In today’s hyper-competitive ecommerce environment, fulfilment strategy has evolved from a back-office necessity to a competitive weapon.

At PARCEL 25, ShipBob’s Chief Supply Chain Officer, Melissa Nick, and SVP of Central Operations, James Solier, shared the playbook that separates industry leaders from everyone else.

Read on to learn how brands engineer their entire supply chain operations to drive revenue, boost conversion rates, and create lasting competitive advantages.

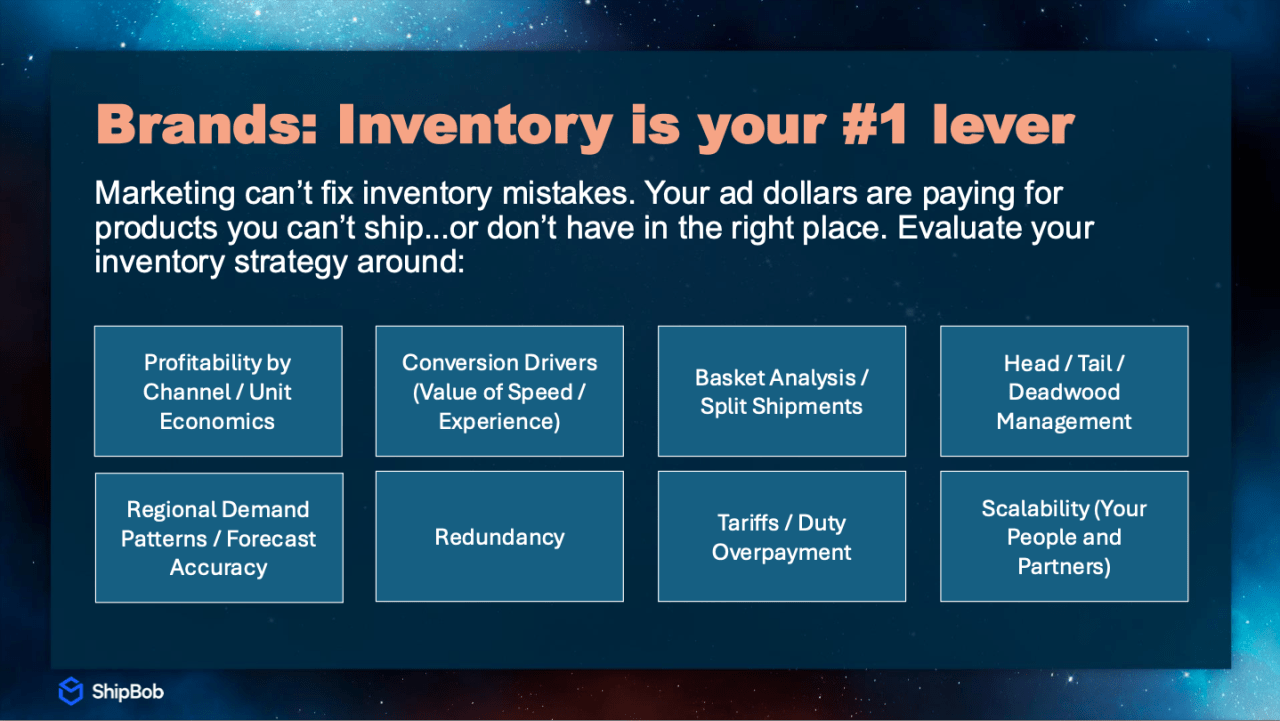

Why inventory optimisation is your secret growth weapon

Inventory optimisation isn’t just about having products in stock. It’s about strategically positioning your inventory to maximise every aspect of your business performance.

When we analyse the ShipBob merchant network, the results are clear. Brands with optimised inventory strategies see:

- Faster delivery speeds through smart inventory positioning

- Lower shipping costs via localised shipping and regional distribution

- Higher conversion rates from accurate delivery promises

- Better gross margins through reduced carrying costs

Inventory strategies that move the needle

Basket analysis

Basket analysis leverages order data to identify which products are frequently bought together, then co-locates them in your fulfilment centres. This simple yet powerful strategy can reduce split shipments by up to 35% while simultaneously increasing average order value.

By strategically placing complementary items near each other (i.e., phone cases next to phone chargers or yoga mats next to resistance bands) pickers can efficiently consolidate multi-item orders into single shipments, reducing both shipping costs and your carbon footprint while improving the customer experience.

SKU velocity segmentation

SKU velocity segmentation ensures fast-moving items are positioned in your “golden zones” for quick access, improving pick efficiency by 40% compared to random slotting. This warehouse optimisation technique categorises inventory based on turnover rates, placing high-velocity SKUs in easily accessible locations closest to packing stations.

Slower-moving items can be stored in less accessible areas, maximising warehouse space utilisation while ensuring your most popular products are always within arm’s reach for faster order processing and same-day fulfilment capabilities.

Regional demand forecasting

Regional demand forecasting uses historical data and demographic insights to predict where demand will spike, enabling proactive inventory positioning that can reduce delivery costs by 25-30%. This allows you to distribute inventory across multiple fulfilment centres based on anticipated demand patterns, seasonal trends, and local market characteristics.

By positioning stock closer to your end customers, you can reduce shipping distances, minimise last-mile delivery expenses, and meet customer expectations for lightning-fast shipping without premium carrier costs.

Here’s the bottom line: you can spend thousands on customer acquisition, but if inventory mistakes create delivery delays, you’re throwing money away.

How 3PLs become true growth partners, not just vendors

Most third-party logistics providers focus on the basics: pick accuracy, shipping speed, and maybe cost savings. But strategic fulfilment partners like ShipBob align with your growth objectives and bring capabilities that actually move your business forward.

What to look for in a strategic fulfilment partner

Forward-thinking fulfilment partners have specialised capabilities such as:

- Omnichannel fulfilment, supporting D2C, retail, marketplace, and B2B from unified pools of inventory

- End-to-end ownership to ensure support all the way from dock to stock to the customer’s doorstep.

- Certified facilities for food, beverage, health, and beauty products

- Temperature-controlled environments for quality control

- Foreign Trade Zone (FTZ) operations for duty optimisation

How to know if you’re working with a strategic fulfilment partner

Multi-year capacity planning aligned with your growth projections

The ability to plan long-term demonstrates a fulfilment partner’s commitment to scaling alongside your business rather than simply processing today’s orders. A strategic partner proactively models your storage and throughput needs based on your growth to ensure you’ll never face capacity constraints. This approach provides the infrastructure foundation needed to support ambitious revenue targets without operational bottlenecks.

Data integration that supports advanced analytics and forecasting

Data integration that supports advanced analytics and forecasting transforms your fulfilment operations into a strategic intelligence centre. True fulfilment partners provide seamless API connections and robust reporting dashboards with real-time inventory, order, and shipping data.

These integrations enable sophisticated demand forecasting, inventory optimisation models, and predictive analytics that inform your operations and turn your logistics data into a competitive advantage.

If your fulfilment provider isn’t helping you make strategic decisions about inventory and network design, they are likely just a vendor, not a fulfilment accelerator.

Engineering fulfilment networks that drive conversions

Here’s where most brands get it wrong: they choose their fulfilment network based on cost minimisation instead of conversion optimisation. The smartest brands flip this approach entirely.

Start with conversion goals

Use customer density data and order velocity patterns to choose fulfilment centres where they’ll have maximum impact on delivery promises and customer satisfaction. ShipBob completes these analyses on behalf of its merchants.

Product-specific strategy

Different products need different approaches.

Consider the following:

- High-velocity, low-weight items, such as supplements, beauty products, and apparel, may need centralised fulfilment with expedited shipping options.

- Bulky, heavy products, such as furniture and appliances, are best suited for regional distribution to minimise shipping costs.

- Temperature-sensitive goods, such as food and beverage products, need specialised facilities with proper handling procedures.

- Hazmat items, such as beauty products with aerosol, hand sanitisers, and other chemical-based products, require certified facilities with compliance protocols.

Semaine Health offers 1-day delivery to nearly 70% of customers

When Semaine Health expanded from one to four strategically positioned fulfilment centres with ShipBob, the transformation was dramatic:

- 67% of customers gained access to 1-day delivery

- Cart abandonment decreased by 22% due to better delivery promises

- Customer lifetime value increased by 19% from improved satisfaction

- Total fulfilment costs dropped 15% despite network expansion

This was the result of postal code-level demand analysis, seasonal adjustments, and strategic carrier mapping for each facility’s coverage area through their partnership with ShipBob.

“Since launching ShipBob’s Inventory Placement Program, we’ve been able to allocate our inventory across 4 of ShipBob’s fulfilment centres in the United States, which cut our shipping times by a third – from 5.2 days down to about 3.6 days. Not only has transit time dropped, but at the same time we reduced fulfilment costs by over $2 per order compared with our old 3PL. This combination has been key to profitable growth this year.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Shipping strategy: Experience beats carrier logos every time

Your customers don’t care which couriers you use. They care about getting their orders fast, affordably, and reliably. This shift in thinking unlocks massive opportunities for cost savings and service improvements.

Advanced shipping tactics

Dynamic carrier selection

Dynamic carrier selection uses real-time algorithms to choose couriers based on multiple performance and cost factors, ensuring every package ships via the optimal route.

Rather than defaulting to a single carrier partnership, sophisticated fulfilment operations evaluate:

- Service level commitments and reliability history

- Cost optimisation across all shipping locations

- Capacity availability during peak periods

- Performance metrics and customer satisfaction scores

Regional carrier integration

Don’t sleep on regional couriers. While international couriers like UPS and FedEx offer broad coverage, regional can deliver packages faster and cheaper in specific areas.

Leveraging specialised couriers can offer superior service at lower costs, significantly improving your customer lifetime value through faster deliveries and reduced expenses. They also provide backup capacity during peak seasons, ensuring your customers receive consistent delivery experiences year-round.

Predictive delivery analytics

Use machine learning to provide accurate delivery estimates that account for carrier performance history, weather patterns, facility processing times, and peak season constraints.

By setting realistic expectations upfront and proactively communicating delays before customers notice them, you build trust and turn the delivery experience into a brand differentiator.

Technology infrastructure for future-ready operations

Future-proof fulfilment requires technology that can adapt as your business grows and market conditions change. Here’s what actually matters:

Core technology requirements

Order Management Systems (OMS)

OMS provide real-time inventory visibility across all channels, intelligent order routing, and automated exception handling to keep orders flowing smoothly. The OMS orchestrates inventory allocation across multiple warehouses, sales channels, and fulfilment methods while preventing oversells and stockouts.

Warehouse Management System (WMS)

A WMS can offer AI-powered slotting optimisation, labour management tools, and quality control automation that maintains 99.5%+ inventory accuracy across your fulfilment network. Going beyond the traditional barcode scanning, a modern WMS can optimise picking workflows, act as a checks-and-balances system against mispicks, and track productivity metrics to transform your warehouse operations.

Unified analytics

Unlock comprehensive insights into SKU profitability, SLA performance tracking, demand forecasting, and network optimisation recommendations with advanced, unified analytics. Rather than juggling data from multiple systems, this approach consolidates fulfilment metrics into an actionable dashboard so you can access holistic, real-time data that can enable informed business decisions.

Integration capabilities

Your systems need to work well together. Look for API-first architecture that seamlessly connects with your ecommerce platform, marketplace channels, ERP systems, and marketing tools.

Order data should flow automatically from your ecommerce platform to your fulfilment provider or WMS, sync inventory updates instantly across channels, and trigger shipping confirmation emails without manual data exports or custom coding projects.

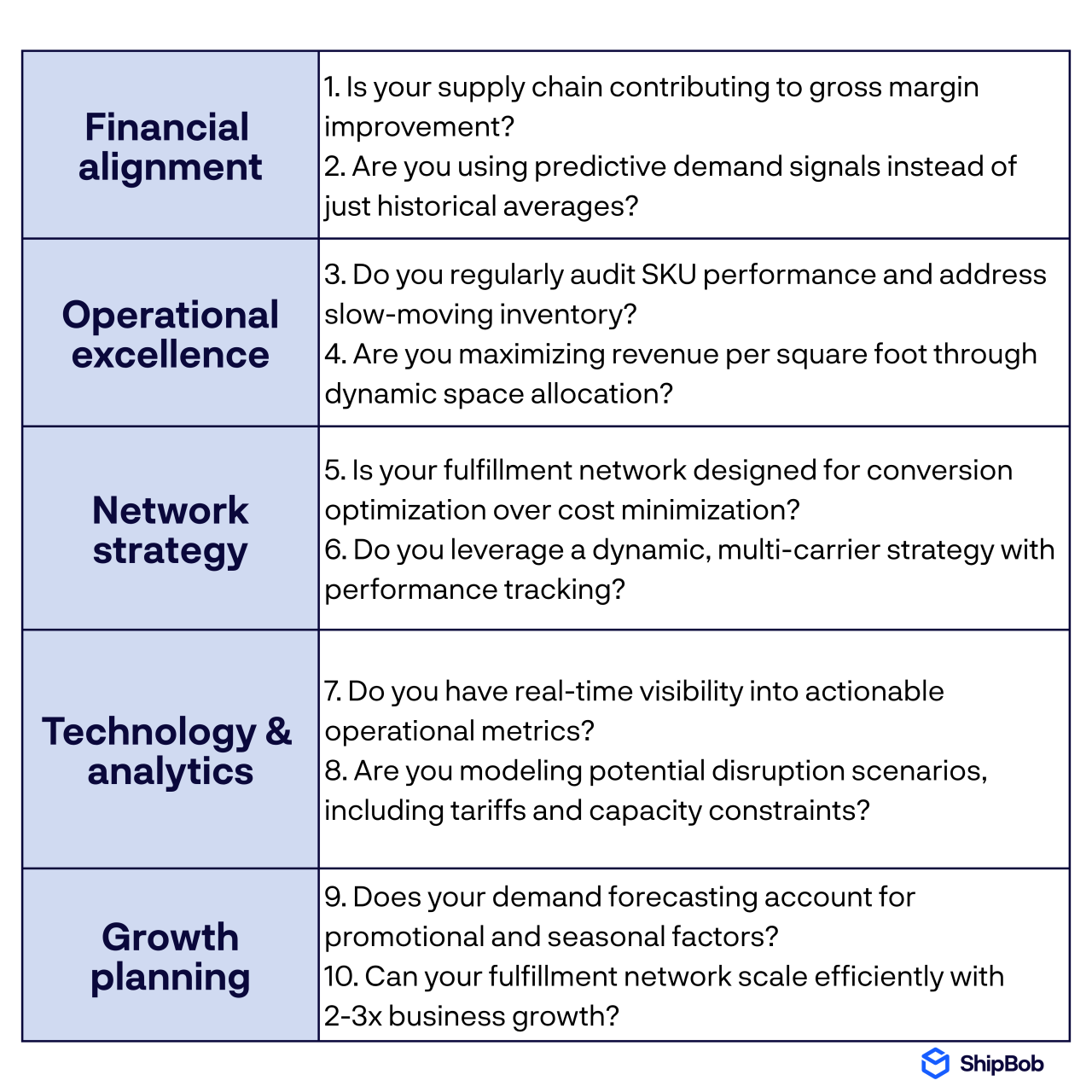

10 questions to pressure-test your fulfilment strategy

Use this framework to evaluate where you stand with your current fulfilment strategy:

Your action plan for fulfilment excellence

Use these tips to enhance your fulfilment strategy over the course of the next year.

Quick wins

In the first thirty days, consider these steps:

- Audit your current inventory positioning for optimisation opportunities

- Implement carrier performance tracking and diversify shipping options

- Start monitoring conversion rates tied to delivery performance

Strategic moves

In the next 3 months, consider these steps:

- Deploy advanced demand forecasting with regional granularity

- Optimise fulfilment network design based on customer distribution

- Implement proactive customer communication for delivery exceptions

Long-term investments

In the next 6 months to a year, consider these steps:

- Build omnichannel capabilities supporting multiple sales channels

- Develop predictive analytics for continuous optimisation

- Create scalable architecture supporting 3-5 year growth plans

Ready to transform your fulfilment operations?

ShipBob’s global network of strategically positioned fulfilment centres and advanced technology platform has helped thousands of brands transform their operations into competitive advantages.

Connect with ShipBob’s order fulfilment and supply chain experts to turn fulfilment into your competitive advantage.