Table of Contents

** Minutes

What is value-added warehousing and distribution?

Why value-added warehousing matters for ecommerce (benefits)

4 strategic value-added warehouse services for ecommerce brands

Technology as the backbone of value-added warehousing

Global expansion through value-added distribution

How to select the right value-added warehousing partner

How ShipBob delivers value-added warehousing and distribution

FAQs about value-added warehousing and distribution services

Value-added warehousing and distribution (VAWD) has evolved from optional to essential. With rising customer expectations, brands must use services beyond basic storage and shipping to stay competitive in ecommerce.

Incorporating services like custom packaging, kitting, strategic inventory placement, and efficient returns management transforms traditional fulfillment into a competitive advantage by enhancing products, streamlining operations, and elevating the customer experience.

This guide reveals how ecommerce brands can maximize VAWD: which services offer the best ROI, how to build customer loyalty through enhanced fulfillment, and how to select the right partner for your needs. Whether you’re growing a startup or refreshing an established brand, you’ll find actionable strategies to turn your warehousing operations into a powerful market differentiator.

What is value-added warehousing and distribution?

Value-added warehousing and distribution (VAWD) elevates traditional warehousing beyond basic storage and shipping to create strategic business advantages. These specialized services add tangible value throughout your supply chain.

Services such as kitting, custom packaging, quality control, and returns processing help ecommerce brands enhance products, streamline operations, and deliver superior customer experiences.

Common value-added services explained

Here are the key VAWD services that can transform your fulfillment operations:

- Kitting and assembly: Combining multiple items into ready-to-ship packages. For example, a skincare brand might offer gift sets with cleanser, toner, and moisturizer that need to be assembled before shipping.

- Custom packaging and labeling: Branded boxes, tissue paper, and inserts that create memorable unboxing experiences. This includes specialized labeling for product information or international requirements.

- Quality control: Rigorous inspection and testing to ensure products meet specifications, are free from defects, and comply with safety regulations.

- Returns processing: End-to-end management of returns, from receiving and inspecting items to processing refunds or replacements, improving customer satisfaction while reducing costs.

How value-added services transform the distribution process

VAWD benefits extend throughout your entire supply chain. Strategic inventory placement across multiple fulfillment centers positions your products closer to customers, dramatically reducing shipping times and costs.

Modern warehouse and order management systems (WMS/OMS) tie everything together, providing real-time inventory visibility, automated order routing, and precise multi-location fulfillment.

This technology-powered approach creates seamless connections between your enhanced services and optimized distribution, enabling your business to adapt quickly to market changes, scale efficiently, and consistently deliver exceptional customer experiences.

Why value-added warehousing matters for ecommerce (benefits)

Value-added warehousing is essential for brands seeking a competitive edge. By going beyond storage and shipping, VAWD helps businesses create memorable customer experiences, streamline operations, and boost revenue.

Modern consumers expect fast delivery and exceptional service at every touchpoint. With VAWD strategies like strategic inventory placement and custom packaging, ecommerce businesses can meet these demands and build lasting customer loyalty.

Building brand identity through enhanced packaging

Ecommerce packaging isn’t just protection; it’s a powerful branding opportunity. Custom packaging and branded inserts transform unboxing into a memorable experience that reinforces your brand identity and encourages social sharing.

For example, a premium skincare brand might use eco-friendly packaging with personalized thank-you notes to convey luxury and attention to detail, creating a lasting impression that sets them apart from competitors.

Driving revenue growth with strategic inventory placement

Strategic inventory placement across multiple fulfillment centers reduces shipping distances and costs while improving delivery speed. This approach is particularly valuable when expanding into new markets or offering expedited shipping.

By storing products closer to customers, you can minimize transit times and meet the growing demand for fast, affordable delivery. Data-driven insights from your VAWD partner help you make smarter inventory decisions, avoid stockouts, reduce carrying costs, and boost your bottom line.

Enhancing customer loyalty through seamless experiences

Value-added warehousing enables seamless customer experiences that drive loyalty and repeat purchases. From personalized packaging to hassle-free returns, these services create moments of delight throughout the customer journey.

A fashion retailer might use services like garment pressing and custom labeling to ensure products arrive ready to wear, demonstrating a commitment to quality. Efficient returns processing and quick refunds turn potential negative experiences into opportunities to build trust.

The benefits of value-added warehousing extend far beyond the warehouse itself. These services help ecommerce brands differentiate themselves, increase revenue, and build lasting customer relationships. As the industry evolves, brands that embrace VAWD will be best positioned to thrive.

4 strategic value-added warehouse services for ecommerce brands

Selecting the right value-added services is a critical component of a comprehensive ecommerce business strategy, so the key is to determine which offerings will deliver the most value for your unique business model. Let’s dive into four strategic value-added warehouse services that can transform your ecommerce operations.

Kitting and assembly services

Kitting and assembly services involve combining individual components or products into a single, ready-to-ship unit. This is particularly valuable for ecommerce brands that offer subscription boxes, gift sets, or product bundles.

The process begins with receiving the individual components at the warehouse, which are then assembled according to specific instructions. The finished kits are packaged and shipped directly to the customer.

Implementing kitting services can streamline your operations, reduce labor costs, and improve the customer experience. By pre-assembling kits, you can reduce the time and resources required to fulfill each order. Additionally, offering curated product bundles can increase average order value and encourage customers to try new products. However, it’s essential to conduct a cost-benefit analysis to ensure that the added efficiency and revenue potential justify the costs of kitting services.

Custom packaging and presentation

Custom packaging and presentation services allow you to create a memorable unboxing experience that reinforces your brand identity. Options range from branded boxes and tissue paper to custom inserts and personalized notes. The right packaging can be tailored to different product categories and price points, ensuring that the presentation aligns with your brand image and customer expectations.

Investing in custom packaging can significantly impact customer perception and loyalty. A premium unboxing experience can encourage social sharing, increase brand awareness, and drive repeat purchases. In fact, studies have shown that customers are more likely to recommend a brand after a positive unboxing experience. When selecting custom packaging options, consider how they will influence customer perception and align with your overall brand strategy.

Returns management and reverse logistics

Effective returns management is essential for maintaining customer satisfaction and protecting your bottom line. Consider returns as an opportunity to enhance customer relationships and gather valuable feedback. A streamlined reverse logistics process begins with a clear and easy-to-initiate returns policy. When a return is requested, the warehouse team receives the item, inspects it for damage or defects, and determines whether it can be restocked or should be disposed of.

Data collected during the returns process can provide valuable insights into product quality, customer preferences, and potential areas for improvement. By analyzing return trends, you can identify issues with specific products or batches and take proactive steps to address them. Additionally, offering a smooth and efficient returns experience can turn a potentially negative situation into a positive one, increasing the likelihood of future purchases.

Quality control and product customization

Implementing rigorous quality control processes at the warehouse level ensures that your customers receive consistent, high-quality products every time. This is particularly important for ecommerce brands, as customers can’t physically inspect items before purchase. Quality control services can include inspections at various stages of the fulfillment process, from receiving inventory to final packaging.

Product customization services, such as engraving, monogramming, or including personalized notes, can add significant value to your offerings. These services allow you to offer unique, tailored products that command premium prices. By providing customization options, you can differentiate your brand from competitors and create a more engaging customer experience. When considering customization services, evaluate the potential return on investment and ensure that the added value justifies the additional costs.

Technology as the backbone of value-added warehousing

Advanced technology is the driving force behind transforming traditional warehousing into strategic, value-added services. By integrating cutting-edge systems and automation, VAWD providers can coordinate complex processes, ensure scalability, and deliver unparalleled visibility and control. In fact, technology is the key differentiator between basic warehousing and advanced VAWD solutions.

Real-time inventory visibility and analytics

One of the most significant advantages of technology-driven VAWD is the ability to access real-time inventory data across multiple locations. Cloud-based WMS provide instant visibility into stock levels, order status, and fulfillment operations. This real-time data empowers businesses to make proactive decisions, prevent potential issues, and optimize their supply chain.

Moreover, advanced analytics tools can help identify opportunities for service improvements and cost savings. By analyzing historical data and trends, businesses can make data-driven decisions about inventory allocation, demand forecasting, and resource optimization. This level of insight is particularly valuable for ecommerce brands that need to maintain consistent customer experiences across multiple channels and locations.

Integration with ecommerce platforms

Seamless integration between VAWD systems and ecommerce platforms is essential to streamline operations and reduce manual processes. By connecting directly to major platforms such as Shopify, Amazon, and NetSuite, VAWD providers can automatically sync order, inventory, and shipping data. This eliminates the need for manual data entry and reduces the risk of errors or delays.

Integrated systems also enable intelligent order routing based on factors like inventory location, shipping speed, and cost. For example, if a customer places an order for a product that is available in multiple warehouses, the system can automatically route the order to the facility that offers the fastest and most cost-effective shipping option. This level of optimization ensures that customers receive their orders quickly and efficiently, while businesses can minimize shipping costs and maximize profitability.

Automation and scalability

Automation technologies are revolutionizing value-added warehousing by enhancing the speed, accuracy, and efficiency of various processes. From robotic picking systems to automated conveyor belts and sorting machines, these solutions can significantly reduce manual labor and improve overall productivity.

For example, an automated kitting line can assemble and package product bundles at a much faster rate than manual processes, while also ensuring consistent quality and accuracy. Similarly, automated guided vehicles (AGVs) can transport goods within the warehouse more efficiently than manual forklifts, reducing the risk of accidents and damage.

Importantly, automation technologies also enable VAWD providers to scale their operations seamlessly during periods of growth or seasonal peaks. By leveraging these solutions, businesses can accommodate increased order volumes without sacrificing service quality or accuracy. This scalability is crucial for ecommerce brands that experience rapid growth or seasonal fluctuations in demand.

Global expansion through value-added distribution

Value-added warehousing and distribution can be a powerful enabler for ecommerce brands looking to expand their reach into international markets. By partnering with a global VAWD provider, businesses can establish a presence in new regions without the need for significant infrastructure investments or local expertise.

International fulfillment strategies

One key strategy for serving international customers is leveraging a combination of domestic and international fulfillment centers. By storing inventory in strategic locations worldwide, businesses can reduce delivery times and shipping costs while also complying with local regulations and customer expectations.

However, determining the optimal allocation of inventory across global locations can be complex. Factors to consider include shipping costs, transit times, local demand patterns, and product-specific requirements, such as climate control or hazardous material handling. A skilled VAWD partner can help businesses navigate these complexities and develop a customized international fulfillment strategy that balances coverage, cost, and service levels.

Navigating cross-border logistics

Expanding into international markets also involves navigating the complexities of cross-border logistics, including customs regulations, duties and taxes, and shipping documentation. Failure to comply with these requirements can result in delays, additional costs, or even legal penalties.

Fortunately, experienced VAWD partners can simplify the process by providing guidance and support for cross-border shipments. This may include assistance with customs documentation, tariff classification, and compliance with local regulations. Some providers also offer localization services, such as language-specific packaging and labeling, to ensure products are well received in each market.

By leveraging the expertise of a global VAWD partner, ecommerce brands can reduce the risks and uncertainties associated with international expansion. This can help businesses enter new markets more quickly and confidently while also providing a consistent, high-quality experience for customers worldwide.

How to select the right value-added warehousing partner

Choosing the right VAWD partner is a critical decision that can significantly impact your business’s success. It’s essential to find a provider that not only has the capabilities and expertise to meet your current needs but also the scalability and flexibility to support your long-term growth objectives.

Key evaluation criteria

When evaluating potential VAWD partners, there are several key factors to consider.

First, assess the provider’s technology capabilities, including their WMS, integration options, and reporting tools. The right technology platform should provide real-time visibility, seamless connectivity, and robust analytics to support data-driven decision-making.

Next, consider the provider’s service offerings and whether they align with your specific business requirements. This may include specialized services like kitting, custom packaging, or quality control, as well as the ability to handle your product category and order volume. It’s also important to evaluate the provider’s geographic coverage and whether their fulfillment network aligns with your target markets and customer base.

Other factors to consider include pricing models, contract terms, and customer support. Look for a provider that offers transparent and competitive pricing, flexible contract options, and responsive customer service. Finally, assess the provider’s experience and track record in your industry or product category, as well as their overall reputation and financial stability.

Implementation and onboarding process

Once you’ve selected a VAWD partner, the next step is to plan for a smooth and successful implementation. This process typically involves integrating your systems and data with the provider’s platform, testing and validating the new workflows, and training your team on the new processes and tools.

The implementation timeline can vary depending on the complexity of your operations and the scope of the services being implemented. However, a typical onboarding process may take several weeks to a few months from initial planning to full go-live.

To minimize disruption and ensure a successful transition, it’s important to work closely with your VAWD partner and establish clear communication channels and project milestones. This may involve designating a dedicated project manager or implementation team to oversee the process and coordinate with internal stakeholders.

How ShipBob delivers value-added warehousing and distribution

Growing brands need fulfillment partners that go beyond basic pick, pack, and ship. ShipBob’s comprehensive VAWD solutions transform standard fulfillment into a competitive advantage while optimizing your supply chain.

Our global network across the US, Canada, Europe, and Australia positions your inventory strategically closer to customers, enabling faster, lower-cost shipping. Our proprietary technology provides real-time visibility across all locations, giving you complete operational control.

ShipBob’s value-added services, from custom kitting and bundling to branded packaging, create memorable unboxing experiences that drive customer loyalty and repeat purchases.

ShipBob’s Inventory Placement Program

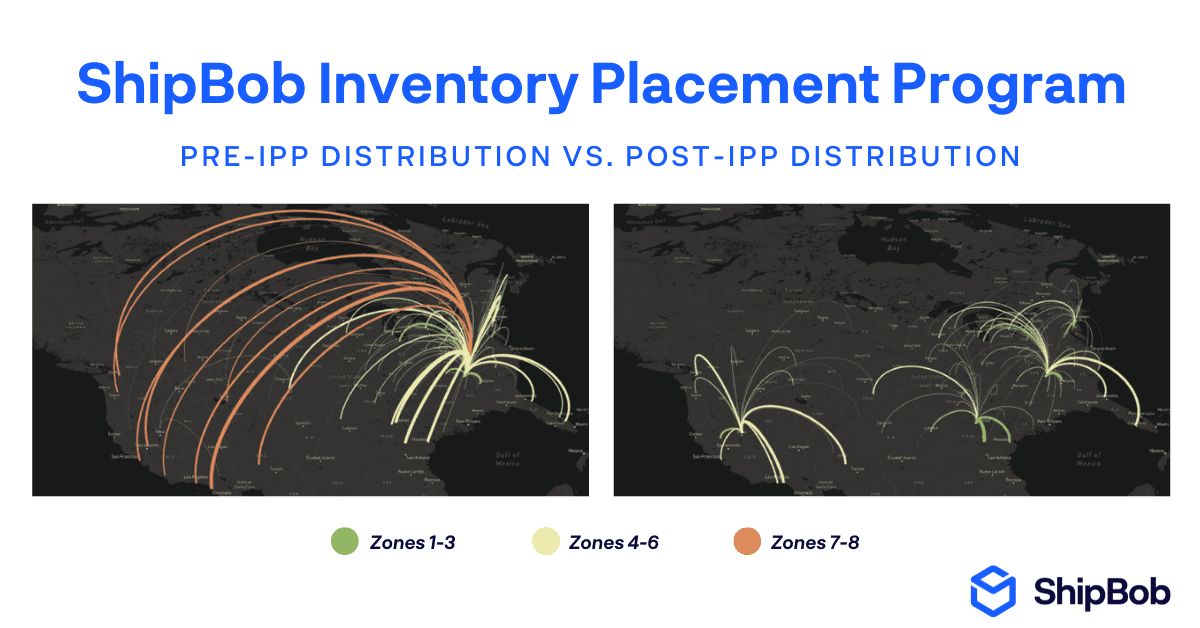

Our Inventory Placement Program (IPP) eliminates multi-warehouse complexity by strategically allocating inventory across our global network using advanced algorithms and historical order data. This data-driven approach significantly reduces shipping costs and transit times by minimizing the distance between products and customers.

With ShipBob’s IPP, achieve fast shipping in the US without the hassle of managing multiple warehouses yourself. Our technology automatically handles inventory balancing, reorder recommendations, and demand forecasting, maintaining optimal stock levels while minimizing holding costs.

“Leveraging IPP has been super helpful for us because it takes a lot of stress off of our very small operations team, especially in terms of planning how many units of our products need to go in each fulfillment center. We have inventory shipments going out almost daily, so managing that process would be a huge undertaking for our 3-person team. Plus, ShipBob’s reporting in the dashboard is really great. We’re able to easily log in and gain visibility into IPP, dig into our inventory movement, and reroute any units on the fly based on certain factors that are specific to our business. Thanks to ShipBob, order fulfillment largely takes care of itself.”

Jay Stephens, Director of Operations, and Ania Giuffra, Supply Chain Manager, at Ancestral Supplements

Technology-driven fulfillment solutions

At ShipBob’s core is our proprietary WMS built specifically for ecommerce fulfillment, optimizing direct-to-consumer operations for speed and accuracy. Our platform seamlessly integrates with all major ecommerce platforms and marketplaces, creating a unified system that automatically synchronizes orders, inventory, and shipping data.

ShipBob’s analytics dashboard delivers real-time insights into key metrics, enabling data-driven decisions about inventory and distribution strategy. Proactive alerts for low stock, potential delays, or unusual order patterns help you address issues before they impact customer satisfaction, even during peak periods.

Brands that fulfill orders from their own warehouses can implement ShipBob WMS in their facilities to access advanced technology and systems developed by ShipBob and used across all of our warehouses.

“ShipBob’s dashboard and systems are incredibly easy to use, and it puts fulfillment into layman’s terms. We have fulfillment information at our fingertips and anyone at the company can easily use the dashboard. Having access to advanced, real-time technology is really important for us, especially now as we continue to scale our brand. We wanted to work with a partner that was continually evolving and could place tech at the forefront. That’s exactly what we’ve gotten with ShipBob.”

Connor Stewart, Head of Operations + Impact at ARTAH

Custom solutions for growing brands

ShipBob can address your brand’s specific challenges and unique needs. For apparel brands, we provide specialized garment handling. Beauty companies benefit from temperature-controlled storage and lot tracking. Subscription businesses leverage our kitting services to create curated packages that delight customers.

As you grow, ShipBob’s flexible infrastructure scales with you, whether you’re expanding product lines, entering new markets, or managing seasonal demand spikes. From brands fulfilling thousands or hundreds of thousands of packages daily, we provide the infrastructure and expertise for every stage.

“We have a close relationship with our Merchant Success Manager and the ShipBob team within the fulfillment center. If we ever need something to go out to an influencer or brand owner, they’ll pack the orders themselves to make them extra pretty with our custom packaging and fancy paper. They give those orders the extra little touch that makes a huge impact. Plus, there are dedicated areas in the warehouse just for kitting, so that when the ShipBob team is assembling our kits, nothing is messed up and everything is perfect.”

Callum Jones, Director of Operations & Marketplace, and Rachel Hicks, Operations Manager at Hairburst

Get started with ShipBob

Ready to transform your fulfillment into a competitive advantage? Get in touch to discover how ShipBob’s value-added warehousing and distribution can help you reduce costs, improve delivery times, and create exceptional customer experiences.

FAQs about value-added warehousing and distribution services

Below are more answers to common queries and challenges surrounding value-added warehousing and distribution.

What exactly qualifies as a value-added service in warehousing?

Value-added services go beyond basic storage and shipping to enhance your products and customer experience. These include kitting, custom packaging, labeling, quality control, and returns processing.

To determine if a service adds value, assess its impact on product perception, operational efficiency, and customer satisfaction. Most brands prioritize services that directly enhance customer experience, like branded packaging and hassle-free returns.

How do value-added warehousing services impact my bottom line?

While value-added services require initial investment, they deliver both direct and indirect financial benefits. You’ll see cost savings through improved efficiency, reduced labor costs, and smarter inventory management.

These services also create new revenue streams through premium products, bundles, and subscription offerings. Calculate ROI by weighing implementation costs against operational savings and potential revenue growth.

Can value-added services help my brand compete with larger retailers?

Absolutely! Value-added services level the playing field for smaller brands by enabling you to offer unique products and personalized experiences that rival larger competitors.

Custom packaging, kitting, and strategic inventory placement help differentiate your brand and build customer loyalty. Many growing ecommerce brands have used these services to carve out profitable niches in competitive markets.

How does distributed inventory placement reduce shipping costs?

Distributed inventory cuts shipping costs by storing products closer to customers. Since shipping costs increase with distance (shipping zones), strategic placement minimizes these expenses.

By using multiple fulfillment centers, you’ll reduce average shipping zones and lower costs. For example, instead of expensive cross-country shipping from a single West Coast warehouse to East Coast customers, using facilities in both regions significantly reduces costs while maintaining fast delivery.

What technology integrations are essential for effective value-added warehousing?

How does distributed inventory placement reduce shipping costs?

How does ShipBob’s approach to value-added warehousing differ from other providers?

ShipBob stands out with our technology-first approach and proprietary warehouse management system built specifically for ecommerce. Our purpose-built software delivers seamless integrations, real-time visibility, and advanced automation.

Our global fulfillment network spans the US, Canada, Europe, and Australia, helping brands of all sizes expand while reducing costs. With expertise across diverse product categories, we create tailored solutions that align with your specific business goals.

How quickly can I implement value-added warehousing services with ShipBob?

Most brands start shipping with ShipBob within 2-4 weeks of initial contact. Your timeline may vary based on product complexity, required services, and inventory volume.

Throughout onboarding, our dedicated implementation experts guide you from initial data sync to inventory migration and system testing. We work closely with your team to ensure a smooth transition and quick results from your value-added warehousing services.