Fulfilling ecommerce orders quickly and cost-effectively starts with how products move through your warehouse, and case picking plays a major role in that process.

Whether you’re shipping full cases to retailers or fulfilling bulk ecommerce orders, case picking boosts productivity, reduces labour costs, and shortens fulfilment times – but to unlock those benefits, you’ll need the right strategy, systems, and workflows tailored to your operations.

In this guide, we’ll break down what case picking is, when it makes sense, and how to optimise it for your fulfilment model, as well as actionable ways to make your warehouse more efficient and your customers even happier.

What is case picking?

Case picking is a warehousing strategy that involves selecting and moving entire cases of product, rather than individual units, to fulfil customer orders.

This method is particularly efficient for high-volume orders, wholesale distribution, and retail replenishment.

In contrast to piece picking (where individual items are picked from shelves or bins), case picking deals with pre-packaged cases that contain multiple units of the same SKU. These cases are typically stored on pallets or in racking systems designed for easy access and retrieval.

Case picking is commonly used when:

- Fulfilling large B2B orders that require multiple units of the same product.

- Replenishing retail store inventory, where full cases are shipped to individual locations.

- Processing orders for products that are frequently purchased in bulk quantities.

For example, a business that sells snack foods might receive an order from a grocery store chain for 20 cases of chips. Rather than picking 20 individual bags, the warehouse team would simply retrieve a single pre-packaged case of 20 chip bags and prepare them for shipment.

What is a “case” in a warehouse context?

In warehousing terms, a “case” refers to a standard packaging unit that contains multiple individual products. Cases are designed to facilitate more efficient handling, storage, and transportation of goods, and they play a crucial role in the supply chain.

Cases come in various configurations, but they typically feature:

- Sturdy construction using materials like corrugated cardboard or plastic to protect contents during shipping.

- Standardized dimensions for easy stacking and palletization.

- Clear labelling with product information, quantity, and barcodes for tracking.

Different types of cases serve specific purposes within the supply chain:

- Manufacturer cases: These are the original packaging units from the manufacturer, often designed for optimal storage and transportation efficiency.

- Retail-ready cases: These cases are designed for easy transfer from the warehouse to the retail shelf, with pre-printed branding and easy-open features.

- Mixed cases: Some cases may contain an assortment of related SKUs, such as variety packs or promotional bundles.

6 key benefits of optimised case picking

Implementing a well-designed case picking strategy can hugely benefit your warehouse operations, and lead to significant improvements in efficiency, cost-effectiveness, and customer satisfaction.

Let’s explore six of the best benefits that underscore the value of optimising your case picking processes.

1. Increased productivity

One of the most significant advantages of case picking is the dramatic boost in productivity it offers.

By reducing the number of individual item picks required, case picking enables warehouse staff to process orders more quickly and efficiently. This batch handling approach also minimises travel time between picking locations and streamlines the overall workflow.

2. Significant cost savings

The productivity enhancements achieved through case picking directly translate into substantial cost savings for your business. Reducing the labour hours required to fulfil orders effectively lowers your staffing expenses – without forcing you to compromise on output.

Additionally, case picking often allows for more efficient use of packaging materials, as items are shipped in their original case configurations rather than being individually repackaged. Over time, these cost reductions can have a profound impact on your bottom line, enabling you to reinvest in growth initiatives or pass savings along to your customers.

3. Optimised space utilisation

If you store products in their original case configurations, you can maximise the capacity of your storage areas, reducing the need for excess shelving or bin locations.

Implementing slotting strategies tailored to case picking (such as organising cases based on product velocity or size) further enhances space efficiency. This optimisation not only reduces storage costs, but also streamlines picker navigation, contributing to overall warehouse productivity.

4. Enhanced customer satisfaction

While case picking is often associated with bulk orders or B2B fulfilment, it also plays a crucial role in enhancing customer satisfaction across all channels.

By enabling faster, more accurate order processing, case picking helps ensure that customers receive their shipments on time and in perfect condition. The reduced handling of individual items minimises the risk of damage or picking errors, leading to fewer returns and customer complaints. For B2B customers in particular, the ability to receive products in case quantities aligns with their operational needs and expectations.

5. Faster order turnaround

In today’s fast-paced ecommerce landscape, speed is a critical differentiator. Case picking helps accelerate the entire order fulfilment process, from picking and packing to shipping.

When you no longer need to individually handle each item, you can significantly reduces the time required to process an order. This efficiency gain directly impacts shipping timelines, enabling you to offer faster delivery options and meet increasingly demanding customer expectations.

6. Seamless scalability for growth

As your business grows and order volumes increase, the ability to scale your fulfilment operations is absolutely key. Case picking provides a flexible and adaptable framework that can seamlessly accommodate increasing demand.

Leveraging case picking strategies lets you efficiently handle higher order quantities without sacrificing accuracy or speed. This scalability is particularly valuable during peak seasons or promotional periods, when order volumes can surge unexpectedly.

5 best practices for implementing case picking in your warehouse

Implementing case picking in your warehouse requires careful planning and execution to ensure maximum efficiency and accuracy.

Let’s explore some key strategies for optimising your case picking operations to drive business growth and customer satisfaction

1. Implement a robust warehouse management system (WMS)

A powerful warehouse management system (WMS) is the backbone of efficient case picking operations. Implementing a WMS designed to optimise case picking routes and decisions streamlines your processes and minimise errors.

If you plan to use case picking in your warehouse, make sure you find a WMS that meets requirements like:

- The ability to track both case-level and individual unit inventory simultaneously (especially if your business handles a mix of B2B and B2C orders).

- Real-time inventory visibility to prevent stockouts and mis-picks.

- Robust and intuitive product catalogue management features.

2. Evaluate automation opportunities

Automation can significantly boost the speed and accuracy of case picking operations. From robotic picking systems to voice-directed picking solutions, there are a variety of options to consider based on your specific needs and budget.

When evaluating automation opportunities, it’s important to weigh the implementation costs against the potential return on investment (ROI). Consider factors such as the size of your operation, the complexity of your product mix, and your long-term growth goals.

3. Design an ergonomic warehouse layout

Cases can be heavy, and lifting them day after day can take a physical toll on workers. To help prevent injuries and look out for your employees, make sure you create an ergonomic warehouse layout. This includes using:

- Proper slotting, which involves organising inventory based on picking frequency and case weight and can significantly reduce travel time and physical exertion for pickers.

- Zone design principles that group similar products together and minimise the distance between high-velocity items.

- Equipment such as height-adjustable pick stations and proper lighting to minimise physical exertion or strain for pickers.

4. Develop comprehensive safety protocols

Case picking involves repetitive lifting and handling of heavy items, which can lead to increased risk of worker injuries. To mitigate these risks and ensure a safe working environment, it’s essential to develop comprehensive safety protocols tailored to your specific operations.

This involves:

- Implementing training programs that teach proper case handling techniques, as well as strategies for preventing repetitive strain injuries.

- Providing appropriate equipment, such as lift assists and protective gear.

- Adding other necessary guidelines to protect both workers in temperature-controlled or specialized environments.

5. Optimise workflow and picking strategies

Optimising your case picking workflow involves selecting the right picking methodologies for your operation, such as wave picking, zone picking, or cluster picking. Each approach has its own advantages and considerations, so it’s important to evaluate which strategy best aligns with your product mix, order profiles, and warehouse layout.

Balancing workloads across picking teams is another key aspect of workflow optimisation. By carefully sequencing orders and considering factors such as case weight and location, you can ensure that pickers are working efficiently and minimising downtime.

For businesses that handle both full-case and mixed-case picking, developing strategies to seamlessly transition between the two can be challenging. Implementing a WMS with the flexibility to handle both scenarios and providing clear guidance to pickers can help streamline these complex workflows.

Ergonomics and worker well-being in case picking warehouse operations

When it comes to case picking, the physical demands placed on warehouse workers can be significant. Lifting, carrying, and maneuvering heavy cases throughout the day can take a toll on the body, leading to increased risk of injury and decreased productivity.

As such, prioritizing ergonomics and worker well-being is both first and foremost a moral imperative, but also a smart business decision that can impact long-term operational costs.

🏥 Common injury risks in case picking

Case picking often involves repetitive motions and heavy lifting, which can lead to a variety of medical issues, including back strain, shoulder injuries, and carpal tunnel.

These injuries not only cause pain and suffering for the affected workers but also result in lost productivity, increased worker compensation claims, and higher turnover rates. When brands understand the common injury risks associated with case handling, they can take proactive steps to mitigate these hazards and create a safer, more efficient workplace.

🛠️ Equipment and tools for safer case picking

Investing in the right equipment and tools can make a significant difference in reducing the physical strain on workers engaged in case picking. Pallet jacks, conveyors, and lift assists are all designed to minimise the need for manual lifting and carrying, allowing workers to move cases more efficiently and with less risk of injury.

When selecting equipment, it’s essential to consider factors such as case weight, volume, and the overall warehouse setup to ensure that the tools are well-suited to the specific needs of the operation.

👷Training and technique improvements

In addition to providing the right equipment, implementing comprehensive training programs that focus on proper lifting and carrying techniques is crucial for promoting worker safety in case picking roles.

Regular training sessions should cover topics such as maintaining a neutral spine, using the legs to lift rather than the back, and avoiding twisting motions while carrying cases. Managers should also consider implementing job rotation strategies that allow workers to alternate between different tasks throughout the day, reducing the risk of repetitive strain injuries.

By prioritizing ongoing safety training and reinforcement, businesses can foster a culture of safety and well-being that benefits both workers and the brand’s bottom line.

How case picking can be leveraged for business growth

🛍️ Expanding into B2B and wholesale channels

Case picking capabilities can open up new revenue streams for businesses by enabling them to serve wholesale and B2B customers effectively. Case picking lets companies efficiently fulfil bulk orders, making it easier to expand into new distribution channels alongside their existing B2C operations.

To successfully serve both individual customers and bulk buyers, businesses must structure their pricing and operations to accommodate the unique needs of each channel. This may involve offering volume discounts for wholesale orders, establishing minimum order quantities, and adapting packaging to suit the preferences of B2B customers.

📦 Fast-shipping advantages with optimised case picking

In today’s fast-paced ecommerce world, quick shipping is key to winning and keeping customers. Efficient case picking helps businesses meet two-day shipping goals by speeding up how bulk orders are prepared and fulfilled.

By cutting down the time and effort it takes to pick and pack cases, companies can ship orders faster and make sure products arrive on schedule. This is especially important for time-sensitive B2B orders, where dependable delivery helps maintain strong business relationships.

Consistently meeting delivery promises builds customer trust and loyalty. When a company proves it can deliver orders accurately and on time, customers are more likely to order again and recommend the business to others. On the other hand, missing delivery deadlines can lead to lost sales and hurt the company’s reputation.

How to scale case picking operations for seasonal demand

📈 Temporary staffing considerations

Seasonal demand fluctuations can put significant pressure on case picking operations, requiring businesses to scale up their workforce quickly to meet increased order volumes. To ensure a smooth ramp-up process, it’s essential to:

- Have a well-defined plan for temporary staffing.

- Prioritize training and onboarding to maintain productivity and accuracy.

- Develop targeted training modules that focus on the specific skills and knowledge required for case picking, such as proper lifting techniques and inventory management protocols.

- Institute effective supervision is also crucial during high-volume periods to ensure that quality standards are maintained.

- Establish clear performance expectations for temporary staff and provide regular feedback to help them improve their skills and efficiency over time.

⚙️ Technology solutions for peak demand

Investing in technology solutions can help businesses adapt to seasonal demand spikes without sacrificing accuracy or efficiency. These could include:

- A warehouse management system (WMS): A robust WMS can automatically adjust picking strategies based on order volumes and product characteristics, ensuring that resources are allocated optimally during peak periods.

- Automation solutions: Temporary technologies (such as mobile robots or voice-picking systems) can also be deployed seasonally to augment the workforce, improve productivity, and reduce the physical strain on workers during high-volume periods, while also minimising the risk of errors and delays.

- Data analysis: Leveraging historical sales data and market trends lets businesses develop more accurate forecasts and proactively adjust their case picking operations to meet anticipated demand. This may involve pre-staging inventory, mapping your warehouse, and securing additional storage space in advance of peak seasons.

🪜 Flexible space utilisation

Maximising warehouse capacity is essential for accommodating the increased inventory levels associated with seasonal demand. To maintain case picking efficiency during peak periods, businesses should explore flexible storage solutions that can be easily adapted to changing needs, such as:

- Temporary storage: Modular racking systems or portable shelving units can be quickly deployed to expand storage capacity without requiring significant infrastructure changes. These solutions allow businesses to accommodate additional inventory while still maintaining optimal picking paths and minimising travel time for workers.

- Cross-docking: By staging inbound shipments directly for outbound distribution, companies can reduce the need for long-term storage and streamline the case picking process. This approach is particularly effective for high-turnover products or time-sensitive orders that need to be fulfilled quickly.

How ShipBob optimises case picking for ecommerce brands

At ShipBob, we know that efficient case picking can make all the difference for ecommerce brands managing both wholesale and direct-to-consumer orders. Our technology and fulfilment processes are built to simplify complex operations, helping merchants pick, pack, and ship faster without sacrificing accuracy or brand experience.

Here are just some of the capabilities ShipBob offers to help ecommerce brands with case picking – and other key fulfilment operations.

SKU-level case picking configuration

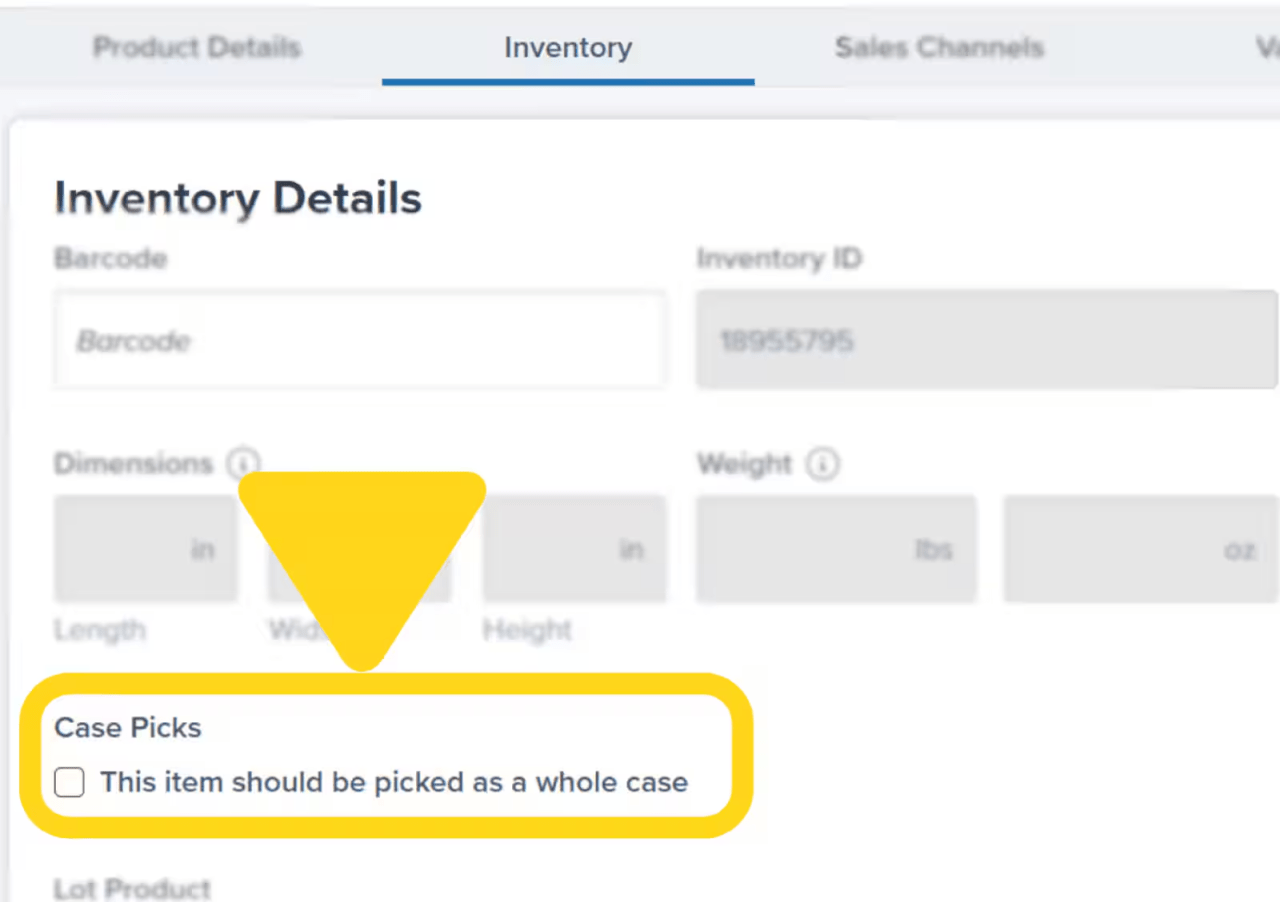

ShipBob’s advanced fulfilment platform offers merchants the flexibility to configure case picking settings at the individual SKU level. With the “This item should be picked as a whole case” toggle feature, businesses can easily designate specific products for case picking, allowing them to optimise their fulfilment strategy based on product characteristics and order profiles.

By enabling case picking for select SKUs, merchants can realize significant cost savings compared to traditional piece-picking methods. This approach reduces the labour required to fulfil bulk orders, while also minimising the risk of errors and damage associated with individual item handling.

Real-time inventory visibility across picking methods

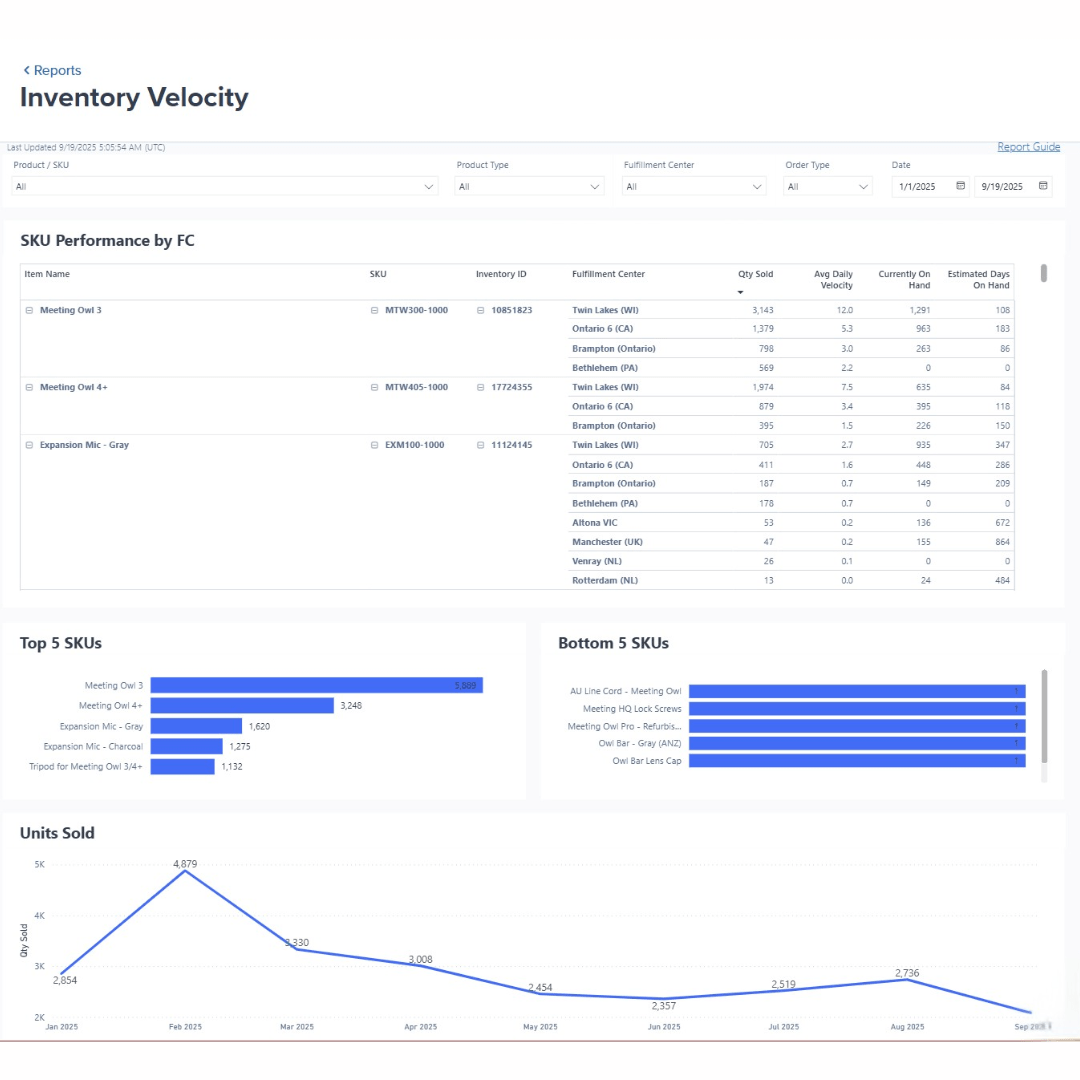

ShipBob’s powerful WMS provide real-time inventory visibility, tracking both case-packed inventory and individual units simultaneously. This granular level of tracking ensures that merchants always have an accurate picture of their stock levels through the ShipBob dashboard, regardless of how products are packaged or stored.

With ShipBob’s advanced reporting capabilities, businesses can easily monitor inventory levels across multiple fulfilment centres and sales channels. This visibility helps merchants make informed decisions about reordering, inventory allocation, and demand forecasting, ultimately preventing stockouts and overstocking.

“One of my favorite parts of ShipBob’s solution is the analytics I get through the ShipBob dashboard. I use the reporting constantly, especially to track my stock. It’s even helping me get better at inventory forecasting.

Before, I was just fumbling through the demand planning process and just ordering inventory based on what sold out. But now I have insight into metrics like SKU velocity and inventory days on hand, and I’m using that to decide what to reorder and how much of it I need. That helps a lot, especially now that the brand is scaling and I’m ordering my products in bigger batches.”

Luke Rolls, Founder of The Protein Pancake

Global case picking capabilities

ShipBob’s expansive international warehouse network enables merchants to distribute their products globally while maintaining efficient case picking operations.

With fulfilment centres strategically located across the United States, Canada, Europe, and Australia, ShipBob offers a seamless solution for businesses looking to expand into new markets.

By leveraging ShipBob’s global infrastructure, merchants can ensure that their products are stored close to international customers, reducing shipping costs and transit times. ShipBob’s standardized processes and technology ensure that case picking standards are consistently maintained across all locations, providing a reliable and scalable solution for businesses of all sizes.

“In 2024, we should be shipping over 1 million parcels out of the ShipBob network. The global scale of ShipBob’s network allows us to go to multiple markets without taking on additional technology costs.”

Ali Shahid, COO of Our Place

For more information on how ShipBob can support brands in managing inventory, fulfilment, and more, click the button below.

FAQs about case picking in the warehouse

Here are answers to some of the most common questions about case picking in warehouses.

What equipment is needed for efficient case picking?

The type of equipment needed for efficient case picking largely depends on the size, weight, and volume of the cases being handled. Essential tools often include:

- Pallet jacks: Ideal for moving smaller cases or navigating tight spaces

- Forklifts: Suited for heavier loads and high-volume operations

- Conveyor systems: significantly streamline case movement, especially in larger facilities

When deciding to invest in specialized case handling equipment, it’s important to consider factors like the average case dimensions, daily picking volume, and available warehouse space to ensure the equipment aligns with your specific operational needs.

How does case picking differ from piece picking?

Case picking involves selecting and moving entire cases, which contain multiple individual product units. In contrast, piece picking (also known as “each picking” or “broken case picking”) involves selecting individual items from within a case to fulfil orders.

What industries benefit most from case picking strategies?

Case picking is particularly advantageous for industries that frequently handle high-volume orders or distribute products to retail partners, such as:

- Food and beverage distributors

- Wholesale suppliers

- Consumer packaged goods (CPG) manufacturers

- Retail distribution centres

How can automation improve case picking operations?

Automation technologies can significantly enhance the efficiency and accuracy of case picking operations. Some common automation solutions for case picking include:

- Robotic palletizers and depalletizers

- Automated storage and retrieval systems (AS/RS)

- Conveyor systems with sortation capabilities

- Voice-directed or light-directed picking technologies

These automated systems can reduce manual labour requirements, minimise picking errors, and improve overall warehouse productivity.

What are the best strategies for reducing worker fatigue in case picking?

Reducing worker fatigue is essential for maintaining a safe and productive case picking operation. Some effective strategies include:

- Proper lifting techniques: Train workers on ergonomic lifting methods, such as keeping the load close to the body and avoiding twisting motions.

- Appropriate equipment: Ensure workers have access to tools like pallet jacks, lift tables, and conveyor systems to minimise manual lifting and carrying.

- Ergonomic workspace design: Optimise the warehouse layout to minimise walking distances and ensure picking areas are at a comfortable height for workers.

- Regular breaks and stretching: Incorporate short breaks and stretching routines throughout the day to prevent repetitive strain injuries.

- Job task rotations: Assign workers to different tasks or zones throughout the day to avoid prolonged repetitive motions and distribute physical demands evenly.

Warehouses can implement these strategies to reduce the risk of injuries, improve job satisfaction, and maintain a more consistent case picking performance.

How can case picking support both B2B and DTC fulfilment?

Case picking is typically reserved for B2B fulfilment operations, as it is a bulk picking method and only retailers, wholesalers, and other B2B sales platforms order in bulk. However, case picking can speed up fulfilment and help brands maintain accurate inventory counts, which frees up time and space for DTC fulfilment while helping to prevent accidental stockouts.

Does ShipBob support case picking for wholesale or bulk shipping?

Yes, ShipBob offers case picking capabilities to support wholesale and bulk shipping for ecommerce brands. With ShipBob’s intuitive dashboard, merchants can easily designate specific SKUs to be picked as whole cases, ensuring efficient fulfilment for B2B orders or high-volume shipments.

This “pick as a whole case” feature allows businesses to optimise their fulfilment strategy, reducing picking times and costs for bulk orders while still maintaining the flexibility to fulfil individual B2C orders as needed. ShipBob’s advanced WMS technology seamlessly tracks inventory at both the case and unit level, providing real-time visibility and preventing stockouts across all sales channels.