Table of Contents

** Minutes

How does the order fulfilment process work? (5 steps + infographic)

Build your order fulfilment strategy around these 10 questions

Order fulfilment options: what are they (+ 3 tips from the experts)

Order fulfilment and 3PL pricing models

Think about the last time you ordered something from an online store and had a less than ideal delivery experience. Maybe your package was lost, late, or damaged.

Are you itching to buy from that seller again? Probably not.

As an ecommerce seller, you would never want your customers to have an experience like that from your brand. Moreover, your brand’s success depends on delivering not just an adequate delivery experience, but a stellar one.

Achieving that outcome for your own ecommerce brand comes down to one thing: your order fulfilment strategy.

In this article, we’ll dive deep into order fulfilment – what it is, what it entails, and how you can optimise and transform it into a competitive advantage for your business.

Main takeaways (TL;DR)

- As your business is growing, make sure your fulfilment strategy can scale with you.

- The order fulfilment process has 5 main steps, from receiving to returns.

- There are different approaches to order fulfilment. Which strategy is best fit for your brand depends on several factors, such as business size, order volume, sales channels, global markets, and customisation needs.

- If you decide to outsource your order fulfilment process, there are 5 questions you can ask a third-party logistics provider in order to choose the right one for your order fulfilment strategy (regarding locations, platform integrations, 2-day shipping, etc.).

What is order fulfilment?

Order fulfilment (also called parcel fulfilment) is the process of receiving, preparing, and delivering ecommerce orders. It begins as soon as a customer places an order, and encompasses every activity involved in getting a finished order into the customer’s hands, including order processing, confirmation, picking, packing, and shipping.

Why is order fulfilment important?

Order fulfilment is a necessary part of running your ecommerce business – without it, there’s no way to get your products into customer’s hands.

But more importantly, it is a critical stage of your supply chain that has huge implications for your brand’s fans, finances, and future. There are 3 key reasons why you should care about your brand’s order fulfilment:

1. It impacts the customer experience.

Orders don’t just magically show up on doorsteps – rather, every item in their order has to be procured, received at a warehouse or fulfilment centre, stored away, picked, packed in a box, and delivered to the end customer.

Even though the customer almost never sees these activities, how they are carried out will affect the customer’s experience.

For example, if a picker can’t find one of the items in a customer’s order (or realizes that item is out of stock), that order will be delayed. The customer is then forced to wait a longer time than they were promised to receive their finished order, which may upset them.

Similarly, if an order is packed in the wrong size box without any protective material to cushion the items, those items may get damaged or broken in transit. The customer will then be disappointed when they open their package, and have to coordinate a refund with the brand.

When you fail to meet your customers’ expectations – that the exact items they ordered arrive in pristine condition quickly – they probably won’t purchase from your brand again. This can cost your brand money in the short term, and make it difficult for you to build up a loyal customer base.

For example, medical equipment brand Baby Doppler noticed that they were getting a lot of complaints from customers because their orders weren’t arriving in 2 days or less (the ecommerce industry standard). By outsourcing fulfilment to ShipBob, and leveraging ShipBob’s fulfilment centre network, they were able to get orders fulfilled and shipped to customers doorsteps much faster, and satisfy customers again.

“Since switching to ShipBob from other 3PLs, our overall customer rating has been climbing steadily to get closer to our previous nearly perfect 5/5 rating, I believe largely due to improved shipping performance and service levels provided by ShipBob.”

Mithu Kuna, Co-Founder and CEO of Baby Doppler

2. It’s a major cost centre. (CS)

Fulfilment costs are part and parcel of running an ecommerce business – in fact, for many brands, order fulfilment is one of their biggest spending areas. Ecommerce brands should pay attention to their order fulfilment to make sure they aren’t accidentally overpaying for sub-par fulfilment – especially if they outsource fulfilment to a third party logistics provider, or 3PL.

For example, eco-friendly jewellerybrand Ocean & Co. agreed to pay a premium price for what they thought would be premium fulfilment – but shortly after partnering with their old 3PL, they found they were paying 50% more than they had been previously, and experienced a huge surge in fulfilment errors and countless complaints about orders being inaccurately fulfilled.

“We quickly realised the grass is not always greener on the other side. After that experience, we moved everything back to ShipBob. While many 3PLs utilise a complex pricing model that makes forecasting expenses nearly impossible, ShipBob has a clear pricing model so we know exactly what we’re going to be billed.”

Gerard Ecker, Founder & CEO of Ocean & Co.

3. It’s an integral part of scaling your business. (CS)

Say you run a candle company, and have been selling via your own ecommerce store. You decide to expand your brand, and start selling through a popular retailer’s website as well.

Up until now, you’ve been able to fulfil all orders yourself – but as additional orders start pouring in from your retail partnership, you realise you can’t pick, pack, and ship the volume of orders you’re getting.

This happens to growing businesses when they discover that their order fulfilment solution can’t scale with their business. To successfully expand your brand into new sales channels, demographics, and even countries, you will need to have a way to manage more inventory, fulfil more orders, and ship out more packages without sacrificing quality or causing delays.

For example, when dog treat brand NutriPaw launched their brand, they fulfilled orders themselves. A year later, the brand had grown so much that self-fulfilment became completely unsustainable.

At the scale they were operating at, keeping everything in-house would mean that we would be picking and packing orders all day. By outsourcing fulfilment to ShipBob, NutriPaw was able to introduce new products and grow their brand without worrying about fulfilment.

“We wanted to free up our time to focus on growing our business, and knew it was time to outsource fulfilment to experts like ShipBob.”

Adelina Zotta & Connor Westby, Co-Founders of NutriPaw

How does the order fulfilment process work? (5 steps + infographic)

The order fulfilment process might look different for different brands, but it’s almost always composed of 5 key stages.

Step 1: Receiving

Your brand needs to have inventory to start fulfilling orders. Receiving refers to the acceptance and storage of incoming inventory at a fulfilment centre.

If your brand fulfils orders in-house, you are responsible for receiving and storing inventory when it arrives from the supplier or manufacturer.

When you outsource to a 3PL, the 3PL will take care of it for you. Each 3PL has its own processes for receiving and storing inventory, often involving documentation submitted by the merchant. This keeps things organised and timely, meaning your orders can start shipping sooner.

Once inventory arrives at loading docs, is counted, and gets checked for quality, the items are then stored in dedicated warehousing storage locations, such as shelves, bins, or pallets.

Step 2: Picking

The order fulfilment process begins with warehouse picking.

When an order is placed on your brand’s ecommerce store, someone needs to go through inventory storage and pick each item in that order.

When you work with a 3PL, each order is pushed to your 3PL’s order fulfilment system, it is assigned to the picking team. A picker receives a packing slip with the items, quantities, and storage locations at the facility to collect the ordered products from their respective locations.

Step 3: Packing

Once all items in an order have been picked, it’s time to get them securely packed up. For merchants fulfilling orders themselves, this means placing the picked items in a box or poly mailer, which gets sent to the customer.

In packing, it’s important to include insulating or protective materials so that the goods don’t get jostled or broken in transit. These materials can include boxes, bubble mailers or poly bags, packing tape, bubble wrap, air fill, and other dunnage.

3PL partners will handle parcel fulfilment for you. Some 3PLs will charge for packing materials, while others include them as part of their fulfilment services. Your 3PL will choose packing materials that will both protect your products and add up to the lowest practical dimensional weight.

If you’d prefer to keep your brand front and centre, some 3PLs allow you to stock your own custom boxes or otherwise use plain brown boxes.

Step 4: Shipping

Once the order is packed, it’s time to ship. Merchants must purchase shipping labels, affix the right label to each packaged order, and mail them to the customer using couriers such as the USPS, FedEx, UPS, and DHL.

Most 3PL partners will purchase shipping labels from shipping courier(s) on the merchant’s behalf. Some fulfilment providers have preferred couriers with whom they partner, while others compare shipping costs from a variety of couriers. The latter helps ensure the most affordable pricing possible for any given shipping option.

One big benefit of outsourcing fulfilment is that major couriers pick up orders directly from the 3PL’s fulfilment centres to ship, saving you a trip to the post office (or the hassle of arranging courier pickups yourself).

Once the order ships, you receive order tracking information. Depending on your 3PL’s technology, you can either automatically or manually share this info with customers.

Step 5: Order returns processing

Although you hope it never happens, on occasion, customers will inevitably want to return some or all items from their orders. This means that ecommerce brands need a plan in place for how customers can ship the items back, and how the brand can either restock those items or dispose of them.

Your brand will need to decide whether you will offer in-store returns, mail-in returns, both, or neither. You will also need to establish a return window (usually between 30 and 60 days), and whether you will cover the cost of return shipping.

Some 3PLs will help you coordinate returns and restock eligible items in your inventory to be resold.

Build your order fulfilment strategy around these 10 questions

There’s no such thing as a one-size-fits-all order fulfilment strategy. Here are some important factors to keep in mind when scaling fulfilment for your online store.

1. Business size and order volume

- How many SKUs does your business sell?

- How many orders are you currently shipping each month?

- How many orders do you predict you’ll be shipping next month? Next year?

The number of products you sell and your monthly order volume play a big role in finding a fulfilment solution that works for you. If you’re new to the world of ecommerce, your fulfilment strategy is likely to look very different from, say, Walmart Marketplace or Target.

Low order volume may make it more cost-effective for you to keep fulfilment in-house, as opposed to outsourcing. If you sell a limited variety of products and are shipping just a few orders each week, you probably don’t need a full inventory or warehouse management system to keep track of your inventory and operations.

If your business is growing quickly and your average order value is steadily increasing, keep in mind when you’re likely to outgrow your fulfilment strategy. It’s important to make sure your ecommerce fulfilment strategy can scale with you.

2. Sales channels and technology

- Where are you selling online?

- Are you selling on an ecommerce website, a marketplace, or both?

- Which ecommerce platform are you using?

Your fulfilment strategy should complement and support your online sales channels, especially from a technology standpoint. Order fulfilment software that already integrates with your ecommerce platform and online marketplaces can help you manage the entire parcel fulfilment process more efficiently without having to do any developer work.

This is especially important if you’re selling across more than one channel. Your technology should streamline the order fulfilment process, not complicate it.

This means that as soon as an online order is placed on any of your sales channels, it should automatically be pushed to your fulfilment operations. Then it can be picked, packed, and shipped in a timely manner.

“We utilise ShipBob’s EDI solution that is connected to our 3rd party EDI platform SPS Commerce for our Chewy orders, and when we don’t ship directly to Amazon, we rely on ShipBob’s direct integration with Amazon for FBA orders. We’re even exploring additional channels that ShipBob supports, such as Walmart.com.

Being an omnichannel brand is critical for us, so we can reach more pet lovers from more places. We’re glad that ShipBob helps us keep up with demand from all the places we reach our customers.”

Stephanie Lee, COO at PetLab

Choosing a fulfilment service with the right inventory management software is also critical. You should always have full visibility into inventory movement and quantities on hand across fulfilment locations, as well as a system in place to prevent stockouts.

Overall, ecommerce businesses need to leverage technology that connects the upstream activities of purchasing and manufacturing to the downstream activities of sales and product demand to make more accurate purchasing and production decisions.

3. Location, location, location

- Are your customers centrally located in one region, or are they spread across the country?

- Do you have a large international customer base?

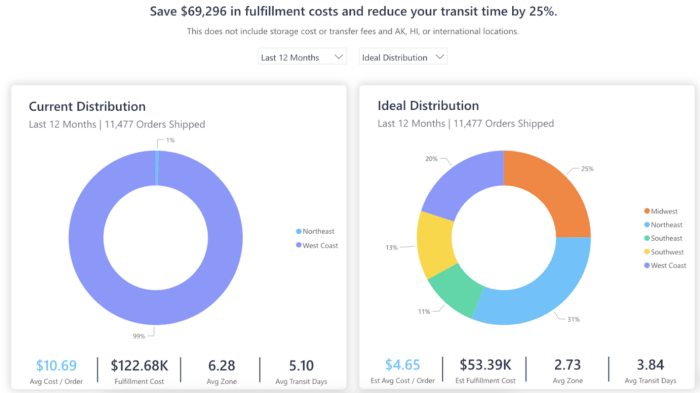

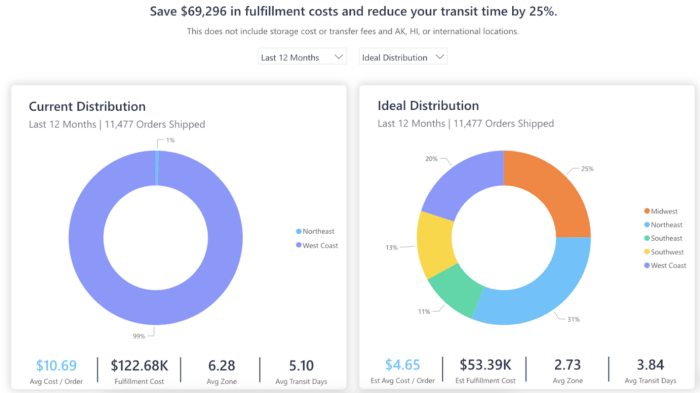

Where you ship to and from are two of the most important aspects that should inform your fulfilment strategy. Customers want ecommerce delivery to be quick and without a high price tag – so make sure you can deliver on customer expectations, try to minimise the number of shipping zones your average package travels. This can reduce shipping costs and times, leading to happier customers.

Leveraging multiple fulfilment centres strategically placed near your customers can also drive down logistics costs and shipping times. This helps you leverage ground shipping more often, which is significantly cheaper than expedited shipping, while still getting orders to customers fast.

For example, the chart below demonstrates how splitting inventory between 3 fulfilment centres (rather than using just one) can actually lower a brand’s average shipping zone, which optimises for speed and cost.

If your brand ships outside of the US, it’s even more important to master your fulfilment strategy. Shipping internationally can be extremely expensive and time-consuming – not to mention complicated, as there are additional duties, tariffs, and taxes that your brand must navigate.

Storing stock and fulfilling orders locally within the countries you sell in can help minimise cross-border complexities, cut costs,and improve shipping times.

If you decide to partner with a 3PL, they may have global locations that your brand can use to expand its reach without breaking the bank. ShipBob, for example, has fulfilment centres in Europe, Canada, and Australia in addition to its US locations.

4. Customisation needs

- Are your products made-to-order?

- Is customisation a key selling point of your brand?

If you sell items that are custom-made, specially gift wrapped, or extremely fragile, you may want to choose a more hands-on approach to your entire supply chain.

Being able to pack items yourself gives you the freedom, flexibility, and reassurance that customisation will be exactly right each time. However, fulfilling orders yourself isn’t always sustainable. While outsourcing fulfilment means giving up some control, the right fulfilment partner will enable you to control quality, deliver an unforgettable unboxing experience, and scale your brand.

“Fulfilment is one of the areas that we were super keen to outsource to a partner who’s been doing it for a while and knows how it’s done. We can trust ShipBob to support and handle fulfilment for us, so that we can focus on the strategic side of our business, helping us grow and develop much faster.”

Adelina Zotta, Co-Founder of NutriPaw

Order fulfilment options: what are they (+ 3 tips from the experts)

It’s clear that different ecommerce businesses have different needs. With all of the factors above in mind, the best order fulfilment strategy for your business might not be the same as that of your competitors.

The most common parcel fulfilment methods are outsourcing to a third-party fulfilment provider, merchant fulfilment, and dropshipping.

Third-party fulfilment

Third-party fulfilment is defined as the outsourcing of fulfilment logistics to an external partner. These processes can include inventory management, generating optimised picking lists, packing boxes, and shipping orders, and managing returns.

Many ecommerce retailers partner with a third-party logistics (3PL) partner to outsource supply chain-related tasks that can often be too unproductive, costly, or complex to manage in-house.

If you no longer have the bandwidth or space to fulfil orders yourself, working with a 3PL can help automate time-consuming tasks. Freeing up the time previously taken up by product fulfilment allows you to focus instead on growing your business.

“As a one-woman show, I was self-fulfilling dozens of orders each day out of my home office and packing boxes myself. I did not want to deal with fulfilment. I barely had any time to work on the creative marketing and branding side of the business. 50% of my time spent was packing boxes.

Before ShipBob I would have been terrified if an influencer posted about our product, and an instantaneous 1,000 orders came in, I would have had no way to handle that. Now I am totally ready for that. I think the biggest benefit and joy of working with ShipBob is the blocks of uninterrupted time I have back. I feel so free today. It really takes the stress out as a lone wolf entrepreneur.”

Leonie Lynch, Founder & CEO of Juspy

3PLs have inbound and outbound logistics expertise that your business can — and should — leverage. They also have the infrastructure needed to ship larger order volumes, making them invaluable as your business scales or needs to ramp up quickly and deliver orders accurately.

Merchant fulfilment

Also called in-house fulfilment and self-fulfilment, merchant fulfilment refers to an ecommerce seller completing the entire order fulfilment process without the help of a third party.

Many online brands choose to fulfil orders in-house when first starting out. This often means storing inventory and packing orders from home.

Merchant fulfilment offers more control over your retail supply chain than outsourcing the same processes, but it can also be costly and hard to scale as your business grows.

When your order volume gets too high to keep fulfilling orders from home, you have two options: Expand your merchant fulfilment operations by investing in fulfilment infrastructure (including warehouses, labour, equipment, and more) or outsource to a 3PL.

The former can be an expensive endeavor, which is why so many businesses choose the latter.

Dropshipping

Dropshipping is a much more hands-off approach to both manufacturing and order fulfilment. Inventory is produced, stored, and shipped by the manufacturer.

When a customer places an order, the order details are forwarded to the manufacturer. The product ships directly from the manufacturer to the end consumer.

Low barriers to entry and minimal overhead make dropshipping an attractive option to many new ecommerce businesses. However, manufacturers are often located overseas, which means that shipping takes significantly longer and is potentially more expensive than fulfilling orders domestically.

Overall, dropshipping offers merchants very little control over the supply chain, especially when it comes to inventory management and order fulfilment.

ShipBob’s top order fulfilment tips

Take it from an expert 3PL – order fulfilment is hard. But there are a few ways your brand can make it a bit easier:

Your receiving processes are key

If you’re owning the receiving part of your order fulfilment processes, you want to make sure that it is optimised so you can act fast. Any shipment should be processed as quickly as possible so that your customers can enjoy a fast delivery.

Have a backup strategy in place

When it comes to shipping products, there are a lot of preventable shipping mistakes to avoid, but also many external factors that you won’t have control over. Goods can be damaged, couriers may decide to increase their fees, exceptional weather conditions might impact your delivery, etc. Having a good backup strategy for your order fulfilment can help you prevent late deliveries.

Use everything you can to anticipate demand

Keeping an adequate amount of supplies in your inventory is essential to keep up with the demand. If it’s not your first year running your business, you could start by analising your data (orders, inventory, etc.) from the previous year to understand if there is any seasonality in your market.

Order fulfilment and 3PL pricing models

Different 3PLs price their fulfilment services in different ways. Here’s how ShipBob prices our ecommerce order fulfilment services.

Note: Order fulfilment pricing depends on your business’s specific needs.

| Fulfilment service | How it’s priced |

| Receiving | Flat rate |

| Inventory storage | Per bin, shelf, and pallet |

| Pick and pack fees | Included in total fulfilment cost |

| Standard packaging | Included in total fulfilment cost |

| Shipping | Courier pricing passed directly on to client |

Read more: Order Fulfilment Costs and 3PL Pricing Models: Everything You Need to Know

Just like there is no one-size-fits-all fulfilment solution, there is no one pricing model that fits all ecommerce businesses. Above is an example of ShipBob’s simple fulfilment pricing. Reach out to our team for a custom fulfilment quote that takes into account your business’s size, needs, strategy and budget.

How to choose a 3PL

If you’ve decided that outsourcing parcel fulfilment to a third-party logistics service provider is the right choice for your ecommerce business, it’s now time to select a 3PL.

However, choosing a 3PL can be a harrowing task. The options can seem endless, with confusing pricing and outdated processes.

It’s important to find an order fulfilment provider that you trust to handle your inventory, provide a positive experience to your customers, and ultimately help you grow your business.

To determine if a third-party fulfilment company is the right partner for your business, be sure to ask them a comprehensive set of questions, including:

- How are you different from a traditional pack-and-pick 3PL?

- How does your technology work? Which ecommerce platform integrations do you support?

- Where are your fulfilment centres located?

- Do you offer two-day shipping?

- How can you help me offer a best-in-class customer experience?

For more questions to ask and criteria to look for in your 3PL partner, you can download our guide on How to Choose a 3PL for Your Ecommerce Business to help you find the right partner for your business.

Leave order fulfilment to the pros

Chances are, you didn’t start your business because you wanted to deal with logistics. Instead of struggling to manage order fulfilment alone, many brands partner with a 3PL like ShipBob to optimise order fulfilment with ease.

Here are just some of the benefits of outsourcing fulfilment to ShipBob.

Save time without sacrificing quality

By outsourcing logistics like inventory storage, picking, packing, and shipping to a professional, you free up time for you and your brand to focus on other strategic priorities. ShipBob takes fulfilment off of thousands of ecommerce brands’ plates, so that they can achieve higher-quality and more efficient fulfilment and focus their attention where it’s most impactful.

Create an order and inventory north star

Visibility into your inventory and orders is crucial to successful order fulfilment. When you outsource fulfilment to ShipBob, you’ll gain access to ShipBob’s dashboard: a one-stop shop for your inventory and order data.

With real-time insight into inventory levels and key performance indicators like inventory turnover, SKU velocity, on-hand inventory, and more, your brand will know exactly how inventory is moving and when to replenish popular products. This same platform also gives you visibility into order data, as well as the ability to edit orders and track an order throughout the fulfilment and delivery process.

ShipBob also tracks inventory and order data over time, so you can improve demand forecasts and plan for your business’s future.

Distribute inventory strategically with ShipBob’s fulfilment network

Customers want to get their orders quickly – but for brands with customers all over the US, long-distance shipping is both time-consuming and expensive.

By distributing and storing inventory across ShipBob’s 50 fulfilment centres, brands can physically place their inventory closer to customers. This minimises shipping distances, reduces shipping costs, and helps orders arrive on doorsteps faster.

ShipBob’s Ideal Inventory Distribution tool can even help you determine the most strategic locations to leverage and how many units to allocate using historical order destination data.

Grow your brand with ease

When you’re ready to scale your brand to the next level, ShipBob is ready to scale with you.

Whether you’re looking to forge retail partnerships, enter new sales channels, or expand into new countries, ShipBob’s DTC and B2B fulfilment solutions (as well as our proprietary in-house warehouse management system, or WMS) can help you grow seamlessly.

Partnering with ShipBob enables your brand to grow with ease, and manage your new partners, integrations, and sales streams through a single, omnichannel platform.

Get in touch to see if we’re a good fit for your business’s unique needs. Request a pricing quote below.

Order fulfilment FAQs

The order fulfilment process doesn’t need to be difficult, but knowing some common questions can help out when choosing a fulfilment partner.

What does it mean when an order is in fulfilment?

If your order is “in fulfilment” that most likely means that it’s been processed and is currently being prepared for shipment. Once fulfilment is completed, an order has been delivered to the customer and the process is complete.

What is order fulfilment rate?

The order fulfilment rate (or order fill rate) is the number of orders that are processed divided by the total number of orders.

What is logistics fulfilment?

Logistics fulfilment is often interchanged with order fulfilment or parcel fulfilment, meaning to complete the logistical process from checkout to delivery of the item.

What is the order fulfilment process?

The order fulfilment process is the steps a business takes from the moment they have received an order until it is delivered to the customer.