Table of Contents

** Minutes

Why you should consider analyzing your SKUs

Tips for analyzing your SKUs to improve your inventory management

Ecommerce success relies heavily on accurate inventory management and a streamlined supply chain. In order to achieve it, businesses need to keep a close eye on their stock-keeping unit (SKU) to understand inventory levels, create bundle offers, and set reorder points. And proper SKU management requires accurate SKU analysis.

In this post, we give you a closer look at what SKU analysis is, why you should analyze your SKUs, and how you can use SKU analysis to improve inventory management.

What is SKU analysis?

SKU analysis is the process of monitoring inventory at the SKU level and interpreting the data to extract actionable insights. At the most basic level, it might involve analyzing inventory levels to see how much stock is available for a particular SKU, when it should be reordered, and how much should be reordered. SKU analysis is also an important step for managing your catalog accurately across different channels.

It may involve analyzing inventory turnover at the SKU level to determine which products are slow-moving and which ones are high in demand. SKU analysis also looks at the carrying cost of different SKUs to identify profitable and non-profitable products. Businesses can combine all of these insights to better manage their inventory and identify opportunities to increase profitability.

Why you should consider analyzing your SKUs

A thorough analysis of your SKUs is a necessity for efficient and accurate catalog management. Beyond that, it also has a number of other benefits to increase ecommerce profitability.

Identify and manage SKU proliferation

SKU proliferation is an important part of every growing ecommerce business. As businesses scale, they often have to introduce new products or new variations of existing products to grow their sales and attract more customers. When left unchecked, however, SKU proliferation could be eating away at your profits.

As a result of unchecked SKU proliferation, you may end up with large volumes of inventory that you’re unable to sell. That means you’re spending money to procure inventory that doesn’t get sold. Plus, you’re also spending more money than necessary to hold the inventory.

This is why it’s important to be very strategic about what SKUs you introduce into your supply chain instead of proliferating for the sake of it. SKU analysis helps you to identify your best-selling item to see if you can introduce variations of it, for example. It could also give you an idea of what your audience likes and doesn’t like, which will help you to manage SKU proliferation more effectively.

Cut unprofitable SKUs out

Not all of your products are getting the same level of attention from your customers. While you have many best-selling items that generate plenty of revenue, others may sell fairly well but have very low profit margins. Even worse, some products may not even sell at all because your customers either don’t need them or don’t like them.

SKU analysis is a great way to keep an eye on these important details so you don’t keep throwing away money on procuring and keeping unprofitable SKUs. With the ability to tell you which SKUs have low inventory turnover and how much profit you were able to generate on average for each SKU, the analysis will identify which SKUs to cut out from your supply chain.

This will help you cut costs on procuring and holding slow-moving items. It will also free up resources and warehouse space to procure higher-value items and best-selling SKUs to increase your overall profitability further down the line.

Organize and consolidate SKUs across different channels

If you’re selling through multiple channels, there’s a chance that you have different inventory systems in place across those selling channels. This not only creates confusion and inefficiencies in your inventory management, but it can also result in costly mistakes. For example, if your inventory data in one system doesn’t automatically sync with another, you could accidentally sell out-of-stock items or place reorders twice.

The right SKU analysis process simplifies your multichannel inventory management as it involves organizing and consolidating your SKUs across all your selling channels. This means you can track your SKUs from different channels in one place, allowing you to monitor inventory levels, reorder points, and inventory movement more accurately.

Tips for analyzing your SKUs to improve your inventory management

Now that we’ve established how vital it is to analyze your SKUs, it’s time to look at some ways you can perform the analysis and subsequently improve your inventory management. Proper SKU analysis is all about knowing what to look for and how to make the most of the data that you’ve extracted.

Performing SKU rationalization

SKU rationalization is an important step in the SKU analysis process. It involves measuring the profitability of the products in your inventory using metrics such as inventory holding costs, procurement fees, fulfillment costs, customer acquisition costs, and historical sales data. As a result, SKU rationalization helps you to identify whether you should keep stocking certain SKUs or whether they should be discontinued.

For example, you may notice that a certain SKU sells fairly well. But it takes up huge amounts of storage space in your warehouse because it’s a bulky item. So your SKU analysis process will help you assess whether the profits gained from this SKU justify the cost of storing it.

Alternatively, your SKU analysis may also reveal that a certain SKU is extremely slow-moving. That means you’re likely losing money on inventory holding costs for this particular SKU while not getting any revenue out of it. In this case, it would be a wise decision to discontinue the SKU so you can keep your inventory holding costs in check while freeing up resources and space for better-selling products.

Analyzing potentially costly SKU proliferation

While SKU proliferation is a natural part of growth for any business, it has to be done strategically. As ecommerce businesses want to increase their SKU counts to attract more customers and grow their revenue, they may end up adding more products that don’t appeal to their target audience. For example, some products may have extremely high price points and are, therefore, not marketable to their current audience base. Or the product doesn’t really solve a key pain point that their customers are experiencing.

Whatever the specifics may be, you’re ending up with products that you’re unable to sell. And these slow-moving SKUs are taking up huge amounts of storage space, driving up your inventory holding costs, and failing to drive revenue. So it’s important to conduct SKU analysis to identify negative or costly SKU proliferation that will help you to keep this in check.

By narrowing down on the SKUs that are causing the issue, you can look for opportunities to fix the problem. For example, it may involve bundling slow-moving SKUs with best-selling items. Or it may involve expanding your target market for higher-priced products.

The argument for a larger SKU count is to get repeat purchases by offering those customers who already bought from you a greater variety. But Ryan believes in keeping his SKU count really simple, which helps with inventory forecasting. The difference between 20 and 40 SKUs can be hard enough, so he doesn’t know how people go from 40 to 400 SKUs. It’s easy to overestimate the use of new colors and slight variations.

It’s the paradox of choice — if you see 900 cereal brands in the grocery store aisle, you’re more likely to leave with zero. A lot of the time for ecommerce, having more than three options is too much to think about. Keep it simple. Feature three options, and know that a lot of the time consumer will choose the middle option.

“Don’t go crazy with your SKU count. Focus on keeping a catalog small while still being able to increase lifetime value and new sales. For a lot of brands, 3 SKUs make up 50% of sales. You probably don’t need hundreds of products that aren’t driving revenue.” – Ryan Treft, Founder & Partner of Coalatree and Peejamas

Coalatree was insolvent when Ryan picked it up several years ago. This was because they pumped out too many SKUs too fast that didn’t make sense for their relative size. Ryan advises to go on pace with cash flow, margin, lead time, MOQ, and to be sensible to what a customer really needs. Too much choice is overwhelming. Sometimes it’s better to pair it down to a simple message.

Utilizing your inventory management software to find important SKU-level data

To conduct your SKU analysis, make sure you’re tracking important inventory metrics at the SKU level. This would include average units sold per day and historical sales performance for each SKU so you can see how well the product is selling over time. You’ll also need to track how much you’re spending on warehousing costs for each SKU so you can accurately measure profitability.

You’ll need to use inventory management software that comes with robust analytics features to keep a close eye on all of these SKU-level metrics. Ideally, the software should also be able to make accurate predictions such as the expected increase in demand based on historical sales data.

How ShipBob makes SKU analysis a breeze

The ShipBob analytics dashboard and inventory management software provides you with in-depth insights into SKU-level inventory data. This simplifies SKU analysis by enabling you to track critical SKU metrics in one place.

Real-time SKU-level inventory tracking

ShipBob simplifies SKU-level inventory tracking with real-time insights into the movement of each SKU in your supply chain. With real-time inventory tracking, you can get the most updated information on which SKUs are running out and set alerts when a certain SKU needs reordering.

Moreover, ShipBob makes it easy to consolidate your SKUs across different channels to streamline your SKU analysis. Even if you use different SKU systems for different sales channels, you can update the information on the product details page to track it from a single dashboard.

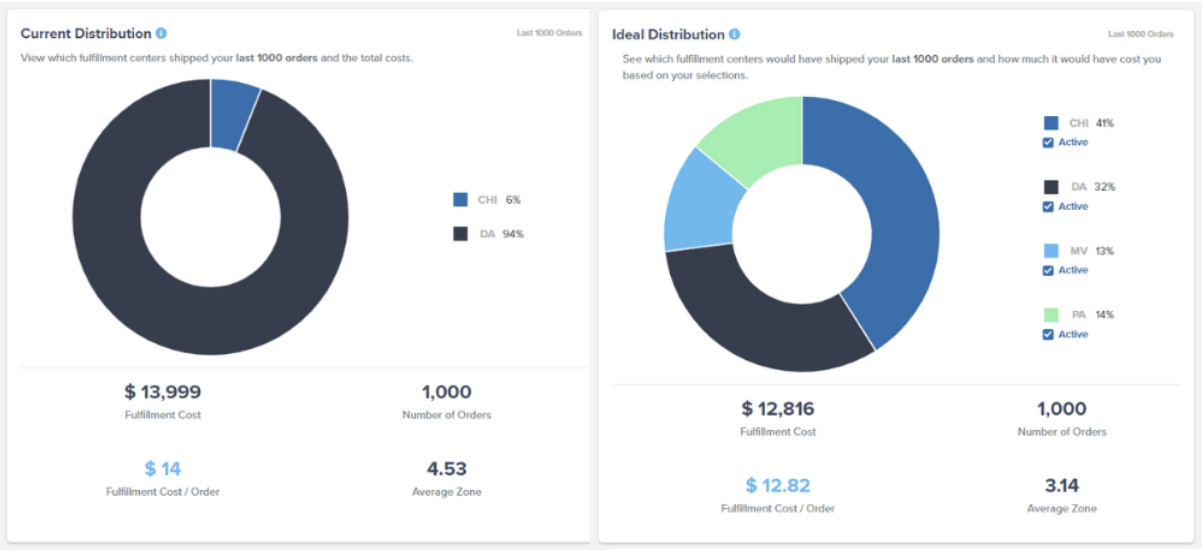

Additionally, you get to see the SKU performance across different fulfillment centers. This will show you where certain SKUs are highest in demand, allowing you to strategically distribute your inventory. In other words, you can remove certain SKUs from regions that don’t see much demand and reallocate them to fulfillment centers that see high inventory turnover for the specific SKU.

Efficient product bundling

Your SKU analysis will reveal a lot of vital information to increase revenue and efficiency. This enables you to perform SKU rationalization and manage SKU proliferation depending on the profitability of each SKU item. During this process, you may also discover product bundling opportunities to increase sales for slow-moving SKUs. Or you may want to add certain products to your supply chain because they’re likely to be profitable.

ShipBob allows you to perform all these tasks from the inventory dashboard. You can easily import products from an Excel sheet or add them manually. And you can quickly bundle items that will likely go well together and help you grow your revenue.

ShipBob is a tech-enabled fulfillment provider that gives merchants insightful data to power their ecommerce business. If you’re ready to get started with a 3PL that can help your business keep track of in-depth SKU data, request a quote from ShipBob.

SKU analysis FAQs

Here are the answers to the top questions about SKU analysis.

When should I analyze my SKUs?

SKU analysis should be performed on a regular basis, ideally in real-time although certain analytics tasks may be performed at monthly, quarterly, or annual intervals.

What is SKU-level data?

SKU-level data refers to the information about each SKU in terms of inventory turnover, historical sales performance, and inventory holding cost.

How does ShipBob help with SKU analysis?

ShipBob enables you to conduct comprehensive SKU analysis by providing you with inventory performance data at the SKU level. It helps you consolidate your SKU tracking, add new SKUs to your supply chain, or even bundle different items to increase profitability.