Table of Contents

** Minutes

Inventory vs. stock: understanding the difference

If you’re ramping up an ecommerce business, you likely use the terms ‘stock’ and ‘inventory’ interchangeably.

But, are they the same?

Is it stock that you store in your warehouses, or is it inventory?

The short answer is stock is part of inventory, but sometimes the terms are used differently depending on the context. Here are the general definitions:

- Stock is the supply of finished goods available to sell to the end customer.

- Inventory can refer to finished goods, as well as components used to create a finished product.

As you can see, all stock is inventory but not all inventory is stock. Since it’s a subtle difference in meaning, it might not seem like a big deal to understand how they are used through supply chain.

But when used in different areas of a business (e.g., manufacturing versus accounting), it can cause some confusion if the terms are not used correctly.

This article offers a deeper dive into how to use the two terms appropriately depending on the context.

What is stock?

Stock refers to the amount of finished products that are ready to be sold to the end user. It can also include raw materials, if the retailer sells the items directly to customers to earn profit (e.g., some forms of B2B ecommerce).

What is inventory?

Inventory refers to finished goods, as well as raw materials (also called production inventory) and work-in-process (WIP) inventory. Since inventory is tied to carrying costs, inventory must be maintained at an optimised level, so all sold and unsold items can be accounted for during tax season.

4 main types of inventory

As inventory and stock moves throughout the supply chain, the type of inventory it is considered can change. Here is a breakdown of the four main types of inventory.

1. Raw materials

Raw materials constitute all the basic components used to produce the finished goods. It is categorized as inventory when the components are used by your business to produce something that can be sold to end user. Raw material is considered stock when the raw material is sold to another business.

2. Work in process (WIP)

In production and supply chain management, work-in-process inventory refers to the valuation of products that have only been partly processed. These items are not yet finished goods, nor are they raw materials; they exist somewhere in the middle of a production round. In the company’s balance sheet, these inventory items are considered current assets.

3. Finished goods

Finished goods inventory is the total amount of items available for customers to purchase that can be fulfiled. By knowing how much finished goods are on hand, retailers can calculate the value of their goods for sale, which is needed to record ending inventory for accounting purposes.

4. MRO

MRO is an acronym for “maintenance, repair, and operations,” and it refers to the tools and equipment used for maintenance, repair, and running of production required to manufacture finished goods. These units are rarely incorporated into the goods being produced, but are considered inventory items in ecommerce bookkeeping.

Inventory vs. stock: understanding the difference

Though inventory and stock are used interchangeably in ecommerce, they have slight differences that set them apart. For one, it’s preferable to only use ‘stock’ for daily logistics operations and ‘inventory’ for inventory accounting purposes.

Below is a simple comparison of the difference between ‘stock’ and ‘inventory.’

| Inventory | Stock |

|---|---|

| Refers to the value of parts and raw material used for manufacturing, work in process goods, and the final product | Refers to the value of all items that are available and directly sold to customers |

| Helps you arrive at the sale price of the stock | Helps you determine business revenue |

| Needs to be updated and managed on a quarterly or yearly basis (end of accounting period) | Needs to be updated and managed on a daily basis (maybe even multiple times a day) |

| Term used in both retail and manufacturing | More common in production and manufacturing |

| Arrive at the value of inventory using methods, such as FIFO, LIFO, and weighted average methods | Value of stock is based on the current market value or the price at which goods are sold to the customer |

Inventory and stock examples

To better understand how and when to use the terms ‘stock’ and ‘inventory’ accurately, let’s look at an example of an online manufacturer and retailer, Paper Corp., which produces and sells notepads.

Inventory examples

For production purposes, ‘inventory’ refers to:

- All the raw materials used to create the notepad, such as pulp, chemicals, metal wires, plastics, and fabric.

- Individual pages (WIP) before they are bound together.

- Finished products (the notepads) that have completed all levels of production and quality checks.

- Materials required for maintenance, repairing, and operating of machines required for notepad production such as lubricants, coolants, nuts, and screws.

Stock examples

Since Paper Corp also sells notepads to the end user, they use ‘stock’ to refer to finished notepads that are stored and ready to fulfiled. Every finished notepad is tied to a SKU number and includes a barcode, which can be scanned to identify and locate finished items, so they can be fulfiled quickly.

Paper Corp also manufactures pulp from wood and sells it to other paper manufacturers. In this case, sellable pulp is also categorized as available stock.

Get a handle on stock inventory control with ShipBob

At the end of the day, differentiating between ‘stock’ and ‘inventory’ doesn’t have a huge business impact. If you run an online store that solely sells finished products to customers, what matters most is the ability to keep track of the flow of inventory throughout your supply chain.

Understanding how much inventory is being delivered, how much is currently in stock, and how much is ready to sell is key to supply chain efficiency.

But inventory management is a time-consuming tasks. That’s why many direct-to-consumer (DTC) brands partner with a third-party logistics (3PL) provider like ShipBob to not only handle fulfilment but also help with inventory accuracy, stock control and inventory optimisation.

ShipBob’s entire international fulfilment network is powered by a best-in-class proprietary fulfilment software, which includes built-in inventory management tools.

This enables fast-growing online brands the ability to track inventory, manage SKUs, optimise product allocation across regions, and expand into new fulfilment centre locations based on current demand.

Inventory management

ShipBob’s 3PL services include access to tech-enabled inventory management capabilities.

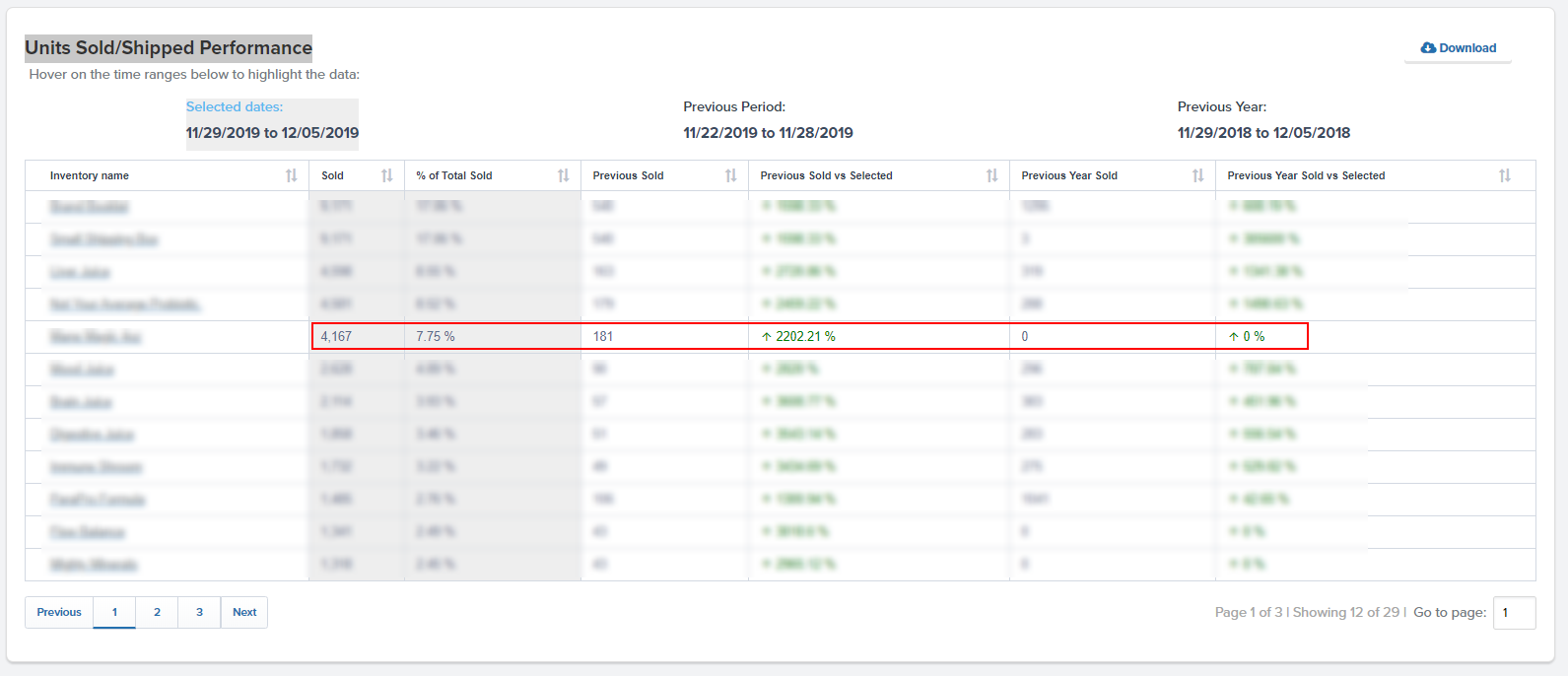

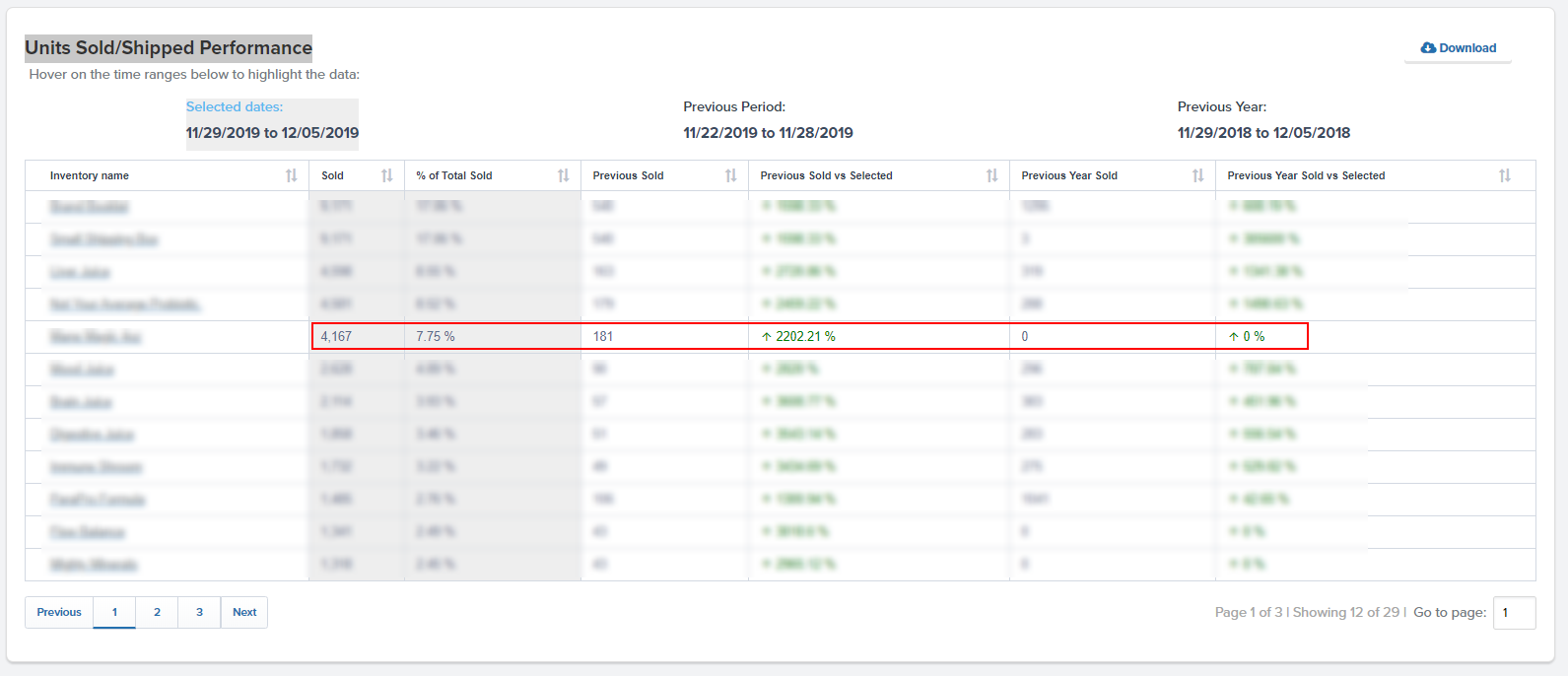

From the ShipBob dashboard, you can identify slow-moving stock along with fast-moving stock, storage costs, your carrying costs, inventory days on hand, and more. Having this deep insight into stock makes it easy to outsource fulfilment while still maintaining control over supply chain decisions.

This single source of truth for your orders and stock is a handy tool to have, especially for inventory planning. You can use the data found on ShipBob’s dashboard to further optimise stock levels and ensure you meet customer demand.

“ShipBob lets you manage your inventory while providing important data in a very digestible way. Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

Track inventory distribution

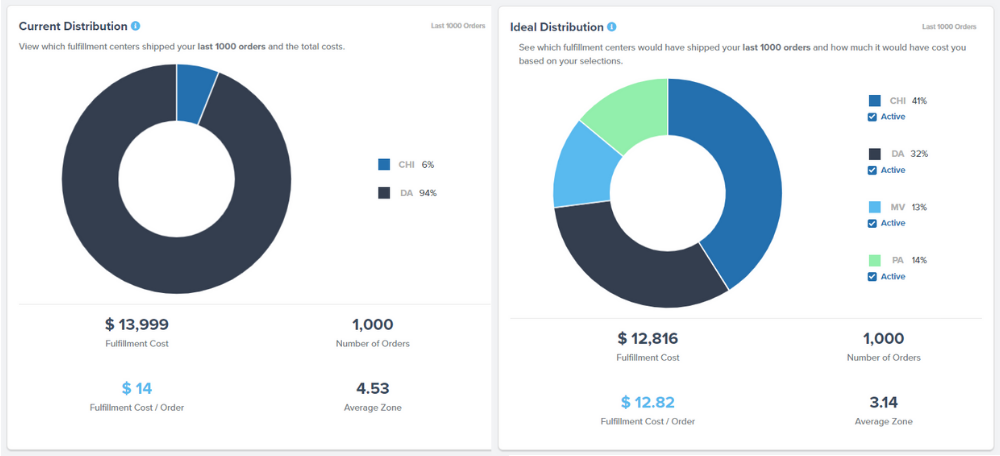

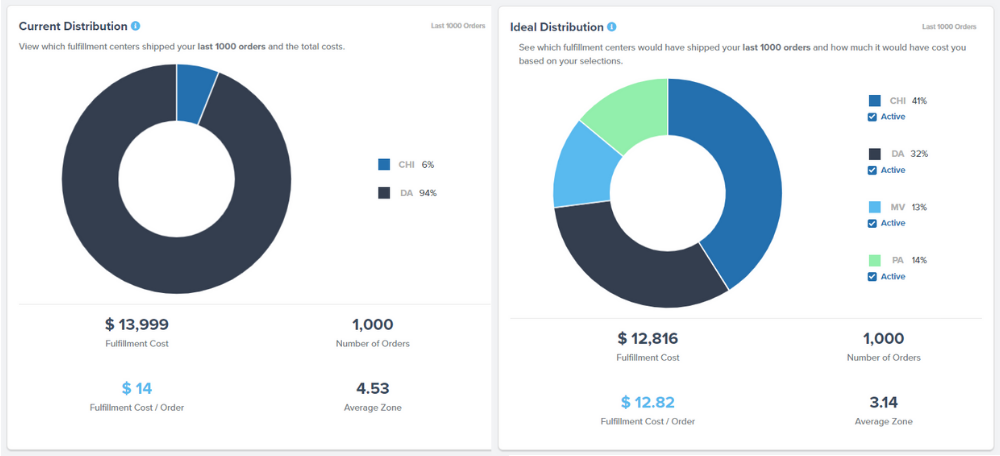

To expand customer reach and offer fast, affordable shipping, you will eventually need to move beyond centralised inventory and expand logistics across distribution centres. Known as distributed inventory, this method is an on-demand logistics solution that makes it easy to reduce shipping costs and improve last-mile delivery.

ShipBob offers a global fulfilment network and gives merchants the choice in which fulfilment centre location(s) to split inventory across. As you collect historical order data, our team of experts can help you identify an ideal distribution strategy, so you can allocate inventory accordingly.

“We are growing really fast and won’t slow down anytime soon. With ShipBob, we have the option to use more of their warehouses to further reduce shipping costs.

Because ShipBob has a lot of people to handle our orders and additional warehouses we can expand into, we can scale up with ease as we continue to grow quickly. If we ran our own warehouse, it would be much harder to hire people and we’d inevitably outgrow the space.”

Oded Harth, CEO & Co-Founder of MDacne

Reporting and analytics

With ShipBob’s advanced analytics and reporting tool, you get access to a streamlined dashboard that visually displays data to help with inventory forecasting, lets you identify inventory trends and patterns, and much more.

The data and insights are shown in real time, which makes it easy to see current stock availability at each fulfilment centre location, which can help you determine when it’s time to restock inventory.

“In terms of tracking inventory, we use ShipBob for everything. The analytics are super helpful. We download Excel files from the ShipBob dashboard all the time and use them to analyse everything from cancelations, to examining order weights, to checking on whether ShipBob is shipping orders on time.”

Ines Guien, Vice President of Operations at Dossier

To learn more about how ShipBob can you help you optimise your supply chain, click the button below.

Inventory vs. stock FAQs

Here are some of the most commonly asked questions about the differences between the terms ‘inventory’ and ‘stock.’

Are stock and inventory the same?

Though very minor, there are differences in the use of the terms based on the context and the industry. For instance, stock can mean one thing to a manufacturer and something different to a business accounting (since inventory is more encompassing of raw materials, where stock is what’s available to be sold today). For most ecommerce brands, the use of inventory and stock are used interchangeably.

How should I account for inventory vs. stock?

Inventory is accounted for with the FIFO, LIFO, and weighted average methods. Meanwhile, the value of stock is pegged at whatever is lower, acquisition cost or market price.

How do I know when to replenish stock and inventory?

Stock and inventory replenishment is a crucial part of supply chain management. There are tools and calculations, such as the reorder point formula that can help you make healthy inventory decisions. However, since inventory management takes up a lot of time, many brands outsource fulfilment to a tech-enabled 3PL like ShipBob, which offers insights and data to save time on managing inventory while performing all fulfilment services as well.

What are inventory management tools?

Inventory management tools are used to complement a brand’s logistics operations. By implementing inventory technology and automation, online brands can expand their logistics network while tracking inventory in real time. This provides brands full visibility into current inventory data without the need to be involved in the day-to-day operations.