Speed matters in ecommerce, especially when it comes to how quickly your products move. That’s where inventory velocity comes in. This essential metric tracks how quickly you’re selling through stock and has direct implications for your cash flow, profitability, and supply chain efficiency.

A high inventory velocity means less capital tied up in unsold goods, fewer risks of markdowns or obsolescence, and greater flexibility to invest in growth. It also ensures you can meet customer demand faster, keeping your brand competitive in a world where delivery speed can make or break a sale.

In this guide, we’ll walk through how to calculate inventory velocity, why it matters, and what actionable strategies you can use to improve it.

What is inventory velocity?

Inventory velocity, also known as stock velocity or inventory turn, is a critical metric that measures how quickly a business sells through its inventory over a given period. In simple terms, it tells you how fast your products are moving. This key performance indicator (KPI) is particularly crucial for ecommerce businesses, as it directly impacts cash flow, profitability, and customer satisfaction.

At its core, inventory velocity is about striking the perfect balance between having enough stock to meet customer demand and not tying up too much capital in slow-moving products. When you have a high inventory velocity, it means you’re efficiently converting inventory into sales, freeing up cash to reinvest in your business. However, low velocity can lead to a host of problems, from increased storage costs to the risk of obsolescence.

For ecommerce businesses, inventory velocity becomes even more important. Customers expect fast shipping and endless product variety, so managing inventory effectively can make or break your success. By closely monitoring and optimizing your inventory velocity, you can ensure that you always have the right products in stock, reduce the risk of stockouts, and keep your customers happy with speedy deliveries.

Why inventory velocity matters for ecommerce

Inventory velocity is more than just a number; it’s a powerful lever for driving growth and profitability. Here are a few key reasons why this metric matters so much:

- Cash flow optimization: The faster your inventory moves, the less money you have tied up in stock sitting idly in your warehouse. This frees up working capital to invest in marketing, product development, and other growth initiatives.

- Reduced storage costs: Holding onto slow-moving inventory can be expensive, especially if you’re paying for premium warehouse space. By improving your velocity, you can reduce your storage footprint and minimize carrying costs.

- Minimized obsolescence risk: The longer a product sits on the shelf, the greater the risk that it will become outdated or obsolete. This is especially true in fast-moving industries like fashion or electronics. By keeping inventory moving, you can avoid the painful markdowns and write-offs that come with stale stock.

- Competitive advantage: In ecommerce, customers have endless options at their fingertips. By optimizing your inventory velocity, you can stand out from the crowd with faster shipping times, better product availability, and a more responsive customer experience.

At the end of the day, inventory velocity is all about finding that sweet spot between supply and demand. By striking the right balance, you can unlock a virtuous cycle of growth: faster-moving inventory leads to happier customers, which leads to more sales, which leads to even faster-moving inventory.

Why tracking inventory velocity matters for ecommerce businesses

Tracking inventory velocity is crucial for ecommerce businesses. When inventory moves quickly, it frees up working capital. This extra cash flow can be reinvested into growth initiatives, such as expanding product lines, enhancing marketing efforts, or improving operational efficiency.

Moreover, faster inventory turnover reduces storage costs and minimizes the risk of obsolescence. By ensuring that inventory is moving at an optimal pace, businesses can avoid being stuck with unsellable merchandise that eats into their profits.

Perhaps most importantly, optimizing inventory velocity gives ecommerce businesses a competitive edge in terms of fulfillment speed and customer satisfaction. In an age where consumers expect fast shipping and near-instant gratification, having the right products in stock and ready to ship is essential. By closely monitoring and improving inventory velocity, businesses can consistently meet or exceed customer expectations, fostering loyalty and driving repeat purchases.

Faster fulfillment as a competitive advantage

In the crowded ecommerce landscape, differentiation is key. While factors like price and product quality are undoubtedly important, the speed and reliability of fulfillment can be a make-or-break factor for many customers.

By optimizing inventory velocity, ecommerce businesses can offer faster shipping times and more reliable stock availability than their slower-moving competitors. This, in turn, can lead to higher conversion rates, increased customer loyalty, and more positive reviews and word-of-mouth referrals.

Aligning velocity with customer expectations

Different customer segments and product categories may have varying expectations for fulfillment speed. For example, customers purchasing everyday essentials or time-sensitive items, such as birthday gifts, may prioritize fast shipping over other factors. On the other hand, those buying luxury or custom-made products may be more willing to wait for delivery.

By segmenting inventory velocity goals based on customer expectations and product characteristics, ecommerce businesses can align their stock management strategies with the needs of their target audience. This targeted approach ensures that resources are allocated efficiently and that the business is well-positioned to meet the demands of its most valuable customers.

Understanding the inventory velocity formula

To calculate your inventory velocity, you’ll need to use a simple formula:

Inventory Velocity = Units Sold ÷ Time Period

This equation gives you the average number of units sold per day, week, or month, depending on the time period you choose to analyze.

For example, if you sold 1,000 units over a 30-day period, your inventory velocity would be 33.3 units per day (1,000 ÷ 30). To get an even more precise velocity metric, you can calculate your average daily units sold by dividing your total units sold by the number of days in the period.

Calculating inventory velocity: step-by-step example

Let’s walk through a realistic example to see how this works in practice. Imagine you’re an ecommerce brand that sells two products: a fast-moving t-shirt and a slower-moving pair of jeans.

In the last 90 days, you sold 5,000 t-shirts and 1,000 pairs of jeans. To calculate your inventory velocity for each product:

- T-shirts: 5,000 units ÷ 90 days = 55.6 units per day

- Jeans: 1,000 units ÷ 90 days = 11.1 units per day

The t-shirts are moving much more quickly than the jeans. But how do these numbers stack up against industry benchmarks?

While it varies by product category, a general rule of thumb is that an inventory velocity of 30-45 days is considered healthy for most ecommerce businesses.

However, it’s important to interpret your results based on factors like product type, price point, and seasonality. For example, you might expect a higher velocity for low-priced, everyday items like t-shirts compared to higher-priced, specialty items like designer jeans.

To get a more complete picture of your inventory performance, track your velocity metrics over time to identify trends. If you notice your velocity slowing down month-over-month, it could be a sign that you need to adjust your inventory management strategy. On the other hand, if you see a consistent upward trend, it’s a good indication that your products are resonating with customers and your operations are running smoothly.

Key factors affecting inventory velocity

Inventory velocity is influenced by a complex interplay of internal and external variables that can either accelerate or hinder the speed at which products move through your supply chain. Understanding these factors is crucial for developing effective strategies to optimize your velocity.

Demand trends and customer behavior

On the demand side, fluctuations in customer preferences, seasonal trends, and the impact of marketing campaigns can significantly shift how quickly certain products sell. For example, a well-timed promotion for a slow-moving item can rapidly deplete stock, while a sudden shift in market trends might leave you with excess inventory that lingers on shelves.

Supplier constraints and lead times

Internally, supplier constraints such as lead times and minimum order quantities (MOQs) can create velocity challenges by forcing you to order larger quantities than immediately necessary, tying up capital and warehouse space. Conversely, stock shortages from suppliers can result in backorders and slower inventory turnover.

Operational efficiency in fulfillment and warehousing

The efficiency of your warehouse operations and fulfillment processes also plays a critical role in overall velocity. Streamlined picking, packing, and shipping workflows can significantly reduce the time products spend in your warehouse, while inefficiencies and errors can lead to costly delays.

External disruptions and supply chain risk

External disruptions, from shipping delays and supply chain bottlenecks to global events like natural disasters, can have ripple effects that slow down inventory movement. Building resilience and flexibility into your supply chain is essential for maintaining velocity in the face of these challenges.

Product lifecycle considerations

It’s important to recognize that expected velocity can vary significantly based on the lifecycle stage of your products. New product launches often require higher initial stock levels to meet anticipated demand, while maturing products may see slower, more consistent turnover. End-of-life products, on the other hand, may require aggressive velocity management to avoid obsolescence.

7 ways to improve inventory velocity

Inventory velocity isn’t a static metric. It’s a moving target influenced by demand patterns, operational processes, and supply chain agility.

We’ll break down seven practical, scalable strategies that businesses of all sizes can use to boost inventory velocity.

1. Leverage accurate demand forecasting

Accurate demand forecasting is essential for optimizing inventory velocity. By analyzing historical sales data, market trends, and seasonal patterns, you can more precisely predict future demand. This helps prevent both stockouts and excess inventory, ensuring that you have the right products in stock at the right time.

To get started with demand forecasting, consider methods such as time-series analysis or regression modeling. These techniques can help you identify patterns and trends in your sales data, allowing you to make more informed inventory decisions.

2. Optimize inbound throughput

Optimizing your inbound processes can have a significant impact on inventory velocity. By streamlining your receiving and stowing operations, you can reduce the time products spend in “incoming” status and make them available for sale more quickly.

To improve inbound throughput, consider implementing techniques like cross-docking, where products are immediately prepared for outbound shipment upon receipt. Utilizing barcode scanning and other automated systems can also help speed up the receiving process and reduce errors. Organizing your receiving area for maximum efficiency and establishing clear SOPs for your team can further enhance velocity.

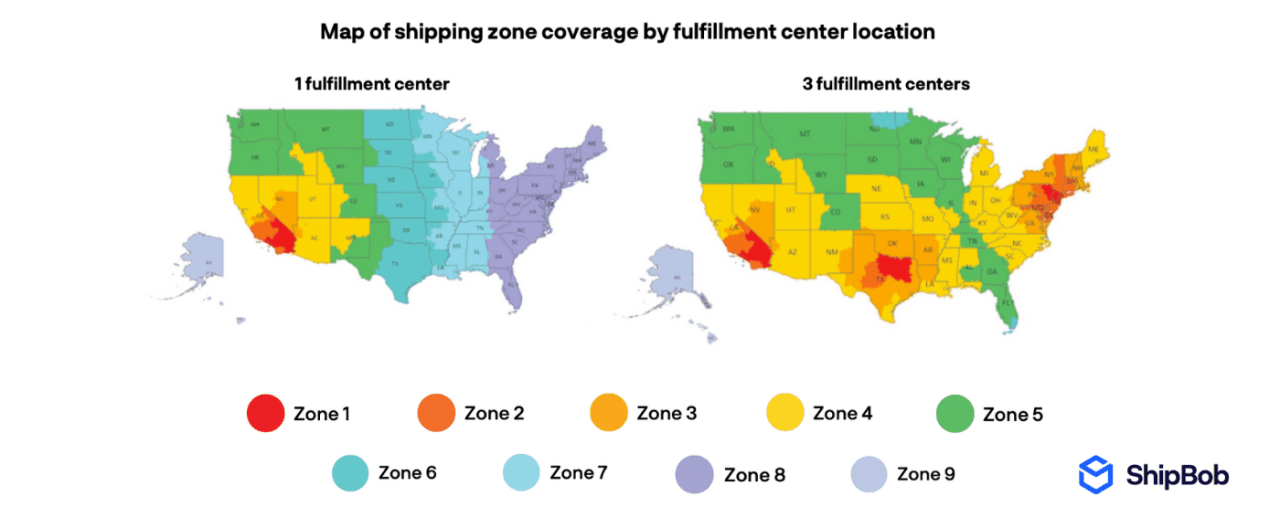

3. Distribute inventory across multiple locations

Strategically distributing your inventory across multiple fulfillment centers can be a powerful way to improve velocity. By positioning products closer to your customers, you can reduce shipping times and improve delivery speed. This not only enhances the customer experience but also helps you move inventory more quickly.

To optimize your inventory distribution, analyze your sales data to identify key customer hubs. Then, allocate your inventory across fulfillment centers based on regional demand patterns. Regularly monitoring location-specific velocity metrics can help you make informed decisions about when to redistribute stock.

4. Adopt real-time analytics & automation

Real-time inventory visibility is crucial for making proactive decisions that improve velocity. By adopting inventory management software with real-time analytics, you can track key velocity metrics and identify trends as they emerge. This allows you to quickly adjust your inventory strategy in response to changes in demand or supply chain conditions.

Automation can also play a key role in optimizing inventory velocity. For example, setting up automated reorder points based on real-time stock levels and velocity data can help you maintain optimal inventory levels without constant manual intervention. Automated reports on inventory aging, turnover rates, and other key metrics can provide valuable insights for decision-making.

5. Integrate FIFO & partial shipment rules

Implementing first-in-first-out (FIFO) principles in your warehouse operations can help prevent inventory from becoming obsolete or expired. By always shipping out the oldest stock first, you can ensure that products don’t linger on shelves past their prime. This is especially important for perishable goods or items with short life cycles.

Partial shipment capabilities can also help keep orders moving even when some items are temporarily out of stock. Rather than holding an entire order until all items are available, shipping what you have on hand can help maintain velocity and keep customers satisfied. Implementing these rules in your warehouse management system can automate the process and ensure consistency.

“All of our products come in a batch and all supplements are date coded, so we operate on a first-in, first-out (FIFO) basis. If we ever have an issue with products, I’m able to track it down to the lot number and where exactly it’s stored in the fulfillment center, which is crucial in our supply chain.

If any other product compliance issues arise, we’re very safeguarded by ShipBob’s technology. We’re backed by ShipBob’s WMS system that has all of the details I need at my fingertips.”

Connor Stewart, Head of Operations + Impact at ARTAH

6. Maintain a healthy balance between velocity and margins

While improving inventory velocity is important, it’s crucial to balance speed with profitability. Selling through inventory too quickly at rock-bottom prices might improve turnover, but can erode your margins. On the other hand, holding out for higher prices can slow velocity and tie up working capital.

To strike the right balance, regularly assess your pricing strategy in relation to your velocity goals. Consider tactics like dynamic pricing, where you adjust prices in real-time based on demand and inventory levels. Regularly monitoring your inventory turnover ratio in conjunction with gross margin can help you find the sweet spot.

7. Plan around supplier lead times and MOQs

Supplier constraints like long lead times and high minimum order quantities (MOQs) can make it challenging to optimize inventory velocity. To mitigate these issues, it’s important to build strong relationships with your suppliers and clearly communicate your velocity goals. Negotiate for more favorable terms where possible, such as lower MOQs or faster production times.

When placing orders, carefully consider the balance between supplier requirements and your ideal inventory levels. Use techniques like economic order quantity (EOQ) analysis to determine the optimal order size that minimizes holding costs while still meeting demand.

Turning inventory velocity into a customer experience advantage

Optimizing inventory velocity isn’t just about improving your bottom line. It’s also a powerful way to enhance the customer experience. When you consistently have the right products in stock and ready to ship, you build trust and loyalty with your customers. They know that they can rely on your brand to deliver what they need, when they need it.

Faster inventory turnover also enables you to offer quicker shipping times and more reliable delivery promises. By strategically distributing your inventory and streamlining your fulfillment processes, you can offer two-day or even next-day delivery to a wider range of customers.

Top ecommerce brands understand the power of leveraging inventory velocity for customer satisfaction. They use real-time inventory data to display accurate stock availability on their websites, preventing disappointment and building confidence. They also prominently feature fast shipping promises in their marketing and on product pages, turning their supply chain velocity into a key selling point.

Ultimately, the connection between inventory velocity and customer experience is clear. By consistently delivering the products your customers want, when they want them, you foster a sense of reliability and trust that keeps them coming back for more. And with the right inventory optimization strategies in place, you can turn your supply chain into a powerful engine for customer loyalty and business growth.

How ShipBob empowers brands to optimize inventory velocity

ShipBob is a best-in-class fulfillment solution that helps ecommerce brands take control of their inventory velocity and achieve their growth goals. With a powerful inventory management system, a network of strategically located fulfillment centers, and a suite of advanced analytics tools, ShipBob provides the infrastructure and insights brands need to optimize their supply chain from end to end.

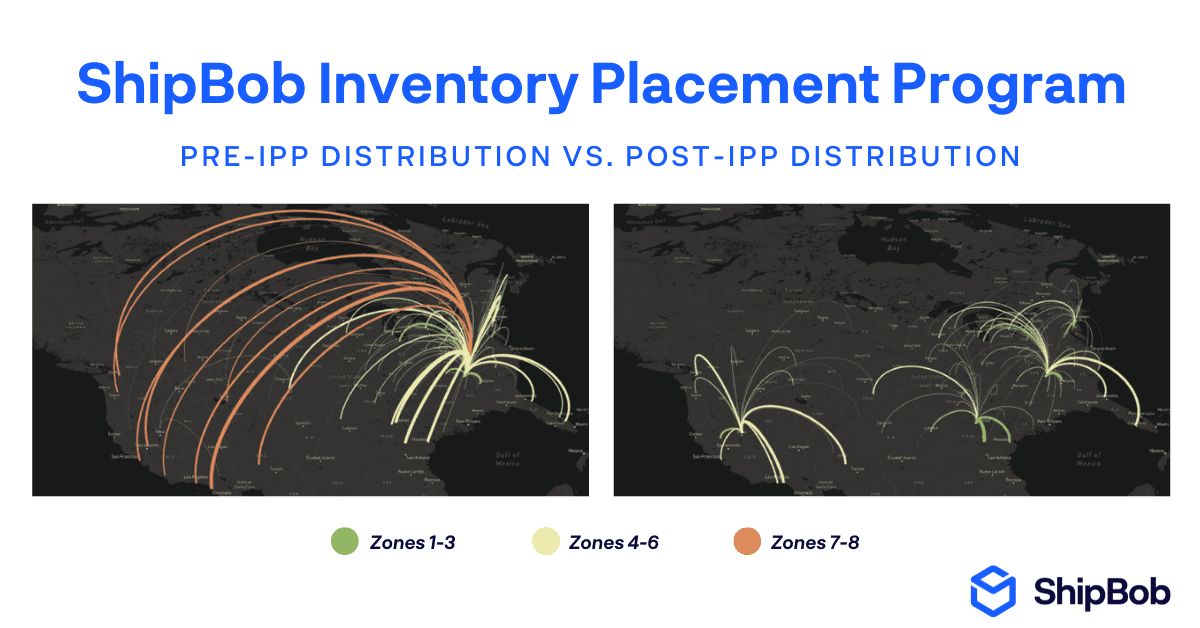

Streamline inventory distribution with ShipBob’s Inventory Placement Program

ShipBob’s Inventory Placement Program (IPP) is designed to enhance inventory velocity by automating distribution across ShipBob’s nationwide fulfillment network. Instead of sending multiple shipments to various fulfillment centers, merchants can send their inventory to a single ShipBob hub. From there, ShipBob’s AI-decision engine analyzes historical sales data, real-time demand, and geographic considerations to strategically allocate inventory to optimal fulfillment centers closer to end customers.

This intelligent distribution not only reduces shipping times and costs but also ensures that inventory is positioned to meet customer demand efficiently. By minimizing the distance between products and customers, IPP helps businesses achieve faster delivery times, lower transit costs, and improved customer satisfaction, all critical factors in maintaining a competitive edge in ecommerce.

Additionally, IPP provides automated replenishment recommendations based on sales velocity and inventory levels, allowing merchants to maintain optimal stock levels without manual intervention. This proactive approach to inventory management helps prevent stockouts and overstock situations, further enhancing operational efficiency.

Real-time inventory visibility and automation

ShipBob’s proprietary software provides real-time visibility into inventory levels, order status, and key performance metrics. With powerful automation tools like reorder points and demand forecasting, brands can maintain optimal stock levels and prevent stockouts without constant manual intervention.

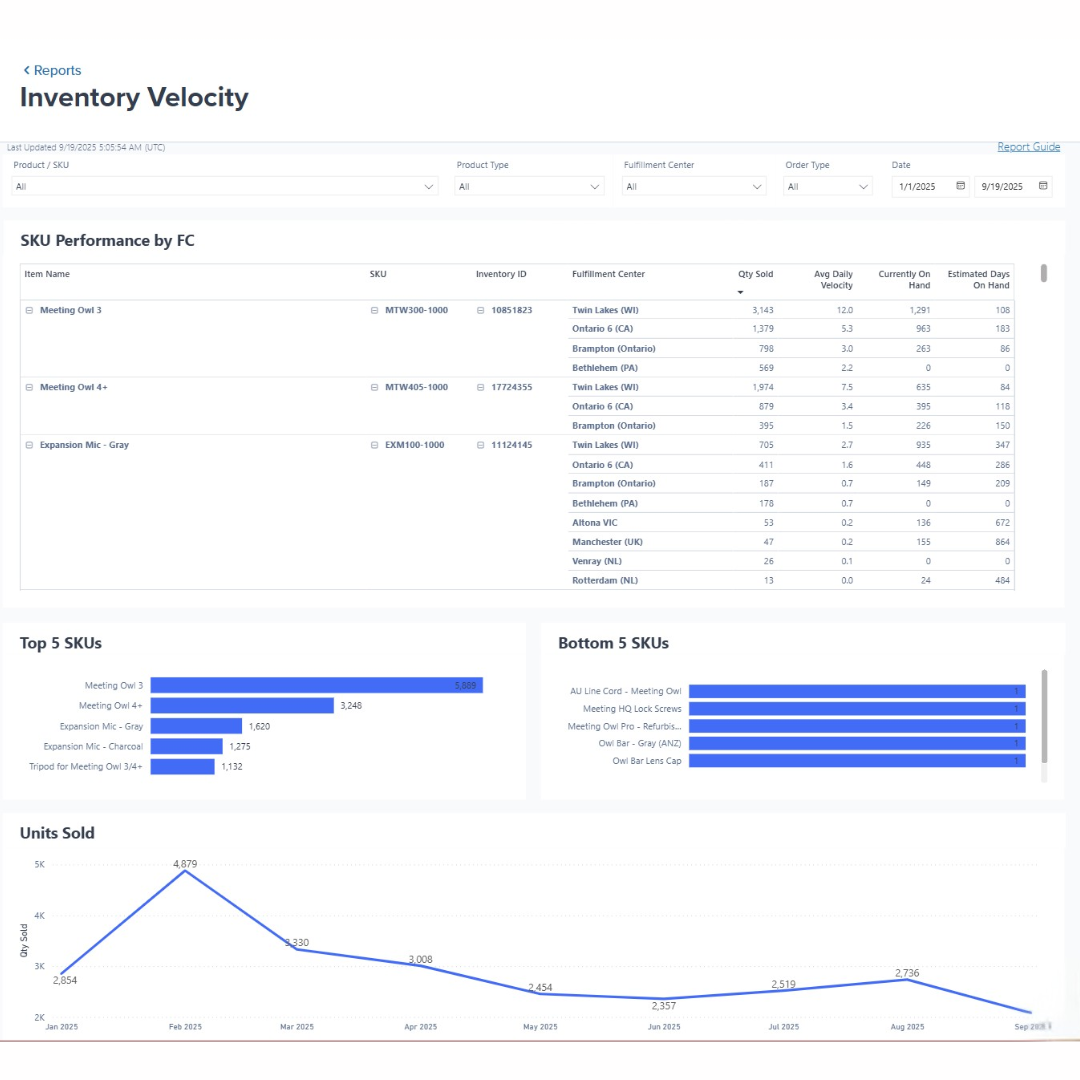

Advanced analytics and reporting

ShipBob provides a suite of advanced analytics and reporting tools that help brands track their inventory velocity, identify trends, and make data-driven decisions. With insights into key metrics like inventory turnover, sell-through rate, and days of inventory on hand, brands can continuously optimize their inventory strategy for maximum efficiency.

“With ShipBob, we can get a really clear picture of where our stock is moving and the sales velocity of our products by region, which is especially helpful when we’re preparing to reorder stock. This level of analytics is hugely important to have, giving us so much data to support decision-making. In the past, we would have had to look at external sources and then bring that data back to other platforms, so having it all together from ShipBob gives us an added efficiency that is very informative.”

– Danica Quilty, Ecommerce Director of Lyres

Flexible order management

ShipBob’s platform seamlessly integrates with leading ecommerce platforms and marketplaces, enabling brands to manage their orders and inventory from a single dashboard. With flexible order management tools and efficient returns processing, brands can streamline their operations and provide a seamless customer experience.

Get started with ShipBob

By partnering with ShipBob, ecommerce brands can leverage the power of optimized inventory velocity to drive growth, improve cash flow, and enhance customer satisfaction. With a trusted fulfillment partner like ShipBob handling the complexities of inventory management and fulfillment, brands can focus on what they do best – creating great products and building lasting customer relationships.

FAQs about improving inventory velocity

Below are answers to common challenges and queries related to inventory and stock velocity.

What is the difference between inventory velocity and inventory turnover?

Inventory velocity and inventory turnover are closely related metrics, but they measure slightly different aspects of inventory movement. Inventory velocity specifically measures how quickly individual SKUs or product lines are selling, usually expressed as units sold per day or week. This metric helps you understand the speed at which specific products move through your supply chain.

On the other hand, inventory turnover measures how many times your entire inventory is sold and replaced over a given period, typically a year. It’s calculated by dividing the cost of goods sold by the average inventory value. While inventory turnover provides a high-level view of overall inventory efficiency, inventory velocity offers more granular insights into the performance of individual products.

How do I calculate and track my average daily sales for velocity?

To calculate your average daily sales for inventory velocity, start by choosing a representative time period, such as the past 30, 60, or 90 days. Ensure this period is long enough to account for any short-term fluctuations or anomalies. Then, divide your total units sold for each SKU by the number of days in the period.

For example, if you sold 300 units of a product over the past 30 days, your average daily sales would be 10 units per day (300 units ÷ 30 days). Repeat this process for each product to determine its individual velocity. To streamline tracking, consider using an inventory management system that automatically calculates and updates these metrics based on real-time sales data.

How can minimum order quantities (MOQs) impact inventory velocity?

Minimum order quantities (MOQs) set by suppliers can significantly impact your inventory velocity. When you’re required to order a large quantity of a product at once, it can lead to excess inventory that takes longer to sell through, thus reducing your overall velocity. This is especially challenging for slow-moving or seasonal products, where demand may not justify the MOQ.

To mitigate the impact of MOQs on velocity, consider negotiating with suppliers for lower minimum quantities or more frequent ordering cycles. You can also explore alternative suppliers with more flexible terms. If you must order in large quantities, focus on optimizing other aspects of your supply chain, such as improving demand forecasting accuracy and implementing FIFO principles to ensure the oldest inventory is sold first.

What happens if I have too high or too low of an inventory velocity?

If your velocity is too high, you may struggle to keep enough inventory in stock to meet customer demand. This can result in stockouts, backorders, and lost sales. You may also incur higher costs from expedited shipping or rush orders to replenish inventory quickly.

Conversely, if your inventory velocity is too low, you may be tying up too much capital in slow-moving stock. This can lead to increased storage costs, a higher risk of obsolescence, and reduced cash flow for other business investments. Low velocity can also indicate underlying issues with product-market fit, pricing, or marketing effectiveness.

What measures the speed of inventory moving through?

Inventory velocity is typically expressed as the number of units sold per day or week for each SKU. By tracking inventory velocity, you can gain valuable insights into which products are selling quickly and which ones are moving more slowly.

Other related metrics that provide insights into inventory movement include inventory turnover ratio, which measures how many times your entire inventory is sold and replaced over a given period, and days’ sales of inventory (DSI), which measures the average number of days it takes to sell your inventory.