Table of Contents

** Minutes

What do picking and packing errors look like?

Understanding the root causes of picking and packing errors

8 proven strategies to reduce picking and packing errors

How to choose the most accurate picking method (and avoid mistakes)

How ShipBob’s fulfilment technology minimises picking and packing errors

In ecommerce, even the smallest fulfilment error can lead to costly consequences. A mispicked item or poorly packed box can result in returns, refunds, damaged goods, and worst of all, lost customer trust. As order volumes grow, reducing picking and packing mistakes is essential.

That’s why the most successful brands treat picking and packing as mission-critical processes. From improving warehouse layout design to leveraging barcode scanning and automation, there are proven strategies for minimising human error, protecting products in transit, and increasing fulfilment accuracy.

In this guide, we’ll break down the root causes of common fulfilment mistakes and share actionable best practices to prevent them. You’ll also see how ShipBob’s technology-driven fulfilment network helps ecommerce businesses of all sizes reduce errors, increase efficiency, and deliver consistently excellent customer experiences, order after order.

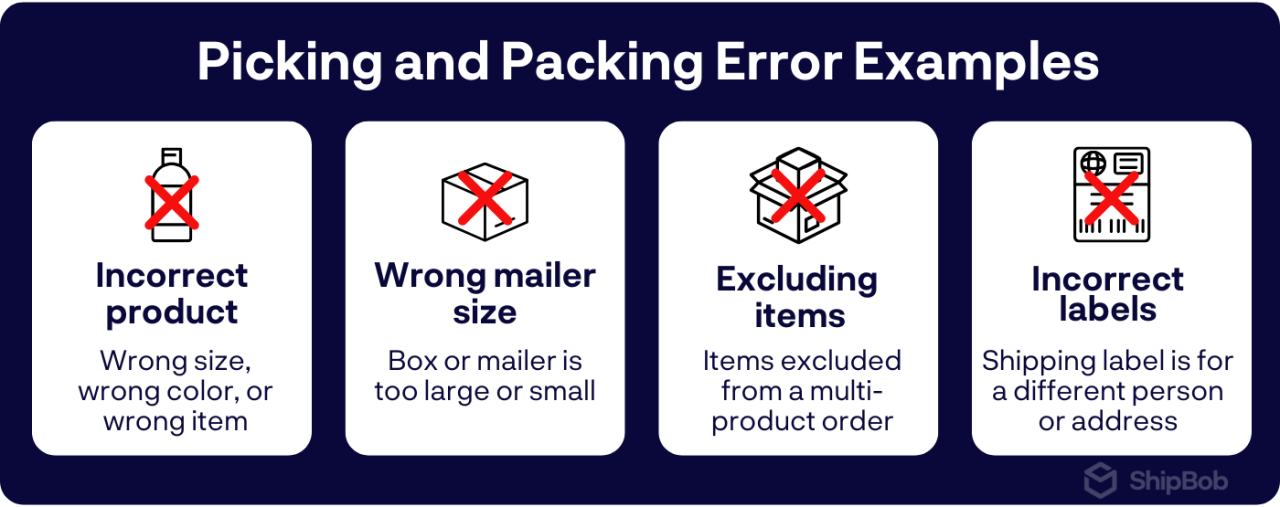

What do picking and packing errors look like?

Picking and packing errors are mistakes that occur during the order fulfilment process in a warehouse. Picking errors involve selecting the wrong items, quantities, or SKUs when pulling products from shelves to fulfil customer orders.

These errors can include:

- Picking the incorrect product altogether

- Selecting the wrong variation (colour, size, etc.) of the correct product

- Pulling too many or too few units of an item

On the other hand, packing errors happen when items are improperly prepared for shipment. Common examples include:

- Using the wrong size box or mailer

- Failing to include all items in a multi-product order

- Damaging products during the packing process due to rough handling or inadequate protection

- Applying incorrect shipping labels

These errors not only create frustrating experiences for customers but also have severe consequences for your business’s bottom line and reputation. Rectifying picking and packing mistakes requires time-consuming rework, costly return processing, and expedited replacement shipments. Over time, a pattern of inaccurate orders erodes customer trust and loyalty, leading to negative reviews, increased churn, and difficulty attracting new buyers.

The negative impact of errors

The costs of picking and packing errors extend far beyond the initial inconvenience to the customer and can impact finances, efficiency, and brand perception.

Financially, every mis-shipment represents money lost on return shipping, restocking, and potentially unsellable inventory. In addition to these direct costs, businesses must invest labour hours in processing returns and sending replacement orders, driving up fulfilment expenses.

Errors also disrupt warehouse efficiency by forcing staff to pause productive picking and packing to handle rework. The time spent investigating and correcting mistakes reduces overall throughput and creates a cascading effect of delays. As backlogs grow, the pressure to catch up can lead to even more errors, creating a vicious cycle of inaccuracy.

Ultimately, the combined impact of these financial and efficiency drains tarnishes the customer experience. Negative reviews, social media complaints, and word-of-mouth criticism stemming from picking and packing errors tarnish your brand’s reputation, making it harder to attract and retain customers in a competitive ecommerce landscape.

Understanding the root causes of picking and packing errors

Before you can effectively tackle picking and packing errors in your warehouse, it’s crucial to understand the underlying factors that contribute to these mistakes. By identifying and addressing these root causes, you can develop targeted solutions that drive meaningful improvements in accuracy and efficiency.

Inadequate staff training and documentation

One of the most common reasons for picking and packing errors is inconsistent or insufficient training for warehouse staff. When employees aren’t properly equipped with the knowledge and skills they need to perform their tasks accurately, mistakes happen. This problem is often compounded by unclear or outdated standard operating procedures (SOPs) that fail to provide clear guidance on best practices.

High employee turnover can also exacerbate training challenges, as new hires may not receive the same level of instruction as their predecessors. This lack of continuity in training can lead to knowledge gaps and inconsistencies in how tasks are performed, increasing the likelihood of errors.

Ineffective warehouse organisation

The physical layout and organisation of your warehouse play a significant role in picking and packing accuracy. Poor design decisions, such as inefficient picking routes or inadequate storage systems, can increase travel time and cognitive load for pickers, leading to more mistakes.

Improper slotting and product placement can also contribute to errors. If high-velocity items are stored in hard-to-reach locations or similar-looking products are placed next to each other, the chances of mispicks increase dramatically.

Manual processes and technology gaps

Relying on manual processes can also lead to more picking and packing errors. Paper-based picking lists and basic inventory management systems create numerous vulnerability points where mistakes can occur, from illegible handwriting to data entry errors.

When warehouses lack real-time inventory visibility, pickers may attempt to fulfil orders with out-of-stock items or incorrect quantities. This can happen when inventory records aren’t updated promptly or when there’s a disconnect between the physical inventory and the digital system. These technology gaps make it difficult to catch and correct errors before they reach the packing stage.

Insufficient quality control measures

Even the most accurate picking and packing processes will occasionally produce errors. That’s why it’s essential to have quality control measures in place to catch mistakes before they reach customers. When verification steps are missing or inadequate, errors can slip through the cracks unnoticed.

The pressure to achieve faster fulfilment times can also lead warehouses to sacrifice accuracy for speed. Without proper checks and balances, this emphasis on velocity can result in a higher error rate. Implementing strategic quality control checkpoints throughout the fulfilment process is critical for maintaining a balance between efficiency and precision.

“We have over 200,000 SKUs on our website, 190,000 of which are stowed in our warehouse. It became difficult to make sure everyone was doing fulfilment in the right way. ShipBob’s WMS makes it almost impossible to do things wrong. Eliminating the potential for human error during picking and packing has been great. That was our biggest problem before. Last time I checked, our error rate was less than 1%. We’re shipping out over 10,000 orders per month.“

Clint Sanders, VP of Operations of Bunker Branding

8 proven strategies to reduce picking and packing errors

Reducing picking and packing errors requires a multifaceted approach that addresses the root causes of mistakes while implementing safeguards to catch issues before they reach customers. By combining these proven strategies, you can create a comprehensive system for error prevention that improves accuracy, efficiency, and customer satisfaction.

1. Optimise warehouse layout with data-driven slotting

The foundation of an error-resistant picking process is an optimised warehouse layout. By analising historical order data and product characteristics, you can determine the most efficient slotting configuration for your inventory.

Place fast-moving items in easily accessible locations near picking stations to minimise travel time. Adjust slotting seasonally to maintain efficiency as demand patterns change. Ensure aisles are wide enough for smooth traffic flow, and use clear signage to guide pickers to the correct locations.

2. Implement robust technology solutions

Investing in modern warehouse technology is crucial for reducing errors and gaining real-time visibility into operations. A warehouse management system (WMS) provides the foundation for accurate inventory tracking, guiding pickers through optimised routes and verifying each step of the process with barcode scanning.

More advanced solutions like pick-to-light systems and voice-directed picking can further streamline workflows and reduce the potential for human error. Integrating your WMS with other business systems eliminates manual data entry and ensures a single source of truth across your operation.

3. Use intelligent packaging selection systems

Choosing the right packaging for each order is a critical step in preventing damage during transit and reducing shipping costs. Intelligent packaging selection software, like ShipBob’s proprietary box algorithm, automatically determines the optimal box size and packing materials based on the dimensions and fragility of the items in an order. This technology removes the guesswork for packers and ensures consistent packaging standards across your operation. By eliminating over-packing and under-packing, you can minimise both errors and waste.

4. Standardize kitting and assembly processes

Kitting, or the process of bundling multiple items together as a single SKU, introduces additional complexity and potential for error in the picking process. To ensure accuracy, create clear, step-by-step kitting workflows that detail how to assemble each bundle.

Use visual aids like diagrams and photos to illustrate proper component placement, and implement standardized labelling to prevent mix-ups. Organise kitting workstations with designated areas for each component, and establish verification procedures to confirm all items are included before sealing the kit.

5. Develop comprehensive training and accountability systems

Equipping your warehouse staff with the knowledge and skills to perform their roles accurately is essential for error prevention. Design onboarding programs that combine classroom-style training with hands-on shadowing to reinforce key concepts. Create clear, visually engaging standard operating procedures (SOPs) that are easily accessible for reference. Implement ongoing training initiatives to keep skills sharp and foster a culture of continuous improvement.

6. Establish data-driven performance monitoring

To identify patterns and root causes of errors, you need a system for tracking and analising performance data. Monitor key metrics like order accuracy rates, error types, and individual picker performance daily. Use this data to inform targeted improvement efforts and coach team members who may be struggling.

Conduct regular root cause analysis sessions to uncover the underlying factors contributing to recurring errors, and develop action plans to address them. Implement continuous improvement cycles that leverage data to drive meaningful, sustained progress over time.

7. Create effective error detection and resolution protocols

Even with robust prevention measures in place, some errors may still slip through the cracks. That’s why it’s crucial to have a systematic approach to catching and correcting mistakes. Implement quality control checkpoints at key stages of the fulfilment process (i.e., post-pick audits and pre-shipment inspections).

When errors are detected, follow a standardized protocol for immediate correction and documentation. Use these incidents as learning opportunities to refine your processes and prevent future occurrences.

8. Partner with a fulfilment provider to immediately curb picking and packing issues

Partnering with a specialized fulfilment provider can be an effective way to quickly reduce picking and packing errors in your operation. Platforms like ShipBob have the expertise, technology, and processes in place to maintain high accuracy standards across multiple clients and facilities.

Fulfilment providers benefit from economies of scale, allowing them to invest in advanced picking and packing technologies that may be cost-prohibitive for individual businesses. They also have standardized processes and training programs that ensure consistency and accuracy across their entire fulfilment network. By leveraging a 3PL’s established infrastructure and best practices, you can achieve significant improvements in order accuracy.

Additionally, partnering with a fulfilment partner like ShipBob provides the flexibility to scale your operation without sacrificing accuracy. As your business grows, you can leverage the fulfilment provider’s existing network and resources to handle increased order volumes without the risk of overwhelming your own facilities. This scalability is particularly valuable for businesses with seasonal demand fluctuations or rapid growth trajectories.

“Another key growth lever for ecommerce brands is selling more products to the same customers – and to do that, you need a fulfilment and logistics partner that delivers the fast, accurate fulfilment that customers expect. ShipBob has been that partner for us. They’re able to receive our products in their fulfilment centres quickly and effectively, making sure that every unit is sorted in the correct place to prevent mispicks in the fulfilment process ShipBob’s system has built-in checks and balances that make sure that the right new products are getting out to the right customers.”

Connor Westby, Co-Founder of NutriPaw

How to choose the most accurate picking method (and avoid mistakes)

The picking method you choose can significantly impact your warehouse’s accuracy rates. Different strategies are better suited for certain order volumes and complexity levels. By selecting the appropriate approach for your operation, you can minimise errors and optimise efficiency.

Single-order picking

In this traditional method, one picker is responsible for completing an entire order from start to finish. This approach works best for low-volume operations or highly customised orders that require special attention. Single-order picking offers the benefit of increased accountability, as each picker is solely responsible for the accuracy of their assigned orders. However, it can be less efficient than other methods, particularly as order volumes grow.

Batch picking

Batch picking involves grouping similar orders together and picking them simultaneously. This method improves efficiency by reducing travel time and allowing pickers to retrieve multiple items in a single trip. To prevent mix-ups, it’s essential to have clear organizational systems in place, such as colour-coded bins or labels for each order within the batch. When processing multiple orders at once, pickers should double-check each item against the corresponding order to maintain accuracy.

Zone picking

In zone picking, the warehouse is divided into distinct areas, each with its own dedicated team of pickers. This method can increase accountability and reduce congestion, as each picker is responsible for a specific section of the warehouse. When an order requires items from multiple zones, it is passed between them until complete. To minimise errors during these handoffs, implement clear communication protocols and verification steps. Zone picking can be an effective way to balance speed and accuracy for medium-volume operations.

Wave picking

Wave picking is an advanced method that involves scheduling picking tasks in “waves” based on priority and resource availability. This approach requires robust technology, such as a warehouse management system (WMS), to coordinate the timing and sequence of each wave. By grouping similar orders and optimising picker assignments, wave picking can significantly reduce congestion and errors in high-volume operations. However, it also requires careful planning and real-time visibility to execute effectively.

How ShipBob’s fulfilment technology minimises picking and packing errors

ShipBob is a tech-enabled fulfilment platform that offers a comprehensive suite of tools and processes designed to minimise picking and packing errors. By combining advanced software with strategic warehouse design and rigorous training, ShipBob creates multiple layers of error prevention throughout the fulfilment process.

Proprietary warehouse management system

At the core of ShipBob’s accuracy-focused approach is its proprietary warehouse management system (WMS). This powerful software guides pickers through optimised routes, ensuring they take the most efficient path through the warehouse. At each step, the WMS requires barcode scans to verify that the correct item and quantity have been selected. This real-time validation prevents pickers from accidentally grabbing the wrong product or overselling inventory.

Customizable picking configurations

ShipBob offers flexibility in how products are picked, allowing merchants to specify the most appropriate method for their unique needs. The “case vs. eaches” configuration for DTC and B2B enables businesses to indicate whether an item should be picked as a whole case or as individual units. This level of customisation, combined with clear system toggles and alerts, helps prevent errors when fulfilling orders with multiple SKUs or varying quantities.

Intelligent packaging selection

ShipBob’s advanced box algorithm takes the guesswork out of packaging selection. ShipBob uses a Cubiscan to scan items for their individual weight and size.

By analising the dimensions and weights of the items in an order, the algorithm automatically recommends the most appropriate box size and type. This not only reduces the risk of damage during transit but also eliminates the potential for human error in the packing process. With intelligent packaging selection, ShipBob standardizes and streamlines the packing workflow, leading to fewer mistakes and more consistent results.

Standardized kitting workflows

For businesses that offer product bundles or subscription boxes, ShipBob provides a systematic approach to kitting that minimises errors. The WMS generates clear, step-by-step instructions for assembling each kit, including visual aids and specific component placement. As items are added to the bundle, pickers scan each one to verify accuracy. Once complete, the kit undergoes a final quality check before being released for shipping. This standardized process ensures that every kit contains the correct items in the proper configuration.

Comprehensive error resolution system

Despite best efforts, occasional errors may still occur. That’s where ShipBob’s robust error resolution system comes into play. When a mistake is identified, whether by a picker, packer, or the merchant, ShipBob’s protocols ensure that it is addressed quickly and thoroughly. Throughout the resolution process, merchants have full visibility into the status of their orders and can trust that ShipBob is working diligently to make things right.

By combining these powerful tools and processes, ShipBob offers a comprehensive solution for minimising picking and packing errors. The result is a more accurate, efficient, and scalable fulfilment operation that empowers businesses to grow with confidence.

Get started with ShipBob

Partner with ShipBob to minimise errors and improve warehouse operations. Request a quote to connect with our team and get started.

FAQs about reducing warehouse picking and packing errors

We’ve addressed more of your pressing picking and packing questions in our FAQs below.

How do you calculate picking accuracy rate?

To calculate your warehouse’s picking accuracy rate, use the formula: (Total correct picks ÷ Total picks) × 100. For example, if your pickers complete 950 correct picks out of 1,000 total picks, your accuracy rate would be 95%.

Industry benchmarks for acceptable accuracy rates vary depending on the type of operation, but generally fall between 97% and 99.5%. To effectively track and measure this KPI, implement systems that record each pick attempt and outcome, such as barcode scanning verification or voice-directed picking confirmation. Regularly review and analyse this data to identify trends and areas for improvement

What technology is most effective for reducing packing errors?

Several verification technologies can help reduce packing errors, each with its own advantages and considerations. Barcode scanning is a reliable and widely-used method that confirms the correct items are packed by scanning each product’s unique barcode. Weight verification systems compare the packed box’s weight to the expected weight of the order, identifying any missing or extra items. Image recognition technology visually inspects the contents of each package to ensure accuracy.

When choosing a technology solution, consider your business size, order volume, and budget. While barcode scanning is generally the most affordable option, weight verification and image recognition offer additional layers of accuracy for high-volume operations. Conduct a cost-benefit analysis to determine which technology will provide the best return on investment for your specific needs.

How can small businesses improve picking accuracy without expensive technology?

Small businesses can improve picking accuracy without significant technology investments by focusing on organisation and process design. Implement a clear, logical warehouse layout with well-labelled storage locations and use colour-coding or other visual management techniques to differentiate similar products. Develop standard operating procedures for each step of the picking process and train staff thoroughly on these guidelines.

Low-cost solutions like pick-to-paper or pick-to-label systems can provide structure and verification without the need for expensive software. Regularly audit your picking processes to identify bottlenecks or error-prone areas, and continuously refine your methods based on these insights. Encourage a culture of accuracy by setting clear expectations, providing ongoing training, and recognizing high-performing staff members.

What are best practices for training warehouse staff?

Effective training is essential for maintaining high picking and packing accuracy rates. Start with a comprehensive onboarding program that includes both classroom-style instruction and hands-on practice. Assign new hires to shadow experienced staff members and gradually increase their responsibilities as they demonstrate proficiency.

Develop a culture of continuous learning by offering ongoing education opportunities, such as cross-training on different tasks or products. Encourage knowledge sharing among team members through regular meetings or mentorship programs. Implement performance incentives that motivate staff to prioritize accuracy, such as recognition for error-free shifts or bonuses for exceeding accuracy targets. Regularly assess individual and team performance to identify training needs and provide targeted coaching.

How does ShipBob handle special picking requirements for fragile or regulated items?

For fragile products, ShipBob’s warehouse management system includes special handling instructions and alerts pickers to use extra care when selecting and packing these items. Pickers are trained to follow specific guidelines for handling delicate goods, such as using appropriate packaging materials and placing items securely within the box.

For high-value or regulated items, ShipBob implements additional verification steps, such as secondary barcode scans or supervisor approvals, to confirm accuracy and prevent costly errors. ShipBob’s staff receives specialized training on the unique requirements for these product types, including any legal or compliance considerations. By tailoring picking procedures to the specific needs of each product category, ShipBob maintains high accuracy rates while protecting your inventory and reputation.

What steps should I take first to reduce picking errors in my warehouse?

Start by conducting a thorough audit of your current processes. Identify the most common types of errors and analyse their root causes, such as unclear labelling, inadequate training, or inefficient layouts. Based on these findings, create a prioritized improvement roadmap that addresses the highest-impact issues first.

Focus on organising your warehouse for optimal efficiency and accuracy. Develop clear, logical storage locations and implement visual management techniques like colour-coding or signage to differentiate similar products. Create detailed SOPs for each step of the picking process and train your staff thoroughly on these guidelines.

As you work through your improvement roadmap, balance the impact of each change with the effort required to implement it. Start with low-effort, high-impact solutions like updating product labels or rearranging your pick paths, then gradually tackle more complex projects like implementing new technology or redesigning your warehouse layout.