Efficiency is everything in ecommerce. As online shopping continues to dominate the retail landscape, brands are constantly seeking ways to optimise their supply chain and deliver orders faster than ever before. Enter goods-to-person (G2P) technology: a revolutionary approach to warehouse automation that promises to transform the way businesses store, pick, and ship inventory.

But what exactly is goods-to-person fulfilment, and how can it benefit your ecommerce operation? In this comprehensive guide, we’ll look into G2P systems and explore the key concepts, benefits, and considerations that every brand should understand before taking the leap into warehouse automation.

What is goods-to-person (G2P)?

Goods-to-person (G2P) is an ecommerce fulfilment methodology that utilises automation to bring products directly to workers, eliminating the need for workers to travel through the warehouse to retrieve items. In a traditional picking process, pickers navigate the warehouse, locating and retrieving products from their storage locations. With G2P, the system automatically identifies, retrieves, and delivers the required items to a pick station, where a worker can efficiently pick and pack the order.

This approach is gaining traction as businesses strive to optimise their supply chain and meet ever-increasing consumer demands. By minimising the time and effort required for workers to locate and retrieve products, G2P systems can significantly improve warehouse efficiency, accuracy, and throughput.

Goods-to-person vs. other picking methods

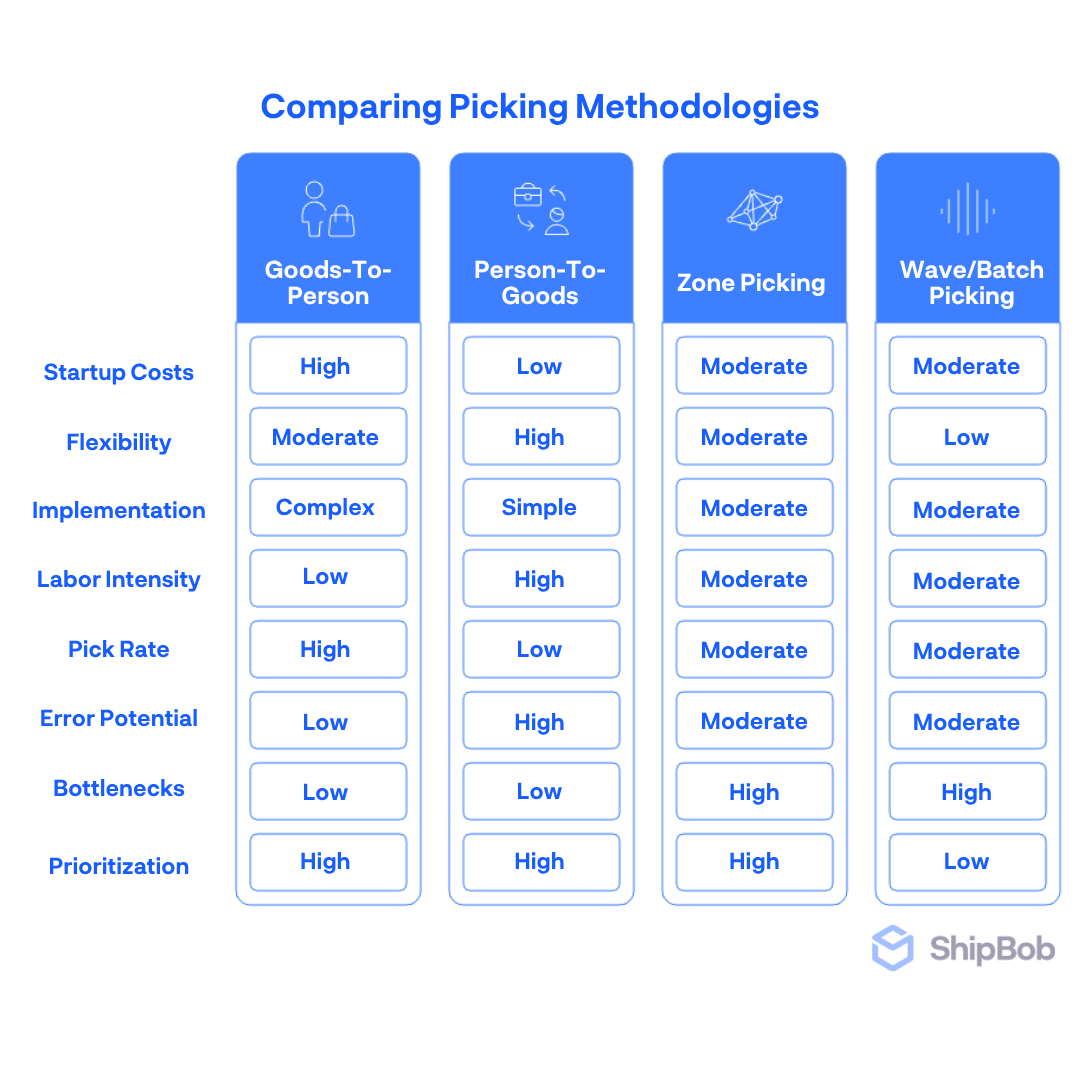

Goods-to-person automation is just one of several picking methods available. The most effective fulfilment strategies often combine multiple approaches based on your specific business needs.

Choosing the right picking method depends on key factors like order volume, SKU count, product types, and available resources. Small businesses with limited catalogues may benefit from simple manual processes, while larger warehouse operations handling thousands of SKUs typically require more sophisticated automation.

Here’s how G2P compares to other common picking methods:

Person-to-goods

This traditional picking method involves workers travelling through the warehouse to retrieve items from storage locations. It’s popular for smaller operations due to its simplicity.

Advantages:

- Low startup costs with no specialized equipment needed

- Highly flexible for changing product mixes

- Simple implementation and training

Disadvantages:

- Labor-intensive with significant walking time

- Slower pick rates than automated systems

- Higher error potential

Despite limitations, this approach works well for smaller operations or those with variable product mixes.

Zone picking

In zone picking, the warehouse is divided into distinct areas with dedicated pickers. Orders move from zone to zone as items are collected.

Advantages:

- Less walking time as pickers stay in their zones

- Specialized product knowledge within zones

- Parallel processing across multiple zones

Disadvantages:

- Potential bottlenecks between zones

- Order consolidation challenges

- Possible idle time with uneven order distribution

Zone picking works well for larger operations with many SKUs and can complement G2P automation in hybrid systems.

Wave or batch picking

Wave picking (also known as batch picking) groups similar orders together for processing as a single batch, reducing warehouse travel time.

Advantages:

- Efficient travel paths for multiple orders at once

- Increased focus and productivity

- Works well with supporting warehouse technologies like pick-to-light

Disadvantages:

- Orders must wait for complete waves to form

- Difficult to prioritize urgent orders

- Less flexible than real-time methods

This method suits operations with predictable order patterns but may not match G2P’s effectiveness in high-volume environments.

Hybrid approaches

For most businesses, combining manual and automated processes creates the optimal solution. Hybrid systems offer both flexibility and efficiency where each is most needed.

For example, you might use G2P automation for fast-moving products while handling oversized or slow-moving items manually. Another effective approach combines G2P with zone picking, creating specialized zones each with their own automation.

The key to successful fulfilment is finding the right balance of methods for your specific business needs. By evaluating your order volume, product mix, and resources, you can design a system that maximises efficiency, accuracy, and flexibility.

5 key benefits of goods-to-person automation

Goods-to-person automation offers a range of compelling benefits that can transform ecommerce fulfilment operations. By bringing inventory directly to workers, G2P systems save time and effort, enabling businesses to process orders faster and more accurately.

Here are five key advantages that make G2P an increasingly attractive option for growing brands.

1. Efficiency gains

One of the most significant benefits of G2P automation is the dramatic improvement in operational efficiency. By reducing walking time by 40-70%, these systems allow workers to focus on the task of picking, packing, and shipping orders.

This translates to increased order throughput and streamlined operations, with many businesses seeing productivity improvements of 2-3x more orders processed per hour compared to manual methods.

2. Faster picks

In addition to overall efficiency gains, G2P systems enable fast picking rates. By automatically delivering items to pick stations, these solutions eliminate the time workers spend navigating warehouse aisles and searching for products. G2P systems can increase pick rates from an average of 50-100 picks per hour in manual systems to an impressive 200-400+ picks per hour. This speed advantage is crucial for meeting tight shipping deadlines and offering competitive delivery options like 2-day shipping.

3. Reduced manual labour

G2P automation offers significant benefits for warehouse associates. By bringing products to workers, these systems reduce physical strain, repetitive motion injuries, and overall fatigue. This not only improves employee safety but also helps address labour shortage challenges by allowing operations to maintain high productivity levels with fewer workers. The reduced physical demands can also contribute to higher employee satisfaction and retention rates.

4. Improved accuracy

Goods-to-person systems help brands boost accuracy. By leveraging technologies like pick-to-light, barcode confirmation, and weight verification, automated solutions can achieve accuracy rates of 99.9% or higher, compared to the 95-98% typically seen in manual systems. This dramatic reduction in errors translates to higher customer satisfaction, fewer returns, and lower costs associated with processing mistakes.

5. Cost savings and ROI

While G2P automation requires a significant upfront investment, there can be substantial long-term cost savings. Many businesses see a payback period of just 2-5 years due to these compounding benefits. Increased throughput and reduced labour costs can lead to improved operational efficiency, and higher accuracy rates can lead to lower costs associated with returns and customer service issues.

As ecommerce continues to grow and evolve, the advantages of goods-to-person automation become increasingly compelling. By improving efficiency, speed, accuracy, and worker well-being, these systems can help brands stay competitive in a rapidly changing market.

However, it’s essential to carefully evaluate your specific needs and constraints before investing in G2P technology.

Considerations before implementing a G2P system

G2P implementation requires significant planning, investment, and understanding of potential challenges. Before committing to warehouse automation, evaluate these five key factors to ensure a successful transition:

1. Implementation costs and ROI calculation

G2P systems require substantial upfront investment. Hardware, software, integration, and facility modifications add up quickly, making thorough cost analysis essential.

When calculating ROI, include both tangible benefits, like increased throughput and reduced labour cost, and intangible advantages, such as customer satisfaction and employee retention.

Consider a phased approach to manage cash flow and risk, scaling your automation as your business grows.

2. Maintenance and downtime

G2P systems improve efficiency but require regular maintenance and create potential downtime risks. Due to the highly automated nature of the system, even minor malfunctions can completely halt operations.

Ask potential vendors about maintenance costs, schedules, spare parts availability, and technical support, and develop a solid contingency plan to minimise the impact of unexpected downtime.

When calculating total ownership costs, include the equipment’s expected lifespan and future upgrade requirements.

3. Scalability challenges (seasonal spikes, expanding SKUs)

Ecommerce businesses face significant volume fluctuations, especially during peak seasons, holidays, or major sales promotions. Ensure your G2P system can handle sudden demand spikes without compromising performance.

As your product catalogue grows, your automation must adapt to changing SKU profiles and dimensions. Choose systems flexible enough to accommodate various item sizes and shapes, and discuss your growth plans with vendors to confirm their solutions can scale with you.

4. Worker experience, ergonomics, and training

While G2P reduces physical strain from manual picking, it creates new workforce challenges. Employees need training to operate and troubleshoot automated systems as their roles shift from pickers to system operators.

Communicate clearly about changes, address job security concerns proactively, and highlight skill development opportunities that come with new technology.

5. Vendor compatibility and WMS integration

Seamless integration between your G2P system and existing warehouse management system (WMS) is critical for success. This connection optimises inventory management, order routing, and overall efficiency.

Ask vendors specific questions about their API capabilities and integration experience with your WMS. Choose providers with proven implementation track records and deep understanding of ecommerce fulfilment.

Consider your vendor’s long-term stability and support capabilities. With significant investment and lengthy deployment timelines, you need a partner who will support your business for years to come.

Effective goods-to-person systems and technologies

Today’s G2P technology offers diverse solutions for different business needs and budgets. While implementations vary, all G2P systems share one goal: bringing products to workers to reduce travel time and boost efficiency.

Most businesses combine multiple technologies rather than using just one approach. Success depends on finding the right balance of automation and manual processes for your specific needs.

Automated storage and retrieval systems (AS/RS)

AS/RS represents the most advanced G2P solution, using shuttles, cranes, and vertical lift modules to move products from high-density racks directly to workstations.

These systems work best for high-volume operations with standardized product dimensions and limited floor space, as they maximise vertical storage. The main drawbacks are higher costs and longer implementation times compared to other options.

Carousels and shuttles

Carousel and shuttle systems offer more affordable G2P solutions for medium-sized operations. These use rotating shelves or trays that bring products to workers at designated stations.

Horizontal carousels maximise storage density in smaller spaces, while vertical carousels are more suitable for taller warehouses with consistent picking patterns.

Though they can’t match the throughput of full AS/RS systems, carousels still significantly outperform manual picking methods in both efficiency and accuracy.

AMRs and robotics

Autonomous mobile robots (AMRs) provide flexible, scalable G2P solutions for businesses of all sizes. These robots navigate warehouses using sensors and software, delivering shelves or totes of products directly to pick stations.

Their key advantage is adaptability. Unlike fixed systems, AMRs can be quickly reconfigured as your product mix, order volume, or layout changes.

Collaborative robotics

Collaborative robots, or cobots, represent the newest G2P innovation. These systems work alongside humans, helping with picking, packing, and material handling tasks.

Cobots feature built-in safety mechanisms that allow them to work near humans without protective barriers. This approach combines robotic precision with human flexibility and problem-solving.

While implementation requires initial training as workers adapt to robotic colleagues, the long-term benefits in efficiency, accuracy, and worker satisfaction can be substantial.

Before investing in any cobot solution, evaluate your specific needs carefully. Product variability, order volume, and facility layout all impact potential ROI.

How ShipBob helps you achieve G2P-level benefits without the complexity

For many brands, outsourcing fulfilment to a trusted provider like ShipBob can offer a more flexible and cost-effective path to achieving the efficiency and accuracy benefits of G2P technology. By leveraging ShipBob’s advanced fulfilment network and technology stack, businesses can access state-of-the-art automation capabilities without the complexity and risk of a direct investment.

Distributed fulfilment network for speed and scalability

One of the key advantages of ShipBob’s approach is its geographically distributed fulfilment network. With strategically located facilities across the United States and in key international markets worldwide, ShipBob enables businesses to store inventory closer to their customers, reducing shipping distances and transit times. Brands can automate inventory distribution, placement, and rebalancing in the US using ShipBob’s Inventory Placement Program (IPP).

This distributed model allows brands to offer fast, affordable shipping options. By splitting inventory across multiple fulfilment centres, businesses can also better accommodate seasonal volume fluctuations and regional demand patterns, ensuring a consistent customer experience year-round.

Real-time inventory data and WMS integration

ShipBob’s proprietary warehouse management system (WMS) is the backbone of its fulfilment operations, providing real-time visibility into inventory levels, order status, and performance metrics. This advanced software seamlessly integrates with leading ecommerce platforms like Shopify, Magento, and NetSuite, enabling automated order routing and real-time inventory visibility.

By leveraging ShipBob’s technology stack, brands can access the same level of inventory optimisation and order tracking capabilities offered by G2P systems, without the integration challenges and maintenance requirements of a direct implementation. ShipBob’s software also provides powerful analytics tools and reporting features, empowering businesses to make data-driven decisions.

Meeting 2-day (and faster) shipping expectations

In today’s competitive ecommerce landscape, fast and reliable shipping is no longer a luxury; it’s a necessity. Consumers have come to expect Amazon-like delivery speeds, and brands that fail to meet these expectations risk losing customers to more nimble competitors.

ShipBob’s fulfilment network and processes are specifically designed to enable consistent 2-day delivery (and faster) across the contiguous United States.

This focus on speed and reliability is made possible by ShipBob’s advanced automation capabilities, which streamline every stage of the fulfilment process. From real-time order routing to automated carrier selection and label printing, ShipBob’s technology stack ensures that orders are processed quickly and efficiently, without sacrificing accuracy or quality.

End-to-end support for ongoing optimisation

One of the most advantageous aspects of partnering with ShipBob for order fulfilment is gaining access to end-to-end support and expertise.

ShipBob’s ongoing support includes assistance with inventory management, demand forecasting, and peak season planning, as well as continuous process improvement initiatives designed to drive efficiency and cost savings over time.

Ultimately, ShipBob’s data-driven approach to fulfilment optimisation offers a compelling alternative to direct G2P investment for many ecommerce brands. By combining advanced technology, strategic facility locations, and a relentless focus on customer success, ShipBob enables businesses to scale their operations efficiently and effectively, without the complexity and risk of a major automation project.

Get started with ShipBob

Connect with our team to discover how your brand can leverage ShipBob’s advanced fulfilment platform.

FAQs about goods-to-person

Below are answers to common and niche queries and challenges related to goods-to-person picking.

What types of ecommerce brands benefit most from goods-to-person automation?

Goods-to-person automation is particularly beneficial for ecommerce brands with high order volumes and consistent product dimensions. Industries such as fashion, beauty, and electronics often see the highest ROI from G2P implementation due to their fast-moving inventory and relatively standardized packaging.

However, smaller brands can still access similar benefits through partnerships with fulfilment providers like ShipBob. Direct G2P investment typically makes sense for larger operations with stable, high-volume order flows and the resources to manage the complexity of automation in-house.

How does G2P picking help reduce operational costs?

G2P picking reduces operational costs in several key areas: labour efficiency, error reduction, and space utilisation. By minimising manual travel time and improving ergonomics, G2P systems can increase labour productivity by 200-300%. Automated picking also reduces errors by up to 99.9%, cutting costs associated with returns and customer service issues.

Additionally, G2P solutions often utilise vertical space more effectively, reducing overall facility footprint and associated real estate costs. While the upfront investment in G2P can be significant, these cost savings can deliver a compelling ROI for the right business model.

Is G2P suitable for high SKU counts?

G2P picking reduces operational costs in several key areas: labour efficiency, error reduction, and space utilisation. By minimising manual travel time and improving ergonomics, G2P systems can increase labour productivity by 200-300%. Automated picking also reduces errors by up to 99.9%, cutting costs associated with returns and customer service issues.

Additionally, G2P solutions often utilise vertical space more effectively, reducing overall facility footprint and associated real estate costs. While the upfront investment in G2P can be significant, these cost savings can deliver a compelling ROI for the right business model.

Can G2P systems handle seasonal spikes?

Fixed G2P automation can struggle with significant volume spikes during peak seasons, as the infrastructure is typically designed for a specific capacity range. Building excess capacity into a G2P system to handle short-term spikes can be prohibitively expensive.

Strategies for managing seasonal fluctuations in a G2P environment include implementing hybrid manual/automated processes, leveraging temporary labour, and distributing volume across multiple facilities. In contrast, ShipBob’s elastic fulfilment network is designed to absorb seasonal spikes without the need for fixed infrastructure investments.

How does ShipBob complement or replace G2P workflows?

ShipBob delivers G2P-like efficiency without the costly infrastructure investment. Our technology combines advanced inventory management software, optimised picking processes, and strategically located fulfilment centres to match G2P speed and accuracy while offering greater flexibility.

Our distributed network positions your inventory closer to customers, cutting shipping costs and delivery times. Unlike fixed G2P systems, ShipBob’s model easily adapts to handle volume spikes during peak seasons.

For brands weighing G2P investments, ShipBob provides a scalable alternative that eliminates the complexity and risk of managing in-house automation.

What are the maintenance requirements for goods-to-person systems?

G2P systems demand regular maintenance to prevent costly downtime. Maintenance needs vary by technology type. For example, AS/RS systems need quarterly or semi-annual visits from specialized technicians to service mechanical components. AMRs require fewer mechanical interventions but need regular software updates and battery replacements.

When calculating G2P ownership costs, remember to include both initial equipment investment and ongoing maintenance expenses. Partnering with ShipBob eliminates these concerns by transferring maintenance responsibilities and technical requirements to our experienced team.