Table of Contents

** Minutes

6 key GMP warehouse requirements

In-house vs. outsourced GMP warehouse management

Advanced GMP warehouse technologies and innovations

Elevate your regulated products with ShipBob’s GMP-compliant fulfilment

When your products are designed to go on bodies or skin, warehousing isn’t just a matter of storage — it’s a matter of safeguarding health. But how do you know if your warehousing is preserving the integrity of your product?

For beauty, supplement, food and beverage, and medical device brands (as well as others), one way to make sure is to use a facility that has a Good Manufacturing Practice, or GMP, certification.

GMP warehouses go beyond standard storage, and enforce rigorous regulations that protect product integrity and consumer safety. These measures ensure your sensitive products remain safe and effective from receipt to delivery.

In this article, we’ll dive deep into GMP-compliant warehousing: its core requirements, key technology solutions to look for, and practical strategies for balancing strict compliance with the speed today’s ecommerce customers demand.

What is a GMP warehouse?

A GMP warehouse is a specialised warehouse or storage facility that follows Good Manufacturing Practice regulations to ensure products are safely handled, stored, and distributed.

GMP-certified warehouses offer more than just basic storage capabilities; rather, they:

- Maintain precise environmental controls (such as temperature and humidity)

- Prevent contamination through strict cleanliness procedures and standards

- Document every product’s movement with meticulous detail

- Enforce rigorous staff practices and protocols to protect product integrity at all stages

Though the GMP certification was created for pharmaceuticals, it’s now used to certify many products impacting consumer health or safety (from supplements and cosmetics to food and medical devices). For ecommerce brands selling these sensitive items, GMP certification is key for regulatory compliance, consumer safety, and brand protection.

GMP warehouse meaning vs. standard warehouse storage

GMP warehouses are very different from standard warehouses.

While standard facilities focus on efficient storage and movement, GMP warehouses function as quality-controlled environments where everything is designed to protect product integrity.

| Standard Warehouse | GMP Warehouse | |

| Environmental Control | Basic climate control for comfort | Precise temperature/humidity monitoring with continuous documentation |

| Access Control | Standard security measures | Restricted-access zones, gowning requirements, contamination prevention |

| Documentation | Basic inventory records | Comprehensive batch records, SOPs, training logs, deviation reports |

| Cleaning Protocols | Regular maintenance cleaning | Validated cleaning procedures with documented schedules and verification |

| Staff Requirements | General warehouse training | GMP-specific training with documented competency assessments |

| Product Segregation | By SKU or customer | By status (quarantine, approved, rejected) with physical barriers |

| Quality Systems | Focus on accuracy and efficiency | Formal quality management systems with CAPA, change control, and audit programs |

6 key GMP warehouse requirements

For a warehouse to be GMP-compliant, it must meet six essential requirements that protect product integrity throughout storage and handling.

Regardless of whether you’re storing supplements, cosmetics, or food products, these core standards apply to all regulated products.

1. Proper documentation and traceability

In GMP warehousing, the rule is simple: if it isn’t documented, it didn’t happen. When handling products people consume or apply to their bodies, complete documentation is non-negotiable for protecting both customers and your business.

GMP facilities must maintain comprehensive records including:

- SOPs (detailing exact procedures)

- Batch records (tracking product lots)

- Training logs (verifying staff qualifications)

- Cleaning records

- Environmental monitoring documentation

Beyond basic record-keeping, you also need robust lot tracking and expiration management systems that pinpoint any product’s location and status instantly. This traceability becomes invaluable during recalls or quality investigations. Modern warehouse systems can also automate this documentation to reduce errors while improving accessibility.

2. Environmental control and monitoring

Product quality depends heavily on storage conditions. GMP warehouses must maintain precise control over temperature, humidity, light, and air quality, with requirements varying by product type. For example, probiotics might need refrigeration, while certain cosmetics require UV protection.

Monitoring goes beyond daily temperature checks. GMP facilities use continuous monitoring systems, from manual logs to automated sensors that track conditions 24/7 and alert staff to deviations. These devices require regular calibration, and you need clear protocols for handling environmental emergencies.

The goal is to create an unbroken chain of custody that stores products properly from receipt through shipping.

3. Contamination prevention and hygiene practices

Contamination prevention starts with facility design: cleanable surfaces, proper material flow patterns, and designated spaces for quarantined or disposed products.

From there, GMP warehouses have preventative SOPs in place to prevent contamination during everyday operations. These include:

- Cleaning protocols that specify frequencies and methods for different areas and equipment.

- Regular inspections and pest control measures (with detailed documentation of findings and actions).

- Staff hygiene requirements (such as handwashing facilities, appropriate protective clothing, and health monitoring procedures)

4. Inventory management and stock control

GMP inventory management should follow FEFO (First Expired, First Out) to ensure products closest to expiration ship first, regardless of what date they arrived at the warehouse. This requires systems tracking not just locations but expiration dates, lot numbers, and quality statuses.

Products must be physically segregated by status: incoming goods awaiting inspection, approved inventory, quarantined items, and rejected products all need separate, clearly marked areas. Receiving procedures must verify quantities and storage conditions during transport, packaging integrity, and proper labelling.

You also need systems for managing recalls. During a recall, a GMP warehouse must be able to quickly identify affected lots, trace customer shipments, and document all actions.

5. Staff training and SOP adherence

Your warehouse is only as compliant as its staff. Every staff member (including temporary workers) needs documented GMP training before handling products, with regular refreshers to maintain knowledge.

Training requirements vary by role, with position-specific competencies verified before work is assigned. This ongoing process ensures staff stay current with evolving procedures and regulations.

6. Quality assurance through audits and corrective actions

Effective quality assurance is about preventing problems – not just catching them after they occur. Regular self-inspections help identify potential issues before regulators do.

When deviations happen, a robust Corrective and Preventive Action (CAPA) system will help the warehouse address the root causes. For example, if temperatures spike because a door seal failed, a CAPA system will not just fix the seal to correct that individual error, but also implement regular seal inspections to prevent the issue in the future.

Since regulatory inspections are inevitable with GMP products, maintain inspection-ready documentation, ensure staff understand their roles during inspections, and demonstrate continuous improvement based on audit findings. The goal isn’t perfection but systems that consistently deliver quality outcomes and improve over time.

In-house vs. outsourced GMP warehouse management

So, your brand needs a GMP warehouse. You have two options:

- You can invest in creating your own GMP warehouse.

- You can outsource to a 3PL or warehousing provider that has GMP-certified warehouses.

Deciding between these two paths is consequential; it affects your budget, operations, and compliance as your regulated products business grows.

In-house warehousing gives you complete control of your operations, but it also requires significant investment in infrastructure, specialised staff training, and ongoing regulatory compliance. Using a 3PL, on the other hand, gives you immediate access to compliant facilities and trained personnel, without forcing you to invest large amounts of time and money.

Smaller brands with limited products and predictable demand may find it easier to obtain GMP certifications, because their operations are simpler. Consider outsourcing if you have multiple product lines, are growing rapidly, or plan to expand into markets with different regulations (since expert partners can handle the extra complexity with ease).

When choosing a 3PL, dig deeper than basic certifications. Ask them:

- Do you have experience handling products similar to mind in compliance with GMP standards?

- What quality systems do you have in place to protect product integrity and viability?

- What is your approach to regulatory inspections?

- How do you achieve fulfilment that is both fast and GMP-compliant?

Cost considerations for GMP warehouse operations

GMP warehousing costs are usually much higher than standard warehousing costs.

Initial setup can reach hundreds of thousands of dollars (for specialised HVAC, cleanable surfaces, segregated storage areas, monitoring equipment, etc.). Ongoing costs also accumulate quickly equipment calibration, specially trained staff, quality personnel, higher insurance, and maintaining your quality management system.

When comparing options, evaluate total cost of ownership. 3PL fees may seem higher initially, but include infrastructure, training, and compliance management that would otherwise be your responsibility.

In the end, remember: the cost of non-compliance dwarfs any short-term savings. A single recall can cost millions in direct expenses – not to mention irreparable plus brand damage. Smart brands view GMP compliance as an investment in sustainable growth, rather than an expense.

Balancing GMP standards with ecommerce speed

Customers expect fast delivery, but GMP compliance requires extra checks that can slow fulfilment.

To meet customer expectations without compromising quality, GMP warehouses can:

- Identify bottlenecks: Observe where GMP requirements create delays (often in documentation, redundant quality checks, or inefficient layouts) and develop solutions that maintain compliance while improving speed.

- Leverage technology and automation: Automating documentation, scanning barcodes to verify inventory movement, and keeping electronic batch records all improve both compliance and efficiency. Choose systems that integrate with your existing quality processes.

- Distribute inventory: If you can split your inventory across multiple GMP-compliant facilities closer to customers, you can reduce shipping times and provide the 2-day shipping customers want while still having time to process everything compliantly.

Global GMP compliance for cross-border fulfilment

International expansion complicates GMP operations. While the core principles remain consistent (preventing contamination, maintaining quality, ensuring traceability etc.), specific requirements will vary between countries.

The main challenge is maintaining consistent quality across global facilities. Each location must meet both local requirements and destination market standards, often requiring implementation of the strictest applicable standard throughout your network.

To make global GMP compliance easier, you can:

- Protect product integrity during international shipping by developing protocols for temperature variations, customs delays, and varying port conditions.

- Use a centralised quality management system with standardised core procedures to maintain consistency while allowing necessary local adaptations.

- Consider appointing regional quality leaders who understand both local requirements and your global standards.

Advanced GMP warehouse technologies and innovations

Modern GMP warehousing is being transformed by technologies that make compliance easier. What once required extensive paperwork now leverages digital solutions that simultaneously improve compliance and efficiency.

These innovations go beyond basic digitisation; instead, they’re revolutionising warehouse operations with always-on sensors and secure blockchain systems that deliver unprecedented accuracy and transparency.

Here are some of the most valuable technologies to implement in a GMP warehouse.

Real-time monitoring and IoT integration

IoT sensors that continuously monitor warehouse conditions can replace manual temperature checks.

These smart sensors capture data every few seconds and instantly alert staff to deviations. They can also track multiple factors beyond temperature (such as humidity, door status, equipment performance, light exposure, and more) that could affect product quality. Data feeds directly into quality systems, creating automatic, uninterrupted records without manual effort.

IoT’s true advantage lies in its predictive powers. Rather than reacting to problems after they occur, you can spot patterns that forecast issues before products are affected. For example, temperature fluctuations during shift changes or humidity spikes when dock doors remain open can be addressed proactively with real-time alerts.

While IoT systems require thorough validation, they ultimately reduce compliance burden by continuously documenting that environmental controls are functioning correctly.

Blockchain for enhanced traceability

Blockchain technology offers unique advantages for GMP product traceability by creating tamper-proof records of every product movement and transaction.

In practice, blockchain captures each step in a product’s warehouse journey – receipt details, inspection results, storage locations, and status changes – in time-stamped, cryptographically secured blocks. This makes record alteration impossible and gives auditors complete confidence in your documentation.

This technology is especially valuable for high-value or high-risk products requiring authentication. By creating unique digital identities for products or batches, blockchain prevents counterfeit items from entering legitimate supply chains, which is crucial for brands concerned with product diversion or grey market issues.

This transparency extends to regulatory and customer interactions. During audits, you can provide inspectors with indisputable handling records. If customers question storage conditions, you can share specific data about their exact product’s journey, building trust while reducing documentation time.

While implementation challenges exist (including system integration and partner participation), blockchain offers powerful traceability advantages for brands where product authentication is essential.

Elevate your regulated products with ShipBob’s GMP-compliant fulfilment

ShipBob provides specialised GMP-compliant fulfilment for beauty, food & beverage, and health & wellness brands where product integrity is essential. Our approach integrates compliance with cutting-edge efficiency in fulfilment through:

- Temperature-controlled environments with continuous monitoring for products requiring specific conditions.

- Advanced lot tracking, FIFO, and FEFO management ensuring customers receive the freshest products while minimising waste.

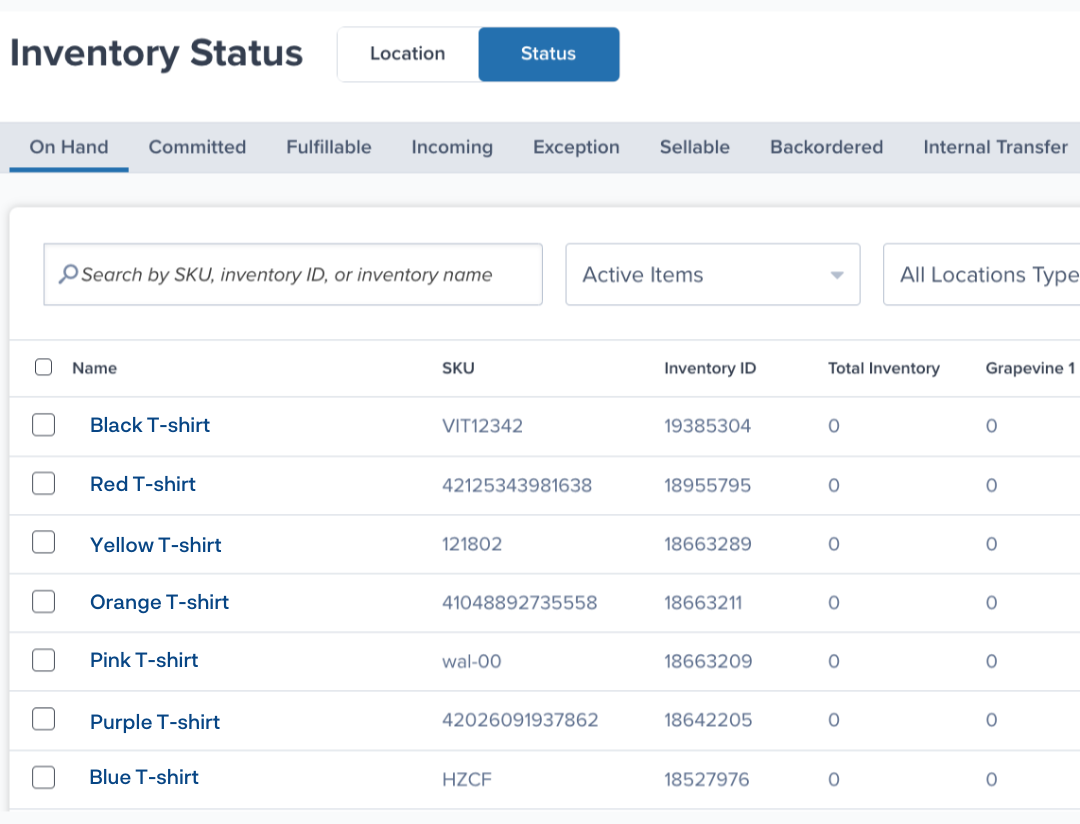

- Documentation and traceability from receiving to delivery with real-time visibility through our merchant dashboard.

- GMP-trained staff with ongoing education on proper handling procedures and quality standards.

Our technology seamlessly connects with your existing ecommerce platforms and tools (Shopify, Amazon, etc.), automatically routing orders to one of our dozens of GMP-compliant fulfilment centres across the U.S. and globally.

By distributing your inventory across ShipBob’s nationwide network of GMP-certified warehouses, you can place products closer to customers while maintaining uniform quality standards. This strategic approach enables faster delivery, mitigates risk, and ensures consistent customer experiences regardless of location.

“It’s important for us that our partners are at the forefront of their industry and are an authority over what’s going on. ShipBob is a leader in the logistics, supply chain, and order fulfilment spaces, and ShipBob having GMP and GFSI warehouse certifications is a great example of that.

Fast-growing ecommerce brands like us aren’t experts in supply chain, and we don’t have large operations teams to navigate the industry’s complexities. We’ve been able to lean on ShipBob to help guide us. Having a partner that can bring ideas to the table and have conversations about how we can level up is helpful.”

Jay Stephens, Director of Operations, and Ania Giuffra, Supply Chain Manager, at Ancestral Supplements

Ready to maintain compliance without sacrificing speed?

Partner with ShipBob to outsource the complexity of GMP certification while maintaining control. We’ll handle execution and compliance, so you can focus on higher priorities and growing your brand.

For more information on ShipBob’s GMP warehousing solutions for brands like yours, click the button below to get in touch.

FAQs about GMP-compliant warehousing

Below are answers to common questions about GMP warehousing requirements and compliance.

What does GMP-compliant warehousing entail in non-pharmaceutical contexts?

GMP principles can guide handling, storage, and care for industries beyond pharmaceuticals, including dietary supplements, cosmetics, food, and medical devices. However, the core requirements of GMP – preventing contamination, maintaining product integrity, and ensuring traceability – remain consistent across verticals.

How do I ensure ongoing GMP compliance in a warehouse?

Once you’ve obtained a GMP certification in a warehouse, your job’s not done; rather, you must maintain the conditions to retain the certification. For example, you should:

- Conduct quarterly internal audits of documentation, environmental monitoring, and staff compliance.

- Establish strict change control where you evaluate how facility or process changes will affect quality.

- Stay up-to-date on all FDA and GMP regulations.

- Provide regular staff training that emphasises both procedures and their importance to product safety.

How is GMP different from GDP or GWP?

GMP covers the entire quality system from raw materials through finished products. Good Distribution Process (or GDP) focuses specifically on distribution after manufacturing. Good Warehousing Process (or GWP) concentrates solely on warehouse operations and storage conditions.

Ecommerce brands may need to be compliant with multiple of these standards, depending on their business’s specific warehousing functions and products.

What certifications or qualifications should GMP warehouse staff have?

While not always mandatory, warehouse managers benefit from CPIM certification or specialised GMP training. Quality personnel should have formal GMP training and potentially ASQ certification. All staff need documented training on GMP concepts, hygiene practices, and role-specific procedures, with annual competency assessments and industry-specific certifications as required.

What are the most common GMP warehouse compliance issues?

Top compliance issues include:

- Temperature excursions

- Incomplete documentation (missing signatures, undated entries)

- Cross-contamination risks from improper product segregation

- Inadequate pest control

You can often prevent these breaches through robust training, clear accountability, regular self-inspections, and thorough root cause analysis when issues occur.

How can technology improve GMP warehouse compliance?

Modern WMS systems automate documentation, reducing human error. RFID and barcode scanning improve traceability, while IoT sensors provide continuous environmental monitoring. AGVs minimise contamination risks by reducing human traffic. Implementation requires validation according to regulatory guidelines, starting with risk assessment to prioritise automation opportunities.

Does ShipBob offer GMP pharmaceutical storage options?

ShipBob provides GMP-compliant storage for beauty, food & beverage, and health & wellness brands. While we don’t handle prescription pharmaceuticals or controlled substances, we support dietary supplements and cosmetics.