Key Takeaways

1

A 3PL RFP is a formal document used by companies to outline logistics needs and evaluate potential third-party logistics partners based on standardized criteria.

2

The RFP process helps businesses clearly articulate service needs, maintain pricing transparency, and streamline communication with potential logistics partners.

3

Key components of a successful 3PL RFP include a company overview, scope of work, operational data, evaluation criteria, and specific questions for the 3PL.

4

To write an effective 3PL RFP, businesses should identify their needs, research potential partners, use templates for drafting, and manage proposal distribution and collection efficiently.

It’s happening – your ecommerce business is on the rise. It’s grown so big, in fact, that you don’t have the time or capacity to fulfill your own orders anymore. You’re ready to outsource to a 3PL. Now the only question is: which one?

While the question is simple, the selection process itself can be pretty complex – and high-stakes. If your business chooses a partner that’s a bad fit for your needs, you could experience a host of issues, including endless order inaccuracies, hidden fees, slow deliveries, and ultimately unhappy customers.

This means that it is paramount to thoroughly vet potential logistics partners to find one that aligns with your needs and budget. To do this, many brands leverage the “request for proposal,” or “RFP,” to evaluate and compare different partners.

This post provides an in-depth guide to what a 3PL RFP is, why it’s important, and how to write one for your business.

What is a 3PL RFP (request for proposal)?

A 3PL RFP (“request for proposal”) is an evaluation method and official documentation that companies use when searching for potential logistics partners for a specific project or service.

It outlines the requirements and expectations needed to fulfill the company’s logistics needs, along with the criteria that the brand will use to evaluate bidders.

Typically, a business will either announce that it is accepting proposals or specifically invite prospective partners to submit a proposal. These proposals usually outline key information about the partner, what the service or project would entail, pricing, and more.

An RFP offers a structured framework for vetting 3PLs, allowing the company to assess the various proposals from different 3PLs using the same set of criteria. This streamlines the evaluation process, as it makes it easier to compare and contrast the pros and cons of each potential partnership.

Why does the 3PL RFP process matter?

Following the RFP process can be game-changing in your search for the perfect fulfillment partner. It allows brands to:

- Clearly articulate their service needs – Since the brand soliciting proposals will explicitly state everything they’re looking for in a logistics partner in the RFP, it improves the chances of finding a 3PL that meets their exact needs.

- Maintain pricing transparency – An RFP almost always requires 3PLs to submit a bid that clearly breaks down pricing and any additional expenses, which helps businesses avoid hidden costs further down the line while getting access to competitive pricing.

- Streamline communication – Having a structured approach to requesting proposals formalizes and simplifies the evaluation process, enabling businesses to get all the information they need about a 3PL in one place, avoid misunderstandings, and make a decision faster.

“I spoke to 12 different fulfillment companies of all shapes and sizes — but our conversation with our ShipBob representative was by far the best. Out of everyone that we had spoken to, our conversations with him felt the most like a real partnership. Altogether, ShipBob was able to provide us with the bespoke solution that we were looking for, and a sense of partnership we just couldn’t find anywhere else.”

Adelina Zotta & Connor Westby, Co-Founders of NutriPaw

What is a 3PL RFP used for?

A 3PL RFP is a versatile tool. Brands use them in several ways to help them find the best fit for their unique fulfillment needs. Here are some of the most common ways that brands leverage RFPs as they choose their next 3PL.

Evaluating provider compatibility

With so many 3PL companies offering different things, it’s easy to get overwhelmed when choosing a fulfillment partner. It’s easy to get distracted by all the bells and whistles of a 3PL without realizing that the company doesn’t really meet your exact requirements.

Clearly documenting your logistics requirements ensures that you don’t lose focus of what’s important to your brand. It allows you to assess a provider’s capabilities and offerings objectively and evaluate compatibility based on your specific needs, helping you narrow down your options.

Standardizing responses for easy comparison

Not all 3PLs are created equal – and while most offer the same core capabilities of storage, picking, packing, and shipping, you’ll want to consider all of a partner’s service offerings before making your decision.

However, this can be difficult when you have different providers describing or listing their offerings in different formats. You may have a hard time finding the information you need, and even miss key details that will help with your evaluation. Alternatively, some providers may leave out certain details about their offering, which could skew your comparison process.

To minimize this confusion, a 3PL RFP lays out all the information that must be included in a proposal, as well as the format that providers must follow when responding to the request. Each provider sends in a standardized response using the same format and listing the most important information. As a result, you can easily compare responses to each other.

Enquiring about specific warehousing projects or services

Since a 3PL RFP allows you to clearly describe your brand’s needs, you can get as granular and specific as you need to. This makes RFPs highly useful for enquiring about specific warehousing projects or services.

For instance, maybe you need a provider who can offer custom-branded packaging, or you may need a provider who’s capable of scaling their ecommerce warehousing capabilities based on seasonal demand fluctuations.

With an RFP, you can inquire as to whether providers offer those services and the scope of their offerings. This streamlines the selection process, allowing you to eliminate providers whose capabilities are aligned with your exact needs.

Key components of a successful 3PL RFP process

For your 3PL RFP to deliver quality responses, it needs to include detailed and relevant sections that will guide respondents. Here are some of the key components of a successful 3PL RFP.

1. Company overview and objectives

Before anything else, you will need to provide 3PLs with the necessary context about your business, so they know “who” they’re sending their proposal to.

First, give an overview of your company and any essential information, including:

- What your business does

- Your business’s mission

- Where your business is located or headquartered

- What types of products your business sells

- Your business’s contact information

Next, explain why you’re issuing the RFP and what you’re looking to get out of it; in other words, describe the objective you’re looking to achieve with a 3PL partner.

For example, perhaps you’re expanding your reach, looking to reduce costs, or improve efficiency. Share the pain points that you want the 3PL to address, such as not having enough space or not having the workforce needed to meet delivery timelines.

2. Scope of work

With the basic facts covered, it’s important to set clear expectations about the scope of work. This means outlining your main service requirements, so providers know exactly what you’re looking for. Don’t just assume that they’d know what you need based on the objectives you shared.

Your service requirements could include both larger initiatives and smaller value-added services, including:

- Warehousing

- Inventory management

- Order fulfillment

- Distributing inventory

- Cross-docking

- Custom-branded packaging

- Kitting

- Expedited shipping

- Returns management

Make sure to specify whether there’s a need for certain supply chain technology. For instance, you may need a 3PL that also offers a standalone WMS to fulfill some of your orders in-house, or you may need technology that rate-shops between multiple carriers to ensure cost-efficiency.

Don’t forget to include instructions for how they are to format and share their responses. This will help providers understand how to lay out their service offerings in a clear and logical manner that you’ll accept.

3. Operational data and requirements

Even if a 3PL offers the specific services you’re looking for, it doesn’t necessarily guarantee that they have the capacity to meet your operational needs. To address this, you’ll want to write an RFP that specifies the exact operational capacity and service scopes that a provider needs to offer.

Include specifics about your operations to set expectations from the start. Use data from your ecommerce analytics to highlight key details, like:

- Average order volume

- SKU count

- Peak season demand trends

- Current fulfillment performance

- Current fulfillment costs

4. Evaluation criteria

In the interest of fairness, it’s important to tell providers upfront about how you will be evaluating them. This helps them understand how they’ll be compared against other providers, so they can be prepared to set themselves apart. It also provides you with a clear framework for comparing providers, so you can focus on the most important details.

Outline the key details of your evaluation process, such as:

- What matters most to you (cost, specializations, technology, speed, scalability, customer service, etc.)

- Who will be evaluating the proposals (procurement, finance, operations, etc.)

- How many stages are in the selection process (initial review sessions, shortlisting, interviews, etc.)

5. Questions for the 3PL

Besides the basics, you’ll also want to ask additional questions to hammer out the details of a partnership and understand the provider even better. A few examples of questions you can ask include:

- What’s your fulfillment capacity and can it scale with changing demand?

- Where are your fulfillment centers located?

- How do these locations serve my fulfillment needs?

- Who are your top carrier partners?

- Can you negotiate shipping fees on our behalf?

- If yes, what kind of lower rates can you guarantee?

- Can I access real-time fulfillment data?

- What type of service guarantees can you offer?

- What happens when an error occurs?

- How do you handle returns and reverse logistics?

You can always customize these questions to address your specific concerns.

How to write a results-driven 3PL RFP

So you know what to include in an RFP – now, it’s time to write it. Here are a few best practices you should follow to write a results-driven 3PL RFP.

Identify your business needs and goals

The whole purpose of an RFP is to seek out providers who can meet your business needs. This makes it crucial to start with a clear understanding of your exact needs and goals before you write the RFP.

Understanding the key internal logistics challenges that need addressing. What are your biggest pain points? For instance, you may be struggling with high error rates or fulfillment delays. Based on this, you can define the goals that you want to achieve with the help of a 3PL – in the previous example, you may want to achieve higher order accuracy rates and on-time fulfillment, or you may want to reduce fulfillment costs.

“We used to work with a different fulfillment provider, but their service was way too expensive and we just couldn’t afford it. It was one of our biggest expenses, so as we were trying to find ways to cut costs over the past year, we wanted to see what other options were out there – and that led us to ShipBob! ShipBob’s billing is also so much more transparent and easy-to-predict.”

Stuart Jones, Co-Founder of Canvas

Make sure to involve a cross-functional team when determining your business needs, so you can get a comprehensive idea of key pain points that your logistics partner needs to address. This includes everyone from warehousing and fulfillment to finance and tech.

Research and shortlist potential 3PL partners

While an RFP is supposed to help you shortlist potential 3PL partners, you don’t need to request proposals from every 3PL.

Before you draft your RFP, do some general research into industry leaders, paying special attention to which offer the key characteristics that you’re looking for in a 3PL (which could include details about their locations, warehouse sizes and setups, types of goods handled, industry specialization, tech offerings, etc.).

Zero in on 3PLs that have all these key characteristics to create a shortlist of some of the most relevant logistics providers to send your RFP to. That way, you don’t have to sort through hundreds of proposals from companies that aren’t relevant to your needs.

“During our search for a new fulfillment partner, one of our founders was recommended to ShipBob. We began researching their solution and it became evident that ShipBob was a great fit and met all of the criteria we were looking for. The pricing aligned with our budget across geographies, so we have been able to standardize our fulfillment across the UK and EU (and eventually other countries they are in). As a result of switching our European fulfillment to ShipBob, we’ve experienced 12% cost savings.”

Callum Jones, Director of Operations & Marketplace, and Rachel Hicks, Operations Manager at Hairburst

Draft your RFP (or use a template)

With so many details to include in an RFP, it’s easy to forget a few. This could result in proposals that don’t quite tell you all that you need to know to make your decision. Not to mention the time-consuming process of putting together a highly detailed RFP.

The best way to save time and ensure that you include all the key details in your RFP is by using a pre-built template. There are plenty to be found online, and some experts (like ShipBob) even offer their own guides to choosing a fulfillment partner that contain pre-made lists of questions and criteria to include.

Distribute the RFP and collect proposals

When it’s finally time to send out your RFP, it’s important to take an organized approach to distribution and proposal management. Distribute your RFPs securely while ensuring that potential vendors have access to all the necessary information. Make sure you’re also tracking whether the 3PLs received your RFP and when they received it.

You’ll want to define a clear deadline for proposal submission so you can stay on track. At the same time, give 3PLs enough time to reach out for clarifications and answers while preparing their proposals.

Provide clear communication channels to quickly exchange information. Let the 3PLs know how they should reach out to you if they have any questions and how to submit their proposals. You’d ideally dedicate a team member or position to managing these RFP-related communications and recording your incoming proposals.

Don’t forget to provide pre-defined forms and tables that 3PLs can use to format their proposals and pricing. This will make it easier to find the information you need and easily evaluate and compare your options once you start receiving proposals.

Bonus: Common mistakes to avoid when writing your 3PL RFP

Besides following best practices, it’s also important to avoid some of the most common pitfalls that businesses make when writing their 3PL RFP. Here are some of the common mistakes you should avoid:

Mistake #1: Rushing the process or failing to involve key stakeholders

While you may be working with a tight deadline, rushing the process often leads to incomplete RFPs and subpar proposals. In your rush, you may even fail to involve key stakeholders, which will result in an RFP that fails to effectively address all of your business needs.

Mistake #2: Providing vague or incomplete data, leading to unhelpful proposals

Without having all the information they need, 3PLs may send in proposals that aren’t relevant to your needs. They may fail to include key details about things like capacity, scalability, or value-added services that could inform your decisions.

Mistake #3: Overemphasizing cost over quality or other important factors

Pricing may be an important factor for you, but it shouldn’t come at the cost of quality or efficiency. Make sure to leave room for negotiation and highlight other important factors that will influence your decisions.

Mistake #4: Not including evaluation criteria or a clear timeline

When 3PLs don’t know what factors you will use to evaluate them, they lack the necessary information to create a proposal that highlights what matters most to you. Moreover, without a clear timeline to submit proposals, you may experience significant delays that could affect other operational schedules.

Choose ShipBob for industry-leading 3PL logistics services

As an expert supply chain enablement partner, ShipBob’s ecommerce fulfillment solutions and powerful technology empower you to optimize your logistics operations at scale. Here are just some of the ways that ShipBob stays on the cutting edge of ecommerce brands’ needs to not only meet, but beat your 3PL expectations.

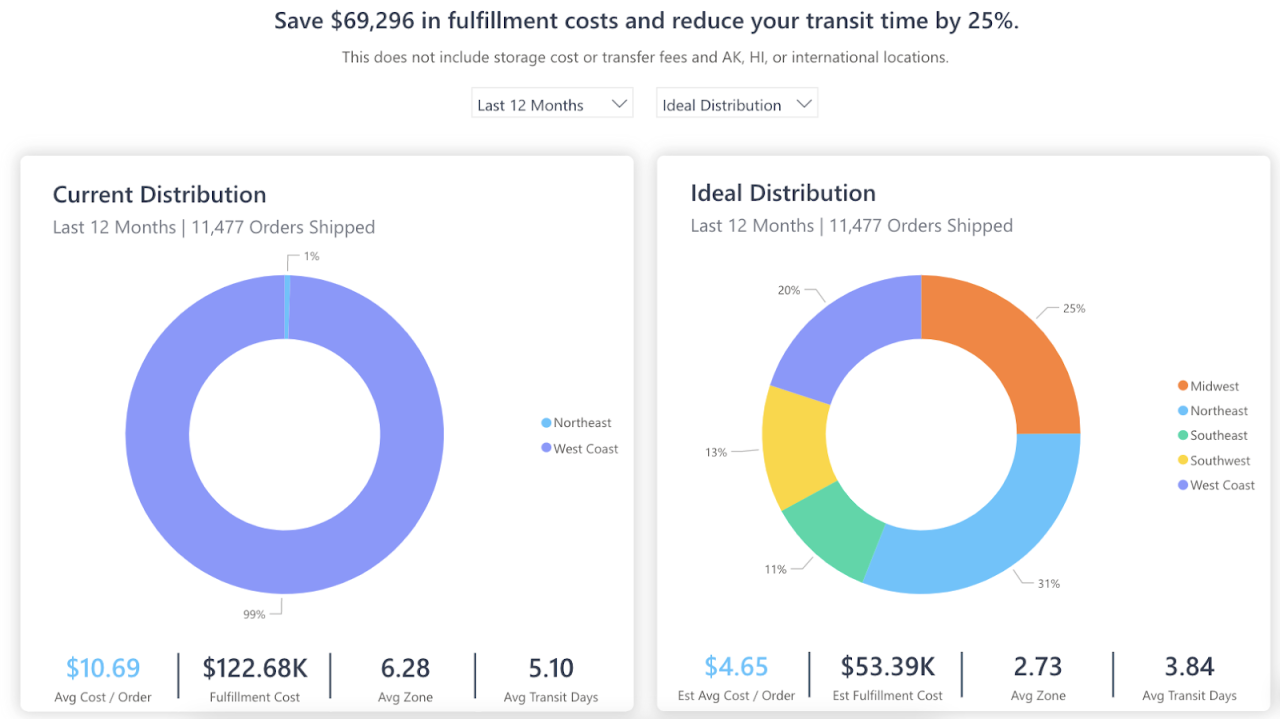

Nationwide fulfillment network for faster and cheaper shipping

If shipping cost reduction and enhanced customer satisfaction are some of your key RFP requirements, ShipBob’s the answer.

With a massive network of 60+ fulfillment centers globally, ShipBob’s geographic footprint enables brands to strategically distribute inventory closer to customers. This means you can lower shipping costs while simultaneously facilitating faster deliveries – both of which lead to happy customers.

Brands like Our Place have been able to save $1.5 million in freight costs after taking advantage of ShipBob’s distributed fulfillment network. It allows them to store inventory closer to their customers and ship locally to lower zones, which has significantly reduced outbound costs. Their fulfillment speed has even dropped from 5-6 days to 2.5 days.

“We sought a fulfillment partner primarily for their exceptional operational capabilities. Our priority was finding a partner capable of efficiently handling large-scale fulfillment while also streamlining our workflows. ShipBob emerged as the perfect fit, meeting our needs beyond expectation.”

Ali Shahid, COO of Our Place

ShipBob also offers you tools that factor their real order data to calculate the optimal split of inventory for you, automating inventory allocation.

You can even take advantage of expedited shipping solutions like affordable 2-Day Express Shipping. With 100% coverage in the contiguous U.S., this lets you deliver orders to your customers in just two days for enhanced customer satisfaction.

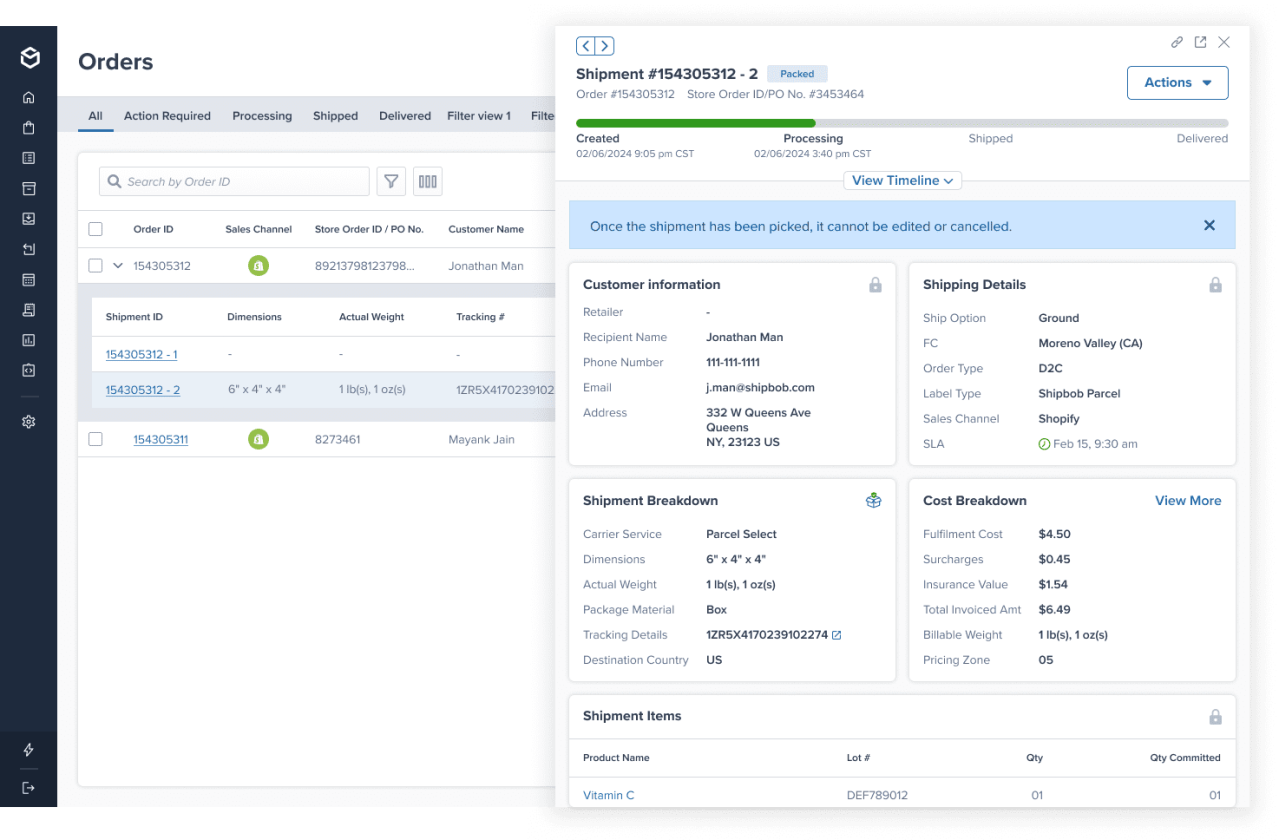

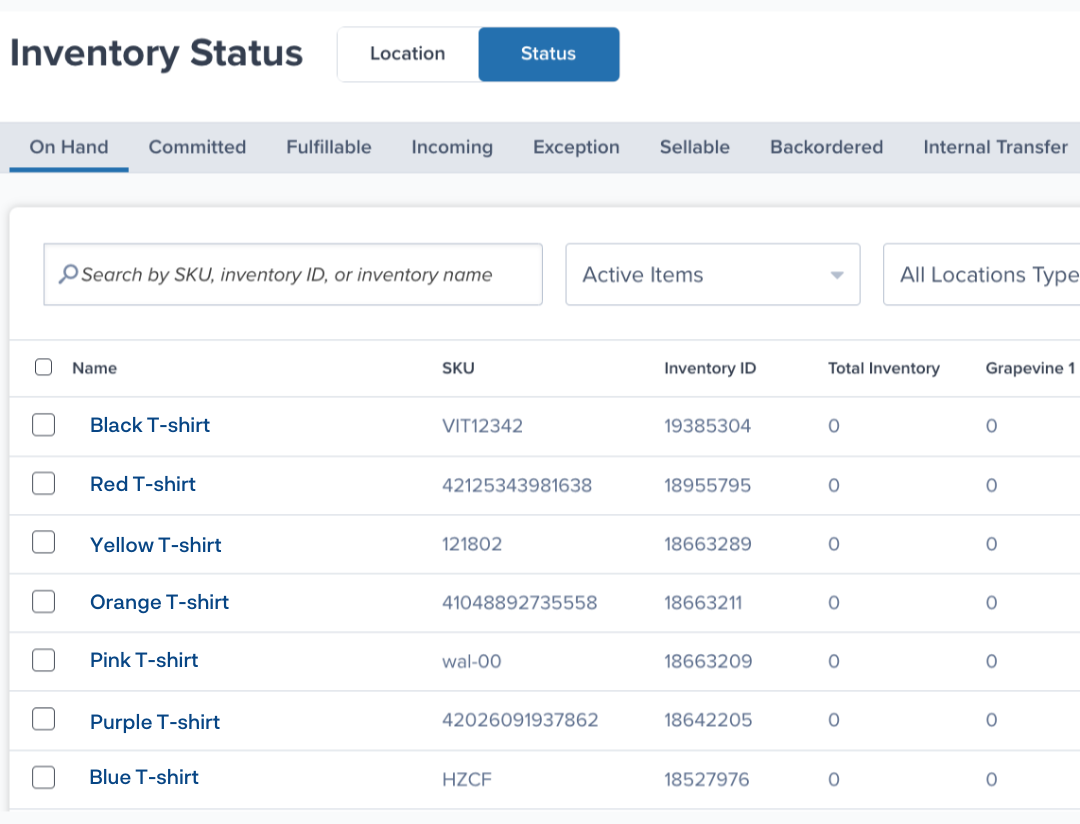

Advanced technology to streamline operations and provide transparency

ShipBob’s proprietary warehouse management system (WMS) is designed to power efficient, accurate fulfillment, so you don’t have to worry about whether or not your fulfillment partner will get things right.

Our WMS integrates seamlessly with your ecommerce platforms. This gives you granular visibility into your inventory, orders, and fulfillment performance, so you can make informed decisions to streamline your operations.

For instance, you can see your top-performing locations and optimize your inventory placement accordingly. Plus, with real-time inventory tracking, you can make timely replenishments to avoid stockouts and meet customer demand.

The WMS also features multiple built-in checks and balances throughout the fulfillment process. With warehouse staff quickly verifying inventory and order information via barcode scanning as they stow, pick, and pack inventory, you can significantly reduce mispicks and enhance transparency.

Omnichannel fulfillment for whatever you sell

You shouldn’t have to juggle multiple 3PLs to fulfill your DTC orders, marketplace orders, and B2B orders separately. With ShipBob’s omnichannel fulfillment solutions, you can seamlessly fulfill orders placed across all your channels.

ShipBob supports retail distribution and dropshipping for dozens of major retailers, marketplaces, social channels, and more, allowing you to fulfill all your orders through one partner, and manage all your inventory and orders from a single, intuitive dashboard.

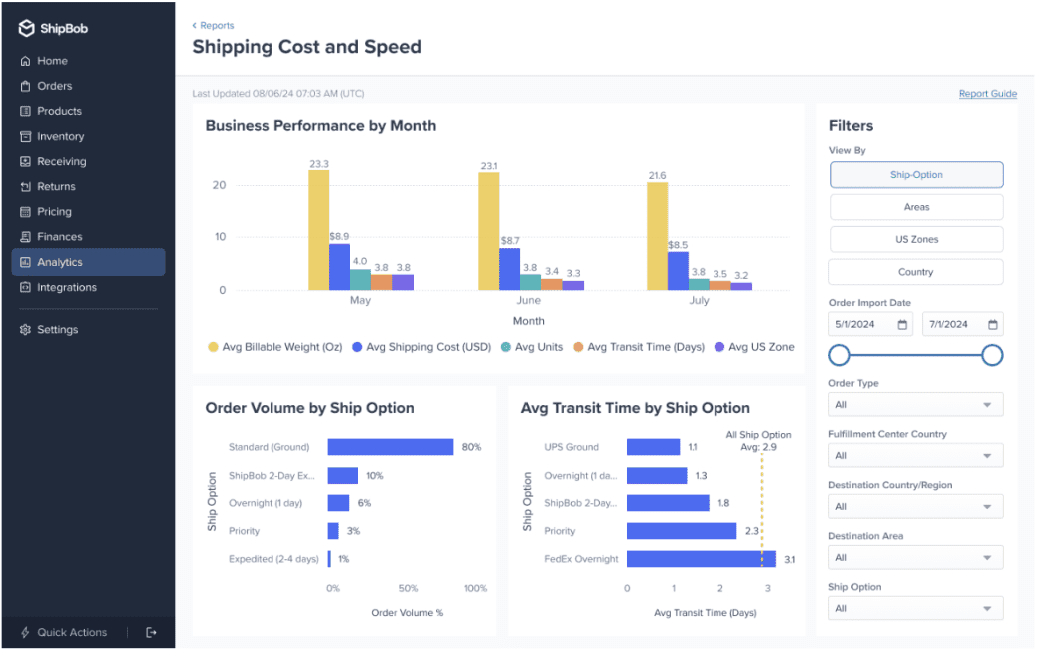

Analytics and reporting for better decision-making

ShipBob’s powerful analytics dashboard gives you comprehensive insights into various aspects of your logistics performance. You can easily access metrics like on-time fulfillment rate, average fulfillment cost, transit times, and inventory levels.

IMAGES: Reports

These insights help you make informed decisions to optimize your logistics performance in real-time, giving you the visibility and data you need to run and scale your business.

For more information on how ShipBob can meet your fulfillment needs, click the button below to get in touch.

3PL request for proposal FAQs

Below are answers to the most commonly asked questions about 3PL RFPs.

Can I use the same RFP template for different logistics needs?

You can use a basic RFP template for different logistics needs. However, it’s always recommended to tailor your RFP according to each logistics need, as the basic template may not effectively address it.

Why should I prioritize technology in a 3PL provider?

Technology is vital for maintaining transparency and efficiency in your logistics operations. It can also give you comprehensive insights needed to make data-driven decisions, and should be a priority in a 3PL provider.

What essential sections does ShipBob recommend including in a 3PL RFP to evaluate fulfillment capabilities?

ShipBob recommends including sections that cover:

- Global fulfillment network: Inquire about the provider’s network for international DDU and DDP shipping. This includes the ability to handle both Direct-to-Consumer (DTC) and Business-to-Business (B2B) orders, including retail dropshipping and distribution.

- Technology & software: Look for a proprietary, full-stack platform encompassing Warehouse Management System (WMS), Inventory Management System (IMS), Order Management System (OMS), and Transportation Management System (TMS). This should offer real-time inventory tracking and reporting/analytics.

- Customization: Capabilities for branded unboxings, custom packaging, marketing inserts, and gift notes.

- Specialized handling: Inquire about lot tracking and expiration date management, temperature-controlled warehousing, GMP and GFSI certifications, and handling of fragile or heavyweight items.

- Returns management: Clear processes for return-to-sender and customer-initiated returns, including restocking, disposal, or quarantine options, and integrations with return partners.

How does ShipBob suggest structuring KPI expectations within an RFP to ensure transparency?

To ensure transparency with KPIs, an RFP should focus on:

- Fulfillment cost per order: Look for transparent pricing with detailed breakdowns of various fee categories (e.g., B2B, B2C, Inbound, Returns, Value Add Services, Warehouse Storage) and fee types, visible in reporting.

- Speed metrics: Include expectations for “Average Days to Fulfill” (from order import to labeling) and “Average Days in Transit” (from label purchase to delivery).

- Order accuracy: Seek commitments on picking and packing accuracy.

- Inventory management efficiency: Transparent reporting on inventory levels across locations, and the ability to identify slow-moving inventory and receive reorder notifications and replenishment recommendations based on forecasting models.

- Billing transparency: The ability to view and manage invoices with detailed breakdowns of charges and credits.

Which technology integrations does ShipBob recommend brands inquire about in their 3PL RFPs?

ShipBob recommends brands inquire about integrations with:

- Ecommerce platforms & marketplaces: Turnkey integrations with major platforms like Shopify, Shopify Plus, BigCommerce, WooCommerce, Amazon (FBA & FBM), Walmart, eBay, Squarespace, Wix, and Square.

- ERP & inventory/order management systems: Native integrations with leading EDI, ERP, and inventory/order management providers, such as NetSuite, SPS Commerce, Cin7, Skubana, and Order Desk.

- Customer experience & marketing tools: Direct integrations with popular returns management (e.g., Loop, AfterShip), customer support (e.g., Gorgias), and marketing (e.g., Klaviyo) platforms.

- Developer API: Availability of a flexible and easy-to-use Developer API for custom builds and integrations, offering control over orders, products, inventory, receiving, returns, shipments, and webhooks.

What critical questions should brands include in every 3PL fulfillment RFP?

When drafting a 3PL fulfillment RFP, including key operational, technical, and strategic questions ensures you account for real-world performance and compatibility:

- What is your average order processing turnaround time across different volumes and seasons? This reveals how they handle demand spikes and scale.

- Which systems and platforms do you integrate with (e.g., e‑commerce, ERP, TMS)? This clarifies compatibility and avoids integration delays.

- How many fulfillment centers do you operate, and how do you optimize geographic coverage for cost and delivery speed? This helps assess your potential transit zone savings and delivery SLAs.

- What value-added services do you provide (e.g., customization, packaging, returns, kitting)? This ensures your branding and post-order logistics are supported.

- How do you measure performance — what KPIs do you report (e.g., order accuracy, on-time shipment, damage rates)? This signals transparency and operational accountability.

- Can you share references or case studies of similar brands you’ve supported?This offers insights into real-world compatibility and reliability.

How can brands accurately compare 3PL pricing models?

Comparing pricing models requires understanding each provider’s cost structure and aligning it to your business needs:

- Request full pricing breakdowns, including onboarding, storage, receiving, picking/packing, outbound shipping, returns, and any customization fees. This helps avoid sticker shock from hidden charges.

- Normalize per-order costs across volume tiers (i.e., calculate cost at low, medium, and peak volumes, including variation for compact vs. large orders).

- Ask for average shipping costs based on your key SKUs and order profiles, so you can model real cost scenarios.

- Clarify how different surcharges and escalations are handled (for example, peak season surcharges or fees for oversized orders).

- Benchmark and estimate costs using each provider’s pricing and your historical order data to project your monthly and seasonal spend.

What legal considerations should be covered in a comprehensive 3PL RFP?

A robust RFP should prompt 3PLs to address the following legal risks and responsibilities:

- Liability and insurance terms: Who covers loss, damage, or mis-picks, and what are the policy limits?

- Termination clauses and notice periods: Especially for seasonal volume shifts or service failures.

- Data security and compliance obligations: Including how customer data, order data, and integrations are protected under regulations like GDPR or CCPA.

- Indemnification clauses: Clarifying responsibility in case of issues like recalls, false claims, or regulatory violations.

- Service-level agreement (SLA) enforcement: Including remedies or penalties for failure to meet agreed metrics.

How many 3PLs should I evaluate?

Some brands only talk to a single fulfillment company before signing on, while others look at dozens. For an RFP to make sense, most brands will generally send their first-round request for an RFP to 10-15 providers. This usually helps weed out any poor fits immediately, so you end up with 2-3 serious contenders.

When should I not use an RFP?

A formal RFP process is not the only way to gather the information you need and answers to your 3PL evaluation criteria. In fact, it’s rarely the preferred method.

You probably don’t need to use an RFP if:

- Your order volume is low.

- You’re considering smaller, mom-and-pop 3PLs.

- You want a more personalized, conversational experience.

- You want to go deep into topics you care about, the 3PL’s experience with your product vertical, their culture, and the solution the 3PL is providing.

What do you do instead of an RFP?

The RFP process is not right for everyone – and if that includes you, you can still look at top 3PLs and go through their sales process to get a feel for whether they meet your needs. They will have experts in-house to help you with discovery and even things you might not know to ask.

When you request a quote or demo on a 3PL’s website, you can still get very detailed information and a data-driven approach to understanding what your costs and transit times will be. A simple scorecard may suffice to stay organized in your search, covering warehouse locations, pricing structure, SLAs, customer support, services, capabilities, scalability, technology, implementation, and much more.

Who typically uses an RFP process when evaluating 3PLs?

Not every brand will need to use the RFP format in their hunt for a fulfillment partner, but it may be helpful depending on your brand’s circumstances. The use cases that warrant an RFP process may include the following:

- When you’re evaluating multiple 3PLs

- When there is a lot of complexity or uniqueness in your operations

- When you have new project(s) or needs for your fulfillment operations

- When you ship a high volume of orders

Should I run the RFPs myself or hire a third-party consultant?

When it comes to running an RFP, these efforts are often led by an individual brand. Some brands use a third party or consultant to run an RFP for them, ranging from someone who is running the entire thing for them, to serving as more of an assistant, with varying involvement at different stages of the process.

Additionally, less sophisticated or mature 3PLs who lack sales and marketing teams are more likely to rely on RFP processes, and to be featured in directories or partner with consultants to obtain new business inquiries. These recommendations can even come in the form of affiliates or pay-to-play listings that incentivize choosing certain 3PLs.

In our experience, it’s best when the brand is running an RFP so there is direct buyer contact with their potential long-term partners.

Do I need an NDA?

If you are sharing proprietary things about your business (e.g., order data, expectations on growth, etc.), you should arrange for an NDA at the beginning (included with packet), but you won’t often need an NDA this early on in the process, as it can introduce complicated and unnecessary redlines and delays. For future rounds, you may want to include that as an expectation. If you don’t have in-house counsel, it might be helpful to ask the 3PL to use their paper, as it might streamline things.