In today’s competitive ecommerce landscape, strong supply chain management separates successful retailers from the rest. With customers expecting faster, cheaper shipping, brands must streamline operations while overcoming key challenges.

Ecommerce supply chains struggle with inventory tracking, delivery speed, and returns processing. Disconnected systems, manual processes, and rigid infrastructure lead to stockouts, shipping delays, and customer dissatisfaction, all of which intensify as businesses expand.

But with the right approach, these challenges become opportunities. This guide outlines the main supply chain obstacles for online retailers and offers practical solutions to build resilient, efficient operations. Whether you’re running a startup or an established business, you’ll learn how to transform your supply chain into a competitive advantage.

What do ecommerce supply chain challenges look like?

The ecommerce supply chain connects manufacturers to consumers through a network of processes, including sourcing materials, managing inventory, warehousing products, fulfilling orders, shipping packages, and handling returns. Today’s online shoppers demand fast shipping, real-time tracking, and easy returns, which puts enormous pressure on retailers to optimize operations.

Even a single breakdown, like a stockout or shipping delay, can damage customer loyalty and cut into profits. Success requires both supply chain efficiency, resilience, and the ability to quickly adapt to disruptions from demand spikes, transportation issues, or supplier problems.

Ecommerce vs. traditional retail supply chains

While both aim to deliver products to customers, ecommerce and traditional retail supply chains operate differently. Traditional retail uses a linear “push” model where products move from manufacturers to distributors to stores, with inventory stored in centralized warehouses and shipped in bulk to retail locations.

Ecommerce follows a “pull” model driven by real-time customer demand. When someone places an order online, it triggers a series of steps: locating the product in a fulfillment center, picking and packing it, and shipping directly to the customer’s door. This direct-to-consumer approach requires exceptional coordination and visibility.

Key differences include:

- Distributed inventory: Ecommerce businesses spread inventory across multiple fulfillment centers for faster, cheaper shipping to different regions, unlike traditional retail’s centralized approach.

- Individual order fulfillment: Each online order is processed individually rather than in bulk, requiring highly efficient picking and packing to prevent errors.

- Higher return rates: Online shoppers return products more frequently since they can’t inspect items before buying, necessitating robust reverse logistics systems.

- Multi-channel complexity: Managing inventory and orders across websites, marketplaces like Amazon, and wholesale partners adds significant complexity.

These differences create unique challenges that traditional supply chain solutions can’t adequately address. Online retailers need specialized tools and strategies designed for the fast-paced, variable nature of ecommerce.

7 major ecommerce supply chain challenges

Ecommerce businesses face supply chain challenges that can significantly impact their bottom line, customer retention, and operational efficiency. These pain points often create cascading problems throughout the supply chain. However, by proactively addressing these challenges, online retailers can minimize disruptions and maintain a competitive edge. Let’s dive into the seven most pressing supply chain challenges facing ecommerce businesses today.

1. Inaccurate inventory management

Inventory discrepancies can lead to overselling, stockouts, and excess inventory costs. When inventory records don’t match actual stock levels, businesses risk losing sales due to unavailable products or incurring unnecessary storage costs for slow-moving items. Manual processes and disconnected systems often contribute to these inaccuracies, highlighting the need for real-time inventory tracking and centralized data management.

2. Shipping bottlenecks and delivery delays

Ecommerce businesses must navigate a range of shipping challenges, such as carrier capacity constraints, last-mile delivery issues, and peak season congestion. These factors can lead to delivery delays, directly impacting customer satisfaction and repeat purchase rates. While some external factors, like weather or labor shortages, are beyond a merchant’s control, supply chain planning and diversified shipping strategies can help mitigate risks.

3. Scaling difficulties and demand fluctuations

Rapid growth can strain fulfillment operations and complicate inventory forecasting. Seasonal spikes, flash sales, and influencer-driven demand surges can overwhelm inflexible warehouse spaces and staffing, creating scaling limitations. Traditional fulfillment models often struggle to adapt to variable demand, making it crucial for businesses to seek out more agile solutions.

4. Cross-border complexities

Expanding into international markets presents supply chain challenges such as customs documentation, duties and taxes, and compliance requirements. These complexities can impact delivery timelines and customer experience and place an operational burden on businesses to manage multiple carriers and navigate international regulations. However, solving these cross-border fulfillment challenges effectively can provide a significant competitive advantage.

5. Data silos across multiple sales channels

Disconnected systems create visibility gaps and decision-making challenges for ecommerce businesses. When inventory, order, and shipping data live in separate systems, operational inefficiencies arise, leading to inventory imbalances and fulfillment errors. Fragmented data hinders supply chain optimization, emphasizing the importance of unified commerce and centralized data management.

6. Reverse logistics and returns management

From processing costs and restocking challenges to customer service burdens, ecommerce returns have a significant financial and operational impact on businesses. Inefficient returns processes can affect customer loyalty and lifetime value, making it essential to streamline reverse logistics. As consumer awareness of the environmental impact of returns grows, businesses must also consider how to transform returns management from a cost center into a customer retention opportunity.

7. Sustainability and ethical sourcing pressures

Consumers are increasingly demanding eco-friendly shipping options and sustainable business practices. Balancing sustainability with cost and speed requirements can be challenging, but failing to address these concerns can negatively impact brand perception. Packaging waste and carbon footprint are becoming key considerations for consumers, making sustainability initiatives a potential differentiator in competitive markets.

How to overcome ecommerce supply chain challenges

Solving ecommerce supply chain problems requires tackling inefficiencies at the source. By implementing strategic solutions across inventory, warehousing, fulfillment, and logistics, you can build resilience while improving the customer experience. These solutions work best when implemented together as part of a comprehensive approach.

Implement real-time inventory tracking and demand forecasting

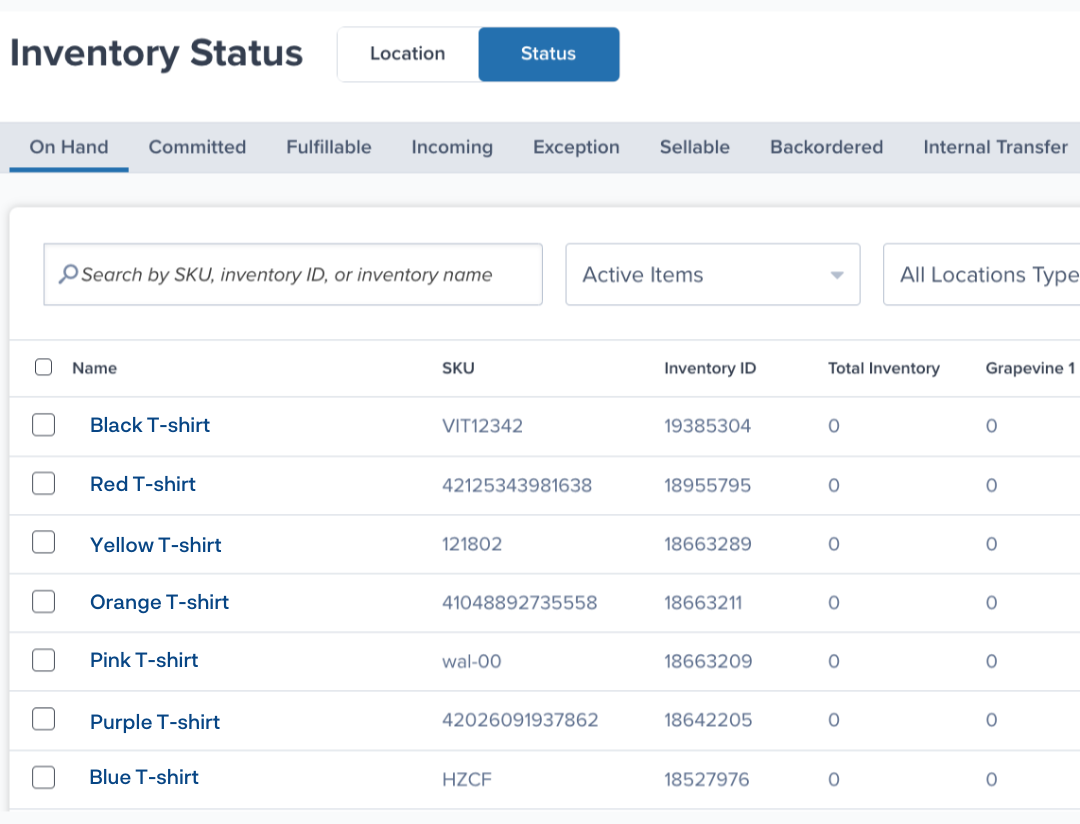

Accurate inventory management forms the foundation of a strong supply chain. Real-time inventory tracking gives you complete visibility across all channels and locations, enabling faster decisions while preventing overselling and stockouts.

Use historical sales data and market trends to forecast future demand. Predictive analytics help identify patterns and seasonal spikes so you can optimize inventory levels. Finding the right balance between safety stock and just-in-time inventory minimizes carrying costs without sacrificing availability.

For example, ShipBob’s software has inventory management systems with real-time updates, low-stock alerts, and automated reorder points that integrate with your ecommerce platform.

Optimize warehouse operations with a robust WMS

Efficient warehousing drives timely fulfillment and customer satisfaction. A modern warehouse management system (WMS), like ShipBob WMS, optimizes your entire process from receiving to shipping.

Key WMS features include real-time inventory tracking, barcode scanning, and advanced picking methods like batch and zone picking. These tools reduce errors and increase throughput, even during peak periods.

Choose cloud-based, scalable WMS solutions that can grow with your business and integrate seamlessly with your other systems.

Leverage distributed fulfillment centers

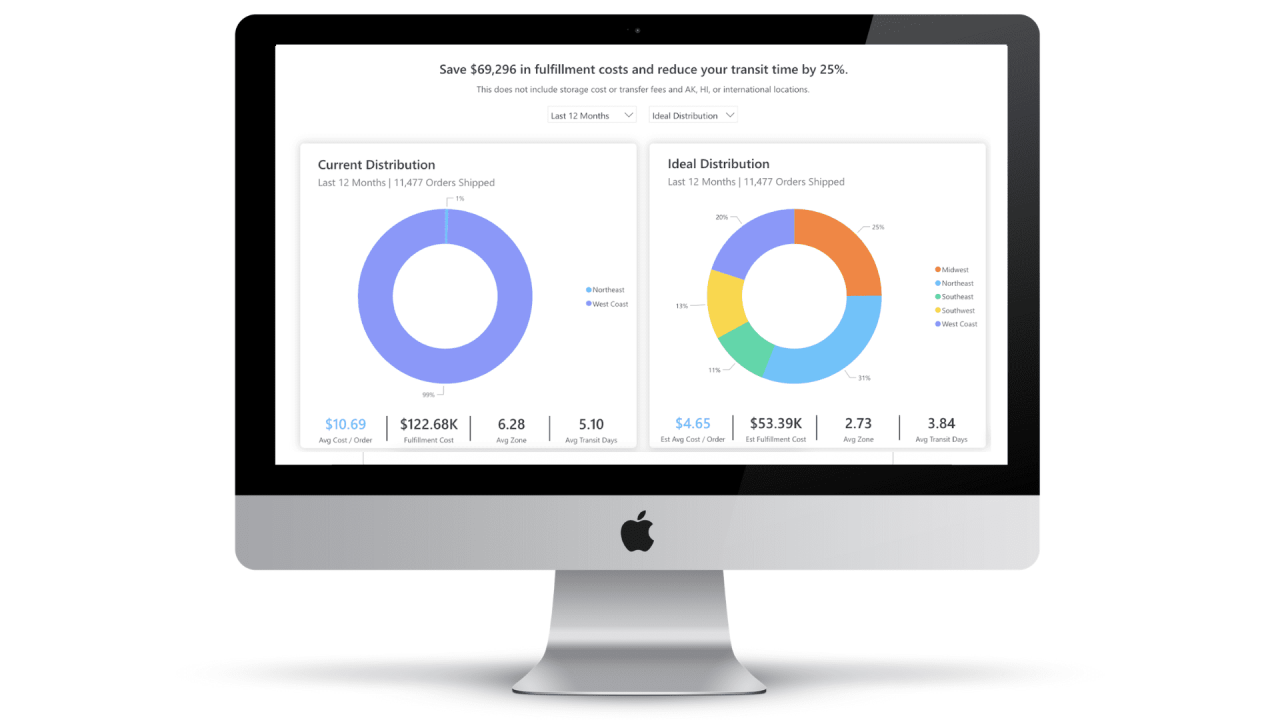

Relying on a single fulfillment center limits your ability to serve customers efficiently as you grow. Distributing inventory across multiple locations reduces shipping distances, lowers costs, and improves delivery speeds.

Choose fulfillment center locations by analyzing your order history and customer demographics to identify high-demand regions. Placing inventory closer to customers enables faster, more affordable shipping options.

This approach also protects against disruptions like weather events or labor shortages—if one facility has problems, orders can route to another location.

For businesses without resources to manage multiple warehouses, partnering with a fulfillment partner like ShipBob provides immediate access to distributed fulfillment infrastructure, helping you scale quickly and cost-effectively.

“ShipBob has been a great advantage for our brand. We have been able to save $4.11 per order on shipping since switching our fulfillment to ShipBob and distributing inventory throughout the country to place it closer to customers.”

Jay Stephens, Director of Operations, and Ania Giuffra, Supply Chain Manager, at Ancestral Supplements

Streamline returns with a dedicated management system

A dedicated returns management system streamlines the process, reduces costs, and can even become a competitive advantage.

Start with a clear, customer-friendly return policy that sets expectations. Provide simple instructions, prepaid return labels, and multiple return options. On the backend, use a returns platform to automate authorization, refund processing, and inventory updates. Look for features like customizable return reasons and integration with your existing systems.

Focus on customer experience by providing timely updates, processing refunds promptly, and offering incentives for future purchases. A seamless returns experience builds trust and loyalty.

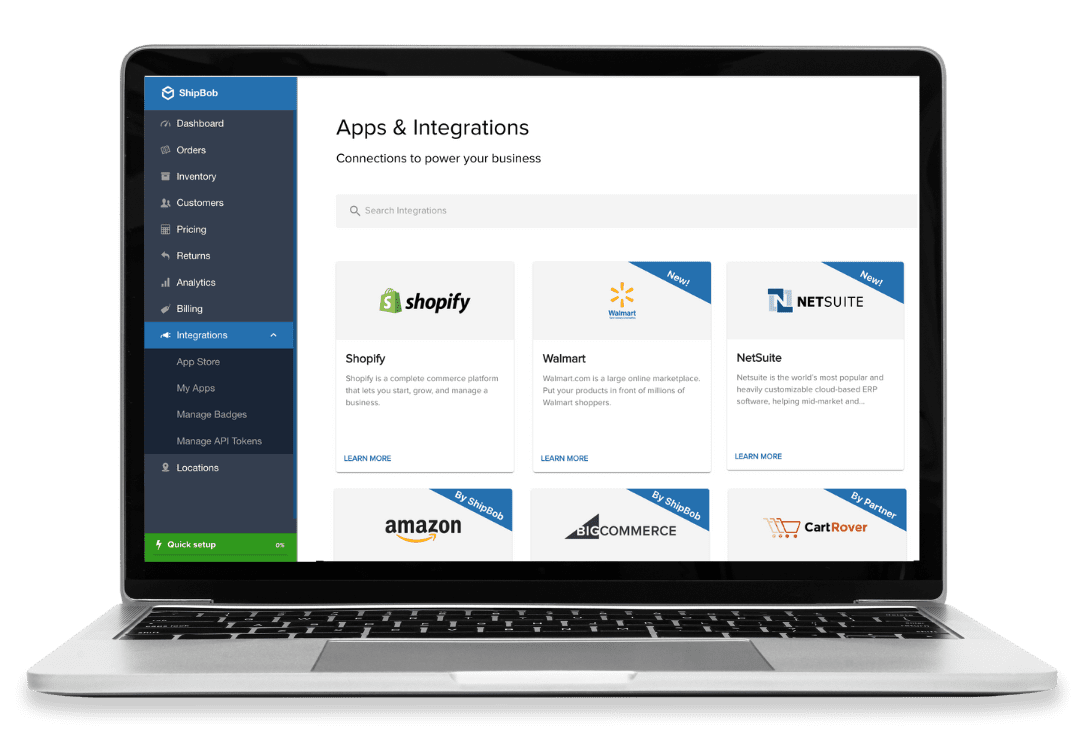

Integrate systems for a single pane of glass view

Most ecommerce businesses use multiple systems to manage their supply chain, creating data silos and inefficiencies. Integrating these systems provides a comprehensive view of operations.

When your ecommerce platform communicates with your inventory system, stock levels stay accurate on your website. When your WMS connects with shipping software, you can automate order routing and tracking updates.

A centralized dashboard lets you monitor key metrics like order volume, inventory turnover, and shipping performance in real-time. This visibility helps identify issues before they escalate and make data-driven decisions.

Start by mapping your current systems and identifying key integration points. Evaluate options like APIs or middleware based on your needs, then work with technology partners to establish reliable connections

Develop cross-border shipping expertise

Expanding internationally offers growth opportunities but brings unique challenges with customs regulations, duties, and taxes.

First, research regulations and documentation requirements for your target markets, as each country has specific rules for product classifications, labeling, and imports. Non-compliance can cause delays, fines, or seizure of goods. Work with customs brokers to ensure accurate product classification under the Harmonized System (HS) code to minimize duties and avoid penalties.

For international fulfillment, choose between direct shipping from domestic warehouses (cost-effective for low volumes) or in-country fulfillment (faster, more affordable shipping for high-volume markets). Set clear customer expectations about delivery times, potential customs delays, and additional fees. Provide tracking information and proactive updates throughout the shipping process.

Partner with logistics providers experienced in international shipping to navigate changing global trade regulations and unlock significant growth opportunities.

Build sustainability into your supply chain

Building eco-friendly practices into your supply chain appeals to conscious consumers while driving efficiency and cost savings. Start by auditing current practices to identify improvement areas. Use recyclable packaging and consolidate shipments to reduce materials.

Optimize shipping routes and methods to lower carbon emissions and costs. Consolidating into full truckloads rather than partial loads reduces road traffic, while partnering with carriers using electric vehicles lowers your carbon footprint.

Communicate your sustainability initiatives to customers through your website and marketing. Share concrete impact data like waste reduction or emissions avoided to differentiate your brand and build loyalty.

Remember that sustainability is an ongoing journey. Continuously seek opportunities to reduce waste, optimize transportation, and engage customers to create a resilient, responsible supply chain.

How ShipBob solves ecommerce supply chain challenges (before they happen)

ShipBob’s integrated fulfillment solution is designed to address the most pressing challenges facing ecommerce businesses today. By combining advanced technology, a distributed fulfillment network, and deep logistics expertise, ShipBob helps brands optimize their supply chains and deliver a seamless customer experience.

Faster, more affordable shipping through distributed fulfillment

ShipBob’s network of fulfillment centers across the United States and the world enables businesses to store inventory closer to their customers, reducing shipping costs and transit times. By strategically distributing inventory based on customer demand, brands can offer fast, affordable shipping to a wider geographic area. ShipBob’s Inventory Placement Program (IPP) automatically routes each order to the optimal fulfillment center, ensuring that customers receive their orders quickly and cost-effectively.

Real-time inventory visibility and advanced analytics

With ShipBob’s proprietary software, merchants have complete visibility into their inventory levels, order status, and shipping performance. Real-time tracking and reporting enable businesses to make data-driven decisions and proactively address potential issues. Advanced analytics provide insights into top-selling products, inventory turnover rates, and shipping costs, helping brands optimize their operations and improve profitability.

Seamless integration with leading ecommerce platforms

ShipBob’s technology integrates seamlessly with major ecommerce platforms, including Shopify, BigCommerce, and WooCommerce. This integration enables automatic order syncing, real-time inventory updates, and streamlined order management. By connecting their online store with ShipBob’s fulfillment solution, merchants can focus on growing their business while leaving the logistics to the experts.

Expertise in navigating seasonal fluctuations and growth

ShipBob’s team of logistics professionals has deep experience in helping brands navigate the challenges of seasonal spikes and rapid growth. With a flexible and scalable fulfillment solution, businesses can easily adjust their inventory levels and shipping capacity to meet changing demand. ShipBob’s account management team provides proactive support and guidance, helping merchants anticipate and plan for peak seasons and growth opportunities.

“On Black Friday I woke up with a smile on my face because I knew our orders were going out smoothly. This BFCM has been incredible for us. We couldn’t have done it without ShipBob.”

Jessica Stoller, Director of Supply Chain and Operations at Arrae

Streamlined returns management and sustainability initiatives

ShipBob’s integrated returns management solution simplifies the process of handling customer returns, from generating return labels to processing refunds. By efficiently managing returns, businesses can improve customer satisfaction and reduce the cost and environmental impact of reverse logistics. ShipBob is also committed to sustainability, with initiatives such as options for eco-friendly packaging and optimized transportation routes to reduce carbon emissions.

Get started with ShipBob

In today’s fast-paced and ever-evolving ecommerce landscape, partnering with a trusted fulfillment provider like ShipBob can be the key to overcoming supply chain challenges and achieving long-term success. With a comprehensive solution that addresses inventory management, order fulfillment, shipping optimization, and more, ShipBob empowers brands to focus on what they do best while leaving the complexities of logistics to the experts.

Partner with ShipBob for ecommerce order fulfillment to streamline operations, delight customers, and improve your bottom line.

FAQs about ecommerce supply chain challenges

Below are answers to common queries and challenges encountered by ecommerce businesses maintaining and improving their supply chains.

How can I reduce shipping costs without compromising delivery speed?

Place inventory strategically across multiple fulfillment centers near your customers to reduce shipping distances and costs. This lets you offer 2-day delivery affordably without expensive air shipping.

Partnering with a 3PL like ShipBob gives you access to a nationwide fulfillment network, plus technology that optimizes carrier selection and packaging to cut costs while maintaining speed.

What technologies are essential for modern supply chain management?

You need four key tools: inventory management software, an order management system (OMS), a warehouse management system (WMS), and shipping software. Together, they provide real-time inventory visibility, streamlined orders, and efficient warehouse operations.

The real power comes from integrating these systems. When your data flows seamlessly between platforms, you can make better decisions, respond to disruptions faster, and improve customer experience.

How can distributed fulfillment help my business scale?

Distributed fulfillment lets you expand your reach without building infrastructure. By storing inventory across multiple locations, you can offer fast, affordable shipping to more customers without managing warehouses yourself.

This approach provides flexibility as you grow—easily adjust inventory at each location for seasonal demands or regional trends. When entering international markets, you can test new regions without long-term commitments.

What’s the best approach to managing cross-border shipping?

Balance compliance with cost-effectiveness. Ensure accurate product classifications and documentation to avoid customs delays and fees, then compare carrier rates for your common shipping routes.

For high-volume international markets, consider in-country fulfillment to reduce cross-border shipping costs and delivery times. ShipBob’s global network (US, Canada, UK, EU, Australia) simplifies expansion with local fulfillment options and carrier partnerships.

How do I balance inventory levels to prevent both stockouts and excess inventory?

Use accurate demand forecasting by analyzing sales history, market trends, and upcoming promotions. This helps calculate optimal safety stock levels—enough buffer for unexpected demand without tying up excess capital.

Real-time inventory visibility is crucial. ShipBob’s software provides a centralized view of stock across all channels and locations, with customizable reorder points and low-stock alerts for timely replenishment.

What strategies ensure cost-effective returns management?

First, clearly communicate your return policy to set expectations and reduce unnecessary returns. Then implement an efficient processing system with clear guidelines for inspecting and restocking returned items.

Depending on your business, centralize returns handling or distribute it across your network. ShipBob’s returns solution integrates with forward logistics, helping you process returns efficiently and quickly return products to sellable inventory.