Inventory issues – like running out of products or having too much stock – can cause major problems for ecommerce businesses. These inefficiencies can slow down order fulfilment and hurt the customer experience.

To prevent this, online retailers should use data-driven inventory management strategies, such as a Plan for Every Part (PFEP), to better manage demand and streamline logistics.

In this post, we’ll explain what a PFEP is, why it matters, and how it helps solve common inventory challenges. We’ll also walk you through how to create an effective PFEP and show how ShipBob can support you in the process.

What is a plan for every part (PFEP)?

A Plan for Every Part, or PFEP, is a central database that stores all the key details about every item in your ecommerce supply chain, from raw materials and components to finished products.

Usually kept in a digital spreadsheet, it includes information such as:

- Product specifications

- Sourcing methods

- Storage locations

- Handling instructions

Originally developed in lean logistics and manufacturing, PFEP has been adapted for modern supply chains to make inventory management more efficient. By keeping all product data in one place, ecommerce businesses can make smarter, data-driven decisions to cut waste, improve inventory organisation, speed up fulfilment, and maintain the right stock levels across all locations.

Why is a plan for every part important for businesses?

PFEP offers ecommerce businesses several advantages, including:

- Better collaboration and visibility: Because a PFEP brings all inventory data into one place, teams across different departments can easily find the information they need without a lot of back-and-forth communication. This improves visibility across the organisation and helps everyone manage their responsibilities more efficiently.

- Fewer mistakes: With greater inventory visibility comes fewer mistakes and inefficiencies. A PFEP helps businesses stay prepared for supply chain challenges, making it easier to plan for inventory and logistics needs even during disruptions or delays.

- Smarter inventory management: Ecommerce companies can use the database to clearly understand their inventory requirements, allowing them to plan purchases and restock on time. This helps prevent stockouts and the high costs that come with them.

- Improved forecasting and cost-efficiency: PFEP helps avoid overstocking, excess inventory, and high carrying costs by aligning replenishment with actual demand.

In short, a PFEP helps ecommerce businesses adopt lean supply chain strategies and enhance supply chain planning.

Common inventory challenges a PFEP solves

Plan for Every Part (PFEP) plays a key role in solving many common ecommerce inventory challenges. Below are some of the biggest issues it helps address.

Overstocking and stockouts

Many ecommerce businesses struggle to keep the right amount of inventory, either ordering too much or too little. Excess stock ties up valuable warehouse space and drives up carrying costs, which can hurt profitability. On the other hand, not having enough inventory often leads to stockouts, backorders, and unhappy customers.

A PFEP solves this problem by centralising all your inventory data in one place. This gives you a clear and accurate view of how much stock you need, when you need it, and where it should be stored. With these insights, you can plan replenishment more effectively, maintain the right stock levels, and ensure products are available across all fulfilment locations.

“ShipBob finally gave us the inventory visibility and analytics we were looking for. Through ShipBob’d dashboard, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.“

Mithu Kuna, Founder and CEO of Baby Doppler

High fulfilment costs due to poor inventory distribution

When all inventory is shipped from a single warehouse, some orders must travel long distances. This drives up shipping costs and delays delivery.

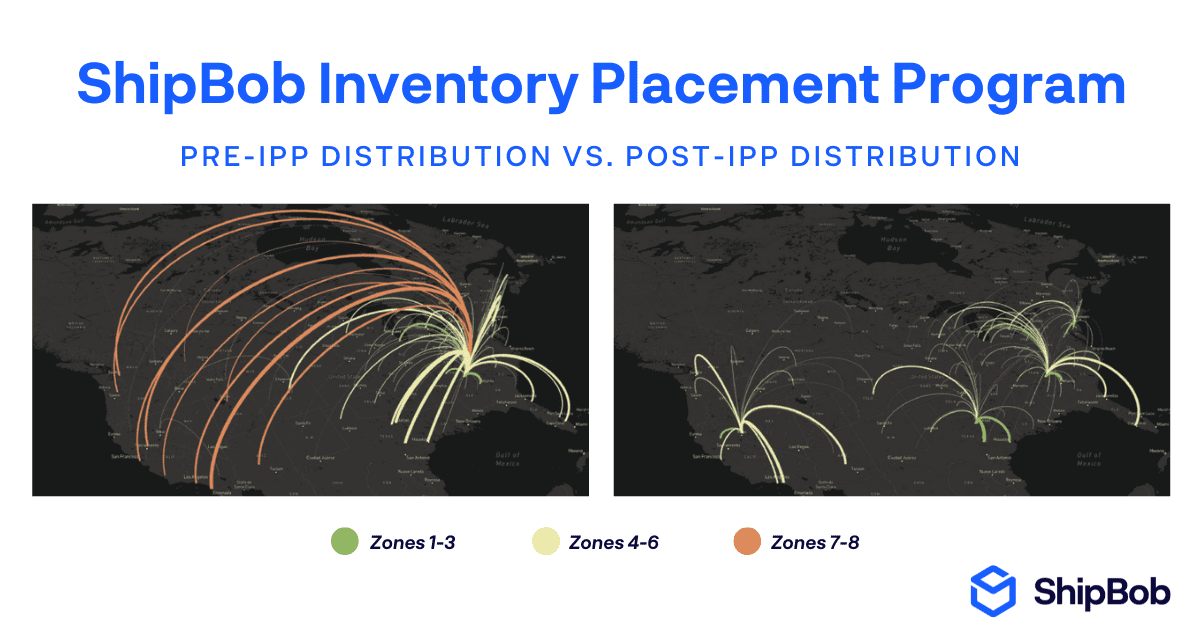

With a PFEP, businesses gain visibility into their entire inventory network, allowing them to distribute products strategically across multiple warehouses. This enables them to ship from the location closest to the customer, reducing shipping costs and ecommerce fulfilment costs, and speeding up last-mile delivery.

“By letting ShipBob handle physically distributing our inventory for us across their hub-and-spoke fulfilment centre network, we’re actually saving money. We’ve seen that shipping to customers is $3 cheaper on average using IPP compared to similar 3PLs’ services, which is a huge upside.”

Oscar Gutierrez, Operations Fulfilment Manager at goPure

SKU complexity and inefficient stock management

Managing hundreds or thousands of SKUs across multiple sales channels can be challenging and prone to errors. Without clear visibility, inventory tracking can become disorganized, leading to inefficiencies across the business.

A data-driven PFEP provides detailed insights for every SKU across all locations. This improves stock accuracy, simplifies inventory management, and ensures each product is tracked and handled correctly throughout the supply chain.

How to create and execute an effective plan for every part (+ free template)

Having a clear plan for each part helps you standardize your inventory management process. This makes it easier for teams to work together while improving accuracy and efficiency. Follow these steps to create and implement your PFEP:

Gather and organise SKU data

Start by gathering all the essential information about every SKU in your inventory so you can build a comprehensive database. Make sure the information is as detailed as possible. Include the basics like part number, description, dimensions, weight, manufacturer, quantities, and storage location. Additionally, you’ll want to collect information on:

- Demand history

- Usage statistics

- Supplier information

- Supplier lead times

- Storage requirements

- Packaging needs

- Reorder points

- Shipment information (couriers, transit times, etc.)

Beyond these, you may also have other data points relevant to your specific business and inventory types. Make sure this data is neatly organised in a collaborative digital spreadsheet that allows real-time updates.

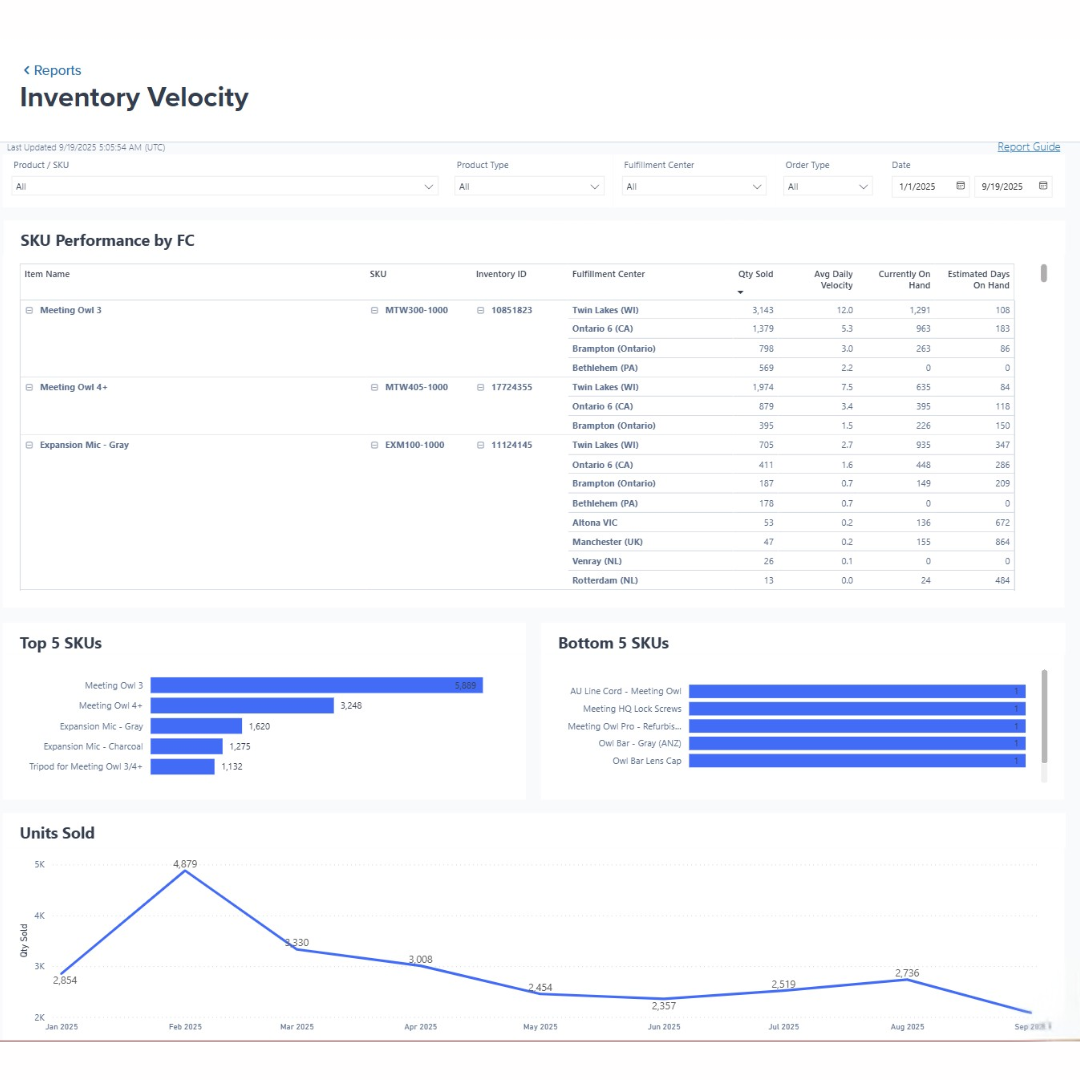

Analyse demand patterns and sales velocity

Now that you have your data in place, it’s time to take a closer look and analyse it for potential inventory optimizations. You can look at the historical sales data and use predictive analytics to understand demand patterns over time.

Identify which SKUs are moving fast and which ones are moving slow. Are there fluctuations based on season or time of year? Are there any events that influence these demand fluctuations? Can you identify any trends in the product lifecycle of specific SKUs?

The goal of this analysis is to help you navigate how demand and sales velocity change over time. This will help you identify any opportunities to optimise your inventory management efforts and adjust your inventory strategy accordingly. It might involve reducing stock levels, adjusting reorder points, and deciding on optimal inventory distribution.

You might even notice patterns in supplier performance that could affect your stock levels and replenishment timeline. These are all important factors that will influence your inventory management efforts.

Define inventory replenishment needs

Based on your analysis, you can now make informed decisions to optimise your inventory. This means figuring out the right amount of stock to keep for each SKU by considering your demand forecasts, supplier reliability, and lead times.

With this information, you can plan when and how much to reorder for each item. This helps you prevent both stockouts and excess inventory. You can also set appropriate safety stock levels to provide an extra buffer in case of unexpected changes in demand or supply delays.

Optimise inventory distribution across warehouses

Another vital step in executing an effective PFEP is optimising how you distribute your inventory across different locations.

Use the insights gained from your analysis to determine where specific SKUs are most in demand and where they’re slow to sell, then strategically store your inventory closer to customer demand hubs.

This is key to reducing transit times, which will result in faster deliveries. It also reduces shipping costs so you can increase your bottom line. You can also use the insights to implement zone-based shipping strategies and lower your overall fulfilment expenses.

Implement a continuous monitoring and adjustment system

Perfecting your PFEP strategy requires making timely adjustments to improve how you stock inventory. For this, you need real-time data insights instead of relying on static information. A continuous monitoring system is essential to provide you with real-time inventory tracking and performance insights.

In addition, make sure to regularly audit various aspects of your performance, including your warehouse efficiency and demand fluctuations, and then make data-driven decisions to optimise your stocking strategies.

How PFEP benefits serve ecommerce brands

Although PFEP is traditionally used in manufacturing, it also offers a number of benefits for ecommerce businesses. Let’s look at the top ways that PFEP works in an ecommerce setting.

🎯 Forecast demand accurately

A PFEP gives you easy access to detailed inventory information, allowing you to track past sales and spot demand patterns or seasonal trends.

With this insight, you can make more accurate forecasts and optimise your inventory levels. This helps you plan purchasing and restocking more effectively, reducing the risk of running out of stock or overstocking.

🔎 Track SKU data at a granular level

With a PFEP, you can track SKU-specific information to inform various aspects of your inventory management. You can effectively document SKU turnover rates, reorder points, and packaging needs. This will help you understand which items to restock, which ones to discontinue, when to order certain items, and how to handle each SKU.

🚛 Optimise inventory distribution across warehouses

A PFEP helps you effectively identify regions where certain SKUs are high in demand. These insights allow you to store inventory closer to key customer demand locations, so you can cut down on transit times and shipping costs.

⚖️ Implement real-time inventory adjustments

Finally, a PFEP gives your teams a comprehensive and real-time look into your inventory based on the latest order data and sales performance. This helps you continuously rebalance inventory levels to prevent inefficiencies and stockouts.

How ShipBob helps ecommerce brands execute PFEP efficiently

As a leading supply chain enablement partner, ShipBob offers ecommerce brands powerful technology that helps to effectively manage their inventory data in real time and automate PFEP execution.

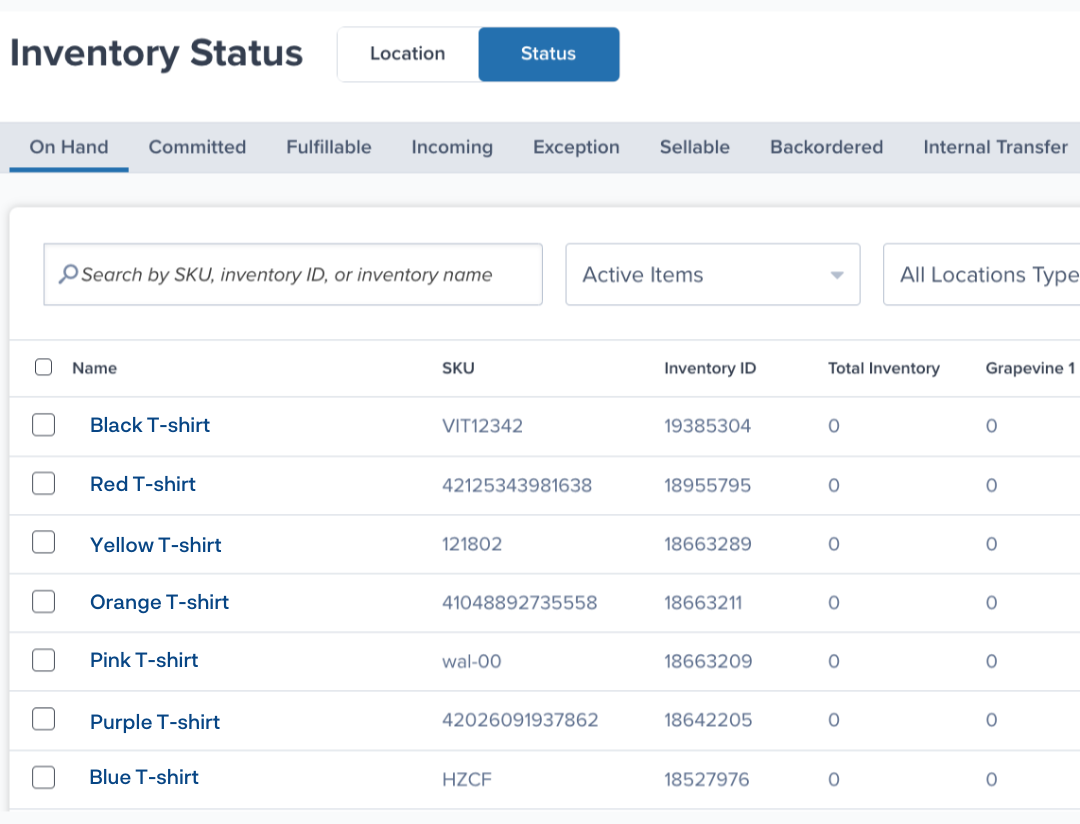

Real-time inventory visibility with ShipBob’s WMS

ShipBob’s proprietary warehouse management system (WMS) automates SKU tracking across multiple locations. It provides you with a centralised database to manage all your SKU data in one place, serving as a single source of truth for order and inventory data.

This automatically collects inventory data from multiple fulfilment centres and updates the information based on order activity across all your sales channels. This significantly reduces the risk of human error in inventory planning and data entry as stock information is updated in real time, which allows for better accuracy.

Multi-warehouse fulfilment for faster delivery

ShipBob boasts an expansive network of 60+ global fulfilment centres for ecommerce brands to leverage. By strategically distributing your inventory across multiple fulfilment centres in the network based on customer demand patterns highlighted in your PFEP, you can store inventory in high-demand locations to speed up fulfilment and minimise high-zone shipping costs.

“We’ve recognised the importance of having a network of warehouses spanning the United States, as it’s crucial for us to be geographically close to our customers. Setting up four warehouses has been remarkably straightforward from a technological standpoint.

ShipBob’s technology streamlines inventory management across our network, ensuring optimal inventory allocation. Once the inventory is allocated correctly, passing orders to ShipBob is seamless. ShipBob automatically routes orders to the nearest warehouse to the customer. We receive notifications confirming the warehouse selected for shipping, eliminating inventory discrepancies between the warehouses. Efficient inventory allocation significantly impacts our outbound shipping costs, and with ShipBob, managing this has been effortless.”

Ali Shahid, COO of Our Place

Data-driven inventory analytics for continuous improvement

ShipBob also provides you with a comprehensive analytics dashboard for real-time insights on stock levels and SKU performance. You can always view the quantity of stock you have for specific products, monitor sales trends across channels and times, track fulfilment and shipping performance, and more.

This detailed information on inventory performance (available in real time) lets you adjust your PFEP strategy dynamically, meaning you no longer have to rely on outdated data to make adjustments and risk inefficiencies in your inventory management efforts.

For more information on how ShipBob’s solutions can help you optimise inventory management, click the button below to get in touch.

Plan for every part FAQs

Here are answers to common questions about PFEP.

Why is PFEP important for ecommerce brands?

A PFEP helps ecommerce brands monitor their inventory performance and understand demand trends. This allows them to make smarter decisions about when and how much to restock, helping prevent both stockouts and overstocking.

What are the key components of a PFEP?

Some of the key components of a PFEP include:

- SKU number

- Description

- Dimensions

- Weight

- Supplier information

- Storage and handling requirements

- Packaging requirements

- Lead times

- Demand history

- Usage statistics

- Reorder points

Can ShipBob help with PFEP implementation?

Yes, ShipBob offers a powerful WMS that centralises all your inventory data from multiple warehouse locations and sales channels. This provides you with real-time stock updates and inventory tracking to effectively implement a PFEP.

How does PFEP help in inventory management?

A PFEP provides you with comprehensive data on your company’s inventory at the SKU level. This allows you to make informed decisions on inventory planning and adjust your strategy in real time. You can inform different aspects of your inventory management, like how much inventory you need, when you need it, which SKUs to prioritize, and which SKUs to discontinue.