When you’re on an airplane taxiing to your runway for takeoff, you might spot an air traffic control tower. These large towers help personnel maintain visibility of the entire tarmac, enabling them to monitor planes on the ground, coordinate takeoffs and landings, and keep flyers safe.

Supply chain control towers are very similar. While they’re not physical structures, supply chain control towers serve the same kind of purpose: to improve visibility. With a supply chain control tower in place, ecommerce merchants can achieve a more comprehensive view of their supply chain operations and network, enabling them to manage it seamlessly.

In this guide, we’ll cover what supply chain control towers are, what role they play in ecommerce brands’ operations, and how to set one up for your business.

What is a supply chain control tower?

A supply chain control tower is a solution (usually a software program, ERP, or other cloud-based platform) that leverages technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) to deliver end-to-end supply chain visibility.

This visibility extends not just within your operations, but throughout your entire supply chain network. That means that a supply chain control tower gathers data on all different aspects of your supply chain (including your suppliers, manufacturers, and other supply chain partners), giving you a 360-degree view of your supply chain operations.

Using this data, brands can:

- Make more strategic supply chain decisions

- Identify and fix issues before they spiral out of control

- Manage risk while building supply chain agility and resilience

- Optimize supply chain operations (including production planning, procurement, receiving, warehousing, fulfillment, shipping, returns, and more) for cost-savings and efficiency

Types of supply chain control towers

There are several types of supply chain control towers, each of which serves a specific supply chain function. These include:

- Inventory control towers – Provide you with real-time inventory tracking and management capabilities to identify shortages, imbalances, and expirations. These towers help you avoid stockouts and time inventory replenishment more strategically.

- Logistics/transportation control towers – Help you manage your supply chain logistics and transportation with inbound and outbound logistics visibility. Besides delivery data, these towers can provide advance shipping notifications and order tracking information.

- Fulfillment control towers – Give you visibility into your fulfillment operations to help you manage them more effectively. You can use these towers to streamline picking and packing activities, expedite orders, and determine the most cost-effective shipping options.

- Supply assurance control towers – Ensure adequate supply availability and on-time deliveries for raw materials or finished goods. They help you maintain your product quality and ensure supplier continuity.

- E2E (end-to-end) supply chain control towers – Give you visibility across your internal and external supply chain processes.

The role of control towers in ecommerce supply chains

Besides end-to-end visibility, supply chain towers play other vital roles in ecommerce supply chain management. Here are just some of the most important capabilities of supply chain control towers, and how brands leverage them.

Communication and collaboration

Supply chain control towers allow ecommerce businesses to seamlessly communicate with teams and supply chain partners. They can use digital playbooks and AI-powered resolution rooms to share information and collaborate in real time. This enables them to quickly resolve issues and improve supply chain efficiency with minimal back-and-forth.

Data analytics and integration

By coordinating with your existing supply chain systems and technology, control towers integrate your data to provide you with comprehensive insights. This enables you to track supply chain KPIs across your entire network and perform vital supply chain analytics to inform your decisions.

End-to-end visibility

Control towers play a vital role in providing end-to-end supply chain visibility. This allows you to better control various supply chain functions to improve efficiency and minimize costs. For example, increased inventory visibility allows you to plan for replenishments and avoid delays caused by stockouts.

Decision support

A supply chain control tower uses predictive and prescriptive analytics to guide decision-making. Real-time, actionable insights allow you to make proactive (rather than reactive) decisions and create a more flexible, durable supply chain – one that can withstand unexpected challenges or circumstances.

Security

Control towers make it easier for ecommerce businesses to share essential information with relevant supply chain partners while still maintaining data security. They help you navigate complex security concerns as you integrate multiple data sources across multiple systems.

How to ensure an effective supply chain command center

Establishing a supply chain control tower can be tricky, especially if your brand has a large supply chain with many different tools, technologies, systems, and data sources to unify. Here are a few initial considerations to help you set up the most effective supply chain control tower possible.

Data quality

Data should drive the majority of actions and decisions in your ecommerce supply chain. The quality of data determines the quality of the insights you can pull from it, so missing or inaccurate data can be very detrimental to your operations. For example, incorrect data about your inventory levels could lead you to believe you are running out of inventory, when in reality you’re already well-stocked. In this case, you may reorder inventory too soon and accidentally overstock on a particular SKU.

With this in mind, it’s important to carefully assess the quality of data that the control tower will access. You need quality data that will provide you with real-time comprehensive insights into your supply chain performance, so find control tower solution providers that offer quality assurance and deliver clean, straightforward, and accurate data from both internal and external datasources throughout your supply chain ecosystem.

Practical and actionable outputs

It’s not enough to simply collect large amounts of data from a bunch of different sources – rather, that data needs to be analyzed to generate actionable and understandable outputs for your day-to-day supply chain activities.

A supply chain control tower should be able to gather data and present it in an easily digestible format, so that you can quickly and easily derive value from it. Whether the data helps you optimize your existing processes or solve your supply chain problems, the outputs should have meaning and implications for your supply chain operations.

Internal, department-wide alignment

To effectively implement a supply chain control tower, you’ll need an organization-wide buy-in. This may involve sunsetting outdated processes and mindsets, and providing teams with extensive trainings and demos to ensure that all workers and stakeholders have the necessary skills to use the supply chain control tower, and are comfortable doing so.

Benefits of implementing a supply chain command center

Implementing a supply chain control tower may be well worth the effort for your business. Here are some of the main ways in which your ecommerce brand can benefit from a supply chain control tower.

Revenue and margin growth

Better visibility across the supply chain allows you to make more strategic decisions that positively impact your margins. For instance, with more holistic data on your supply chain, you can identify the most profitable suppliers or find the optimal supply routes to reduce logistics costs.

Similarly, you can prevent stockouts by making timely replenishments that help you avoid revenue loss. One Europe-based CPG brand was able to use a supply chain command center to identify $90 million worth of revenue loss due to stockout risk within just six months.

Increased cost control

Supply chain control towers can also increase cost savings. Leveraging the data, information, and visibility a supply chain control tower offers, brands can optimize their ecommerce operations to save money through:

- More accurate demand forecasts: Being able to accurately predict your inventory needs minimizes the need to stock up on excess inventory, which helps to reduce your inventory holding costs and avoid stockouts.

- Minimize obsolete inventory and inventory spoilage: With real-time inventory data, you can prioritize selling inventory that is at risk of going out-of-date, so you can maximize your ROI.

- Adjusting fulfillment processes: Analyzing your fulfillment operations using supply chain data can help you identify where the picking, packing, and shipping processes could be faster and more accurate. This boosts both order accuracy (resulting in fewer returns and reshipment costs) and helps manage labor costs.

Efficient resource utilization

The increased visibility from your supply chain command center helps you allocate your resources more efficiently. For example, you’ll be able to see which areas of the supply chain that require more labor to run smoothly, as well as which areas experience congestion or bottlenecks. That way, you can adjust your labor resources to quickly align them with your needs.

Similarly, a supply chain control tower makes it easier to automate repetitive, manual tasks using systematic workflows. This not only speeds up your processes, but also frees up human time and attention to devote to functions where it’s truly needed.

Shorter lead time

With end-to-end visibility, a supply chain control tower proactively flags delays while helping you pinpoint areas that are experiencing a bottleneck. This allows you to quickly address these issues before they have a major impact on your production lead times, which subsequently sets your later supply chain operations for streamlined success.

Supply chain control towers also enable brands to optimize fulfillment and shipping operations to minimize lead times and create a positive customer experience.

Rapid disruption response

When you have access to both historical and real-time data about your supply chain functions, you are in a better position to respond to unexpected supply chain disruptions or challenges. Using the data from a supply chain control tower, brands can make their supply chain more agile and prepare contingency plans to seamlessly continue meeting consumer demand, even when things go wrong.

Strong ecommerce supply chains start with ShipBob

A supply chain control tower can play a vital role in streamlining your supply chain processes – but it’s only one component in a healthy supply chain.

Supply chain control towers work best when deployed alongside other powerful inventory and warehouse management solutions, as well as the expertise of third-party logistics experts like ShipBob.

Here are just a few of the ways that ShipBob can help ecommerce brands strengthen their supply chain operations through our industry-leading technology, global network, and best-in-class logistics solutions.

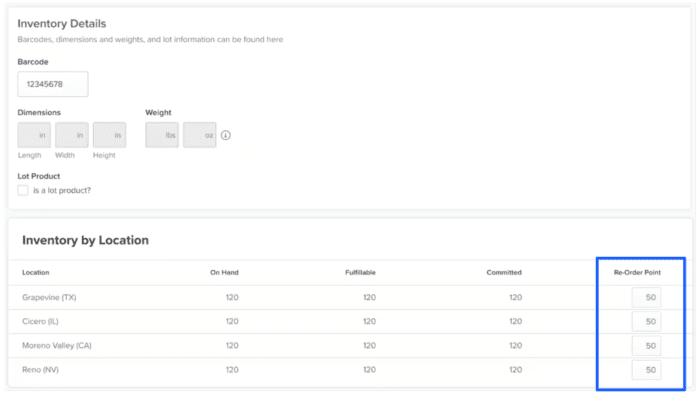

Real-time inventory management for seamless fulfillment

ShipBob’s dashboard provides you with real-time inventory insights to improve visibility across your supply chain. Merchants can view SKU levels, on-hand inventory, units sold, and other key inventory metrics at a glance, so you always know where your inventory is and where it’s going.

This level of visibility also help brands plan procurement, while automatic reorder notifications alert you to when SKU levels hit a set threshold to help you time replenishment.

IMAGES: INVENTORY SUMMARY, REORDER POINT NOTIFICATIONS

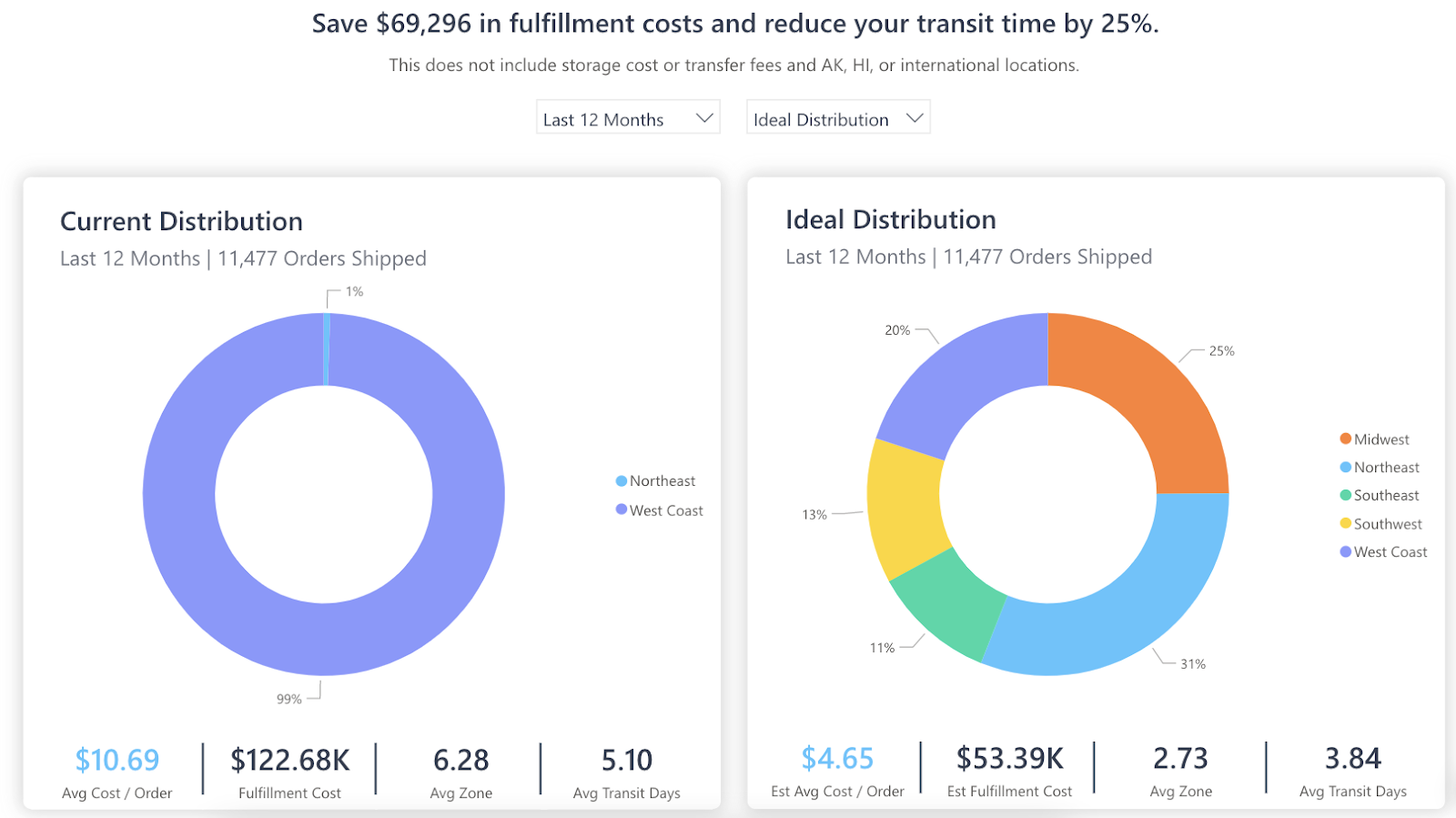

Distributed inventory for faster, cost-effective shipping

ShipBob has dozens of fulfillment centers across the continental US, which ecommerce brands can use to place inventory closer to popular order destinations. This minimizes shipping costs and times, making shipping not only faster but more affordable for both you and your customers.

ShipBob’s Inventory Placement Program will even take care of allocating and distributing inventory for you. First, brands can use our Ideal Inventory Distribution tool to determine the optimal split of inventory across ShipBob’s network to lower their average shipping zone. A merchant sends inventory to a single hub, at which point ShipBob takes care of physically distributing it to and storing it in multiple regional fulfillment centers to save you time and money.

Seamless integration with major ecommerce platforms and channels

ShipBob integrates with major ecommerce tools, platforms, and marketplaces to fit seamlessly into your existing tech stack. That way, your supply chain has a single source of truth from which you can monitor orders, check inventory, and manage omnichannel fulfillment.

ShipBob also supports retail dropshipping and distribution solutions for B2B channels like Target, Ulta, CVS, and more, as well as fulfillment for ecommerce marketplaces (such as Amazon and Walmart Marketplace) and social channels like TikTok. This lets you manage your entire fulfillment strategy through a single partner to simplify your ecommerce logistics.

International fulfillment solutions to expand your reach

You can even streamline international logistics with ShipBob’s global fulfillment solution. ShipBob has fulfillment centers in Europe, Australia, Canada, and the UK, so you can provide fast and affordable deliveries to all your customers while saving on fulfillment costs and minimizing cross-border complexities.

For more information on how ShipBob can help you streamline and optimize your supply chain, click the button below.

Supply chain control tower FAQs

Below are answers to the most commonly asked questions about supply chain control towers.

What are the essential capabilities of a supply chain control tower?

End-to-end visibility, data integration and analytics, decision support, security, and collaboration are some of the key supply chain control tower capabilities.

How do supply chain control towers benefit ecommerce logistics?

Supply chain control towers provide real-time visibility into the supply chain that allows ecommerce businesses to seamlessly manage their logistics to improve efficiency, reduce costs, and increase revenue.

Which industries can benefit from supply chain control towers?

Most industries can benefit from supply chain control towers, particularly ecommerce brands with large or complex supply chains.

Can small businesses benefit from supply chain control towers?

While supply chain control towers are often used by larger ecommerce brands with complex supply chains, growing brands may be able to leverage supply chain control towers to improve visibility and efficiency while reducing costs.