Table of Contents

** Minutes

Being flexible in accommodating influencer merchandise

Finding the right WMS after trying 5 other subpar solutions

Seamlessly onboarding 200K+ SKUs

Using ShipBob’s WMS to accurately pick and pack 10K+ orders/month

Pulling insightful reports with ShipBob’s WMS

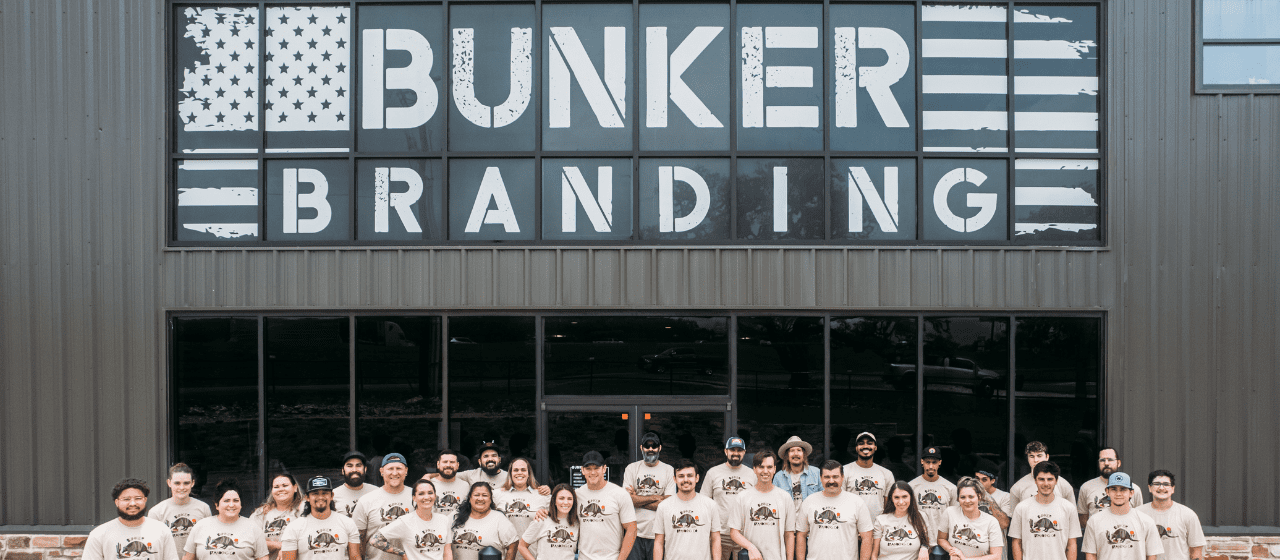

Learn how Bunker Branding creates merchandise for today’s most popular YouTube creators and influencers and uses ShipBob’s WMS to ship more than 10,000 orders per month.

Customer Profile

Matt Carriker is the creator of the YouTube channels Demolition Ranch (YouTube’s most popular firearms channel), Off The Ranch, and Vet Ranch. Matt has expanded his business repertoire to include Bunker Branding, an online merchandise company that creates shirts, stickers, cups, and more for social media influencers and creators like himself while handling the fulfilment process when orders are placed.

Key metrics

- 12,000 sq. ft. warehouse in Boerne, Texas

- 20 – 50 warehouse employees throughout the year

- 2 automatic screen printing presses, 5 direct-to-garment (DTG) machines & 1 embroidery and sticker machine

- 200,000 SKUs (95% of which are created in-house)

- 10,000 orders shipped per month

- 90+ clients served

About Bunker Branding

Matt Carriker has a laundry list of titles including veterinarian, firearms expert, content creator, entrepreneur, and small business owner. While not a common combination of traits, Matt has strategically used each of them to create an empire.

In 2011 while working as a full-time veterinarian, Matt began creating YouTube videos under the channel Vet Ranch. In the years since, Matt started two additional channels, Demolition Ranch and Off The Ranch, and today the three channels have amassed a combined total of over 18.4 million subscribers.

After years of struggling with creating merchandise through various vendors, Matt figured there had to be an easier way to get items out to fans who are eager to rep his channels. That’s when he decided to bring merchandise in-house.

Initially, Matt and his wife, Meredith, bought t-shirts from a local company and fulfiled orders out of their garage. When they experienced a boom in orders, they hired high school students to help ship out orders after school. As demand continued to climb, Matt decided to do the screen printing himself in order to cut out the middleman. By 2018, the Bunker team was operating out of a warehouse.

In the beginning, Matt intended for in-house screen printing to be a way he could efficiently and cost-effectively create quality merchandise for his channels. However, as Bunker grew, they acquired not only more equipment and warehouse space, but additional creators to make merchandise for. Now, the brand creates items for 90 YouTubers (and counting).

Bringing 13 years of experience in the screen printing industry, Clint Sanders joined Bunker Branding’s team to help the brand scale. As Bunker Branding grew, Clint knew they needed a better way of shipping out the items they created.

We spoke with Clint to discuss how Bunker Branding uses ShipBob’s warehouse management system (WMS) to fulfil orders for their merchandise and on-demand printing business.

Being flexible in accommodating influencer merchandise

As told by Clint Sanders, Vice President of Operations at Bunker Branding.

While we’ve grown a lot, Bunker Branding is still a small business. We pride ourselves on offering personal touches to the creators we work with. Because our owner is a content creator himself, we understand the struggles that our customers face.

It’s difficult to focus on getting merchandise out to fans while still creating content for YouTube. For our customers, content creation is their main revenue stream and that’s what they need to be focusing on. Offering merchandise is a great way to create additional income while allowing fans to feel engaged.

We’re able to help creators offer high-quality products to their passionate group of fans. And because YouTube is a tight knit group, word of mouth spread about us being able to take that off their hands. So when one of our creators is happy, they tell another creator, and so on and so forth.

Since our owner is a huge name in the YouTube industry, people trust that he will provide great products. Plus, people can even watch how Bunker got off the ground on his YouTube channel. There’s a lot of transparency. You can even watch how we fulfil orders in our warehouse.

At any moment, we know one of our creators can go viral. We need to have the capacity to stop on a dime and shift what we’re doing to make that our first priority. That’s important for the types of people that we work with. We aren’t going to ignore those unique nuances, as compared to a big company where you’re just an account number.

We try to keep our production schedule a few weeks out. However, something could go crazy overnight, and we come in the next day with 5,000 shirts to make that we weren’t anticipating. Flexibility and scalability are two crucial pillars for us.

Finding the right WMS after trying 5 other subpar solutions

When I came on board with Bunker, we were printing shirts for 5 clients, we had 10 employees and used one printing press. Now we have 6 different types of machines – including direct-to-garment (DTG) and embroidery – and we print stickers in-house. We moved into a custom 12,000 sq. ft. warehouse and after the first month, our warehouse was full because we were growing so quickly.

We’ve been on a journey for 5 years to find the perfect WMS. For what we’ve spent on trying various warehouse management software on the market, we should have just invested in writing our own code and creating our own system.

We do things a little differently than other businesses and require a system that suits our specific needs — 75% of what we sell is made-to-stock, meaning we make it and then it’s stocked on our shelves ready to be ordered, and the other 25% of what we do is create one-off items as they’re ordered. We needed to find a WMS that catered to both of those needs.

I think we went through 5 warehouse management systems before we found ShipBob. When one system didn’t work out, we always went back to doing fulfilment the old school way: printing orders out on paper and picking them from that list. It was super archaic, very slow, and it got messy. It made our warehouse manager’s and fulfilment manager’s jobs so much harder. They were combing through old orders to see where things got missed. It was a huge pain for us.

When we were using our own fulfilment strategy, we got into a routine and could get orders out pretty quickly, but when we tried a new WMS our efficiency dropped significantly. We’d gotten jaded that a WMS would just bog us down. By the time we were about to adopt ShipBob’s WMS, we were stuck in our ways and we weren’t sure how switching warehouse management systems again would go. But it turns out ShipBob’s system is set up perfectly for what we need.

Seamlessly onboarding 200K+ SKUs

We decided post-peak was the perfect time to check out making a switch to ShipBob’s WMS and even got to tour one of their fulfilment centres that uses their WMS.

When we were getting started with ShipBob, they had someone come into our warehouse and help us get set up with the new WMS. 200,000 SKUs is a lot, and they helped us set up all of them in the system and in the warehouse, including getting the individual shelf locations stickered. It was surprisingly easy and straightforward.

“A big part of the appeal of ShipBob’s WMS is the cost. The fact that it’s so cost-effective made it such an easy decision. I’ve recommended ShipBob to 10 people already this year.”

Clint Sanders, Vice President of Operations at Bunker Branding

There’s always people willing to help and improve the product at ShipBob. We’ve even bounced ideas off the team who created the WMS and ShipBob’s CEO. We’ve gotten a lot of support to help us get what we need from the WMS.

Using ShipBob’s WMS to accurately pick and pack 10K+ orders/month

We’ve always had a pretty low fulfilment error rate. But keeping that number low has become harder the larger we get. When we were small, everyone knew what products were called and where they were in the warehouse. But now we have over 200,000 SKUs on our website, 190,000 of which are stowed in our warehouse. It became difficult to make sure everyone was doing fulfilment in the right way.

“ShipBob’s WMS makes it almost impossible to do things wrong. Eliminating the potential for human error during picking and packing has been great. That was our biggest problem before. Last time I checked, our error rate was less than 1%. We’re shipping out over 10,000 orders per month.“

Clint Sanders, Vice President of Operations at Bunker Branding

Being an online retailer, we always see a big spike in Q4, so I’m looking forward to having this system in place for Black Friday and Cyber Monday.

Pulling insightful reports with ShipBob’s WMS

ShipBob’s WMS is intuitive and easy to use with great reporting. Being able to track real-time metrics at the person-by-person level is awesome. We told our team that we wouldn’t be tracking their fulfilment metrics everyday, but having the functionality to see how people are doing is helpful for forecasting and also to reference if we have to say, “Last month you were here and everyone else was here, where is there a disconnect?”

We have been able to set some standard practices of what’s fulfilable and what can be done in a day. In our old system, we knew we had a certain amount of orders to get to in a day, but we didn’t know which ones to prioritise. Our managers had to manually go in and see which orders took priority. Using ShipBob’s WMS has cleared up a lot of time for our managers because now they don’t have to dictate which orders need to be fulfiled first, the system does that for us.

The future of Bunker Branding

What next for us? In a word: growth. A good portion of what I do is trying to find new clients and reaching out to creators that we can work with. In the next few weeks alone, we have 5 or 6 new creators launching on the site. We’re gonna keep pushing!

We just turned on DDP shipping as well to improve the cross-border shipping process. We have creators in Canada, Finland, and I recently talked to someone in Australia. We already ship to any country that accepts US mail, but DDP will help us reach more people and provide a better customer experience.

We look forward to scaling our growth more and having a partner like ShipBob to help.

Bunker Branding’s team at ShipBob

Bob LeGere

Bob is the Enterprise Account Executive that brought Bunker Branding onboard with ShipBob.

Christopher O’Hara

Christopher is a Merchant Success Manager at ShipBob. He supports the Bunker Branding team.

Jivko Bojinov

As ShipBob co-founder and SVP of Strategy, Jivko serves as Bunker Branding’s Executive Sponsor.

Get started with ShipBob

Interested in using ShipBob’s warehouse management system in your facility? Connect with our team to learn more about our WMS and how it can help your brand scale.