importance | Percentage of Inventory | Percentage of Sales | Good OTIF Score (Target) | Average OTIF Score | Bad OTIF Score | |

|---|---|---|---|---|---|---|

| Class A | High-dollar value | 10%-20% | 50%-80% | 95%-99% | 85%-95% | <85% |

| Class B | Medium-dollar value | 20%-30% | 20% | 85%-99% | 79%-85% | <79% |

| Class C | Low-dollar value | 50%-70% | 10%-30% | 99%-100% | 85%-99% | <85% |

When it’s time to track OTIF as a KPI

If you’re not tracking your OTIF score yet, it may be a good time to start looking at this KPI more seriously. You know it’s time to track OTIF as a KPI when you start to experience any of the following issues:

Late deliveries

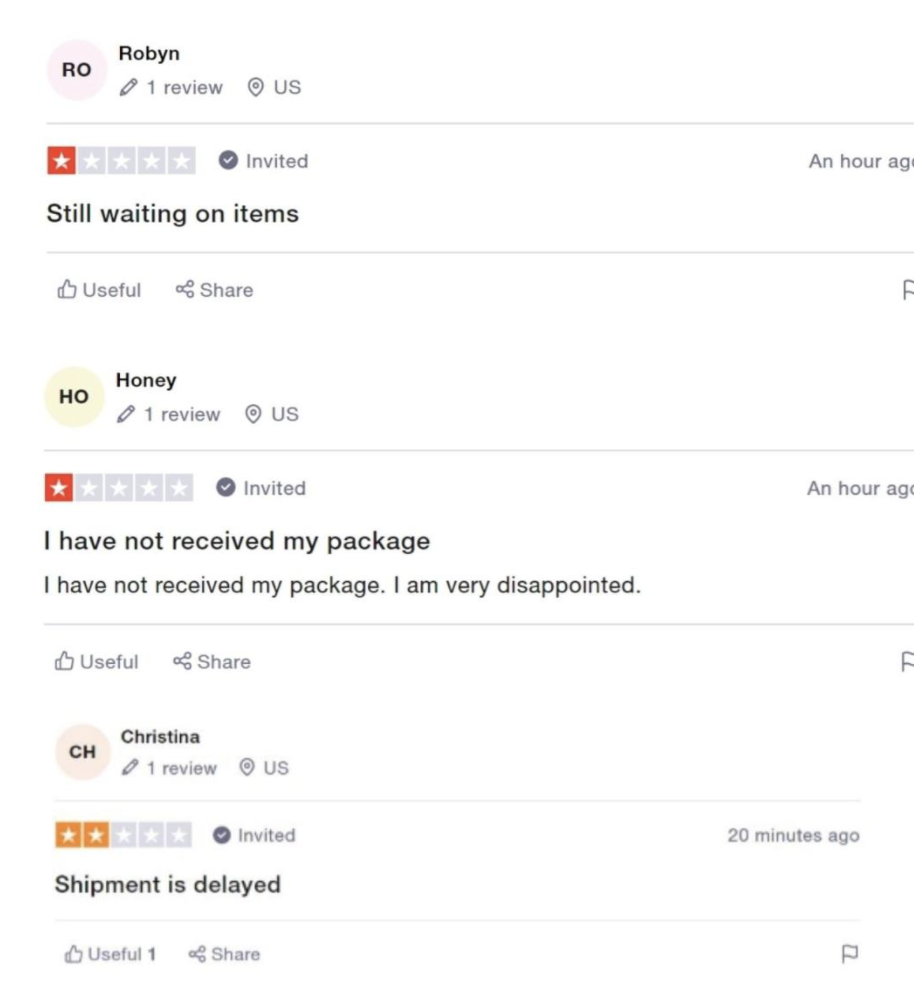

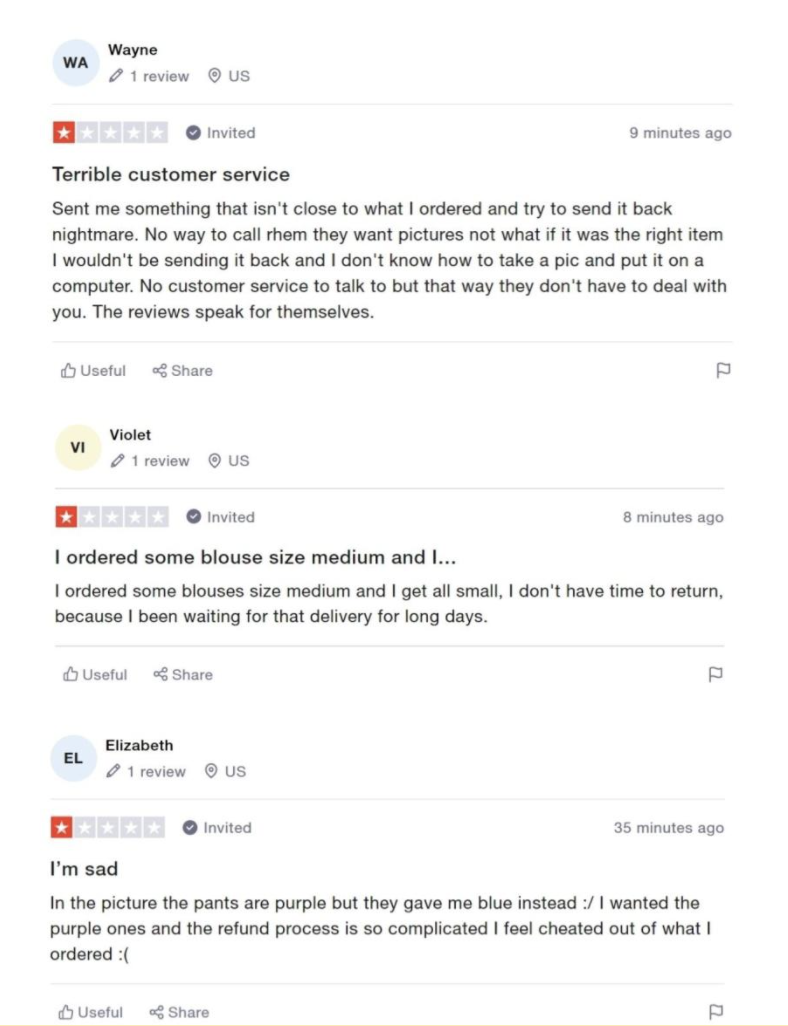

Are you getting a lot of calls from customers asking/complaining about delayed orders? Or perhaps your review section is filling up with customers who are still waiting on their orders. Maybe you’ve been seeing more email complaints relating to delivery delays. Or your recent feedback survey revealed that your slow delivery times were the major cause of customer disappointment.

Repeat issues with late deliveries or a sudden increase in delivery delays are a sign that your OTIF needs to be monitored more closely. It could be a problem from the supplier front, where manufacturing is taking longer than usual and there are lots of backlogged orders. It might even be an issue with your shipment provider taking longer than usual to complete last-mile deliveries.

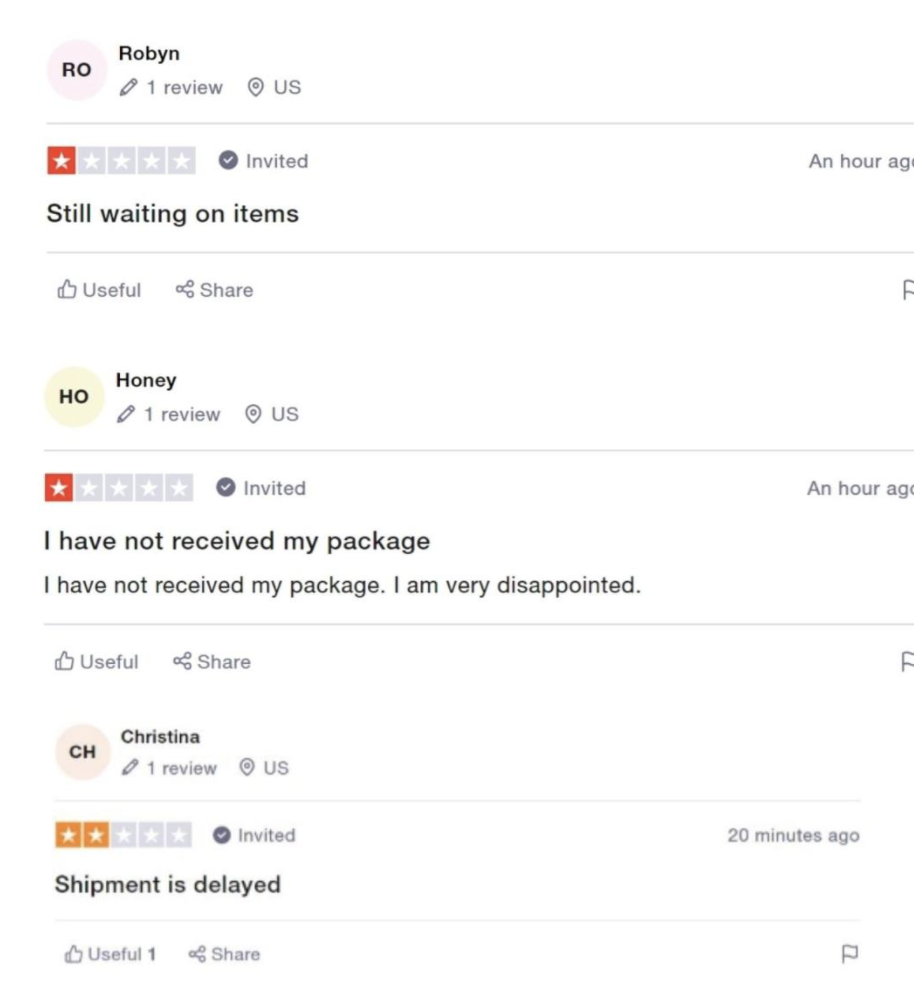

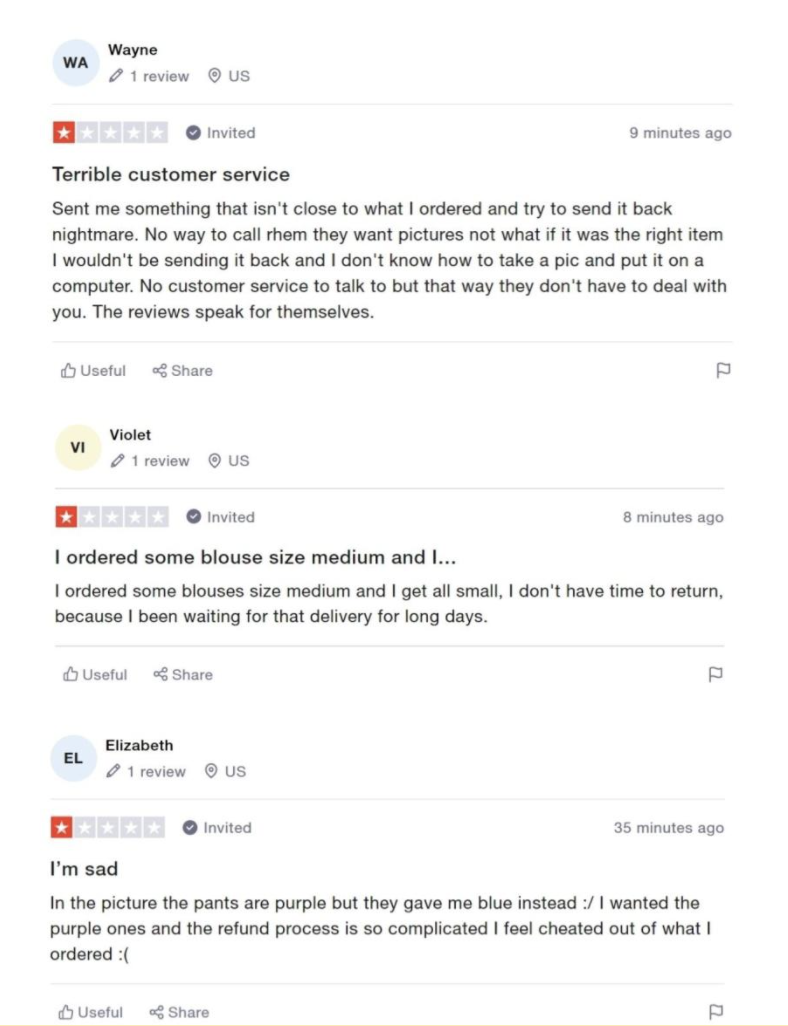

Inaccurate orders

Your reviews and customer support requests may reveal a critical issue with your order accuracy rate. How many customers are complaining about receiving the wrong size product? Are there complaints about receiving something in a different colour? Or are there any instances of customers receiving a completely different item from what they ordered?

Not only will this affect your perfect order metrics, but it also tells you that it’s high time to start measuring your OTIF score. A high rate of inaccurate orders may suggest a problem in your warehousing and picking operations, which will also affect your OTIF rate.

Lack of inventory visibility

Are you struggling to get accurate inventory visibility in your supply chain and across your fulfilment network? When you don’t have proper visibility into inventory levels, you’re likely to experience issues with stockouts, backorders, split shipments, and fulfilment delays. For example, you may constantly experience issues with items not being available when your customers order them. Or you may regularly have to send out different items from the same order in multiple shipments.

These issues can then impact your OTIF rate because orders are either not getting delivered on time or being shipped out in full. So if you don’t have enough inventory visibility, it’s time to take a closer look at your OTIF score.

Warehouse processing issues

Constantly facing issues in your warehouse processing is another sign that you need to take action. For example, if you don’t have an automated warehouse receiving system set up, it may take ages for your warehouse to receive orders after they’re placed. And this is bound to cause a delay in order fulfilment.

Or if you don’t have a proper warehouse inventory management system, you may have a hard time tracking inventory movement and picking orders accurately. Additionally, your warehouse management process itself may be a problem with poorly-trained staff, staff shortages, improper workload planning, and inefficient storing systems.

Ways to improve your On Time & In Full score

If your supply chain analytics reveals that your OTIF score is lacking, here are some tips to help you improve your numbers:

Implementing a warehouse management system

A proper warehouse management system can significantly improve inventory visibility while making your warehouse processing more efficient. It helps you keep track of your inventory levels and integrates with your ecommerce store to keep your stock levels updated in real-time. This reduces errors and speeds up the fulfilment process while improving order accuracy rates. Moreover, the improved visibility into where certain SKUs are stored will speed up picking and improve order completion rates.

Analising real-time order data

You also need a good order management system to analyse your order data in real-time. This allows you to speed up order processing by automatically sending customer order data from your ecommerce store to your warehouse. And with real-time inventory data, you can avoid stockouts, reorder at the right time, and keep optimal inventory levels across your fulfilment network.

Distributing inventory for faster delivery

A lot of delivery delays happen because shipments have to travel through long journeys to reach the customer. Distributing your inventory across multiple fulfilment centres can help you keep your inventory closer to your customers, which means orders have to travel for shorter durations to reach their final destination. This is a great way to deliver orders faster and improve your OTIF score.

Using automation for higher accuracy numbers

From order processing to fulfilment and shipping – many processes in your supply chain can be automated for accuracy. Automated order processing automatically sends order details to your warehouses, which eliminates the need for manual entry and thus, human errors. Meanwhile, inventory automation gives you real-time updates on inventory levels so you can keep optimal stock levels at all times and avoid stockouts and backorders.

You can also improve accuracy in the picking, packing, and shipping processes when you automate your fulfilment. This involves warehouse automation to reduce the number of decisions needed to be made by a warehouse associate and eliminate picking and packing errors. It also involves automating your shipping by automatically getting orders into the fulfilment queue and setting up an automated tracking system.

Implementing order tracking software

Getting real-time updates into order status can improve visibility across the board. By keeping track of how your shipments are moving, you can quickly follow up with the carrier in case of delays and work on resolving the issue.

Optimising order fulfilment processes regularly

Your order fulfilment processes need to be reviewed and optimised on a regular basis. This could involve investing in new technology or introducing better processes based on feedback from your staff. Constantly look for areas that are causing backlogs and delays so you can work on fixing them.

How ShipBob can improve OTIF scores and make your business run more efficiently

While you worry about growing your sales, you may make the mistake of undervaluing the fulfilment experience. As a result, you could end up with delayed shipments, incorrect orders, damaged orders, and more. This can take a toll on your customer satisfaction and retention rates.

ShipBob provides you with the solution you need to improve your OTIF scores and take your customer fulfilment experience to the next level. You can take advantage of ShipBob’s distributed fulfilment network to store your inventory closer to your customers and ensure faster, more affordable deliveries. This allows you to deliver your orders in as quickly as two days, significantly boosting your OTIF figure.

The ShipBob software integrates with your ecommerce platform to speed up your order processing and fulfilment. That means orders are automatically sent to our fulfilment centres, from where they’re picked, packed, and then shipped out as quickly as possible. So orders go out the door faster, helping you improve your on-time fulfilment rate.

ShipBob also provides you with a free analytics reporting tool to gain full visibility into your inventory levels and store performance. This keeps track of historical sales data to accurately forecast demand so you can plan your inventory purchases accordingly. It also gives you suggestions on how to optimally distribute your inventory across different fulfilment centres to optimise performance.

“There are a lot of issues with shipping products like ours, but we’ve been able to do it successfully with ShipBob. I’m very glad we found a 3PL partner that can ship hundreds of 25-pound blankets everyday, while providing a great customer experience.”

Founder of My Calm Blanket

Have your own warehouse?

With ShipBob’s WMS, you can utilise our best-in-class warehouse management technology in your own facility. Access to real-time order data, improved inventory and data visibility, and more can help boost your OTIF figure.

Even with your own warehouse, you can take advantage of ShipBob’s hybrid fulfilment solution in order to better reach customers outside of your region or country. With fulfilment centres in the US, Canada, Europe, and Australia, you can penetrate international markets to ensure orders arrive when and how they’re supposed to.

Connect with our team to learn more about this solution and how it can improve your on-time fulfilment rate.

OTIF FAQs

Here are answers to the most common questions about On Time & In Full (OTIF).

How do you maintain an OTIF?

To maintain an acceptable OTIF score, it’s crucial to keep optimal inventory levels and expedite the shipping process.

How to improve OTIF?

You can improve OTIF by optimising your warehousing process, improving inventory visibility, and distributing your inventory strategically for faster delivery.

How often should you calculate OTIF?

Calculating OTIF on a daily basis is ideal so you can quickly respond to any signs of problem. What’s even better is getting real-time insights into your OTIF.