Table of Contents

** Minutes

What is anticipatory shipping?

Inside Amazon’s anticipatory shipping model

Key benefits of anticipatory shipping

Challenges and controversies in anticipatory shipping

Democratizing anticipatory shipping: Strategies for brands

What if you could ship products before customers even order them? That’s Amazon’s anticipatory shipping patent. It’s a game-changer that’s reshaping delivery expectations across ecommerce.

This approach requires massive investment in analytics, complex inventory systems, and risks sending products nobody wants. This makes true anticipatory shipping impractical for most companies.

In this blog, get a full explanation of anticipatory shipping from start to finish and learn how businesses of any size can achieve similar benefits without Amazon’s resources.

What is anticipatory shipping?

Anticipatory shipping is a fulfillment strategy patented by Amazon in 2013 that ships products before customers order them, using predictive analytics. This shifts logistics from reactive to proactive, anticipating demand instead of just responding to it.

The system has three key components:

1. Pre-shipment logistics: Products are picked, packed, and staged before customers click “buy,” using advanced robotics and automation.

2. Regional pre-positioning: Inventory is strategically placed in warehouses near predicted customer demand, based on data analysis of purchasing patterns and demographics.

3. Late-select addressing: Shipping labels remain partially incomplete until the last moment, allowing packages to be rerouted mid-transit as demand shifts.

This system runs on AI, machine learning, and predictive analytics that forecast demand accurately, ensuring products are in the right places at the right times to dramatically improve delivery speed and convenience.

The evolution of Amazon’s anticipatory shipping

Anticipatory shipping evolved from Amazon’s traditional demand forecasting techniques. While Amazon had long optimized inventory placement, this patent took a bold step forward by actually shipping products based on predictions, not just positioning them.

The development was influenced by AI research like “Prediction Machines” by Agrawal, Gans, and Goldfarb, which highlighted how machine learning could transform business decisions. Amazon applied these insights to solve fulfillment challenges.

Inside Amazon’s anticipatory shipping model

Amazon’s anticipatory shipping model is a complex and innovative system that leverages advanced technologies and data analytics to streamline the fulfillment process. By predicting customer demand and proactively shipping products to strategic locations, Amazon has revolutionized the way businesses approach logistics.

Pre-shipment logistics and robotics

At the heart of Amazon’s anticipatory shipping model is a sophisticated pre-shipment logistics system. This system relies on warehouse automation and robotics to pick, pack, and stage items before a customer even places an order. Amazon’s fulfillment centers are specifically designed to support this proactive approach, with Kiva robots playing a crucial role in making anticipatory shipping operationally feasible.

These robots navigate the warehouse floor, locating and transporting products to the packing stations, which enables Amazon to significantly reduce the time and labor required to prepare orders for shipment. Additionally, AI-powered inventory management systems analyze data to determine which products should be pre-shipped and in what quantities, ensuring that the right items are always ready to go when a customer clicks “buy.”

Regional pre-positioning strategies

Strategic positioning of inventory in warehouses closer to predicted customer locations is another key component of Amazon’s anticipatory shipping model. By analyzing historical sales data, customer demographics, and other relevant factors, Amazon can predict which products are most likely to be purchased in specific regions.

This information is then used to determine which products should be stored in which distribution centers, allowing Amazon to place inventory as close to potential customers as possible. With a vast network of fulfillment centers across the country, Amazon can effectively pre-position products to reduce transit times and shipping distances.

For example, if data suggests that a particular item is frequently purchased by customers in the Northeast, Amazon may choose to store a larger quantity of that product in that region. By doing so, the company can ensure that the item is readily available when a customer there places an order, enabling faster delivery times and a better overall customer experience.

“Late-select addressing” technology

One of the most innovative aspects of Amazon’s anticipatory shipping model is its use of “late-select addressing” technology. This advanced system allows Amazon to keep shipping labels partially incomplete until the last possible moment, providing an unprecedented level of flexibility in the fulfillment process.

With late-select addressing, packages can be rerouted mid-transit based on real-time demand signals. For instance, if a customer in a different location unexpectedly purchases a product that has already been pre-shipped, Amazon can quickly adjust the shipping label to ensure that the package is delivered to the correct address.

This dynamic addressing capability is made possible by a sophisticated technical infrastructure that enables real-time communication between Amazon’s predictive analytics systems and its fulfillment network. By keeping shipping labels fluid until the last possible moment, Amazon can adapt to sudden changes in customer behavior and maintain its commitment to rapid delivery times.

Key benefits of anticipatory shipping

Anticipatory shipping delivers several compelling advantages that can transform how businesses fulfill orders and serve customers. Let’s explore the most significant benefits this innovative approach offers.

Dramatically faster delivery times

Anticipatory shipping slashes delivery times by positioning inventory near predicted customers. Instead of shipping from distant warehouses, products are already waiting at nearby fulfillment centers, reducing delivery windows from days to hours.

Consider a customer in North Carolina whose predicted purchase is pre-positioned locally. When they place their order, same-day or next-day delivery becomes possible, which is a major improvement over traditional shipping from warehouses states away.

Research confirms faster delivery directly boosts conversion rates. When customers know they’ll receive items quickly, they’re more likely to complete purchases, giving businesses a competitive edge and increasing sales.

Enhanced customer satisfaction and loyalty

Meeting customer needs before they explicitly express them creates a powerful “wow factor” that builds loyalty. Fast deliveries make customers feel understood and valued, encouraging repeat purchases and word-of-mouth recommendations.

This proactive approach to fulfillment delivers a seamless experience that resonates with shoppers. Data shows customers who receive orders quickly develop stronger brand relationships, becoming repeat buyers who spend more over time.

Operational cost efficiencies

Despite requiring upfront investment, anticipatory shipping ultimately reduces costs. Pre-shipping products in bulk and distributing them strategically lowers per-order fulfillment expenses while minimizing costly expedited shipping.

Accurate demand forecasting prevents emergency logistics and last-minute inventory shuffling. This results in fewer split shipments and more consolidated deliveries, reducing overall shipping costs.

Smart inventory placement also optimizes warehouse space. By stocking the right products in the right locations based on predicted demand, businesses avoid excess storage costs for slow-moving items while keeping popular products readily available.

Challenges and controversies in anticipatory shipping

While anticipatory shipping offers numerous benefits, it also presents some significant challenges and potential controversies that brands must navigate carefully.

Data privacy and ethical considerations

Anticipatory shipping requires extensive customer data collection to power its predictive algorithms. Companies need purchase histories, browsing behaviors, and demographic information to forecast demand accurately.

This data-heavy approach raises privacy concerns. With regulations like GDPR and CCPA now in place, businesses must ensure their practices are compliant and prioritize customer privacy.

Brands face the challenge of balancing personalization with privacy protection. To maintain trust, companies should be transparent about how they use customer data and offer clear opt-out options to prevent their anticipatory shipping efforts from feeling invasive.

Managing over-shipment risks

Another major challenge is over-shipment risk, or sending products to customers who never actually buy them. This creates financial losses, higher return costs, and unnecessary environmental impact.

To address this, brands need effective strategies for managing unwanted deliveries, such as partnering with charities, using resale platforms for excess inventory, or implementing efficient return systems.

Clear customer communication is essential when delivering items not explicitly ordered. Brands should explain the anticipatory shipping process, offer simple return options, and consider providing incentives for customers to keep the products.

Technical and operational hurdles

Setting up anticipatory shipping is challenging and requires seamless connection between data systems and physical warehouses. Most businesses will need to redesign their warehouse layouts and processes to handle pre-shipment preparation and flexible routing.

Managing inventory becomes trickier, especially during peak seasons. You’ll need advanced inventory forecasting tools and real-time systems to ensure products are positioned correctly at all times.

The tech requirements are substantial, from data processing to machine learning and communication systems. Building this infrastructure is particularly difficult for smaller businesses with limited resources.

ROI and financial considerations

Anticipatory shipping requires careful ROI analysis before implementation. The substantial upfront costs of predictive analytics systems, additional inventory, and warehouse modifications must be balanced against the benefits of faster deliveries, happier customers, and streamlined operations.

Measuring ROI can be challenging since many benefits (like improved customer loyalty) are long-term or difficult to quantify directly. To minimize financial risk, start with small-scale tests before full deployment, allowing you to refine your approach based on real performance data.

Your decision to invest in anticipatory shipping should align with your specific business model, customer expectations, and growth goals. While the potential rewards are significant, success requires thoughtful planning and ongoing optimization to navigate the associated challenges.

Democratizing anticipatory shipping: Strategies for brands of all sizes

You don’t need Amazon’s resources to achieve faster deliveries and happier customers. Here are practical strategies any business can implement to gain anticipatory-style benefits without Amazon’s scale.

Partial anticipatory approaches for smaller merchants

You don’t have to be an ecommerce giant to take an anticipatory shipping approach.

- Analyze your sales history, product lifecycles, and regional trends to determine which SKUs deserve priority placement.

- Start small by pre-positioning only your bestsellers in strategic locations.

- Identify which products are most likely to sell in specific regions and place inventory closer to those customers.

This targeted approach lets you test anticipatory concepts and speed up deliveries without stretching your resources too thin.

Leveraging real-time data for dynamic inventory placement

Combine historical sales data with live signals from marketing campaigns, social media, and seasonal factors to improve prediction accuracy. Today’s affordable analytics tools give smaller brands access to forecasting capabilities once available only to enterprise businesses.

These tools help you process data quickly and generate actionable inventory insights. With real-time information, you can create flexible forecasting models that adapt to emerging trends and sudden shifts in customer behavior.

Multi-warehouse distribution as an anticipatory alternative

Distribute inventory across multiple fulfillment centers to achieve faster deliveries without pre-shipping orders. By strategically placing products in warehouses near key customer hubs, you’ll reduce shipping distances and transit times while minimizing risk.

Analyze customer demographics and regional sales patterns to determine optimal warehouse locations. Many 3PLs offer established fulfillment networks that make this strategy accessible without having to operate your own warehouses.

Hybrid fulfillment models that balance risk and speed

Implement a hybrid approach by blending “just-in-time” and “just-in-case” strategies for different product categories. Pre-position your bestselling, high-margin items in regional warehouses while keeping slower-moving products centrally located.

This balanced approach improves speed for your most important products without overinvesting across your entire catalog. You can also adjust inventory placement before predictable sales spikes like holidays or annual sales events. Modern warehouse systems provide the flexibility to adapt your inventory allocation as needed.

How ShipBob enables anticipatory-like fulfillment

For brands seeking to implement anticipatory-style fulfillment without the complexity of managing it themselves, partnering with a fulfillment partner like ShipBob can be a game-changer. ShipBob’s fulfillment platform and global network of warehouses offer several key advantages that mirror the benefits of Amazon’s anticipatory shipping model.

Strategic inventory distribution across a global network

With over 60 fulfillment centers across six countries, ShipBob’s extensive network allows brands to position their inventory strategically close to end customers, regardless of where they’re located. This distributed approach achieves the same goal as anticipatory shipping: reducing the distance and time required for orders to reach their destination.

ShipBob’s hub-and-spoke model streamlines the process of transferring inventory to the optimal fulfillment centers. Brands can send their bulk inventory to a central receiving warehouse, and ShipBob will automatically redistribute those products to the locations that best serve their customers. This efficient process ensures that the right inventory is always in the right place at the right time.

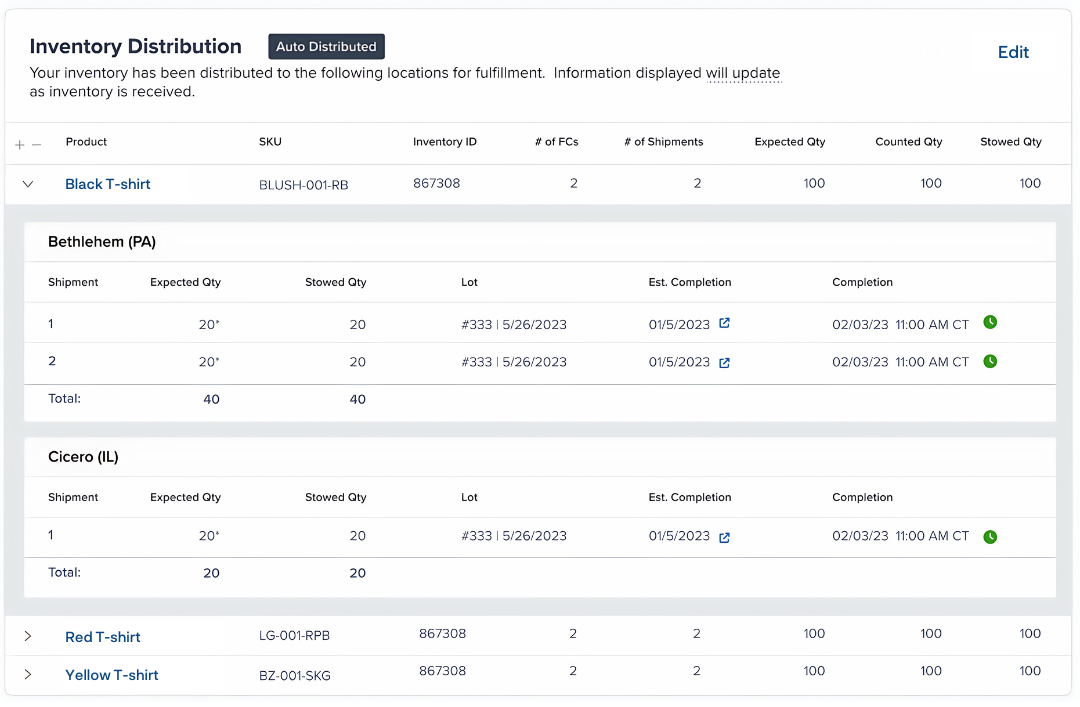

In the US, ShipBob offers automated inventory placement, distribution, and rebalancing through our Inventory Placement Program (IPP). Based on each merchant’s historical order data, demand forecasts, and ShipBob’s AI Decision Engine, brands can streamline inventory placement throughout the country.

“On top of cost savings and fast shipping, we’ve been able to take a more hands-off approach to fulfillment and inventory distribution. We don’t have to be super involved in the day-to-day details and coordination, which is very helpful for our team. IPP works overwhelmingly well. It’s efficient, seamless, and super automated. When you combine that with the fast, personal customer support ShipBob provides us with, it allows us to have full confidence that things are running well.”

– Lizzie Vance, Sales Director at P.F. Candle Co.

Data-driven inventory placement and demand forecasting

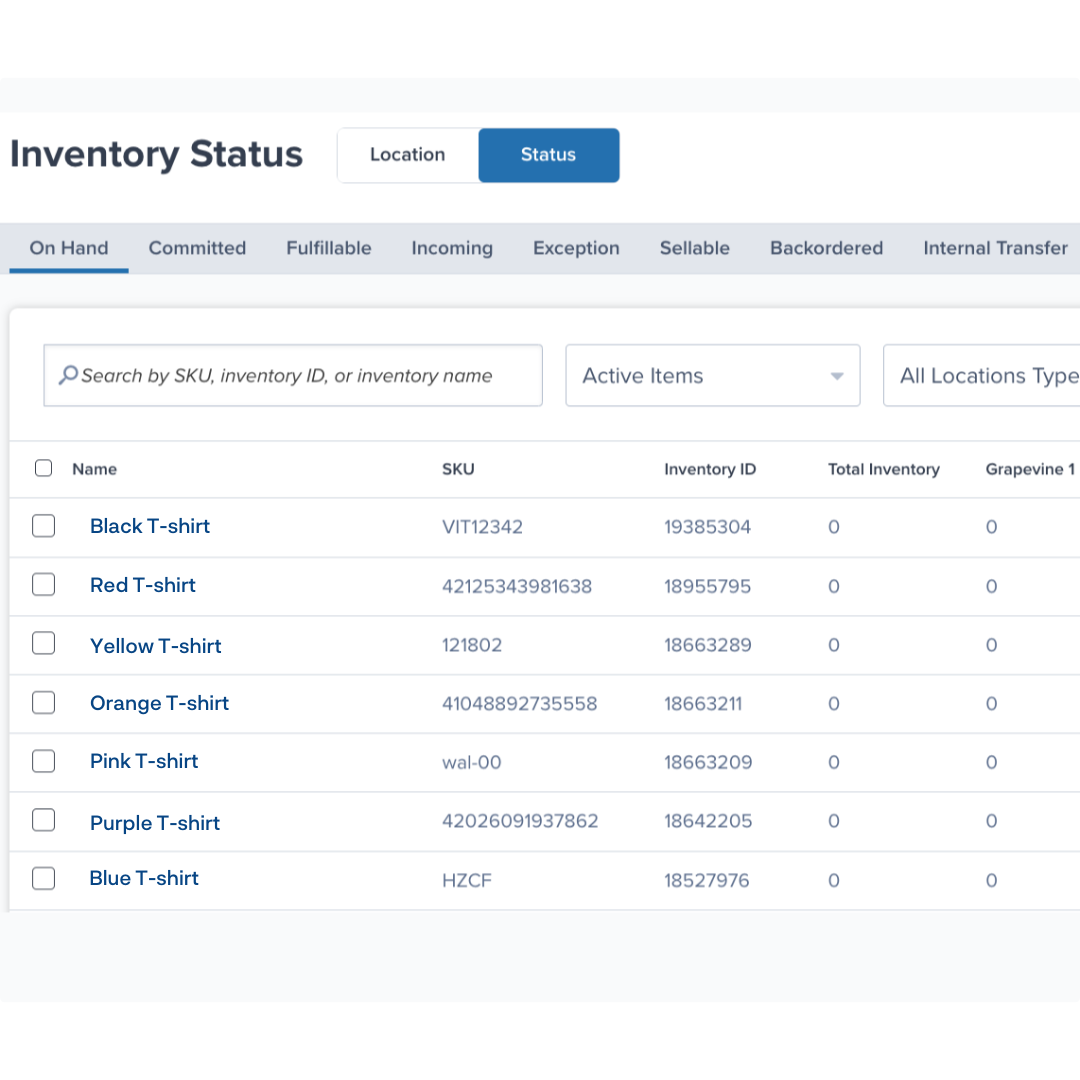

ShipBob’s platform provides advanced analytics tools that help brands predict future demand and make informed decisions about inventory placement. By analyzing historical order data, seasonal trends, and product performance metrics, ShipBob’s algorithms can recommend the ideal distribution of SKUs across its network.

These data-driven insights allow brands of all sizes to access the kind of predictive intelligence that powers Amazon’s anticipatory model. With ShipBob, merchants can confidently position their inventory in the locations most likely to generate sales, without the risk of over-shipping or stockouts.

“Forecasting where demand will be highest is always a tricky exercise, especially when coupled with how much inventory we want to put into each fulfillment center. We’ve been working together with ShipBob to figure out how much inventory we want to place in each of the fulfillment centers so that we can get our products into customers’ hands as quickly as possible.”

– Stephanie Lee, Co-CEO of PetLab Co.

Real-time inventory visibility and proactive management

One of the key challenges of anticipatory shipping is maintaining accurate visibility into inventory levels across multiple locations. ShipBob solves this problem with a centralized dashboard that provides real-time insights into stock quantities, order volume, and fulfillment performance at every warehouse.

This level of transparency empowers brands to manage their inventory proactively and make timely adjustments as needed. ShipBob’s platform offers intelligent features like automated reorder points and low-stock alerts, ensuring that brands can replenish inventory before it runs out. By staying ahead of demand in this way, merchants can achieve the speed and reliability of anticipatory shipping without actually pre-shipping orders.

Omnichannel fulfillment optimization

Finally, ShipBob’s seamless integration with major ecommerce platforms like Shopify, BigCommerce, and Amazon enables brands to maintain a cohesive fulfillment strategy across all sales channels. When an order is placed on any connected platform, ShipBob’s technology automatically routes it to the optimal fulfillment center based on inventory availability and proximity to the end customer.

This automatic order routing ensures that every order is shipped from the location that will provide the fastest and most cost-effective delivery. For brands that sell on Amazon, ShipBob also offers FBA Prep services, allowing merchants to leverage both Amazon’s fulfillment network and ShipBob’s distributed warehouses in a unified approach.

By optimizing fulfillment across channels in this way, ShipBob helps brands provide the fast and flexible shipping options that modern consumers expect. This omnichannel approach captures the essence of anticipatory shipping – getting products to customers as quickly as possible, no matter where or how they shop.

Get started with ShipBob

Leverage ShipBob’s global network of dozens of fulfillment centers, best-in-class technology, and AI and ML-backed solutions to ship orders faster and more efficiently.

FAQs about anticipatory shipping

Below are more answers to common questions, queries, and challenges regarding anticipatory shipping.

Can small to mid-sized brands implement anticipatory shipping?

While full anticipatory shipping requires substantial resources, smaller brands can still capture many benefits through simplified approaches.

A practical strategy is distributing inventory across multiple fulfillment centers near key customer locations. Partnering with a 3PL like ShipBob gives mid-sized brands access to a strategic warehouse network, enabling faster deliveries without pre-shipping products.

Even brands with limited budgets can analyze sales data to identify bestsellers and maintain optimal stock in strategic locations. Starting with partial approaches, like pre-positioning only high-velocity items, offers a manageable entry point for smaller merchants.

What data is needed to power anticipatory shipping models?

Effective anticipatory shipping relies on three key data categories:

- Purchase history (frequency, volume, and timing of past orders) to identify buying patterns

- Browsing behavior (pages viewed, time spent, wishlist/cart additions) to gauge customer interest

- Demographic information (location, age, gender, income) for targeted segmentation

This data helps forecast demand at local levels by analyzing how different customer groups interact with products. To maintain trust, brands must collect and use this information ethically, with transparent consent practices and compliance with regulations like GDPR and CCPA.

How accurate are anticipatory shipping predictions?

Prediction accuracy varies based on product type, seasonality, and price point. Products with consistent, high-volume sales generate more reliable forecasts than seasonal or variable items.

While Amazon reports up to 85% accuracy for certain categories, most brands should expect lower initial rates. Accuracy improves over time as algorithms learn from both successful and failed predictions.

Approach anticipatory shipping as a continuous improvement process rather than expecting immediate perfection. Start with a focused, data-driven strategy on your most predictable products, measure results consistently, and gradually expand while managing risk.

What happens when anticipatory shipping predictions are wrong?

When predictions miss the mark, brands need ready strategies to handle pre-shipped products that don’t find buyers:

- Reroute items to fulfillment centers with higher demand

- Offer targeted discounts to clear excess inventory

- Use personalized marketing to match products with potential customers

- Implement efficient return processes to reintegrate unsold items

To reduce errors, continuously analyze your data to identify patterns contributing to inaccurate forecasts. Refining algorithms based on these insights helps minimize financial risks over time.

How does ShipBob’s approach compare to Amazon’s anticipatory shipping?

ShipBob offers a more accessible alternative to Amazon’s anticipatory model with key differences:

- ShipBob doesn’t pre-ship before customer purchase, eliminating the risk of sending products to areas with uncertain demand

- Instead, ShipBob provides a distributed network that positions inventory strategically near customers

- When orders come in, ShipBob’s technology routes them to the nearest warehouse with available inventory

- ShipBob’s analytics help brands make data-driven inventory decisions that achieve similar goals to anticipatory shipping

While this approach may not match the extreme speed of Amazon’s pre-shipment model, it offers a more practical, risk-balanced solution for brands looking to optimize fulfillment and meet customer expectations.

How can I start implementing anticipatory-style fulfillment for my brand?

Start your anticipatory-style fulfillment journey with these steps:

- Build your data foundation by analyzing sales patterns, product affinities, and regional trends

- Partner with a fulfillment provider like ShipBob to access a distributed warehouse network

- Begin with your bestselling products, placing them strategically near customer hubs

- Monitor performance metrics and customer feedback closely

- Gradually expand your approach based on data insights

Remember that anticipatory fulfillment is an ongoing process of refinement. By starting with a focused approach and scaling methodically, you can optimize your strategy to meet customer expectations while driving sustainable growth.