In ecommerce, the smallest details can have a huge impact.

Inventory errors are the perfect example of this. A discrepancy between your actual and recorded inventory may not seem like a big deal, especially if it’s not a big one, but even a little mismatch has the potential to wreak havoc on your business’s operations.

From increased inventory costs to stockouts, from tax troubles to bungled orders, there are many ways an inventory error can hurt your brand and its bottom line. As a result, it’s important to catch inventory errors and correct them as quickly as possible.

In this article, we’ll dive deep into the most common types of inventory errors, how to mitigate them, and how partnering with an expert like ShipBob can help you prevent them altogether.

What are inventory errors?

An inventory error (also called an inventory discrepancy) is when your physical inventory count does not match the amount of inventory stated in your records.

Inventory errors are almost always caused by some sort of human error, usually during regular warehousing operations such as receiving, counting, storage, and fulfillment. As such, discrepancies due to theft do not count as inventory errors.

7 common types of inventory errors

There are several types of inventory errors that can create issues in your ecommerce operations. Here’s a breakdown of the most common errors, so you can get a better idea of how to prevent or mitigate them.

Overstocking

An overstocking error is when you actually have more of a particular SKU than you had listed in your records.

This can inflate your holding costs, and may result in obsoletion or deadtock if there isn’t enough demand to sell the extra stock.

Understocking

Alternatively, an understocking error is when you have less in-stock inventory than you list in your records.

This often happens when inventory is lost or misplaced, received incorrectly, or if your inventory system fails to keep track of sales across various channels.

Mis-picks

Mis-picks are one of the most common types of inventory errors, resulting from issues or mistakes in the warehouse order picking process.

A mis-pick occurs when a warehouse associate picks the wrong inventory item(s) or the incorrect number of units for a customer order. This not only means that your recorded inventory counts for two different SKUs are incorrect, but also results in fulfillment errors that disappoint customers.

The technology employed by ShipBob guarantees accurate deliveries to our customers. ShipBob’s warehouse management system is equipped with numerous checks and balances, minimizing the possibility of incorrect items being shipped by warehouse associates.

Ali Shahid, COO of Our Place

Valuation mistakes

When your brand records more or less inventory than you actually have, it means that your inventory’s value will be higher or lower than it actually is. This is because the amount of inventory you have directly impacts beginning inventory, ending inventory, and cost of goods sold (COGS) – all of which are used to determine inventory value.

Overstatement or understatement of inventory value will cause a number of financial reporting and accounting issues. Regardless of which inventory valuation method you use (such as LIFO, FIFO, or weighted average inventory), inventory value is a key factor on financial statements such as balance sheets, and misrepresenting your current assets (of which inventory is one) can have huge legal ramifications for your business.

Receiving errors

Mistakes in the warehouse receiving process can also lead to inventory errors. This may be a result of receiving the wrong inventory, miscounting inventory, or making a clerical error in recording incoming inventory.

Consignment inventory oversight

For businesses that deal in consignment inventory, there’s a risk of errors resulting from oversight. Whether you’re the consignor or consignee, if you’re not maintaining accurate records, you may not be able to get an accurate understanding of product flow, which will create errors further down the line.

Failure to record purchases or sales

Inventory purchases and sales impact your cash flow and your inventory balance, making it crucial to accurately record them.

Failing to record a purchase may lead you to understate your inventory, which can lead you to overspend on overhead without realizing it or reorder stock too soon (leading to a lot of surplus inventory).

When you fail to record a sale, you may accidentally assume you have more inventory than you actually do, and oversell products as a result. This can cause backorders, which are costly and negatively impact the customer experience.

The effects of inventory errors on ecommerce businesses

Inventory errors do not benefit a business; in fact, they can have some very negative effects on your brand. Here are some of the ways that inventory errors harm your brand (and some red flags that may indicate you’re dealing with one you haven’t caught yet).

Customer satisfaction dips

While inventory management may seem far removed from customer satisfaction, the former can hugely impact the latter. Inventory errors of all kinds have the potential to hurt the customer experience, such as when:

- Mis-picks result in a customer receiving the wrong type or quantity of items

- Inaccurate inventory levels lead a brand to accidentally oversell units they don’t have, causing stockouts and lengthy backorders

- Receiving errors causing inventory to go missing, extending lead times and delaying fulfillment

- Fixing inventory takes time and energy that could have been devoted to customer support

Any one of these errors can damage customer satisfaction, which can come back to bite your brand later.

Operational cost spikes

Inventory errors aren’t just inconvenient; they’re costly, too.

There are tangible costs to consider, such as increased holding costs and expensive reshipments to correct mis-picked orders, which eat away at your bottom line.

There are also opportunity costs. Inventory errors slow the efficiency of your whole warehouse by:

- Forcing inventory counts and audits, which take time and resources to complete

- Necessitating rework (especially re-picking orders)

- Requiring you to recalculate inventory value and review your financial accounting

Business reputation damage

If you’re constantly sending out the wrong items, stocking out, putting customers on backorder, or delaying fulfillment due to inventory errors, it will eventually have an impact on your reputation. Customers will come to associate your brand with unreliability and inaccuracy, and may even stop buying from you – or worse yet, discourage others from buying from you, too.

Preventative strategies and how to mitigate inventory errors

The good news? Inventory errors aren’t inevitable. With the right strategies in place, your brand can minimize and even avoid inventory errors altogether.

Here are a few best practices to for mitigating and preventing inventory errors in your ecommerce business.

Conduct regular inventory audits

Periodic inventory audits are a crucial part of catching and fixing inventory errors before they snowball into a bigger problem. Counting your inventory and comparing the result to your records allows you to detect inventory mismatches. The sooner you identify a discrepancy, the sooner you can pinpoint the cause and adjust records and financial statements accordingly.

Train your warehousing staff to manage inventory effectively

Lots of inventory issues are the result of human error in operations. Detailed training upfront and continued training refreshes sets your team up for success, and helps ensure that your warehousing staff handles inventory correctly.

Make sure to train your staff on:

- Warehouse receiving operations (including how and where to count, scan, and stow each item)

- Your storage system, warehouse layout, and labeling conventions

- How to record inventory movement across the supply chain

- The picking process, including when and how to scan product barcodes

- How to use all necessary equipment and technology safely and efficiently

- Inventory accounting procedures

Optimize your inventory layout

Organizing the warehouse effectively is the first step to creating a streamlined operation.Make sure your warehouse setup is optimized for safety, ease of movement, quick storage, and efficient retrieval. Warehouse staff should be able to seamlessly move between different shelves and areas of the warehouse in a logical flow. Reducing the back-and-forth will minimize confusion, which will reduce the risk of errors. Similarly, your staff can easily identify and retrieve the correct items, which minimizes the risk of mis-picks.

Implement barcoding and scanning tech

Adding barcoding and scanning technology to your inventory management process builds in checks and balances every time a piece of inventory is moved. This makes it less likely that inventory will end up in the wrong place, or that pickers will pick the wrong item.

An inventory scanner that feeds back to a unified tracking system also lets your update inventory levels the moment inventory moves, so that inventory doesn’t get lost or misplaced in transition. If items are scanned correctly, you will be able to follow it throughout your supply chain and get an accurate understanding of what inventory is in which stage, helping you minimize inventory errors.

Invest in real-time inventory management software

Being able to track and manage your inventory in real-time is one of the best ways to prevent inventory errors. Invest in inventory management software that will sync with your ecommerce platform and update your inventory records in real-time, as this helps you prevent your inventory data from being out of sync with your physical count.

A real-time inventory management system allows you to see your most up-to-date inventory levels, providing you with better internal insight and control. You can easily see when you’re running low on a specific product, and plan your replenishment accordingly.

Right before ShipBob, we worked with a small 3PL out of Leicester, UK. After we’d already partnered with the fulfillment company, we found out that they didn’t use barcodes to input inventory into the warehouse. Instead they just manually counted each one.

As you can imagine, this caused numerous issues. We often had situations where products would go missing or customers would tell us they received the wrong product. With ShipBob, that’s not an issue. All of those problems are in the past.

Will Kerr, Apparel Lead at Quadrant

Leave inventory errors in the past with ShipBob

With superior inventory management technology and outsourced fulfillment services, ShipBob helps you tackle inventory errors head-on. You can take advantage of ShipBob’s software to optimize your inventory management process or even outsource the entire fulfillment process to the experts.

Seamlessly integrate your ecommerce platform

It can be hard to track and manage inventory correctly when you’re juggling multiple technology solutions. ShipBob integrates directly with dozens of major ecommerce platforms and tools, so you can view inventory levels across locations and channels through a single dashboard.

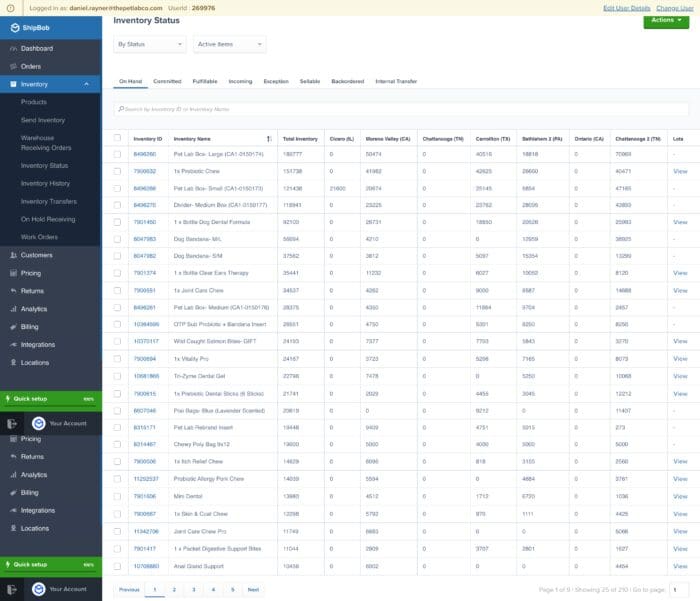

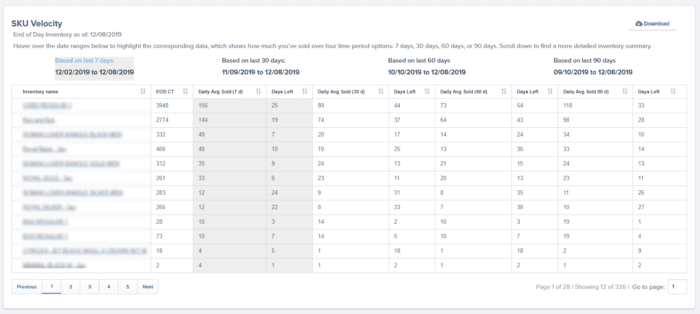

Real-time inventory tracking and analytics

ShipBob’s software delivers real-time inventory visibility, so you are always working with the most up-to-date and accurate data. Leveraging your ShipBob dashboard, you can track exactly how many units you have left at various stages of fulfillment. This will allow you to plan your procurement and replenishment strategy to avoid issues such as stockouts and overstocking.

ShipBob’s software also offers comprehensive analytics dashboard that you can leverage to monitor inventory turnover, individual SKU performance, average fulfillment and shipping costs, and more. These on-hand insights make it easier and faster to identify errors and nip them in the bud for minimal impact on your operations.

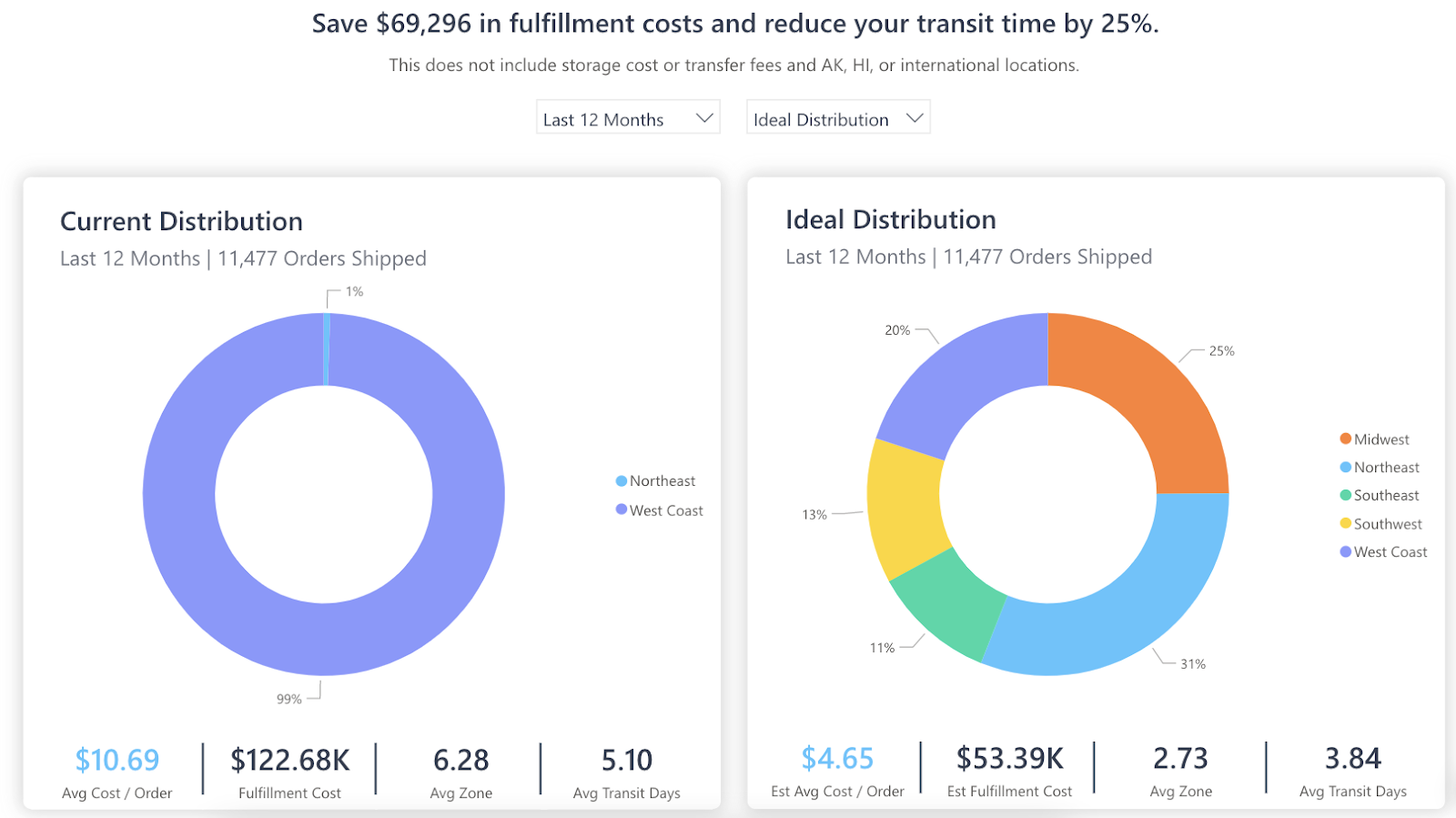

Distributed fulfillment centers for widespread growth

ShipBob’s network of fulfillment centers helps you effectively scale your operations without inventory errors or confusion. You can store inventory across multiple of ShipBob’s dozens of global fulfillment centers to minimize shipping costs and times, while still maintaining control and visibility of your inventory through your dashboard.

Brands can even leverage our Ideal Inventory Distribution tool to calculate the most strategic split of inventory across ShipBob’s locations that will put your inventory closer to more customers while achieving optimal cost-savings.

Unmatched outsourced fulfillment accuracy

By outsourcing your entire fulfillment process to ShipBob, you put your operations in the hands of experts. Our combination of resources, best practices, and technology delivers a 99.96% accuracy rate, and can minimize the risk of receiving, picking, and packing errors for your brand. With ShipBob as your partner, your business can boost your OTIF rate and transform fulfillment from a cost center into a competitive advantage.

Fulfillment is hard, so there’s always going to be mistakes – and with our previous 3PL, we were used to having about a half of a percent error rate (meaning 0.5%-1% of the DTC orders that we shipped out were wrong in some way).

With ShipBob, I feel like our error rate is a hundred times less. I’m just stunned by how accurate our orders are, and our error rate is just vanishingly small now.

Honestly, it’s been a game-changer for us, because we’re experiencing way fewer customer service issues than before, while growing 4x.

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

For more information on how ShipBob can reduce your inventory errors, click the button below.

Inventory error FAQs

Below are answers to the most commonly asked questions about inventory errors.

How can ShipBob help small businesses scale their operations?

ShipBob can help small businesses scale their operations by storing their inventory across our distributed fulfillment network, fulfilling orders for them, optimizing their operations for efficiency and cost, and helping them manage inventory across multiple sales channels.

What should I do if I’m experiencing high levels of inventory errors?

If you’re experiencing high levels of inventory errors, conduct an inventory audit and review your operational procedures to pinpoint the issue and act accordingly. In addition, consider implementing real-time inventory management software to monitor inventory levels, and refresh inventory management training for your employees.

How can real-time inventory tracking help reduce errors?

Real-time inventory tracking allows you to see your inventory levels and statuses in real-time. This means that your inventory records are also updated with each inventory movement, so there is less chance of losing or miscounting inventory.

What are the most common causes of inventory errors in ecommerce?

Forecasting errors, outdated software, and accounting errors are some of the most common causes of inventory errors in ecommerce.