Inventory Days on Hand Guide

When it comes to inventory management, you might find yourself wondering how long your inventory will last before it runs out. This is where the metric of inventory days on hand comes into play.

We covered inventory forecasting in-depth to demonstrate how you calculate how much inventory you need. It’s time to combine these two metrics to determine how quickly your products are being sold and accurately predict future inventory levels.

So, what do you want to learn?

Request Fulfilment Pricing

Let’s talk. Our experts can help you boost your order volume by 30% year over year.

A fulfilment expert will get back to you shortly. Privacy Policy

What is inventory days on hand?

Inventory days on hand (or days of inventory on hand) measures how quickly a business uses up its inventory levels on average. Calculating accurate inventory days on hand allows businesses to minimise stockouts. In general, the fewer days of inventory on hand, the better — and we’ll explain why in this article.

Why inventory days on hand matters

Managing inventory levels is vital for most businesses. It’s increasingly more challenging for ecommerce businesses to predict accurate inventory counts as new customers can come in from all over the world, making demand harder to predict than ever before.

In addition to general growth, you must factor in prime online shopping days like Black Friday, Cyber Monday, Labour Day, Independence Day, and other large promotions or flash sales you run to ensure your business has the right amount of products to ship out.

Without getting accurate projections, you may experience many canceled or delayed orders and angry customers — which can then turn into negative reviews and feedback for your business.

While inventory turnover ratio is one of the best indicators of a company’s level of efficiency at turning over its inventory and generating sales from that inventory, inventory days on hand helps with letting you know when it’s time to restock inventory levels. If the inventory days on hand is low, the inventory turnover will be high (and vice versa).

How to calculate inventory days on hand

You can calculate inventory days on hand for your business using either of two formulas.

Formula #1: Average Inventory

The first formula calculates inventory days on hand by dividing your average inventory value for a year by the cost of goods sold for that year, and then multiplying that result by 365.

Days on hand = (Average inventory for the year / Cost of goods sold) x 365

Real-world example

Say a company has inventory that’s worth $43,780 and its cost of goods sold (COGS) is worth $373,400 for the year 2018.

Using the formula above, the company would calculate inventory days on hand like so:

Inventory days on hand: 43,780 / (373,400) x 365 = 42.795 days

This means that on average the company had 42.795 days of inventory on hand during 2018.

Formula #2: Inventory Turnover

If you know your inventory turnover ratio, you can also calculate inventory days on hand using this formula:

Inventory Days on Hand = # of days in your accounting period/inventory turnover ratio

Real-world example

Say a company wants to calculate its inventory days on hand for the past year, and knows that their inventory turnover ratio for the past year was 4.2.

Using the formula above, the company would calculate inventory days on hand like so:

Inventory Days on Hand: 365 / 2.5 = 86.904

This means that on average the company had 86.904 days of inventory on hand during the past year.

Key benefits of reducing inventory days on hand

While businesses generally strive to achieve a high inventory turnover, they typically want a lower inventory days on hand. There are several advantages to having a lower inventory days on hand, which can benefit your business and your bottom line.

Lower costs

The fewer inventory days on hand you have, the less capital you’ll have tied up in physical inventory, and the less money you’ll need to spend on warehousing and holding costs.

Faster profits

If you can reduce your inventory days on hand (meaning, if you can speed up the rate at which you deplete inventory), you will move inventory more quickly, and presumably earn back the cost the inventory sold — plus a profit — more quickly as well.

Fewer stockouts

Knowing how quickly your business is using up its inventory levels on average lets you set up accurate reorder points, so that you can replenish stock on time and have the right amount of a SKU available when you need it. With fewer stockouts, you can ensure a consistent customer experience and prevent backorders.

Flexibility to meet consumer demand

Having a small inventory days on hand naturally means that you are holding less stock — and when you hold less stock, you have more freedom to pivot and cater to shifting customer demands.

For example, if your industry suddenly experiences a new trend or a certain product becomes popular, and you have space on your shelves, you will be able to order more inventory and can capitalise on the trend.

Reduced risk of obsolescence and dead stock

Trends and consumer preferences can change fast — so when your inventory days on hand metric is high, you run the risk that consumer demand will change faster than you can sell your products. Keeping your inventory days on hand low makes it less likely that you’ll be left with deadstock and obsolete inventory that are difficult and costly to offload.

7 ways to get rid of slow-moving inventory

There are many adjustments you can make in managing your inventory to reduce the amount of time inventory is sitting on your warehouse shelves. Here are some best practices for optimising your inventory days on hand.

1. Improve demand forecasting

The best way to get rid of slow-moving inventory is to prevent it from building up in the first place.

High-quality demand forecasting can more accurately identify which products have been popular with consumers in the past, and which are most likely to sell in the upcoming season or sales period.

With this knowledge, merchants can invest in inventory that will probably move quickly, and avoid or discontinue products for which there is little demand.

2. Improve customer service

If a customer is on the fence about purchasing an item, a positive customer service experience could mean the difference between a unit of inventory getting picked and packed for a sale, and that unit sitting on shelves for another week. Swift, clear, and helpful customer service can help close more sales, which helps your business keep inventory moving through your supply chain.

3. Create product bundles

One easy way to sell more of a slow-moving product is to bundle it with a more popular item — especially if the two items naturally go together (e.g., shampoo and conditioner) — and offer the bundle at a discount. That way, you can move less popular items out while still recouping most (if not all) of your initial investment in the inventory.

4. Offer discounts and promo deals

Sometimes, there isn’t enough demand for a product for it to sell at full price. Discounting less popular items or running special promotions (seasonal or timed) can give customers the extra incentive to add the slow-moving item to their cart.

5. Include it as a free gift

Everyone loves getting free stuff — so as long as an unpopular product is still functional and in good condition, you can include it as a freebie in future purchases. Even if a customer doesn’t use it, they will probably enjoy the surprise, which can even boost customer loyalty.

6. Donate and write off excess stock

You can always donate deadstock or inventory that you cannot sell. While you won’t necessarily earn your investment back, you can still write it off, and many customers will appreciate your company’s charitable efforts.

7. Automate inventory management processes

Implementing automations throughout your inventory management process can help prevent slow-moving inventory from amassing by taking human error out of the replenishment process.

With the right inventory management software, merchants can set up automatic reorder point notifications when SKU levels reach certain thresholds, which enables you to reorder inventory at just the right time. Some systems even allow merchants to fully automate the purchase order process to avoid replenishing inventory too early or too late.

Streamline your inventory with ShipBob

ShipBob ecommerce fulfilment services for online brands of all sizes, taking the hassle out of storing, picking, packing, and shipping your products. ShipBob lets you focus on creating and selling great products — we’ll handle the rest.

Here are a few key ways that ShipBob helps improve your inventory days on hand:

Inventory management

With ShipBob’s network of nationwide fulfilment centres, you have access to a powerful geographic footprint. Our fulfilment centres are powered by our proprietary technology, which makes it easy to strategically split and manage your inventory to reduce shipping costs and time in transit.

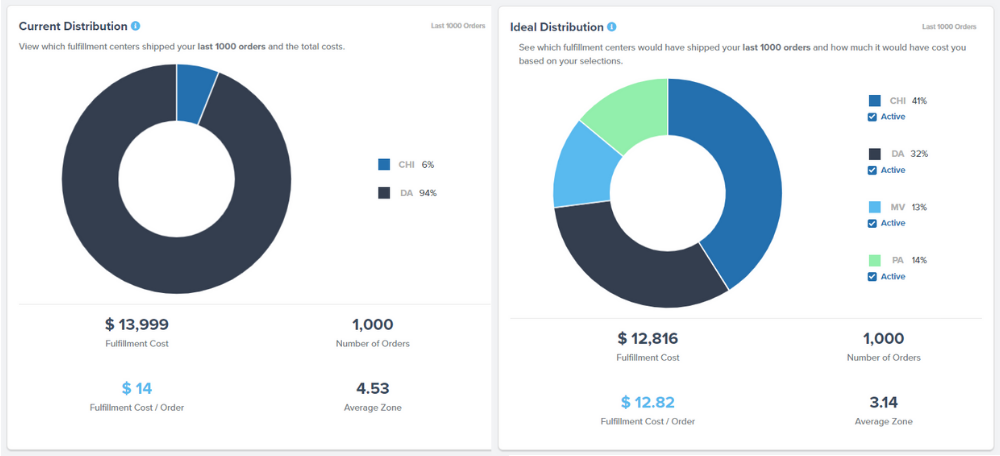

ShipBob makes it easy to take a data-driven approach to inventory distribution. By aggregating historical order data, you get an analysis of which fulfilment centres you should stock to best leverage ShipBob’s network of fulfilment centres for the most cost-effective and fast deliveries.

Inventory tracking

ShipBob’s technology powers our network of fulfilment centres across the country. As soon as an order is placed on your store, it is automatically sent to the ShipBob fulfilment centre closest to the customer to be picked, packed, and sent to the customer. You can view real-time inventory counts at the SKU level by location.

Lower fulfilment costs

For each order, ShipBob finds the fastest and most cost-effective option to get it delivered to its shipping destination. ShipBob’s algorithm selects the fulfilment centre you have inventory in that’s closest to the customer. As soon as the order ships, ecommerce order tracking info is pushed back to your online store and sent to your customers so they stay in the loop every step of the way.

Reorder point calculations

Using the reorder point formula to calculate reorder points for each product can take a lot of time. ShipBob’s proprietary technology lets you set automatic reorder points for each product, so that you are notified when stock is running low, taking into account your inventory days on hand, safety stock, and how your product has historically moved — all of which can be tracked in the ShipBob dashboard.

What’s next?

Lowering your inventory days on hand should be a priority for your business. With proper inventory control and management, you can account for and prevent stockouts, no matter how small or large your business is.

As your ecommerce business grows and managing inventory levels becomes too expensive or challenging to manage in-house, consider using an expert order fulfilment company to help you. They can help you manage your inventory turnover rate and reduce your inventory carrying costs to save your business money.

A 3PL like ShipBob helps direct-to-consumer (DTC) brands manage their inventory and ship orders quickly and affordably. To see if you’re a good fit and to get a pricing quote, click the button below.

Inventory Days on Hand FAQs

What are the implications of low days of inventory on hand?

A low number of days inventory is on hand is a sign that inventory is moving fast and not being stored for long, meaning it might be time to order new inventory.

What does high days of inventory on hand mean?

A high amount of inventory days on hand means a low turnover rate with inventory. This could happen for a few reasons, like low sales, low demand, or more valuable products that do not get bought and sold often.

What are the average days of inventory on hand?

The average number of days inventory is on hand is dependent on a few factors, each of which will change by business, time of year, average days sales, and industry (think perishable goods vs. diamond rings). Use this formula to calculate your average inventory days on hand.