Today’s shoppers expect more than just fast delivery; they want convenience, transparency, and seamless experiences from click to doorstep. For ecommerce brands, that means the supply chain can’t just operate in the background anymore – it has to be a customer experience engine.

Enter the customer-centric supply chain: a logistics strategy built around evolving buyer expectations. By aligning operations with what customers actually want (faster delivery, flexible fulfillment, easy returns, etc.), brands can turn their supply chain into a driver of loyalty, retention, and revenue.

But delivering on that promise takes more than good intentions. It requires real-time visibility, smart inventory distribution, and a flexible fulfillment network that can adapt as your business grows.

In this guide, we’ll break down how to build a supply chain that puts the customer first without sacrificing efficiency. From distributed and digital logistics to data-driven optimization, you’ll get actionable strategies for turning operational excellence into a competitive edge.

What is a customer-centric supply chain?

A customer-centric supply chain is an approach to logistics that prioritizes the needs, preferences, and expectations of end consumers at every stage of the fulfillment process.

This model goes beyond traditional metrics like cost and efficiency, instead focusing on delivering a seamless, personalized experience from the moment an order is placed to the moment it arrives at the customer’s doorstep.

Why this approach matters for ecommerce brands

In the ecommerce landscape, customer expectations are constantly evolving. Today’s consumers demand fast, affordable shipping, real-time order tracking, and flexible delivery options. They expect proactive communication, easy returns, and a consistent experience across channels. Meeting these expectations is no longer optional – rather, it’s a critical differentiator in a crowded market.

For direct-to-consumer brands, the challenge is even greater. Without the established infrastructure of traditional retailers, these brands must build supply chain capabilities from the ground up. They must navigate complex logistics networks, manage inventory across multiple channels, and deliver a premium experience with limited resources.

The stakes are high: A single negative incident, such as a late delivery or incorrect order, can erode brand loyalty and lead to lost revenue. Conversely, a consistently positive experience can drive repeat purchases, higher customer lifetime value, and organic word-of-mouth growth.

From product-focused to customer-focused supply chains: a paradigm shift

Traditionally, supply chain management has been primarily product-focused, with an emphasis on efficiency, cost reduction, and inventory optimization. However, as consumer expectations continue to evolve, a new paradigm is emerging: the customer-centric supply chain.

Making the shift from a product-focused to a customer-focused supply chain requires a fundamental change in both mindset and operations. It means looking beyond simple cost metrics and instead considering how each decision impacts the overall customer experience.

This shift affects every aspect of the supply chain, from inventory placement and fulfillment methods to technology adoption and data analytics.

Brands succeeding with customer-centric supply chains (examples)

While some may assume that putting the customer first always comes at a higher cost, the reality is that a customer-centric approach can actually drive profitability in the long run. By reducing returns, increasing average order value, and improving customer retention, brands that prioritize the customer experience often see a positive impact on their bottom line.

Consider the example of a fashion retailer that uses advanced analytics to predict seasonal demand patterns. By ensuring that the right products are in stock and readily available during peak periods, they can minimize lost sales and reduce the need for costly markdowns. Similarly, a beauty brand that creates memorable unboxing experiences with customized packaging and samples can foster a sense of loyalty and encourage repeat purchases.

Transforming returns into opportunities for customer engagement is another hallmark of a customer-centric supply chain. By making the returns process seamless and hassle-free, brands can turn a potentially negative experience into a chance to build trust and demonstrate their commitment to customer satisfaction. This, in turn, can lead to increased lifetime value and positive word-of-mouth referrals.

7 key strategies for building a customer-centric supply chain

To truly put customers at the center of your supply chain, you’ll need a comprehensive logistics approach that spans all aspects of your operations.

Implement these seven key strategies to create a cohesive, customer-focused fulfillment experience that drives loyalty, satisfaction, and growth.

1. Distribute inventory for faster shipping

One of the most effective ways to meet customer demands for fast delivery is to strategically distribute your inventory closer to your end customers. When you store products in multiple fulfillment centers across key geographic regions, you can dramatically reduce the distance each order needs to travel. This results in shorter transit times and lower shipping costs.

This approach, known as “inventory distribution optimization,” involves using data and analytics to determine the optimal placement of your products based on factors like historical sales patterns, customer location, and product velocity. With the right technology in place, you can intelligently allocate inventory across your network to ensure that the right products are always in the right place at the right time.

For example, ShipBob’s network of over 60 fulfillment centers enables ecommerce brands to offer 2-day shipping to 95% of the US population. By leveraging ShipBob’s advanced algorithm, merchants can automatically route each order to the nearest fulfillment center with available inventory, reducing both transit times and shipping costs.

“Expanding our warehouse network from 2 to 4 warehouses has translated into $1.5 million in freight cost savings for Our Place. It also cut our fulfilment and shipping times in half, from 5 or 6 days to just 2.5 days.”

Ali Shahid, COO of Our Place

2. Enhance the unboxing experience

While fast delivery is certainly a key component of a customer-centric supply chain, it’s not the only factor that matters. To truly differentiate your brand and build lasting customer relationships, it’s important to focus on the overall service experience throughout the fulfillment process.

This means going beyond basic pick, pack, and ship operations to offer value-added services that create a memorable unboxing experience. For example, you might offer:

- Branded packaging options (including boxes, poly mailers, tissue paper, etc.)

- The option to add custom gift notes

- Marketing inserts (such as coupons, promotions, or announcements)

By paying attention to these small details, you can turn a routine transaction into a delightful customer experience that encourages social sharing and repeat purchases.

Of course, none of these extras matter if you don’t get the basics right. Accurate order picking, rigorous quality control, and proactive communication are all essential for building trust and preventing costly mistakes that can damage your reputation. Look for a fulfillment partner that prioritizes these fundamentals while also offering the flexibility to customize your fulfillment workflows to match your unique brand vision.

3. Use real-time data and analytics for proactive decision-making

In today’s fast-paced ecommerce landscape, brands need to be able to anticipate and respond to customer needs in real-time. This requires visibility into every aspect of your supply chain, from inventory levels to order status to delivery times.

By leveraging advanced analytics and reporting (often using technologies like artificial intelligence and machine learning), you can gain insight into demand patterns. This allows you to proactively adjust inventory levels and prevent stockouts before they occur. Real-time monitoring and alerts can also help you identify and resolve issues as they arise, minimizing the impact on your customers.

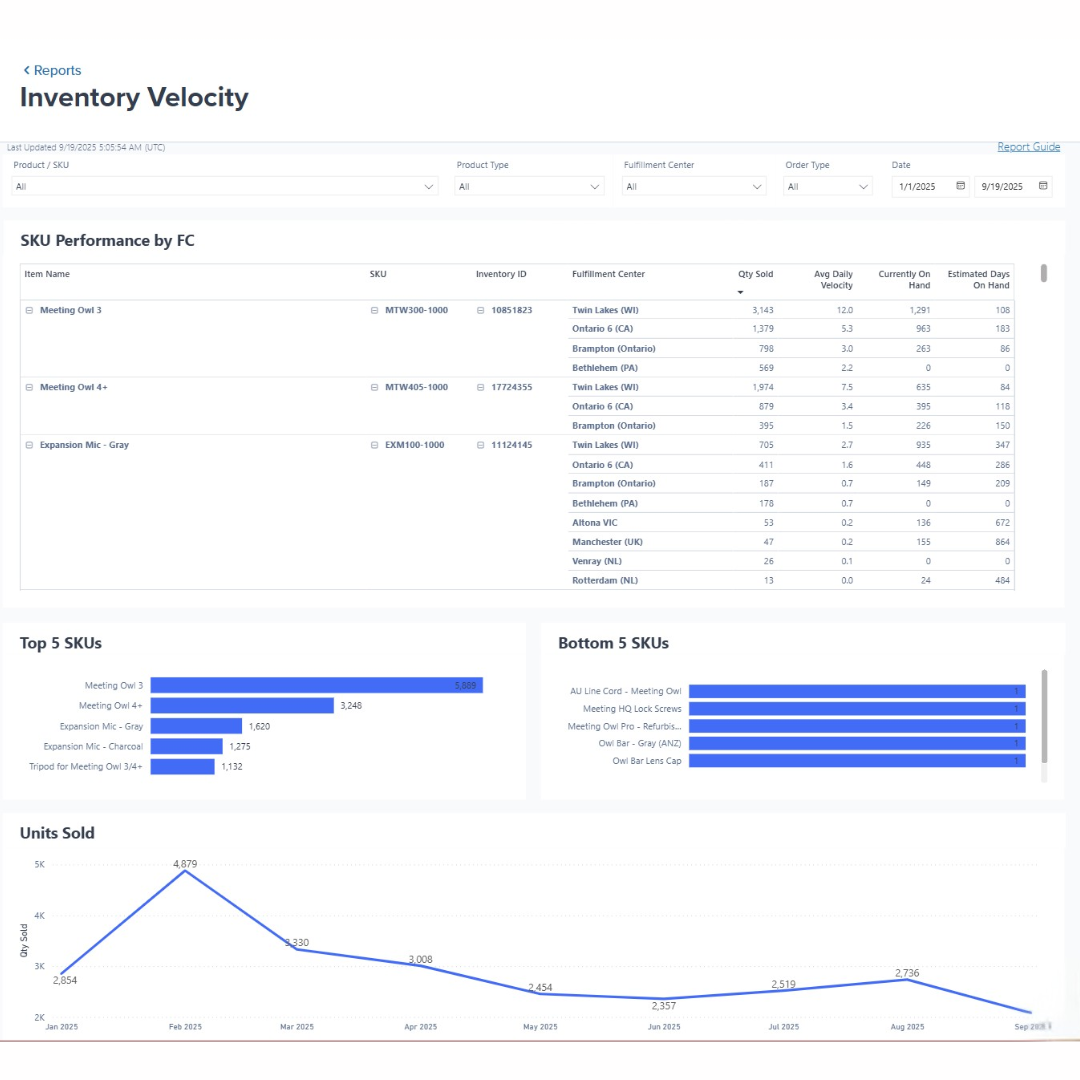

For example, ShipBob’s analytics dashboard provides ecommerce brands with actionable insights into key metrics like inventory turnover, order accuracy, and fulfillment speed. Combining real-time data with predictive analytics helps merchants make informed decisions about inventory allocation, product assortment, and fulfillment strategies, so they can boost customer satisfaction and drive growth.

“One of my favorite parts of ShipBob’s solution is the analytics I get through the ShipBob dashboard. I use the reporting constantly, especially to track my stock. It’s even helping me get better at inventory forecasting. Before, I was just fumbling through the demand planning process and just ordering inventory based on what sold out. But now I have insight into metrics like SKU velocity and inventory days on hand, and I’m using that to decide what to reorder and how much of it I need. That helps a lot, especially now that the brand is scaling and I’m ordering my products in bigger batches.”

Luke Rolls, Founder of The Protein Pancake

4. Adopt omnichannel fulfillment for a consistent customer experience

Customers expect a seamless experience across all channels, regardless of whether they’re shopping on a brand’s website, a marketplace like Amazon, or in a physical store. Omnichannel fulfillment is the key to meeting these expectations and providing a consistent level of service however a customer chooses to engage with your brand.

At its core, omnichannel fulfillment involves managing inventory and orders across multiple sales channels from a single, unified platform. This approach:

- Ensures that customers have access to the same products and delivery options regardless of where they shop.

- Prevents channel conflicts and stockouts by providing real-time digital warehousing visibility into inventory levels across your entire distribution network.

- Integrates your sales channels and standardizes your fulfillment processes to create a cohesive experience that builds trust and loyalty with your customers.

One key aspect of omnichannel fulfillment is managing returns effectively. Customers expect to be able to return products purchased online to a physical store or vice versa, and they demand a hassle-free process with clear communication and quick refunds. By creating a streamlined, cross-channel returns process, you can turn a potentially negative experience into an opportunity to demonstrate your commitment to customer satisfaction.

ShipBob’s omnichannel fulfillment platform integrates seamlessly with all major ecommerce platforms and marketplaces, enabling brands to manage their inventory and orders from a single dashboard. With real-time visibility across channels and the ability to set channel-specific inventory allocation rules, ShipBob empowers brands to provide a consistent, customer-centric experience at scale.

5. Reimagine returns as a brand opportunity

Returns are often seen as a necessary evil in ecommerce – a cost center that eats into profits and creates operational headaches. However, by reframing returns as an opportunity to build customer loyalty and gather valuable feedback, brands can turn this challenge into a competitive advantage.

Offering a streamlined, hassle-free returns process:

- Lets you demonstrate your commitment to customer satisfaction and build long-term loyalty.

- Provides valuable data and insights into product quality, fit, and customer preferences (which you can analyze to identify opportunities for product improvements).

To create a customer-centric returns experience, start by clearly communicating your policy upfront and setting realistic expectations around processing times and refunds. Make the process as easy as possible by providing pre-printed return labels, offering multiple return options (mail, in-store, etc.), and proactively communicating the status of each return.

ShipBob’s returns management capabilities are designed to create positive post-purchase experiences that build brand loyalty. With automated return label generation, customizable return rules, and real-time tracking and reporting, ShipBob enables brands to handle returns efficiently while gathering valuable data to inform product and process improvements.

6. Leverage a global fulfillment partner for scalability and localization

For brands looking to expand their reach and tap into new markets, a global fulfillment network is essential. However, managing international logistics in-house can be complex and time-consuming, and requires deep expertise in local regulations, customs requirements, and consumer preferences.

Partnering with a global 3PL (third-party logistics) provider can help brands navigate these challenges and offer localized shipping experiences that meet the expectations of customers in each market. Using a 3PL with an established network of international fulfillment centers means brands can reduce cross-border shipping costs and transit times while ensuring compliance with local regulations.

When evaluating potential 3PL partners, look for providers with:

- A proven track record of success in your target markets.

- Extensive geographic coverage.

- The technology and capabilities to meet your brand’s needs.

- Experience working with brands in your industry.

- The ability to scale with your business as you grow and expand into new regions and channels.

ShipBob’s global fulfillment network spans the US, UK, Europe, Canada, and Australia, enabling brands to reach customers globally with fast, affordable shipping. With a unified platform for managing inventory and orders across all locations, ShipBob makes it easy for brands to expand internationally without the headaches of managing multiple logistics providers.

“We have a lot of customers in Canada, and we just recently expanded into one of ShipBob’s Canadian fulfillment centers. With all the tariff uncertainties that have been going on in the US, we didn’t want to pass along the extra cost to our customers, so it made more sense for us to go ahead and store our products within Canada to ship domestically there.

Even though we’re taking on the tariff, we’re providing a better delivery experience for Canadian customers since we’re shipping locally. If customers get their products shipped directly from that Canadian warehouse, they’re saving three to four days of transit time and getting their orders faster – so being able to leverage ShipBob’s international footprint has been really beneficial.”

Oscar Gutierrez, Operations Fulfillment Manager at goPure

7. Tie your approach to tangible ROI and business growth

While building a customer-centric supply chain is essential for meeting evolving consumer expectations, you also have to make sure your business stays afloat. By tracking a couple of key metrics, you can monitor the ROI of your investments and make sure you’re not sacrificing profitability.

Your brand should track:

- Customer experience metrics, like on-time delivery rate, shipping speed, customer satisfaction scores, and net promoter score (NPS).

- Operational and financial metrics, such as order accuracy, return rates, inventory turnover, shipping costs, and labor efficiency.

- Technology and maintenance metrics, including the cost of implementation, ongoing maintenance and support costs, and training or change management expenses.

ShipBob’s reporting and analytics tools provide real-time visibility into key fulfillment metrics, enabling brands to track the impact of their supply chain improvements over time. With customizable dashboards and detailed performance reports, ShipBob empowers brands to make data-driven decisions that drive business growth and customer satisfaction.

Balancing supply chain cost management with fast, reliable shipping

As ecommerce brands strive to meet the ever-increasing demands of their customers, it’s easy to fall into the trap of thinking that a customer-centric approach always comes at a higher cost. However, with the right strategies and technology in place, it’s possible to optimize your supply chain for both speed and cost efficiency.

Some best practices to keep customers front and center while keeping costs down are:

📦 Strategic inventory placement

By distributing your products across multiple fulfillment centers located closer to your customers, you can significantly reduce shipping zones and transit times. This not only results in faster delivery speeds but also helps to minimize shipping costs.

🚚 Intelligent order routing

Advanced algorithms can automatically determine the optimal fulfillment center for each order based on factors like inventory availability, shipping destination, and carrier rates. This ensures that every order is shipped from the most efficient location without sacrificing delivery speed.

🎯 Proactive inventory forecasting and demand planning

Knowing how much stock is needed where can help you avoid costly expedited shipping fees. When you accurately predict future demand and maintain optimal stock levels across your distribution network, you can minimize the need for last-minute inventory transfers or rush shipping.

⚙️ Automation and technology

Automating repetitive processes and leveraging the right technology solutions both reduce labor costs while improving accuracy and efficiency. Together, they streamline processes like order picking, packing, and shipping while reducing manual errors and improving throughput without adding headcount.

Choosing the right fulfillment partner for a customer-centric supply chain: a checklist

Building a customer-centric supply chain requires more than just technology and processes – it also requires the right partners who share your commitment to putting customers first. When evaluating potential fulfillment partners, it’s important to look beyond basic capabilities and consider how well a provider aligns with your brand values and customer experience goals.

As you assess a potential provider, look for:

- A technology platform that integrates with your existing systems.

- Robust and real-time inventory management, order tracking, and reporting capabilities

- The ability to customize workflows and business rules to match your unique needs.

- An extensive fulfillment network (particularly if you’re looking to offer fast, affordable shipping to customers in multiple regions of the US or world)

- A geographic footprint that aligns with your customer base

- The operational capabilities and services to scale with your business as you grow (such as B2B fulfillment solutions, lot and expiration date tracking, etc.).

- Responsive and timely customer service and support.

- A proven track record of responsiveness, reliability, and proactive communication, as well as a deep understanding of your brand and customer needs.

- Value-added services such as customization, kitting, or specialized handling options

How ShipBob enables a customer-centric approach

ShipBob is a best-in-class fulfillment partner for brands looking to build a customer-centric supply chain. With a purpose-built technology platform and a network of strategically located fulfillment centers, ShipBob empowers brands to offer fast, affordable shipping while maintaining complete control over the customer experience.

ShipBob’s proprietary software provides end-to-end visibility into inventory levels, order status, and fulfillment performance across all locations. Automated order routing and real-time inventory management ensures that every order is shipped from the optimal fulfillment center for speed and cost efficiency, while advanced analytics and reporting tools provide actionable insights into key metrics like shipping speed, order accuracy, and inventory turnover.

In addition to its powerful technology, ShipBob offers a range of value-added services designed to help brands create a differentiated customer experience. From custom packaging and kitting to subscription fulfillment and lot tracking, ShipBob works closely with each brand to understand their unique needs and tailor solutions accordingly.

Add in our global network of fulfillment centers, our open API allows for seamless integration with other customer experience tools, and a team of experienced logistics professionals, and ShipBob emerges as the premiere partner choice to support brands as they scale and expand into new channels and markets.

Transform your supply chain with ShipBob

When you partner with ShipBob, you gain more than just a fulfillment provider – you gain a strategic partner who is invested in your success and committed to helping you build a customer-centric supply chain.

To learn more about how ShipBob can help you transform your supply chain and deliver an exceptional customer experience, click the button below.

Customer-centric supply chain FAQs

Here are answers to some frequently asked questions about building a customer-centric supply chain.

What is the difference between a product-focused and a customer-centric supply chain?

A product-focused supply chain prioritizes efficiency and cost minimization above all else. The primary goal is to move products from point A to point B as quickly and cheaply as possible, with success measured by metrics like cost per unit and inventory turnover.

In contrast, a customer-centric supply chain puts the customer experience at the forefront of every decision. While efficiency and cost management are still important, they are balanced with factors like delivery speed, order accuracy, and personalization, and success is measured by customer satisfaction scores, repeat purchase rates, and customer lifetime value.

How do you measure success in a customer-centric supply chain?

Measuring success in a customer-centric supply chain requires a comprehensive set of metrics that go beyond traditional operational KPIs, including:

- On-time delivery rate: The percentage of orders that arrive by the promised delivery date

- Shipping speed: The average time from order placement to delivery

- Customer satisfaction (CSAT) scores: Surveys that measure how happy customers are with their overall experience

- Net Promoter Score (NPS): A measure of how likely customers are to recommend your brand to others

- Order accuracy: The percentage of orders that are picked, packed, and shipped without errors

- Return rate: The percentage of orders that are returned due to issues like damage, inaccuracy, or customer dissatisfaction

How can AI and machine learning improve supply chain responsiveness?

AI and machine learning are powerful tools for creating a more agile, responsive supply chain. Predictive analytics can anticipate demand fluctuations and help brands proactively adjust inventory levels to prevent stockouts. ML algorithms can also optimize inventory distribution across fulfillment centers based on factors like historical sales data, seasonal trends, and real-time order patterns.

When it comes to order routing, AI can intelligently balance speed and cost considerations to determine the optimal shipping method and fulfillment location for each order.

What role does omnichannel fulfillment play in the customer experience?

With unified inventory management across channels creates a cohesive customer journey, regardless of where the purchase journey begins or ends.

Omnichannel data also provides a more complete view of customer preferences and behaviors. By analyzing cross-channel insights, brands can make more informed decisions about inventory planning, product assortment, and customer engagement strategies.

How does distributed fulfillment improve both cost efficiency and delivery speed?

From a cost perspective, distributing inventory helps to reduce shipping zones and, in turn, lower transportation costs. Brands can also optimize their inventory allocation based on regional demand patterns, reducing the need for costly expedited shipping.

In terms of delivery speed, having inventory closer to customers dramatically reduces transit times. With the right technology in place, orders can be intelligently routed to the fulfillment center that offers the fastest and most cost-effective shipping option. This allows brands to offer competitive delivery options like two-day or even same-day shipping without sacrificing margins.

What technologies are essential for a customer-centric supply chain?

Building a customer-centric supply chain requires a robust technology stack that enables real-time visibility, automation, and data-driven decision making. Some essential components include:

- Inventory management systems that provide real-time stock levels and proactively alert brands to potential stockouts or overstocking issues.

- Order tracking capabilities that keep customers informed of their package’s status at every step of the fulfillment process.

- Warehouse management systems that streamline picking, packing, and shipping processes to improve accuracy and efficiency.

- Integration platforms that connect disparate systems and create a unified view of the customer journey.

- Analytics and reporting tools that provide actionable insights for continuous improvement.

How is ShipBob uniquely positioned to support customer-centric fulfillment?

ShipBob is more than just a fulfillment provider; we’re a strategic partner for brands looking to build customer-centric supply chains. Our technology platform was purpose-built for the unique needs of ecommerce fulfillment, with features like real-time inventory management, automated order routing, and advanced analytics.

With an extensive network of fulfillment centers across the United States, Australia and Europe, ShipBob enables brands to offer fast, affordable shipping to their customers.

But it’s not just about speed and efficiency. ShipBob’s technology also enables brands to deliver personalized experiences at scale, with capabilities like custom packaging, branded inserts, and more.