Table of Contents

** Minutes

The core EDI documents in logistics

5 key benefits of EDI for ecommerce shipping

6 steps to implement EDI in your ecommerce business

1. Assess your business needs & requirements

Best practices for error management & compliance

In today’s fast-paced ecommerce landscape, efficiency is a competitive necessity. That’s why Electronic Data Interchange (EDI) has become a cornerstone of modern logistics. By automating the exchange of critical business documents like purchase orders, invoices, and shipping notices, EDI enables brands to speed up operations, reduce manual errors, and strengthen relationships with retail partners.

But while EDI can dramatically streamline your supply chain, getting started isn’t always simple. From decoding document types and data standards to integrating with your existing tech stack and meeting retailer compliance requirements, the learning curve can feel steep – especially for growing brands.

This guide is here to make it easier. Whether you’re exploring EDI for the first time or optimizing a current setup, this blog walks you through how EDI can drive efficiency, reduce costs, and help you scale with confidence.

What is EDI in logistics?

Electronic Data Interchange (EDI) is a standardized digital method of exchanging business documents between organizations, replacing manual, paper-based processes with automated electronic transfers.

EDI enables companies to communicate and share critical information seamlessly, reducing errors, saving time, and streamlining operations. It eliminates the need for manual data entry and ensures that all parties have access to accurate, up-to-date information, which makes it especially crucial for businesses that work with large retailers or have complex supply chains.

The most common EDI document types in logistics include:

- Purchase Orders (850): Electronic versions of traditional purchase orders, detailing the items, quantities, and prices of goods to be purchased.

- Invoices (810): Digital invoices that facilitate faster payment processing and reconciliation.

- Advance Shipping Notices (856): Electronic documents that provide detailed information about pending deliveries, allowing recipients to prepare for receipt and manage inventory accordingly.

- Inventory Updates (846): Automated notifications of changes in inventory levels, helping businesses maintain accurate stock counts and prevent overselling.

As ecommerce continues to grow and evolve, understanding and implementing EDI solutions has become increasingly important for businesses looking to optimize their shipping logistics processes, reduce costs, and meet the demands of their trading partners.

What does EDI mean in logistics operations?

In the context of modern logistics operations, EDI represents a standardized “language” for business communications, using transaction sets and codes (such as X12 or EDIFACT standards) to ensure that all parties can interpret and process the information being exchanged.

By automating communication between trading partners across the entire supply chain, EDI reduces errors, improves efficiency, and provides real-time visibility into the status of shipments, inventory levels, and orders. This enhanced transparency and traceability is essential for businesses looking to optimize their logistics processes and make informed decisions based on accurate, up-to-date data.

Moreover, EDI has become a requirement for doing business with many major retailers and distributors. These large companies often mandate that their suppliers and logistics partners use EDI to ensure seamless integration, reduce processing times, and maintain strict compliance with their specific requirements. As such, implementing EDI capabilities has become a critical factor in securing and maintaining relationships with key trading partners in the ecommerce landscape.

The core EDI documents in logistics

Electronic Data Interchange (EDI) relies on standardized transaction sets to ensure that all parties involved in the supply chain can effectively communicate and exchange critical business documents. These transaction sets provide a consistent format for the data, using specific codes and structures that adhere to established EDI standards like X12 or EDIFACT.

In the world of ecommerce logistics, there are several core EDI documents that facilitate the smooth flow of goods from suppliers to retailers and ultimately to the end customer. Here’s a closer look at the most common EDI transaction sets used in logistics operations.

Purchase orders (EDI 850)

The EDI 850 document, also known as a purchase order (PO), is the electronic equivalent of a traditional paper-based PO. When a buyer, such as a retailer, wants to place an order with a supplier, they will send an EDI 850 to initiate the purchasing process.

This document contains all the essential information needed to fulfill the order, including:

- Product SKUs and descriptions

- Quantities requested

- Pricing and discounts

- Delivery dates and locations

- Payment terms and conditions

EDI 850s let businesses eliminate the need for manual data entry, reducing the risk of errors and ensuring that orders are processed quickly and accurately. This streamlined approach helps to improve the overall efficiency of the supply chain, enabling faster order fulfillment and better customer service.

Advanced shipping notices (EDI 856)

Once an order has been processed and the products are ready to ship, the supplier will send an EDI 856 document, also known as an advanced shipping notice (ASN), to the buyer.

This document provides detailed information about the impending delivery, allowing the receiving warehouse to prepare for the arrival of the shipment.

A typical ASN will include:

- Shipment tracking numbers

- Carrier information and expected delivery dates

- Detailed contents of each carton or pallet

- Product SKUs, quantities, and lot numbers

- Special handling instructions or requirements

By providing visibility into upcoming deliveries, ASNs help warehouses optimize their receiving processes, reducing the time and effort required to check in and put away incoming goods. This improved efficiency can lead to faster inventory turnover, reduced carrying costs, and better overall supply chain performance.

Invoices (EDI 810)

After a shipment has been delivered, the supplier will send an EDI 810 document, or electronic invoice, to the buyer for payment.

This document serves as a request for payment and includes all the necessary details to ensure accurate and timely processing, such as:

- Invoice number and date

- Purchase order number for reference

- Product SKUs, quantities, and prices

- Applicable taxes, discounts, and fees

- Payment terms and due dates

- Remittance information

By automating the invoicing process with EDI 810s, businesses can streamline their accounts payable workflows, reducing the time and effort required to manually match invoices with corresponding purchase orders and shipping documents. This electronic reconciliation process helps to identify and resolve any discrepancies quickly, ensuring that payments are made accurately and on time. As a result, suppliers can improve their cash flow and maintain healthy relationships with their trading partners.

Inventory advice (EDI 846)

In today’s fast-paced, omnichannel retail environment, maintaining accurate inventory levels across multiple systems and locations is critical for success. EDI 846 documents, also known as inventory advice or inventory inquiry/response, enable trading partners to exchange real-time information about product availability and stock levels.

These documents typically include:

- Product SKUs and descriptions

- Current on-hand quantities

- Available-to-promise (ATP) quantities

- Reorder points and safety stock levels

- Expected replenishment dates

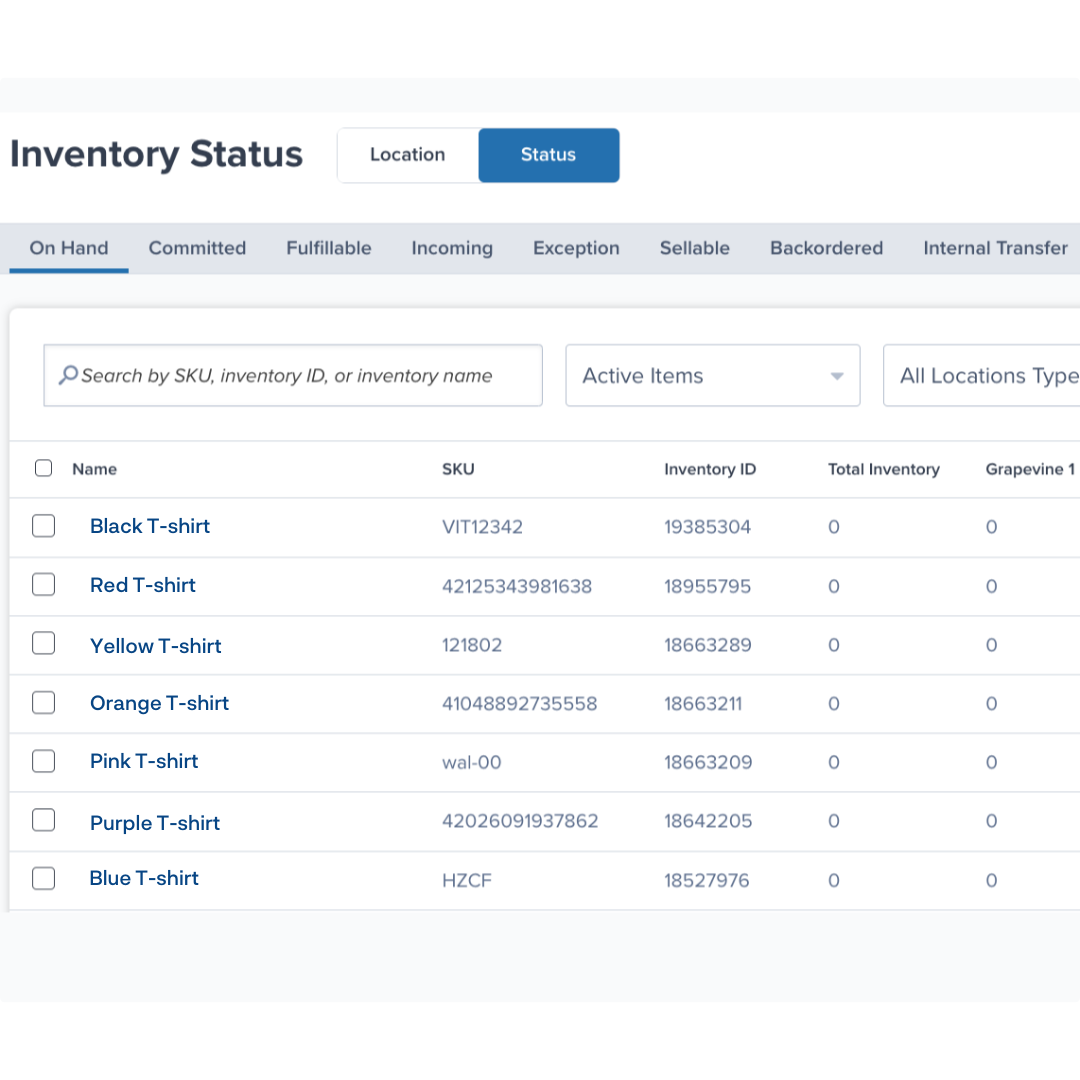

Regularly sharing inventory data via EDI 846s means that all parties have a consistent, up-to-date view of stock levels. This visibility helps to prevent overselling and stockouts, while also enabling more accurate demand forecasting and replenishment planning. With better inventory management, companies can reduce their carrying costs, improve their order fill rates, and ultimately provide a better experience for their customers.

5 key benefits of EDI for ecommerce shipping

EDI offers numerous advantages that can transform logistics operations for growing ecommerce brands. Here are some of the most notable benefits of using EDI to automate your ecommerce shipping.

1. Automation & cost savings

One of the most compelling benefits of EDI is its ability to automate manual processes, eliminating the need for time-consuming data entry.

Imagine automated workflows where purchase orders are automatically received, inventory levels are checked, and shipping notices are generated without human intervention. This level of automation not only saves time, but also significantly reduces paper and processing costs.

As a result, the entire order-to-cash cycle is accelerated, enabling businesses to operate more efficiently and cost-effectively.

2. Improved inventory visibility

EDI enables real-time inventory updates, ensuring that stock levels are accurately reflected across all connected systems. This enhanced visibility helps prevent overselling and stockouts, as businesses have a clearer picture of their available inventory at any given moment.

With access to up-to-date information, companies can also:

- Make more accurate demand forecasts to optimize their inventory planning.

- Reduce the need for safety stock and minimize the risk of overstocking.

- Better utilize their capital and reduce carrying costs.

3. Faster shipping & order turnaround

The speed and efficiency of EDI can have a profound impact on shipping times and order processing. By eliminating the need for manual data entry and document exchange, EDI can reduce order processing times from days to mere minutes.

This accelerated pace allows for quicker picking, packing, and shipping of orders, ultimately leading to faster delivery times for customers. Leveraging EDI to streamline logistics processes helps brands enhance customer satisfaction and build a reputation for reliable, speedy fulfillment.

4. Reduced errors & disputes

EDI’s standardized formats and automated processes significantly reduce the likelihood of errors compared to manual data entry. By adhering to predefined standards, EDI eliminates the potential for misinterpretation and ensures that all trading partners are speaking the same language.

Additionally, built-in validation rules catch any discrepancies or missing information before documents are transmitted, preventing errors from impacting customers downstream. Fewer errors translates to fewer chargebacks and disputes with retail partners, saving businesses time and money while maintaining strong relationships.

5. Streamlined compliance & retailer requirements

For ecommerce brands working with major retailers, meeting strict compliance requirements is essential. EDI helps streamline this process by ensuring that all necessary documents and data points are exchanged according to the retailer’s specifications.

Non-compliance can result in costly fines, chargebacks, and even the loss of valuable partnerships – but by implementing EDI, businesses can meet retailer-specific requirements, (such as those set by Walmart or Target) with ease. Partnering with an EDI-enabled 3PL like ShipBob can further simplify compliance management, as they have the expertise and systems in place to ensure seamless integration with retail partners.

EDI vs. API in logistics

While EDI and API both facilitate data exchange between systems, they have fundamental differences in their approach and use cases within the supply chain.

| EDI | API | |

| What it is | A standardized method of exchanging business documents between trading partners. | Code that you can integrate and customize in your current tech stack so that shipping capabilities can be communicated and accessed across multiple applications. |

| Best for | High-volume, recurring transactions that require strict adherence to established standards | Real-time, ad-hoc data exchange Connecting internal applications or providing customer-facing functionality |

| Implementation | More upfront setup and coordination with trading partners | Quicker to implement May require ongoing management to ensure compatibility as systems evolve |

EDI is a standardized method of exchanging business documents between trading partners, using specific formats like X12 or EDIFACT. It’s well-suited for high-volume, recurring transactions that require strict adherence to established standards. EDI is often used for exchanging critical documents like purchase orders, invoices, and shipping notices with external partners.

APIs, on the other hand, are more flexible and typically used for real-time, ad-hoc data exchange. They allow systems to communicate directly, making them ideal for connecting internal applications or providing customer-facing functionality. APIs often have a more modern, web-based architecture and can be customized to fit specific needs.

In terms of implementation, EDI typically requires more upfront setup and coordination with trading partners to establish document formats and communication protocols. APIs can be quicker to implement but may require ongoing management to ensure compatibility as systems evolve.

Why modern logistics might use both

Many businesses today are adopting a hybrid integration strategy that leverages both EDI and APIs to meet their diverse supply chain needs. This approach allows them to maintain EDI compliance with trading partners while also taking advantage of the flexibility and real-time capabilities of APIs.

For example, a company might use EDI to exchange standard documents like purchase orders and invoices with suppliers and retailers, ensuring seamless communication and adherence to industry standards. At the same time, they could use APIs to connect their internal warehouse management system with their ecommerce platform, enabling real-time inventory updates and order tracking for customers.

This hybrid approach is particularly valuable for businesses pursuing an omnichannel strategy, as it allows them to efficiently manage data flows across multiple sales channels and fulfillment locations. It also supports global expansion by enabling integration with international trading partners and logistics providers.

Checking compatibility with ecommerce platforms

When implementing EDI, it’s crucial to ensure compatibility with your existing ecommerce platform. Popular platforms like Shopify, BigCommerce, and WooCommerce offer varying levels of EDI support.

Some platforms have built-in EDI functionality or offer direct integrations with major EDI providers. For example, Shopify has partnered with DiCentral to provide an EDI app that connects with major retailers like Walmart and Target.

In other cases, you may need to use middleware solutions or iPaaS (integration platform as a service) tools to bridge the gap between your ecommerce platform and EDI systems. These tools can help translate data between different formats and manage the flow of information between systems.

It’s also important to consider how EDI will integrate with your other key systems, such as your warehouse management system (WMS) or enterprise resource planning (ERP) software. Many EDI providers offer pre-built connectors for popular WMS and ERP systems, streamlining the integration process.

When evaluating your ecommerce platform and other systems for EDI readiness, consider factors like data structure, API capabilities, and existing integration partnerships. Working with an experienced integration partner or EDI-enabled 3PL can also simplify the process, as they often have pre-built connectors and expertise in navigating common compatibility challenges.

6 steps to implement EDI in your ecommerce business

Implementing EDI in your ecommerce business can seem daunting, but with proper planning and execution, it can be a smooth process that unlocks significant benefits.

Here’s a step-by-step guide to help you navigate the implementation journey.

1. Assess your business needs & requirements

Before diving into EDI implementation, it’s crucial to understand your specific business needs and requirements. Start by evaluating which EDI documents are essential based on your business model and trading partner relationships.

For example, if you’re working with major retailers, you’ll likely need to exchange purchase orders (850), invoices (810), and advance shipping notices (856). If you’re managing inventory across multiple locations, inventory updates (846) may also be critical.

Next, assess your technical readiness by reviewing your current systems and processes. Identify any gaps or areas that may require updates to support EDI integration. It’s also important to understand your trading partners’ specific EDI requirements, as they may have unique document formats or communication protocols.

Finally, consider your internal resources and capabilities. Do you have the technical expertise to manage EDI in-house, or will you need to partner with an EDI service provider or 3PL? Answering these questions upfront will help guide your implementation strategy.

2. Choose an EDI solution or partner

Once you’ve assessed your needs, it’s time to choose an EDI solution or partner. There are several options to consider:

- In-house EDI systems: This involves purchasing EDI software and managing the entire process internally. This option provides the most control but also requires significant technical resources and expertise.

- EDI service providers: These companies specialize in EDI and can handle the technical aspects of implementation and ongoing management. They typically offer a range of services, from basic document exchange to full-service integration and support.

- 3PL-provided solutions: Many third-party logistics providers (3PLs) like ShipBob offer EDI capabilities as part of their fulfillment services. This can be a good option for businesses that want to outsource both logistics and EDI management.

When evaluating potential partners, consider factors like scalability, customer support, trading partner network, and cost structure. Look for providers that can accommodate your current needs and future growth plans.

Pricing models can vary, with some providers charging setup fees, per-transaction costs, or monthly subscription fees. Be sure to understand the total cost of ownership, including any hidden fees or long-term contracts.

Finally, consider the level of implementation support and training provided. A good partner will offer comprehensive onboarding and ongoing support to ensure a smooth transition to EDI.

3. Configure EDI mappings & document formats

One of the most critical aspects of EDI implementation is configuring your data mappings and document formats. This involves translating your internal data fields and structures to align with EDI standards and your trading partners’ specifications.

For example, you may need to map your product SKUs to the appropriate UPC codes or ensure that your invoice numbers follow a specific format. This process can be complex, especially if you have a large number of SKUs or unique data requirements.

Working with an experienced EDI partner can help streamline the mapping process, as they’ll have pre-built templates and expertise in common document formats. However, it’s still important to thoroughly review and test your mappings to ensure accuracy.

Common mapping challenges include handling missing or optional fields, converting between different units of measure, and managing multiple trading partner specifications. Establishing clear communication channels with your trading partners can help resolve any discrepancies or questions that arise during the mapping process.

Before going live with EDI, be sure to thoroughly test your mappings with sample data and scenarios. This will help identify any errors or inconsistencies early on, preventing costly mistakes down the line.

4. Integrate with ecommerce platforms & WMS/ERP

To fully realize the benefits of EDI, you’ll need to integrate it with your other key business systems, such as your ecommerce platform, warehouse management system (WMS), and enterprise resource planning (ERP) software.

Integration methods can vary depending on your specific systems and requirements. Some common approaches include:

- Direct integration: This involves building a custom connection between your EDI system and other platforms using APIs or flat file exchange. This option provides the most control but also requires significant technical resources.

- Middleware: Middleware solutions act as a bridge between your various systems, translating data and managing the flow of information. They can be a good option for businesses with complex integration needs or legacy systems.

- iPaaS: Integration Platform as a Service (iPaaS) solutions provide pre-built connectors and workflows to streamline integration between cloud-based applications. They can be a good fit for businesses with primarily cloud-based systems.

Regardless of the approach you choose, it’s important to ensure bi-directional data flow between your systems. This means that data can move seamlessly from your ecommerce platform to your EDI system and vice versa, ensuring that all systems are in sync.

Integration testing is also crucial to validate that data is being passed correctly between systems. This involves running test transactions and scenarios to ensure that orders, inventory updates, and other key data points are being accurately transmitted and processed.

Common integration challenges include handling data format discrepancies, managing multiple systems and versions, and ensuring real-time data synchronization. Thorough documentation of your integration processes and data flows can help with ongoing maintenance and troubleshooting.

5. Validate & troubleshoot common errors

Before going live with EDI, it’s essential to thoroughly validate your system and processes to ensure a smooth launch. This involves working closely with your trading partners to test document exchange and troubleshoot any issues that arise.

Start by conducting test transmissions with your trading partners, beginning with a small subset of documents and gradually expanding to cover all necessary transaction types. This allows you to identify and resolve any errors or discrepancies in a controlled environment.

Common validation issues include missing or incorrect data fields, formatting errors, and timing problems (e.g., sending documents out of sequence). Establishing clear error handling and resolution procedures with your trading partners can help streamline the troubleshooting process.

It’s also important to have robust error monitoring and notification systems in place to quickly identify and address any issues that arise. This can include automated alerts for failed transmissions, data discrepancies, or other anomalies.

Before launching, conduct a thorough pre-launch validation checklist to ensure all systems are ready to go live. This should include verifying connectivity with trading partners, testing all document types, and ensuring that internal teams are trained and prepared to manage EDI processes.

6. Monitor & refine EDI workflows

Once you’re live with EDI, it’s important to continuously monitor and refine your processes to ensure optimal performance. This involves tracking key metrics like transmission success rates, processing times, and error frequencies.

Regularly review your EDI workflows to identify any bottlenecks or inefficiencies. This may involve analyzing data flows, reviewing error logs, or soliciting feedback from internal teams and trading partners. Use this information to prioritize process improvements and optimize your EDI operations.

Continuous improvement should also involve staying up-to-date with changes to EDI standards and trading partner requirements. Establish processes for regularly reviewing and implementing updates to ensure ongoing compliance.

Finally, conduct periodic audits of your EDI processes to ensure adherence to internal policies and external regulations. This can help identify any gaps or areas for improvement, as well as ensure that you’re meeting all necessary compliance requirements.

By continuously monitoring and refining your EDI workflows, you can ensure that your ecommerce business is maximizing the benefits of this powerful supply chain technology.

Best practices for error management & compliance

Effective error management and compliance are critical for maintaining smooth EDI operations and strong trading partner relationships. Proactively addressing these areas can help prevent costly chargebacks, delays, and other supply chain disruptions.

Preventing data discrepancies & rejections

One of the keys to successful EDI is ensuring that the data being exchanged is accurate, complete, and properly formatted. Implementing automated validation procedures can help catch errors before they’re transmitted to trading partners.

For example, you can set up business rules that check for missing required fields, validate data formats, and ensure that key values (like quantities and prices) fall within expected ranges. These rules can be applied at various points in the EDI process, from initial data entry to final document generation.

Reconciliation processes are also important for catching discrepancies between related documents. For instance, comparing purchase order quantities to those on the corresponding advance ship notice (ASN) can help identify any shipping errors or inconsistencies.

Establishing clear exception handling procedures is also critical for managing data issues that do arise. This should include processes for quickly identifying, communicating, and resolving errors with trading partners. Setting up automated alerts for potential issues (e.g., mismatched invoice amounts) can help speed up resolution times.

Staying updated on EDI standards

EDI standards are constantly evolving to keep pace with changing business needs and technological capabilities. Staying up-to-date with these changes is essential for maintaining compliance and interoperability with trading partners.

The two main EDI standards are X12 (used primarily in North America) and EDIFACT (used primarily in Europe and Asia). Each standard has its own version control system, with new releases typically published annually.

To stay informed about updates and changes, participate in industry associations and user groups focused on EDI standards. These organizations often provide resources, training, and forums for exchanging best practices and navigating standards changes.

It’s also important to have processes in place for managing trading partner-specific requirements. While EDI standards provide a common foundation, individual partners may have their own unique specifications or business rules. Regularly reviewing and updating your partner-specific mappings and processes can help ensure ongoing compliance.

When new versions of EDI standards are released, establish a clear plan for testing and implementing the updates. This should include coordinating with trading partners to ensure a smooth transition and minimizing any disruptions to your EDI operations.

How ShipBob helps you leverage EDI and simplify logistics

ShipBob is more than just a fulfillment provider; we’re a strategic partner that can help your ecommerce business unlock the full potential of EDI and streamline your supply chain operations.

Comprehensive EDI integration & management

Our platform integrates seamlessly with major EDI providers like SPS Commerce, enabling you to connect with trading partners and automate key documents like purchase orders, invoices, and advance ship notices.

With ShipBob, you don’t have to worry about the technical complexities of EDI setup and management. Our team of experts will handle the initial integration, mappings, and testing to ensure a smooth onboarding process. We’ll also monitor your EDI operations on an ongoing basis, proactively identifying and resolving any issues that arise.

“Getting EDI connections set up is always complicated, but ShipBob’s implementation team was amazing, and the way they treated us during the whole process was just fantastic. The team really worked hard to fix any issues, sort out any challenges, and make sure that we could get orders to retailers following all compliance guidelines.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Retail compliance expertise

Navigating the complex world of retailer requirements can be a daunting task for ecommerce brands. ShipBob has deep expertise in retail compliance, with a proven track record of helping customers meet the strict EDI and fulfillment standards of major retailers like Walmart, Target, and more.

Our team stays up-to-date on the latest retailer requirements and best practices, ensuring that your orders are always compliant and ready to ship. We’ll work with you to understand your specific retail partnerships and tailor our processes to meet their unique needs.

“The reality is that expanding into a huge retailer like Target is a very big undertaking, and brands shouldn’t try to tackle it alone. It’s really going to grow our business – possibly double it – and having an expert partner like ShipBob that’s been in the B2B game for a while and already knows how to manage compliance for retail distribution will save us so many growing pains. Given how easy it was to integrate our systems with ShipBob’s, we’re confident that we can go live in six months, as opposed to a year. We’re super excited for this new chapter in goPure’s growth, and to continue our partnership with ShipBob Plus.”

Oscar Gutierrez, Operations Fulfillment Manager at goPure

Automated order & inventory management

With ShipBob’s EDI capabilities, you can automate key order management and inventory tracking processes. Our platform can automatically import orders from your retail partners, validate the data, and route them for fulfillment – all without manual intervention.

We also support real-time inventory updates via EDI, ensuring that your stock levels are always accurate and up-to-date across all sales channels. This helps prevent overselling and stockouts, while also enabling more efficient inventory planning and forecasting.

Global fulfillment network

ShipBob’s international fulfillment network enables you to expand your retail and B2B partnerships on a global scale. With locations in the United States, Canada, Europe, and Australia, we can help you efficiently distribute your inventory and reach customers around the world.

Our EDI capabilities extend across our entire network, enabling you to seamlessly manage orders and inventory across multiple countries and regions. Whether you’re looking to expand into new markets or optimize your existing international operations, ShipBob can provide the infrastructure and expertise you need to succeed.

“The beautiful thing about ShipBob is everything was connected. I could log on to our ShipBob account and see everything in one place, no matter if I’m looking at our facility in Kankakee, IL, or the ShipBob fulfillment centers in Canada or Europe. It was all the same system. I didn’t have to learn various different platforms or deal with support representatives at different companies.

Plus, if we experience any issues with syncing orders between systems, there’s one place we go to reconcile it. ShipBob is connected to our ERP, NetSuite, which is our single source of truth. Now we only have one place to troubleshoot and resolve potential issues across all logistics. The hybrid fulfillment solution is a connected web. The interconnectedness is why we chose ShipBob.”

Adam LaGesse, Global Warehousing Director at Spikeball

For more information about how ShipBob can help you automate your B2B fulfillment with EDI, click the button below to get in touch.

FAQs about EDI in logistics

Here are answers to some of the most common questions about EDI logistics.

What does EDI stand for in logistics?

EDI stands for Electronic Data Interchange. In the context of logistics, it refers to the standardized electronic exchange of crucial business documents between companies, such as purchase orders, invoices, and shipping notices.

What role does EDI play across supply chain processes?

EDI facilitates the rapid, accurate exchange of information, streamlining and automating key processes such as ordering, inventory management, shipping, and payment. This enables all parties to work together more efficiently, reducing lead times, minimizing errors, and improving overall supply chain visibility.

What are the most common EDI transaction sets in logistics?

The most common EDI transaction sets in logistics include:

- 850 (Purchase Order): Used to electronically place an order for goods or services.

- 856 (Advance Ship Notice): Provides detailed information about a pending delivery, including contents and packaging.

- 810 (Invoice): Represents a request for payment for goods or services rendered.

Other important transaction sets include the 846 (Inventory Inquiry/Advice), 940 (Warehouse Shipping Order), and 945 (Warehouse Shipping Advice).

Typically, companies begin by implementing the 850, 856, and 810 documents, as these form the core of the order fulfillment process.

How do you implement EDI with Shopify or Amazon?

Integrating EDI with Shopify or Amazon typically involves working with a specialized EDI service provider or middleware solution. These providers offer pre-built connectors that can map your ecommerce platform’s data to EDI transaction sets and manage the exchange of documents with your trading partners.

The implementation process generally follows these steps:

- Assess your EDI requirements and select an appropriate provider.

- Configure your data mappings and connection settings.

- Test your EDI transactions with your trading partners.

- Go live and monitor your EDI performance.

Partnering with a 3PL like ShipBob can simplify this process even further, as we offer pre-built EDI integrations and handle the technical setup and ongoing management on your behalf.

Do I need EDI for smaller ecommerce operations?

The need for EDI often depends on the specific requirements of your trading partners and the volume of orders you process. Many larger retailers and distributors mandate EDI compliance regardless of a supplier’s size, as it helps them streamline their own operations.

However, for smaller ecommerce businesses that don’t work with such partners, the upfront investment in EDI may not always be justified. As a general rule of thumb, if you process more than 100 orders per month or work with major retailers, EDI can provide significant benefits in terms of automation, accuracy, and efficiency.

How does ShipBob specifically support EDI?

ShipBob offers comprehensive support for EDI, enabling ecommerce businesses to seamlessly integrate with their fulfillment operations. Key features include:

- Pre-built integrations with leading EDI providers such as SPS Commerce and Logicbroker

- Automated exchange of key documents such as 850 (Purchase Order), 856 (ASN), and 810 (Invoice)

- Expertise in managing retail compliance requirements and B2B fulfillment workflows

- End-to-end visibility and reporting on EDI performance and transaction status

By partnering with ShipBob, brands can offload the technical complexity of EDI and focus on growing their business, while ensuring fast, accurate, and compliant order processing.

What are the costs associated with implementing EDI?

The costs of implementing EDI can vary depending on factors such as the size and complexity of your operations, the number of trading partners you work with, and the specific EDI solution you choose. Typical cost components include:

- Setup and implementation fees

- Monthly or annual subscription costs

- Per-transaction or per-kilo-character fees

- Mapping and testing with trading partners

- Ongoing maintenance and support