Table of Contents

** Minutes

What is supply chain redundancy?

Why supply chain redundancy is essential for ecommerce brands

5 proven strategies to build redundancy into your supply chain

Advanced redundancy strategies for scaling ecommerce brands

Measuring the ROI of supply chain redundancy

For ecommerce businesses, an uninterrupted supply chain is essential for success. While customers expect fast, reliable deliveries, supply chain disruptions can happen at any moment, threatening your ability to fulfil orders and retain customers.

Supply chain redundancy solves this problem by building backup systems into your logistics network. Think of it as insurance for your supply chain operations. When disruptions occur, these alternatives keep your business running smoothly instead of watching revenue disappear.

This guide explores practical redundancy strategies to protect your ecommerce business from disruptions. You’ll discover real-world examples of brands that maintained operations during challenges, learn how to implement redundancy in your own supply chain, and see how ShipBob’s fulfilment network provides built-in redundancy that grows with your business.

What is supply chain redundancy?

Supply chain redundancy is the strategic practice of building multiple options and backup systems into your logistics network. By intentionally creating alternatives for critical components like suppliers, distribution centres, shipping couriers, and inventory reserves, you establish a robust safety net that keeps your business running smoothly even when the unexpected strikes.

Think of it as the opposite of putting all your eggs in one basket. Instead of relying on a single supplier or warehouse to fulfil all your needs, redundancy means having multiple pathways to get your products to customers. So if one route is disrupted by a natural disaster, port closure, or labour shortage, you have other options ready to go.

Redundancy vs. resilience: Understanding the difference

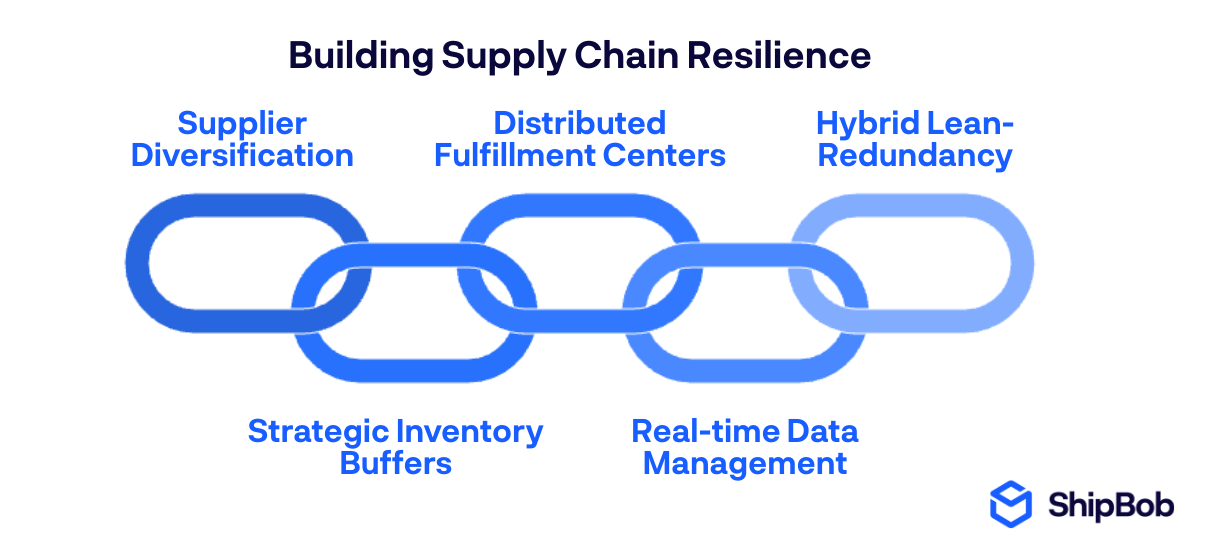

It’s important to note that while redundancy is a key component of supply chain resilience, they’re not quite the same thing. Redundancy specifically refers to having backup resources and alternatives in place, while resilience is the broader ability to adapt to and recover from disruptions.

In other words, redundancy creates the foundation that enables resilience. It’s like having an insurance policy for your supply chain – the tangible assets and relationships that you can fall back on when things go wrong. Resilience, on the other hand, is more like your overall supply chain health plan. It encompasses not just your backup systems, but also your ability to anticipate risks, quickly pivot operations, and bounce back from challenges.

So while redundancy alone won’t make your supply chain invincible, it does provide the critical infrastructure needed to build true resilience. By investing in redundancy measures that fit your business needs, you’ll be well on your way to creating a supply chain that can withstand whatever curveballs come your way.

Why supply chain redundancy is essential for ecommerce brands

Today’s ecommerce customers expect fast, reliable delivery every time. When orders are delayed or unfulfilled, negative reviews and lost customer loyalty quickly follow, directly impacting your revenue. Supply chain redundancy provides critical protection against disruptions that can derail your operations.

Ecommerce brands face unique challenges compared to brick-and-mortar retailers. Without face-to-face customer service or the ability to offer alternatives on the spot, your business success depends entirely on delivering orders as promised, even during unexpected challenges.

These numbers confirm that supply chain disruptions aren’t just inconvenient, they threaten your business viability. Redundancy measures are essential for brands aiming to thrive in competitive ecommerce markets.

Beyond survival, redundancy offers competitive advantages. While competitors struggle with stockouts and shipping delays, your ability to consistently fulfil orders attracts new customers and strengthens your market position.

The true cost of supply chain disruptions

While redundancy requires upfront investment, these costs pale compared to the potential losses from supply chain failures. Disruptions impact far more than immediate sales or shipping fees.

Consider these ripple effects:

- Damage to brand reputation: In today’s social media landscape, one negative experience can become a viral moment or PR crisis. Consistently missing delivery promises erodes customer trust and brand credibility.

- Reduced customer lifetime value: Customers will switch to competitors after just one poor delivery experience. Each lost customer represents years of potential future revenue.

- Operational inefficiencies: Disruptions trigger cascading challenges, from emergency inventory shuffling to customer service backlogs, straining your team and diverting resources from growth initiatives.

- Investor and stakeholder concerns: Supply chain problems raise red flags for potential investors and partners. Redundancy measures demonstrate proactive risk management, making your business more attractive to stakeholders.

Brands that prioritize redundancy navigate challenges more effectively, maintaining customer satisfaction and protecting their reputation while competitors struggle. In the long run, supply chain redundancy delivers ROI that far exceeds the initial investment.

5 proven strategies to build redundancy into your supply chain

Building supply chain redundancy isn’t about duplicating everything; it’s about creating multiple pathways for products to reach customers during disruptions.

Start with these strategies and scale them as your business grows:

1. Diversify your supplier base

Relying on a single supplier creates significant risk. If they face issues, you’ll experience immediate stockouts and lost revenue. Here’s how to build supplier diversity:

Identify your most critical products, then find backup suppliers through industry networks and trade shows. Request samples to verify quality and assess their capacity and reliability.

Maintain relationships with backup suppliers through regular communication and occasional small orders to ensure they’ll prioritize you when needed. Create detailed product specifications to maintain consistent quality across suppliers.

While diversification may cost more than volume discounts from a single supplier, consider it insurance against costlier disruptions. Negotiate flexible contracts and consider geographic diversification to protect against regional issues.

2. Implement strategic inventory buffers

Safety stock provides crucial protection during disruptions, but excess inventory is expensive. Focus on data-driven decisions for your buffer strategy.

Start with a critical SKU analysis to identify which products need redundancy most. Prioritize items with high sales volumes, importance to customers, and supply chain vulnerability.

Calculate optimal safety stock using:

Safety Stock = (Maximum Daily Usage × Maximum Lead Time) − (Average Daily Usage × Average Lead Time)

Use inventory management systems that provide real-time visibility into buffer levels and automatically flag when replenishment is needed. Consider storing buffer inventory strategically based on regional demand.

3. Distribute inventory across multiple fulfilment centres

Spreading inventory geographically creates natural protection against regional disruptions like weather events or power outages. When one centre faces challenges, others continue operations seamlessly.

Multi-location fulfilment reduces dependency on any single warehouse while improving delivery speeds and cutting shipping costs. Analyse your customer distribution and place fulfilment centres to reach the maximum customers within 1-2 day ground shipping.

Stock high-volume SKUs at all locations, while concentrating slower-moving items in fewer centres with plans for quick transfers if needed. Most growing brands start with 2-3 strategically located centres and expand as they scale.

Implement technology that enables automatic order rerouting between locations when one centre faces inventory shortages or operational issues.

4. Leverage real-time data for proactive management

Technology is the central nervous system of a redundant supply chain. Modern systems provide end-to-end visibility from suppliers to customers, helping you spot potential bottlenecks before they impact operations.

Predictive analytics transform historical data into forward-looking insights. For example, identifying patterns in supplier lead times to flag potential delays so you can activate backup suppliers proactively.

Connected inventory management systems provide a unified view across all locations, enabling smarter allocation decisions. Automated order routing can instantly redirect orders to centres with available inventory during disruptions.

Implement real-time dashboards that monitor key metrics like inventory levels and fulfilment rates across all locations, serving as early warning systems for potential issues.

5. Adopt a hybrid lean-redundancy approach

Balance lean efficiency with strategic redundancy instead of viewing them as contradictory. Apply lean principles to stable, predictable parts of your supply chain, and reserve redundancy investments for critical components with volatile demand or vulnerable supply.

Focus on flexibility rather than duplication to avoid excessive costs. Cross-training staff, using modular product designs, and developing flexible manufacturing capabilities create redundancy without the carrying costs of excess inventory.

Use this framework to determine appropriate redundancy levels:

- High criticality, high vulnerability: Implement comprehensive redundancy (multiple suppliers, significant safety stock, distribution across all fulfilment centres)

- High criticality, low vulnerability: Focus on monitoring and rapid response capabilities

- Low criticality, high vulnerability: Implement basic redundancy measures like backup suppliers

- Low criticality, low vulnerability: Apply lean principles with minimal redundancy

Advanced redundancy strategies for scaling ecommerce brands

As your ecommerce brand grows, you’ll need more sophisticated redundancy strategies to protect your business. These approaches not only shield you from disruptions but also create competitive advantages that support rapid scaling.

Multi-channel fulfilment as a redundancy strategy

Selling through multiple channels (your website, Amazon, retail partners) diversifies revenue streams and reduces risk when any single channel faces issues.

The key is using different fulfilment methods for each channel. For instance, fulfil website orders through ShipBob, use FBA for Amazon, and dropship for retail partners. This way, problems in one fulfilment channel won’t halt your entire business.

Success requires robust inventory management systems that give you real-time visibility across all channels, enabling quick decisions about inventory allocation during disruptions.

Geographic diversification and nearshoring

Spreading production and fulfilment across different regions reduces dependency on any single location and builds resilience against localised disruptions.

Nearshoring, or moving production closer to customers, has gained popularity. For example, a US brand might shift some manufacturing from Asia to Mexico, reducing long-distance supply risks while improving delivery speeds.

When diversifying geographically, evaluate which products make sense to produce in different regions based on cost, quality, lead times, and regulations. Aim for meaningful risk reduction without sacrificing efficiency.

Building redundancy into transportation networks

With customers expecting fast, free shipping, your transportation network needs built-in flexibility to handle disruptions.

Courier diversification is essential. Brands should use multiple shipping couriers and maintain backup relationships. When one courier faces issues, you can quickly switch to alternatives without disrupting deliveries.

Focus on last-mile delivery redundancy through partnerships with multiple regional couriers, a mix of traditional and gig-economy services, or even in-house delivery options for critical areas.

Create detailed contingency plans and routing guides for quick adjustments during disruptions, and negotiate flexible courier contracts that allow for volume shifts and include service level guarantees.

By implementing these strategies, you’ll build a supply chain that’s both resilient against disruptions and agile enough to support growth. Approach redundancy as a strategic investment in your business’s long-term competitiveness, not just a cost centre.

Measuring the ROI of supply chain redundancy

Supply chain redundancy is a strategic investment, not just an added cost. To make informed decisions, you need a clear framework for measuring both costs and benefits. This helps demonstrate value to stakeholders and guides data-driven decisions about your supply chain resilience.

Calculating the true value of avoided disruptions

To calculate redundancy ROI, estimate the revenue losses and costs you prevented by having backup systems in place:

- Lost sales avoided from preventing stockouts or shipping delays

- Customer lifetime value preserved through consistent delivery experiences

- Cost savings from avoiding emergency shipping or production

- Brand reputation and customer sentiment are protected

For example, if your multi-location fulfilment strategy keeps orders flowing during a regional disruption, compare the revenue generated to what you would have lost without redundancy to see the direct financial benefit.

Creating a business case for redundancy investments

To secure resources for redundancy initiatives, present a compelling business case that includes:

- Clear definition of the problem and your proposed solution

- Projected ROI, including revenue protection and cost savings

- Qualitative benefits like improved customer experience

- Phased implementation plan with incremental value

- Alignment with company priorities and risk tolerance

Frame redundancy as a proactive investment in long-term success, not just insurance, to build stakeholder support and secure necessary resources.

How ShipBob provides built-in supply chain redundancy

Partnering with a fulfilment partner like ShipBob is one of the most effective ways for ecommerce brands to build supply chain redundancy without the complexity and capital investment of managing it themselves. ShipBob’s fulfilment infrastructure and technology platform provide built-in redundancy that scales with your business, allowing you to focus on growth while ShipBob handles the operational details.

Distributed global fulfilment network

ShipBob’s redundancy strategy centres on our network of 50+ fulfilment centres across six countries. This geographic spread protects your business against regional disruptions, ensuring orders continue flowing even when one location faces challenges.

When issues like natural disasters or labour shortages affect one centre, we automatically route orders to other locations with available inventory, keeping deliveries on schedule despite unexpected challenges.

“When it comes to fulfilment, DTC and B2B channels require different skill sets and have their own unique challenges, so a lot of brands end up juggling multiple different partners. Having just one omnichannel fulfilment partner in ShipBob who can handle these two very different aspects of the business is really important, and definitely makes our job easier.”

– Sergio Tache, Founder and CEO of Dossier

Real-time inventory visibility and allocation

Our technology platform gives you instant visibility into inventory across all fulfilment centres. This centralised system helps you spot potential issues early and make smart decisions before disruptions occur.

When inventory runs low at one location, our system can automatically redistribute stock from other centres to prevent stockouts. This ensures products are always where they need to be without requiring manual intervention.

Flexible courier networks and shipping options

ShipBob partners with multiple shipping couriers, creating another layer of redundancy for your business. By working with diverse national and regional couriers, we quickly adapt when specific couriers face disruptions.

Our technology automatically selects the best courier and service level for each order based on speed, cost, and reliability. This ensures packages always take the most efficient route, even as courier conditions change.

“ShipBob has been a great ally as they have fulfilment centres all over the US, facilitating a 2-3 day delivery time for any customer in the US. This is helpful, especially when weather challenges happen; being able to have different locations to ship from allows for a more seamless supply chain.”

– Andrea Lisbona, Founder & CEO of Touchland

By combining distributed fulfilment, real-time inventory management, and flexible shipping options, ShipBob offers a complete redundancy solution that grows with your business. You can focus on expansion while we handle the logistics complexities of today’s ecommerce landscape.

Get started with ShipBob

Leverage ShipBob’s fulfilment platform to help build supply chain redundancy.

FAQs about supply chain redundancy

Below are more answers to common supply chain redundancy queries and challenges.

What’s the difference between supply chain redundancy and excess inventory?

Supply chain redundancy creates backup options throughout your logistics network, not just extra inventory. While safety stock is one component, true redundancy builds alternatives into your processes, relationships, and systems.

Effective supply chain redundancy includes diverse suppliers, multiple fulfilment locations, and backup shipping options. When implemented strategically, it improves efficiency by preventing disruptions that would otherwise halt operations.

How much does implementing supply chain redundancy cost?

Costs vary based on your business size and chosen strategies. Options range from low-cost tactics like identifying backup suppliers to larger investments in additional inventory or new fulfilment locations.

Always compare these costs against potential losses from disruptions. Think of redundancy as an investment in business continuity and customer satisfaction. Partnering with ShipBob reduces upfront costs by providing access to an established network with built-in redundancy.

Is supply chain redundancy feasible for small or growing ecommerce brands?

Yes! Brands of all sizes can implement redundancy by scaling strategies to fit their needs and resources. Even small brands can start by identifying backup suppliers or keeping extra inventory of critical products.

Growing brands can leverage 3PLs like ShipBob to access enterprise-level redundancy without building their own systems. Using ShipBob’s distributed network, you can position inventory closer to customers in multiple locations, reducing risk from any single point of failure.

How can I implement redundancy without sacrificing efficiency?

Target your most vulnerable supply chain points instead of duplicating everything. Focus on key risks and create specific backup plans that maintain lean operations while building resilience.

Use technology to manage redundancy efficiently. Centralised inventory systems, real-time visibility, and automated routing coordinate multiple locations seamlessly.

ShipBob balances redundancy with efficiency through strategically placed fulfilment centres and integrated technology that provides backup options without compromising performance.

How does ShipBob’s approach to redundancy compare to managing my own warehouses?

Running your own redundant warehouses requires significant investments in facilities, equipment, and technology, plus the headache of coordinating multiple locations is typically too expensive and complex for most brands.

ShipBob gives you access to a distributed fulfilment network without these upfront costs or management challenges. You can quickly establish redundancy using their existing infrastructure and expertise.

Our platform offers real-time visibility across all locations, enabling quick adjustments to changing conditions. That level of flexibility can be hard to achieve with self-managed warehouses.

How quickly can I implement supply chain redundancy with ShipBob?

You can set up redundancy with ShipBob in just weeks. Their onboarding process integrates with your existing systems, allowing you to distribute inventory across your network quickly.

ShipBob’s technology connects directly to your sales channels and order systems, giving you immediate visibility across all fulfilment centres from day one.

Most brands start with one fulfilment centre and add locations as they grow. This phased approach ensures a smooth transition while optimising your redundancy strategy over time.

What redundancy measures does ShipBob have for its own operations?

ShipBob builds redundancy into its own operations with backup systems for power, connectivity, and data management to protect your business from disruptions.

Their technology includes failover capabilities that ensure continuous operation, with regular backups and security measures that protect against outages and breaches.

Within fulfilment centres, ShipBob maintains contingency plans for everything from equipment failures to natural disasters. Cross-trained staff and the ability to shift operations between locations provide additional protection.

This comprehensive approach creates a resilient fulfilment solution that withstands supply chain challenges, helping your business grow with confidence.