Learn how probiotic supplement brand ZBiotics utilises ShipBob’s Inventory Placement Program to balance their inventory throughout the fulfilment network to offer cheaper shipping to customers.

Customer Profile

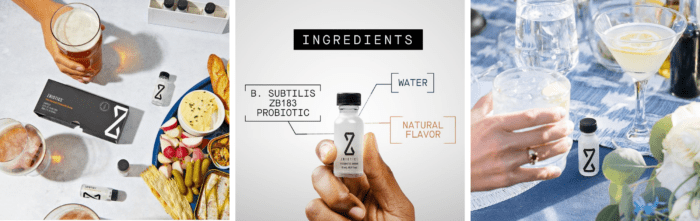

Zack Abbott and Stephen Lamb joined together to launch the world’s first genetically engineered probiotic in order to help people feel better the day after drinking alcohol. Customers drink the bottle of ZBiotics probiotic 0-120 minutes before their first alcoholic beverage in order to feel better the next morning after drinking.

Key metrics

- 15x increase in production scale

- 3 person supply chain team

- 4 ShipBob US fulfilment centres used in PA, NY, CA, and TX

About ZBiotics

After learning about the power of genetically engineered microbes and the role they could play in the human body during his PhD candidacy, ZBiotics founder Zack Abbott wanted to create a product that could help people live happier and healthier lives.

With dozens of ideas conjured up, Zack shared the list of potential products with friends and family members to help him decide which product to take to market. Surprisingly, the consensus pointed to a microbe that helped break down acetaldehyde, a byproduct of alcohol, aimed at helping people feel better the day after drinking.

Once he created the product, Zack partnered with Stephen Lamb, a student wrapping up his JD and MBA, in order to launch ZBiotics and bring this technology to the masses. After working tirelessly for many years, the ZBiotics team launched the world’s first genetically engineered probiotic in 2019.

Since then, ZBiotics has used the power of engineered probiotics to make mornings easier and more productive for tens of thousands of people worldwide. As a result of the product’s popularity, ZBiotics needed a fulfilment provider that could be a partner in their growth and provide solutions to help them scale.

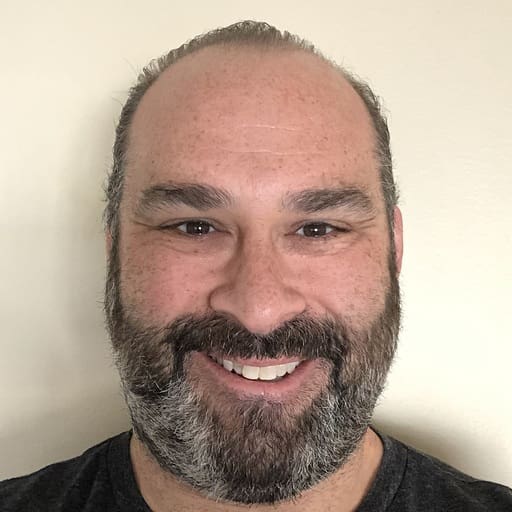

We talked to Michael Mullaney, ZBiotics’ VP of Supply Chain, to learn more about how the brand is optimising their supply chain, how a quick hiatus made them realise the grass isn’t always greener on the other side, and how ShipBob’s continuous improvements have helped the brand succeed.

Overhauling production and packaging to optimise the supply chain

As told to ShipBob by Michael Mullaney, VP of Supply Chain at ZBiotics.

I was brought onboard as the first supply chain hire at ZBiotics. As a high-growth company, we wanted to optimise how we were managing our supply chain. Things have changed drastically in the 2 years since I joined as we are making a concerted effort to improve our quality systems, build redundancy and resiliency in the supply chain, and manage overall costs.

My first task was securing a new manufacturer. We were working with a company out east, but we needed a partner who could scale faster and adapt their bottling process to the specifics of our probiotic. We pivoted to a new process and have a more consistent and higher quality product as a result.

Our production orders have scaled greatly, by 15X in the past 2 years. This growth opens the door to more opportunities to reduce costs and improve efficiencies throughout the supply chain. Through RFPs in the past 2 years we have reduced both material and manufacturing costs, improved quality and food safety, and created a more robust and risk-resilient supply chain.

Specifically, we redesigned our secondary packaging (product boxes), reducing costs by source reduction (using less material), domestic manufacturing (lower freight), and greatly reduced lead times (for better cash flow). Downstream we reduced material and fulfilment costs, and minimised product breakage in transit.

Our Merchant Success Manager at ShipBob was helpful through this process. When we were deciding on new packaging, the ShipBob team would analyse dimensions to ensure we were staying under a certain weight band.

For instance, when they tested the first iteration of our new packaging, they found that the update wouldn’t have afforded us any cost savings based on how couriers charge for dimensional weight and weight/size tiers. So we went back to the drawing board to make the box smaller to get there.

Switching to a 3PL with flashy promises but archaic technology…and coming back

When I joined the ZBiotics team, we were working with ShipBob, but we actually transitioned to a different fulfilment provider shortly after. The experience was a bit of a mess, to be honest.

The other provider offered same-day delivery, which was the big draw for why we wanted to try working with them. But they were still in startup mode and had a lot of issues to work out with their dashboard. Their technology was a long way behind ShipBob’s software and didn’t have a lot of the core functionality we had become used to at ShipBob.

Using them was not a good experience, and we ended up working with them for less than 6 months. That led us back to ShipBob. And since switching back, working with ShipBob has been a really great experience.

Leveraging ShipBob’s Inventory Placement Program to balance SKU mix

At the beginning of this year, we got introduced to the team at ShipBob working on their Inventory Placement Program. They said ZBiotics had the right profile for the program because we sell a single product in various size options.

We talked through details like the volume and frequency we would be shipping to ShipBob’s Southwest receiving hub in California, which would cross-dock and send our inventory to several other regions from where we ship orders. We also talked in detail about how our pallets are set up and the amount of product that is on each pallet. This way, ShipBob knew exactly what they were receiving from us and how to break it down in order to send units to other fulfilment centres.

The way ShipBob has set up the Inventory Placement Program is pretty straightforward. We ship all of our products to the Moreno Valley, California facility and ShipBob’s real-time data analyses our recent inventory positions across locations to decide how much of the new inventory to move to each fulfilment centre. This is a great process because it takes a load off of our team, making inventory replenishment simpler and more up-to-date.

“All we have to do is send a truckload of product to one location, and ShipBob does the rest. They push the product out with the right SKU mix by fulfilment centre based on calculations for which fulfilment centres need what. It was a no-brainer to start using ShipBob’s Inventory Placement Program program.”

Michael Mullaney, VP of Supply Chain at ZBiotics

ZBiotics VP of Supply Chain, Michael Mullaney, on the benefits of ShipBob’s Inventory Placement Program at ShipBob’s merchant event, Fulfiled.

Before being a part of the Inventory Placement Program, we were shipping LTLs to each fulfilment centre, so it made a lot of sense for us to take advantage of this program. Previously, our Inventory Planner was doing calculations to determine which SKUs needed to go where, but she doesn’t have to do that now. This solution has made our jobs easier, and the pricing was competitive.

There’s a level of visibility that allows us to see the internal transfers being made, so we know when products are expected to arrive at each fulfilment centre. While I love working within spreadsheets, that type of modeling is rough because it isn’t updated in real-time. Using ShipBob’s real-time data and being able to see when inventory reaches the initial hub location really takes work off of our plates.

“My favourite thing about the Inventory Placement Program is that it takes the burden off of our team and it’s based on real-time calculations, giving us the right distribution by SKU at each fulfilment centre. It’s comforting to know that we have a good balance between fulfilment centres on a day-to-day, week-to-week, and month-to-month basis, so our customers receive packages via the lowest shipping zone possible among the four ShipBob fulfilment centres we’re in across the US.

That ultimately helps us get products to our customers faster, giving them a great ZBiotics experience from start to finish.”

Michael Mullaney, VP of Supply Chain at ZBiotics

ZBiotic’s team at ShipBob

Brian Hruskocy

Brian is the Senior Manager, Mid Market Sales that brought ZBiotics into ShipBob.

Michael Conigliaro

Michael is the Senior Merchant Success Manager at ShipBob who supports the ZBiotics team.

Marc Fontanetta

Marc is part of ShipBob’s Merchant Care Team. He provides support to several IPP merchants like ZBiotics.

Get started with ShipBob

Interested in leveraging ShipBob’s fulfilment platform and Inventory Placement Program for your business? Connect with our team to get started.